Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Guaranteed stable clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

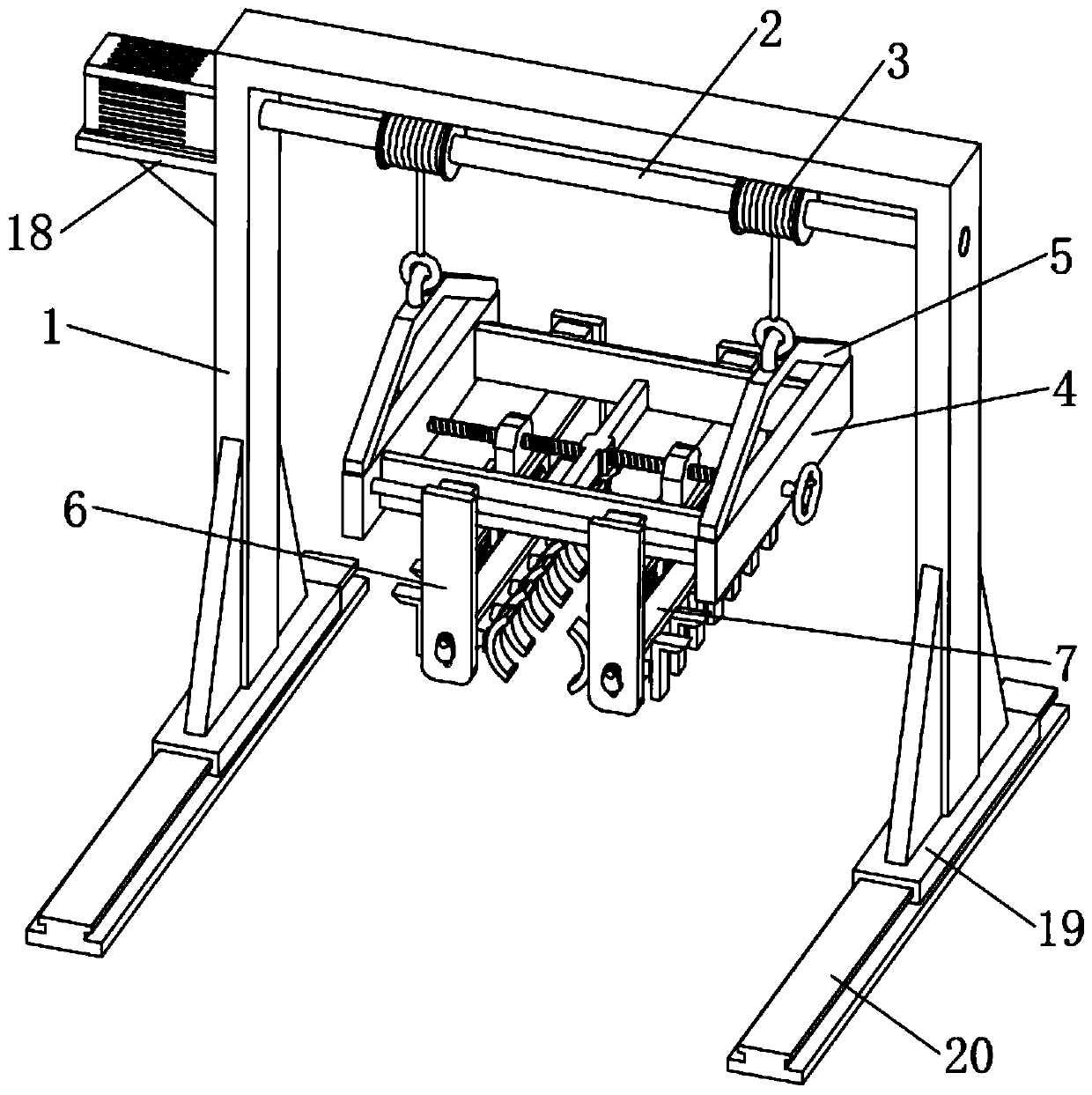

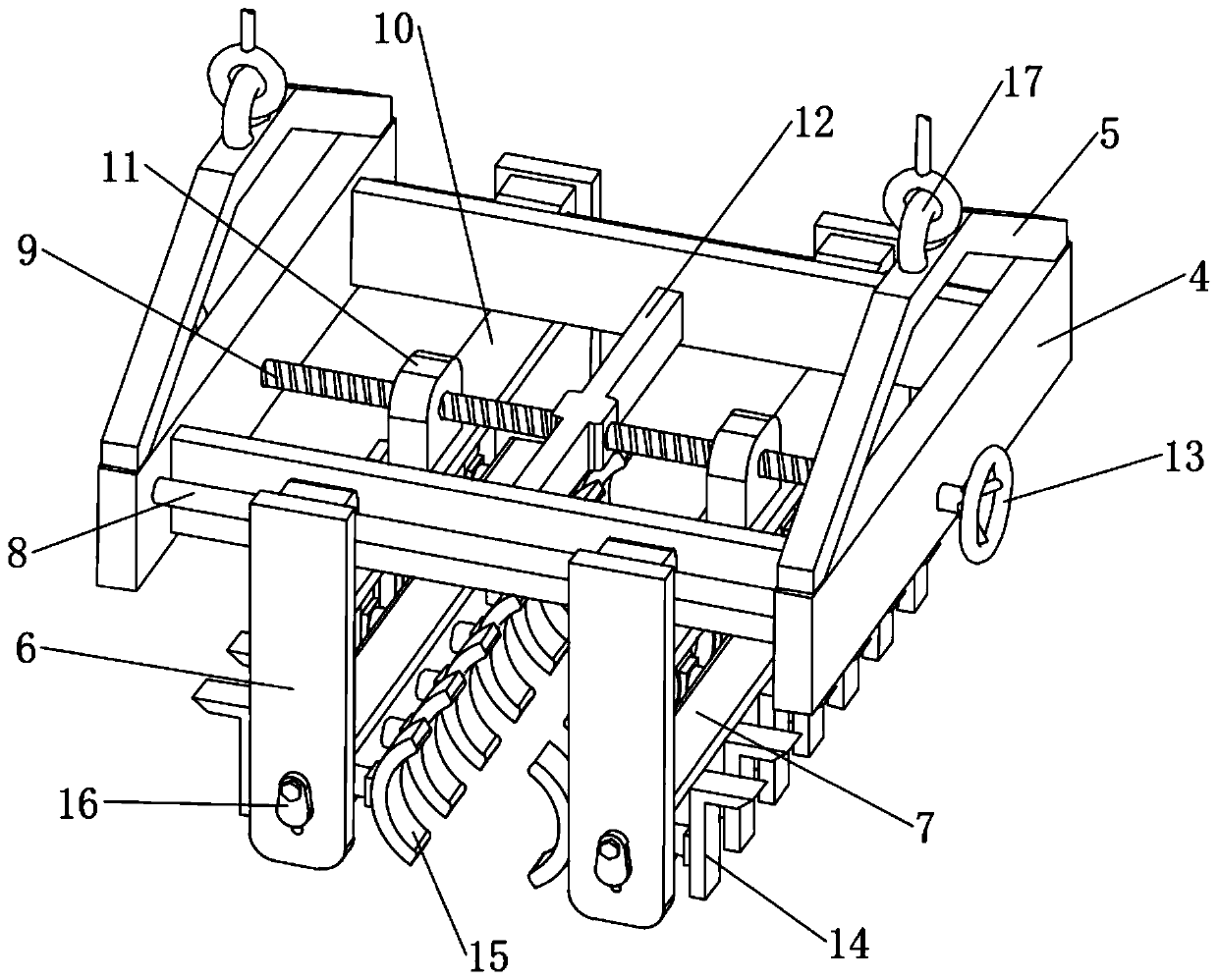

