Multi-station silica gel air bag clamping device for clamping ultrathin wall deep cylinder part

A multi-station, ultra-thin-walled technology, applied in chucks, metal processing, manufacturing tools, etc., can solve problems such as inability to clamp small parts, easy wear, low efficiency, etc., to increase the contact area and improve clamping Efficiency, contact force reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

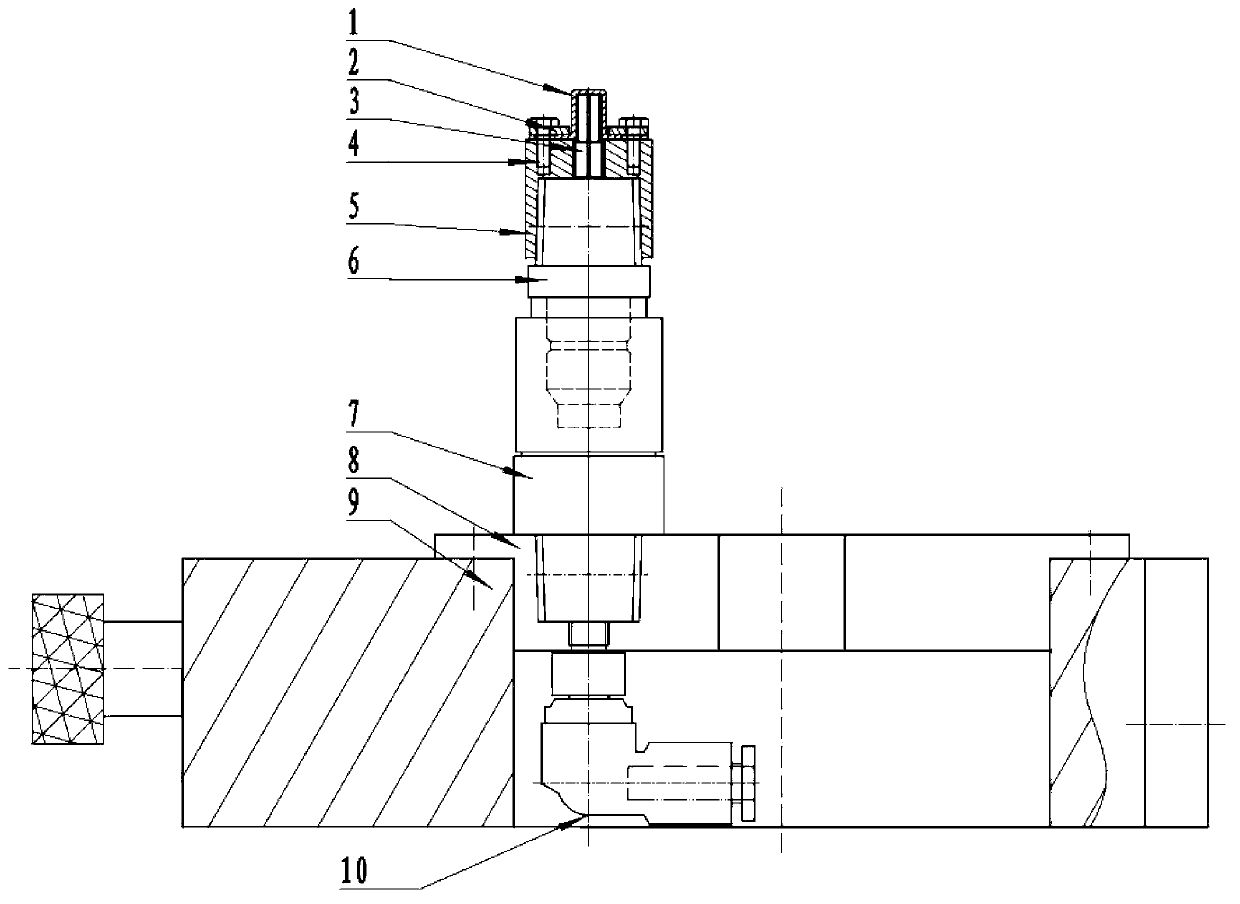

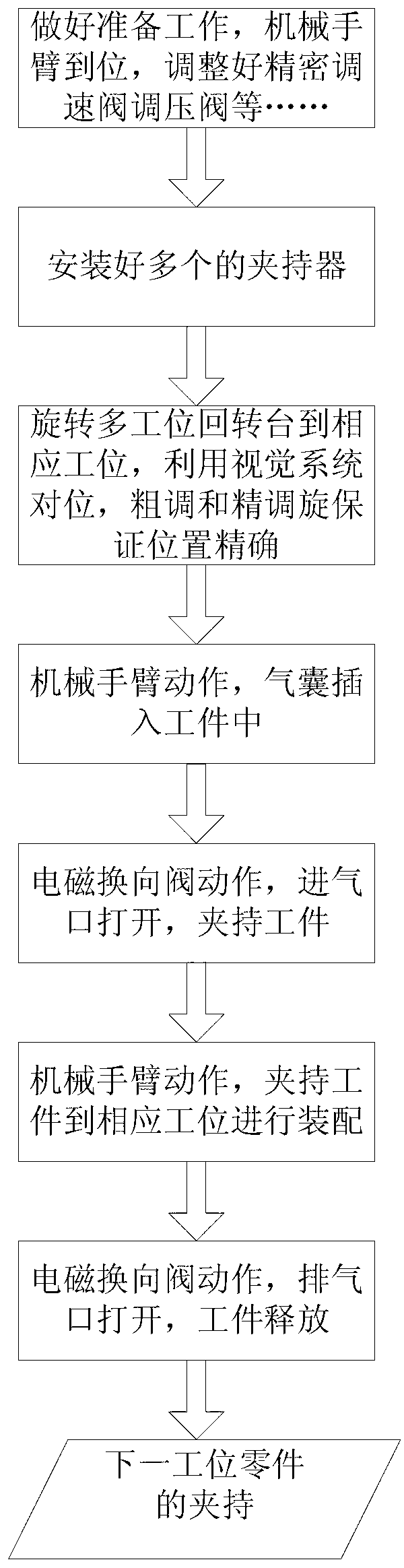

[0027] The structure of the multi-station silicone airbag holder of the present invention is as follows: figure 1 with Figure 7 As shown, it includes airbag clamping head, conical push-in joint, multi-station rotary table and air system. The airbag clamping head includes the airbag 1, the center cage 3, the tight ring gasket 2 and the connecting transition piece 5; the conical quick-connect joint includes the quick-change joint plug 6 and the quick-change joint socket 7; the multi-station rotary table includes 360 °Manual rotary table 9 and adapter plate 8; air circuit system includes air source, filter, pressure regulating valve, speed regulating valve, electromagnetic reversing valve and air pipe joint 10.

[0028] The material of the airbag of the present embodiment is silica gel, and the shape of the airbag is matched with the ultra-thin-walled deep tube parts to be clamped, such as Figure 4 As shown, it can be inflated and deflated; the central cage plays the role of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com