Novel functional flexible clamp and application method thereof

A flexible fixture and multi-functional technology, applied in the field of mechanical processing, can solve the problems of high use and maintenance cost, inconvenient operation, complicated operation control, etc., and achieve the effect of improving processing accuracy, adjusting support stiffness, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

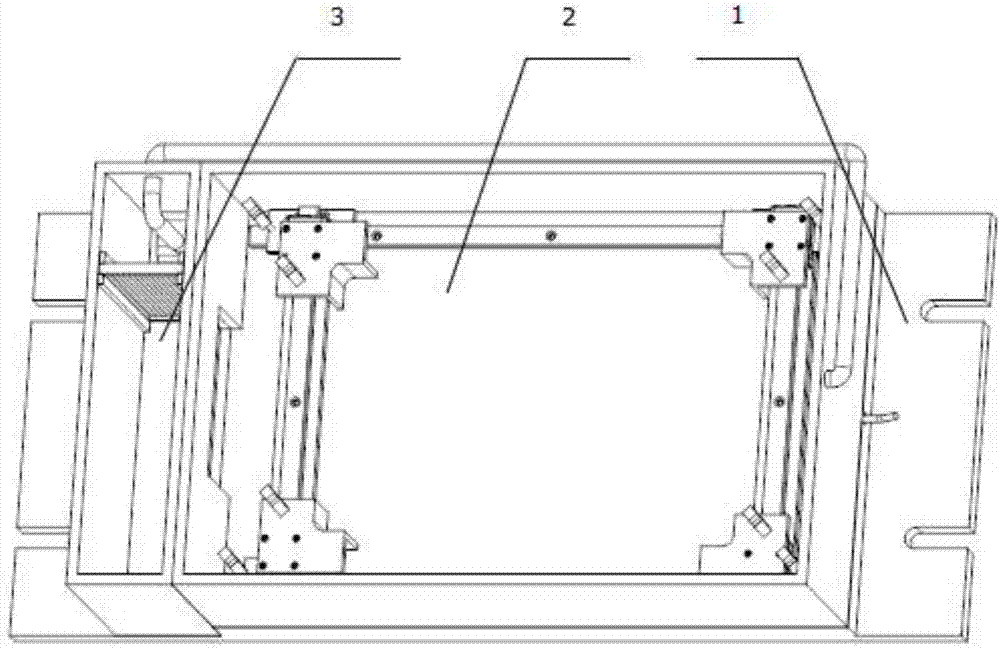

[0039] Example 1

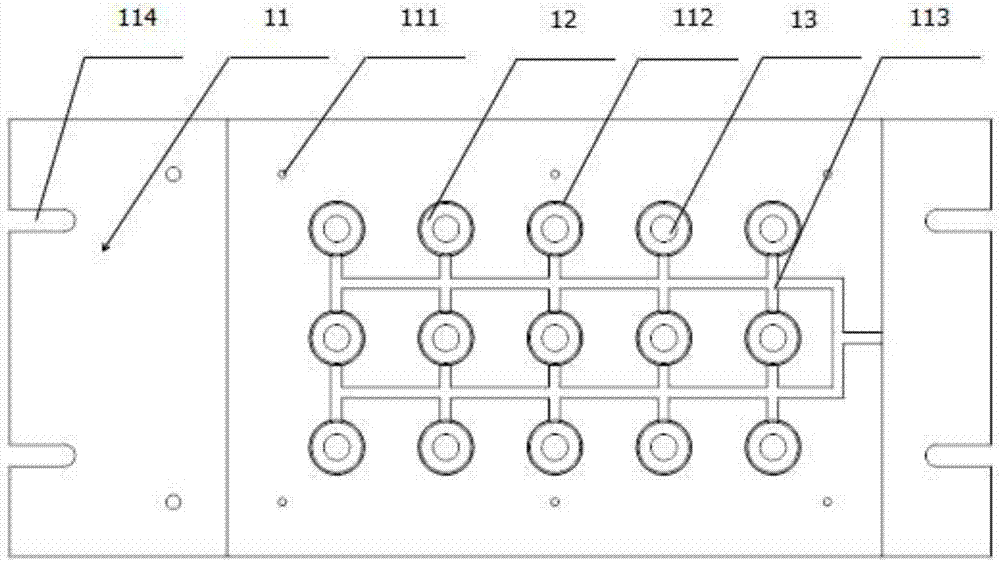

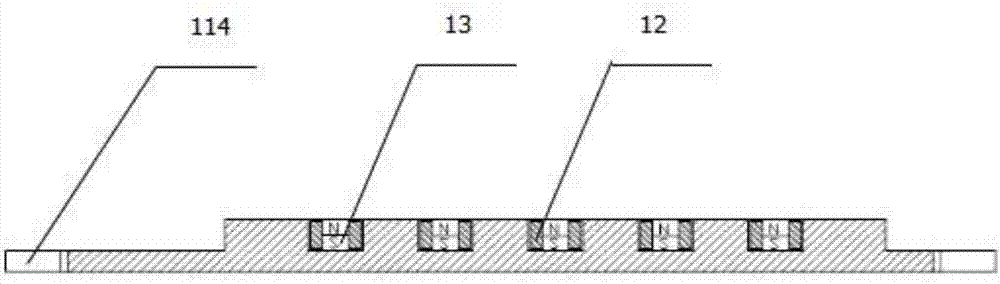

[0040] The novel multi-functional flexible fixture of this embodiment includes a fixture base 1, a positioning clamping groove 2 and a cleaning recovery groove 3; The fixed connection of the platform mainly includes a connection base plate 11 , an electromagnet 12 and a permanent magnet 13 . The connecting bottom plate is a plate-shaped structure with a flat bottom surface and a raised middle part of the upper surface. Two U-shaped grooves are symmetrically arranged on the left and right sides of the fixture base, which are used to realize the fixed connection between the fixture and various machine tool platforms through bolt connection. There are 10 connection through holes in the middle of the bottom plate that match the threaded blind holes at the bottom of the positioning and clamping groove 2 and the cleaning and recovery groove 3, which are used to realize the rigid connection between the fixture base 1 and the positioning and clamping groove 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com