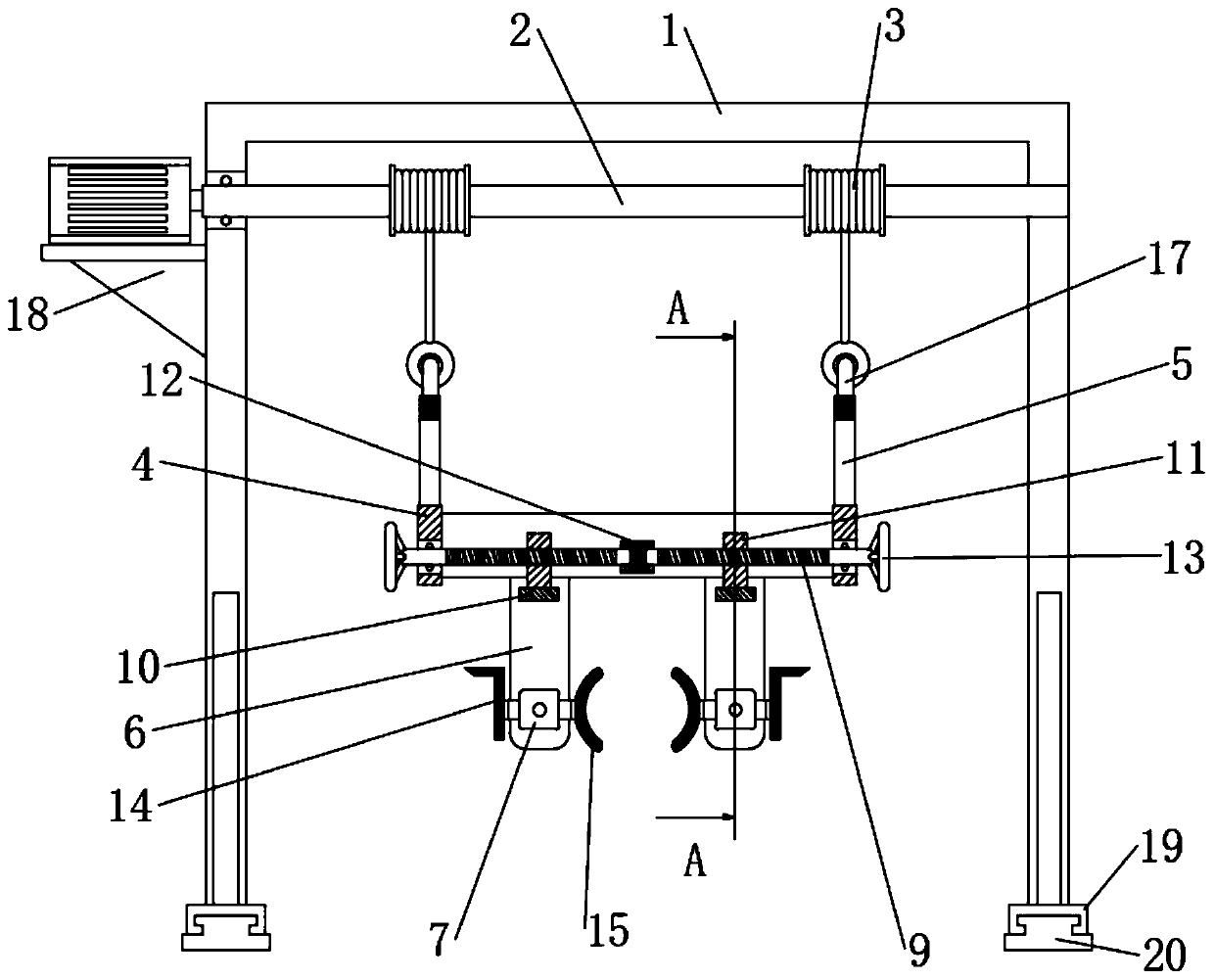

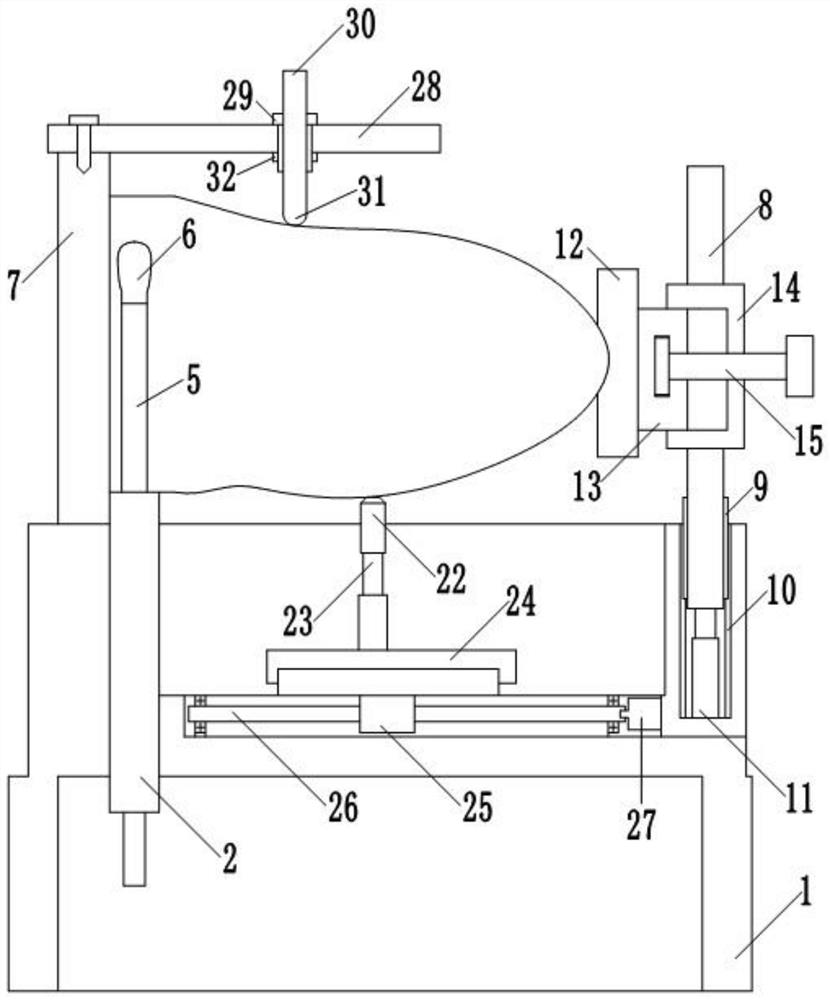

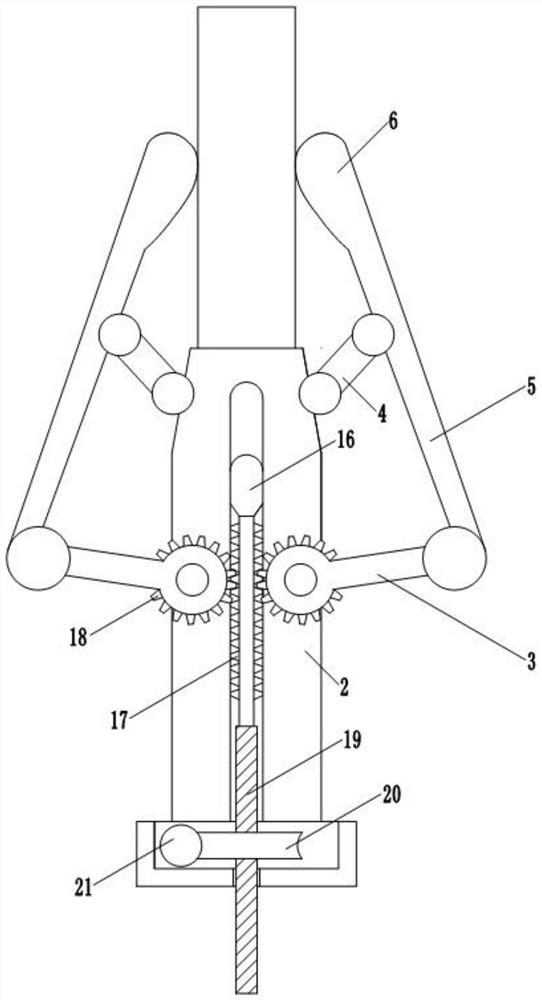

