Clamping device for automobile parts

A technology of auto parts and clamping devices, which is applied in the direction of clamping devices, positioning devices, metal processing machinery parts, etc., can solve the problems of inconvenient removal of parts, improve processing efficiency, improve efficiency, and ensure clamping stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

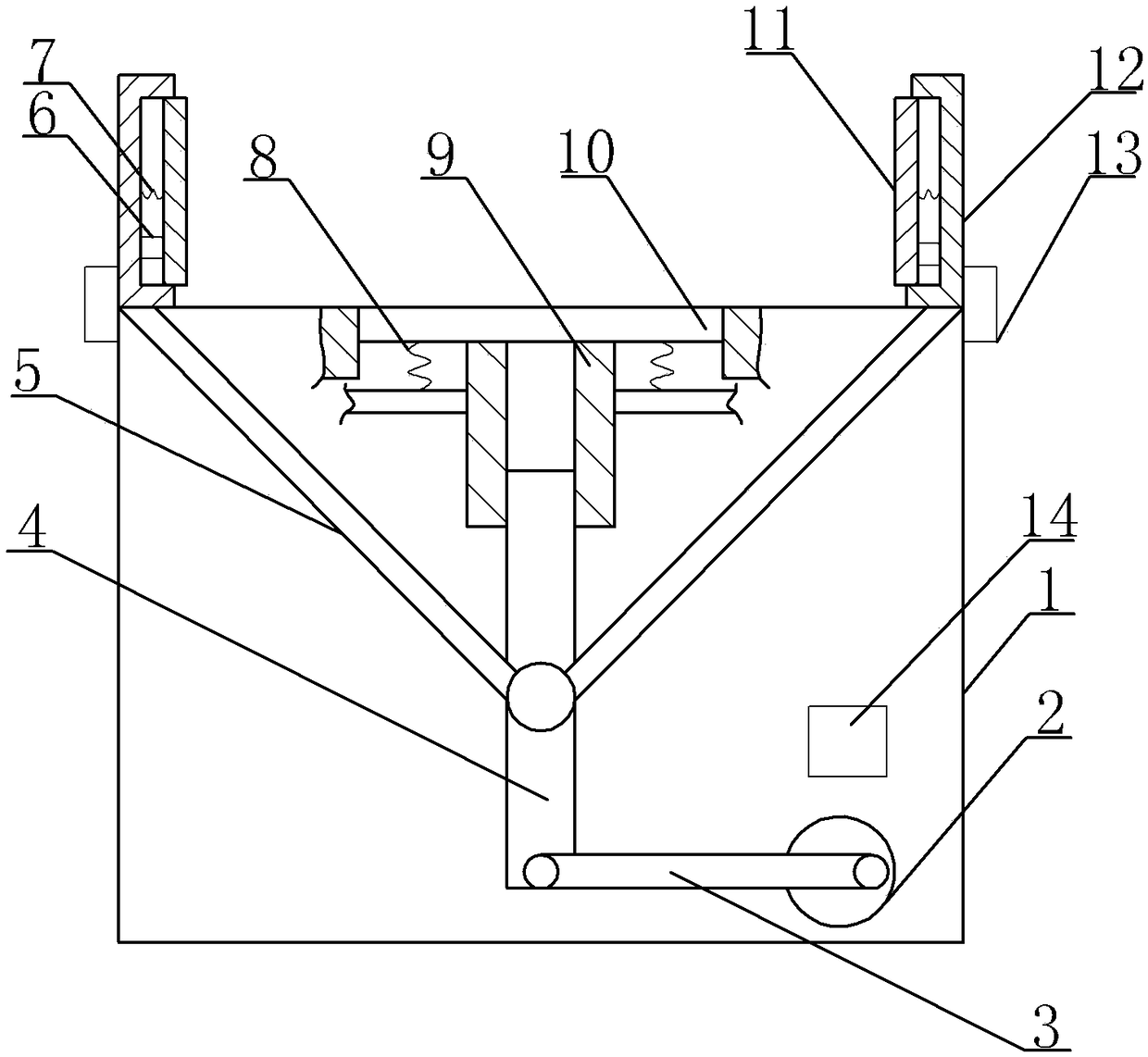

[0020] as attached figure 1 Shown is a clamping device for auto parts, a frame 1 and a clamping mechanism. The clamping mechanism includes clamping blocks 12 arranged on both sides of the frame 1 , and the clamping blocks 12 are slidably connected to the frame 1 . Clamping block 12 is provided with sliding groove, is provided with vertical clamping plate 11 in sliding groove, clamping plate 11 is connected with clamping block 12 slidingly and clamping plate 11 can slide horizontally on clamping block 12, and clamping plate 11 is provided with clamping plate 11. The spring 7 that holds the block 12 against each other, the button switch 6 that can be resisted by the splint 11 is also provided on the clamping block 12, and the both sides of the frame 1 are also provided with a limit block 13 for limiting the clamping block 12, The movement of the clamping block 12 to the limit block 13 is just the maximum sliding distance on the frame 1 , preventing the clamping block 12 from sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com