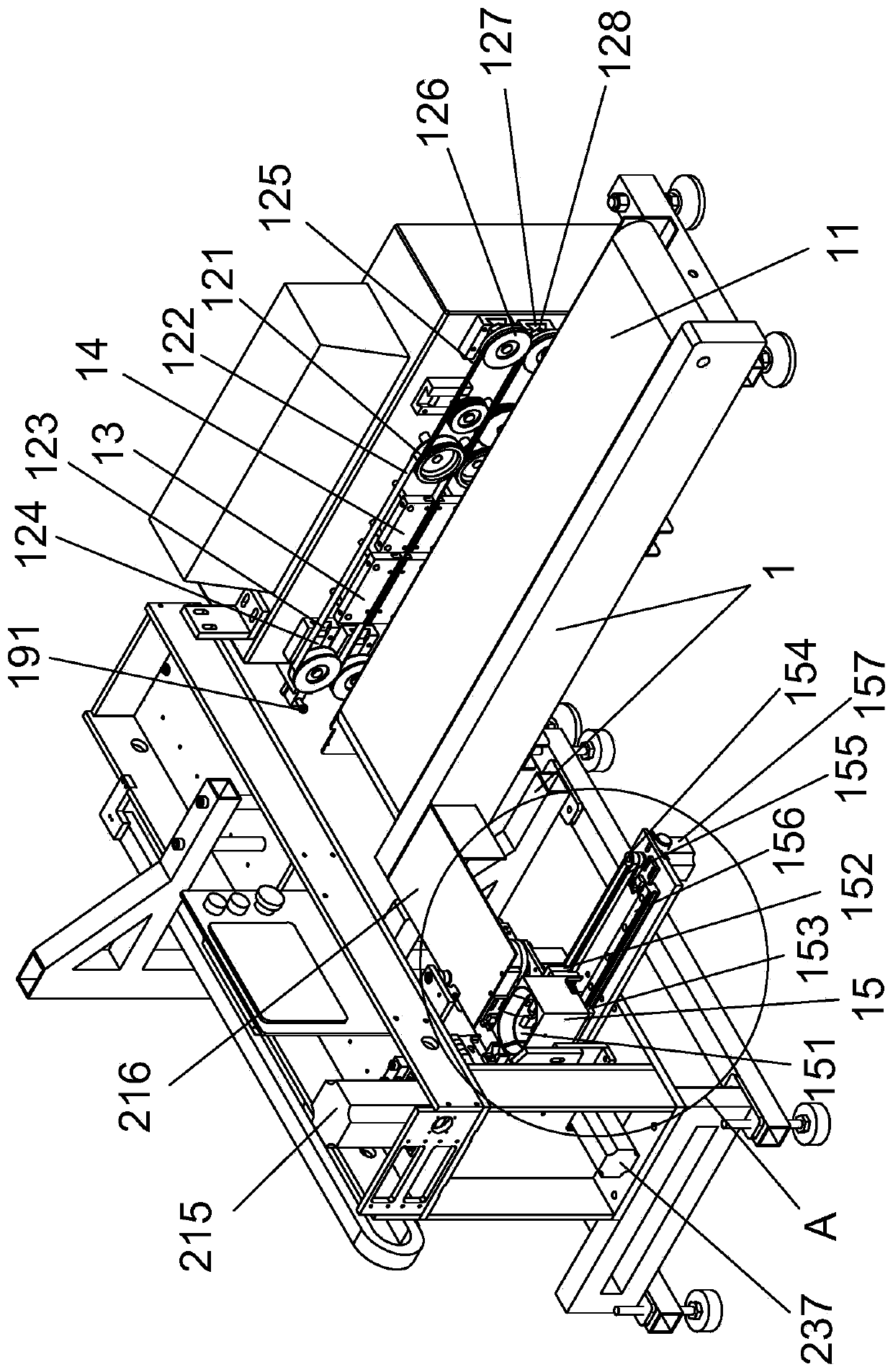

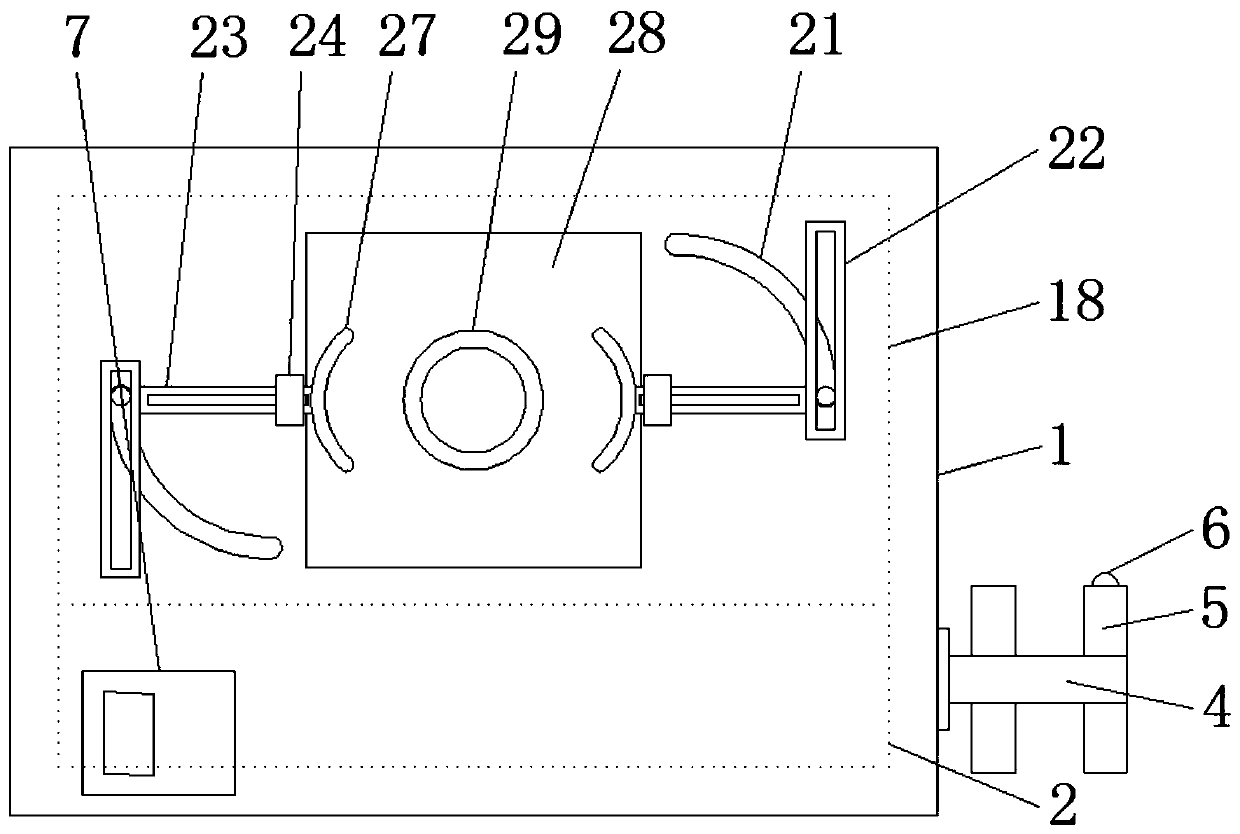

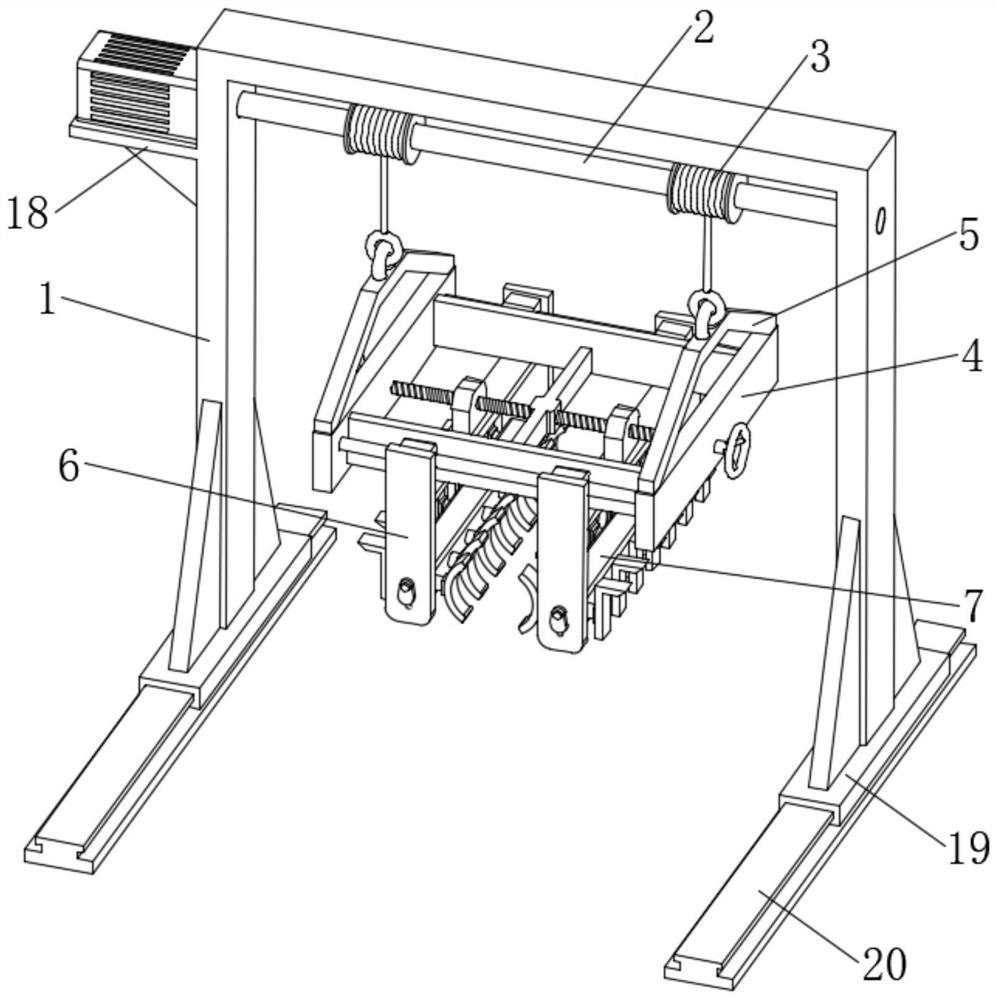

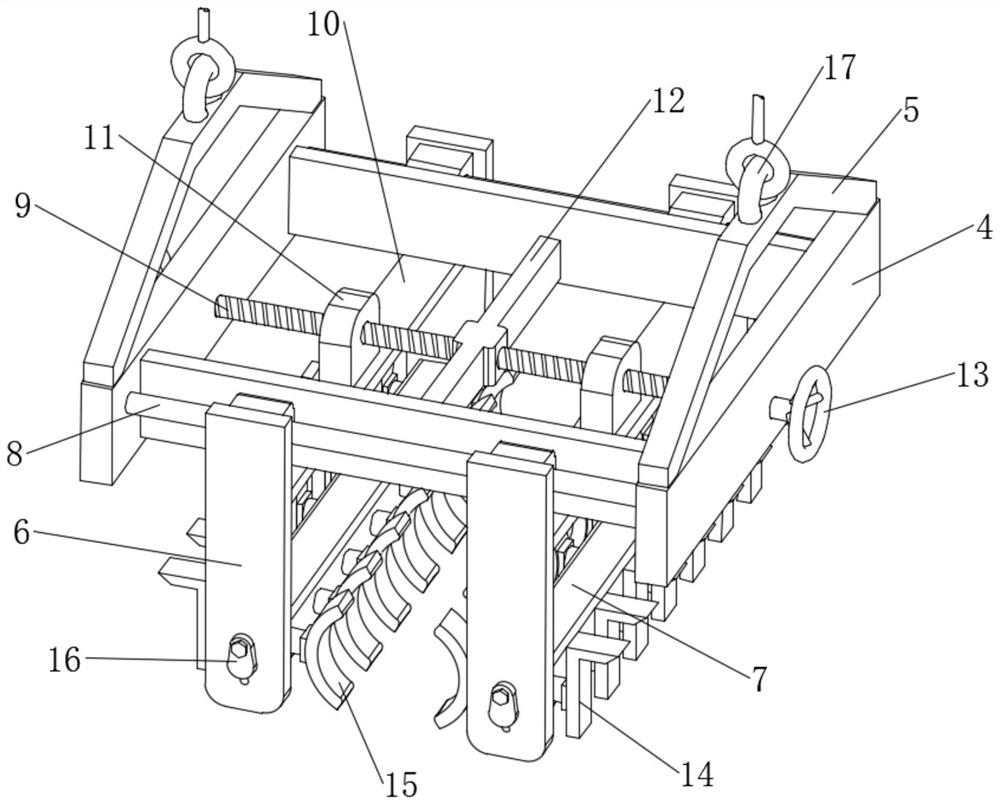

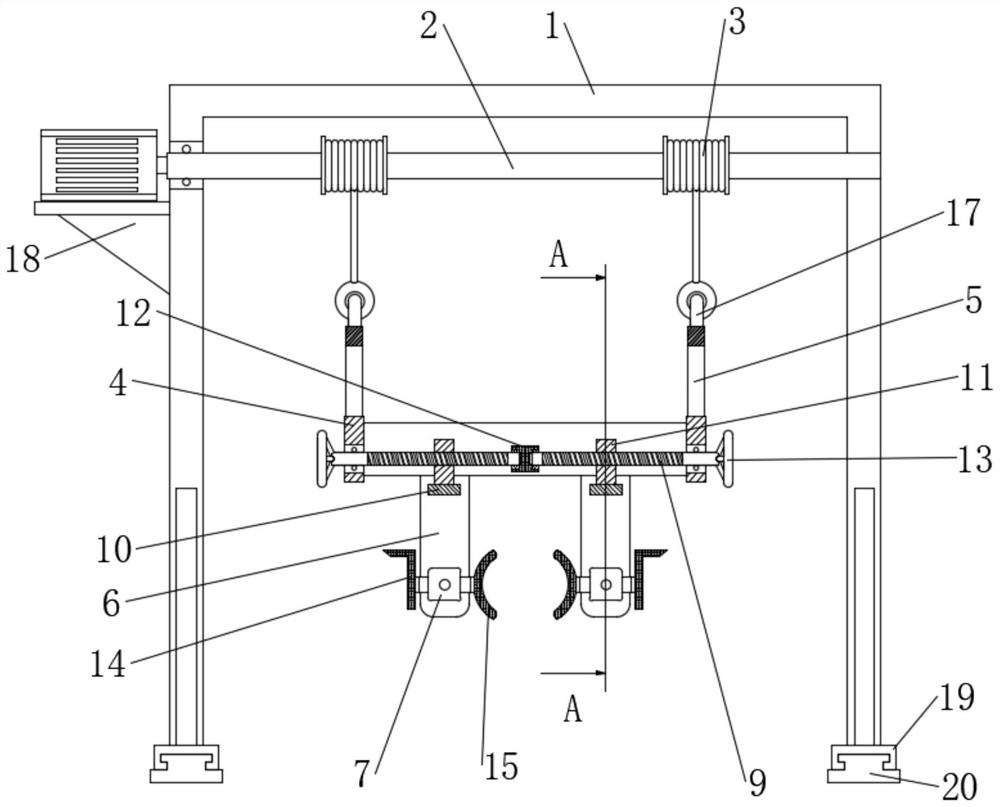

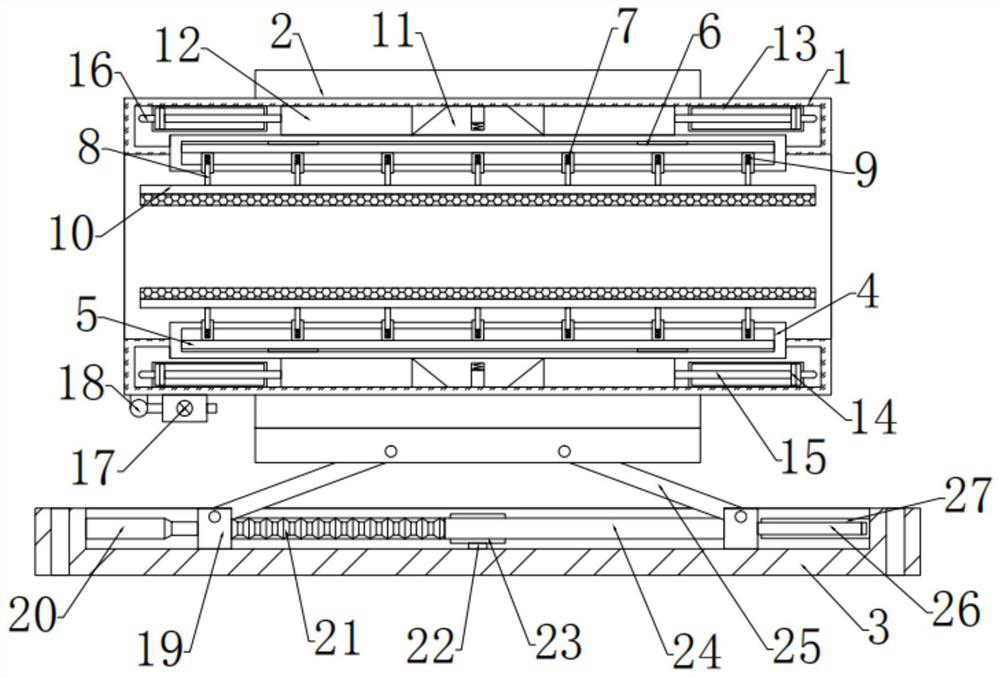

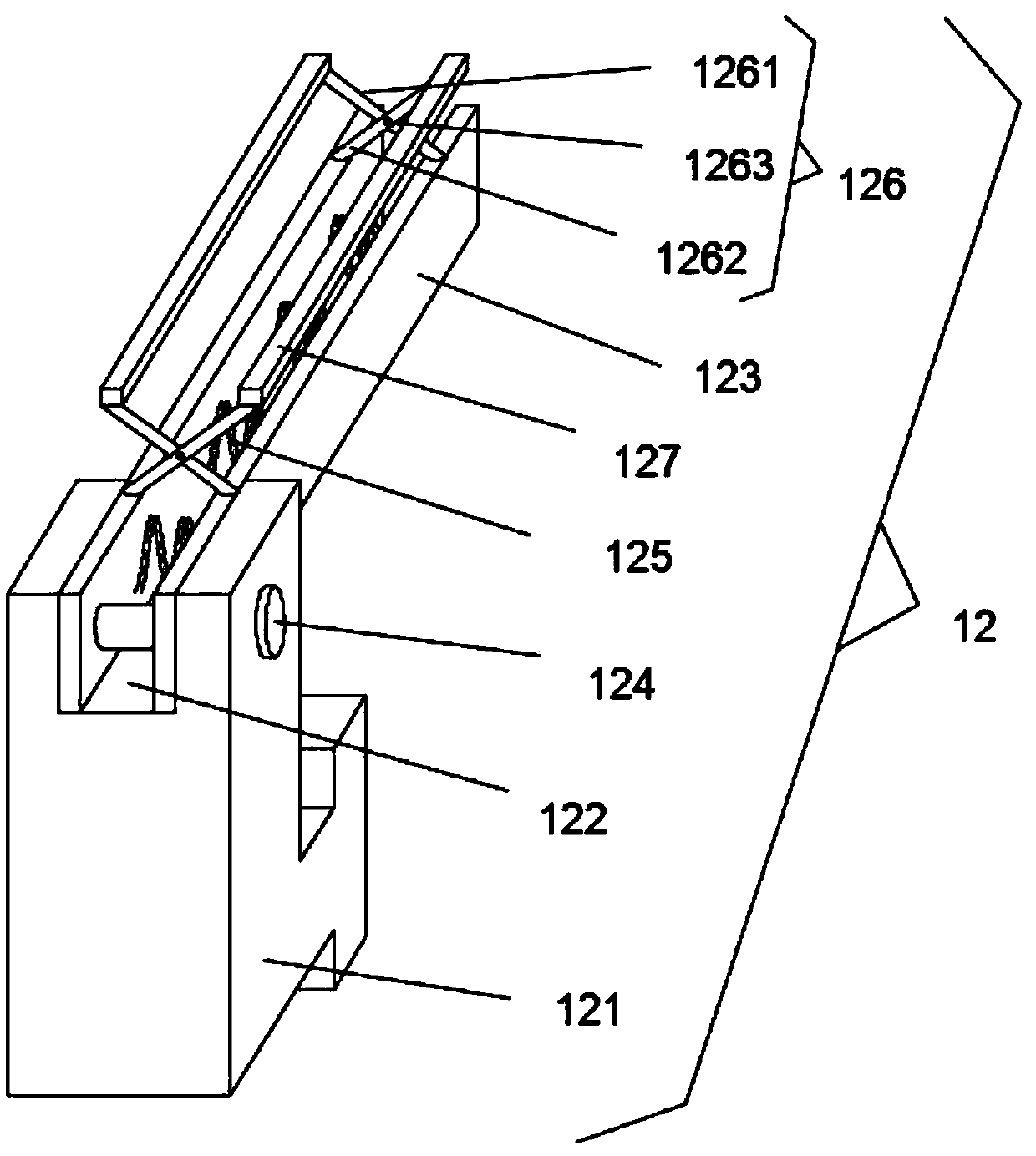

Portal crane capable of switching over clamps and used for hardware pipe fitting

ActiveCN110329903AFlexible deletionMulti-job environmentBase supporting structuresBraking devices for hoisting equipmentsPipe fittingEngineering

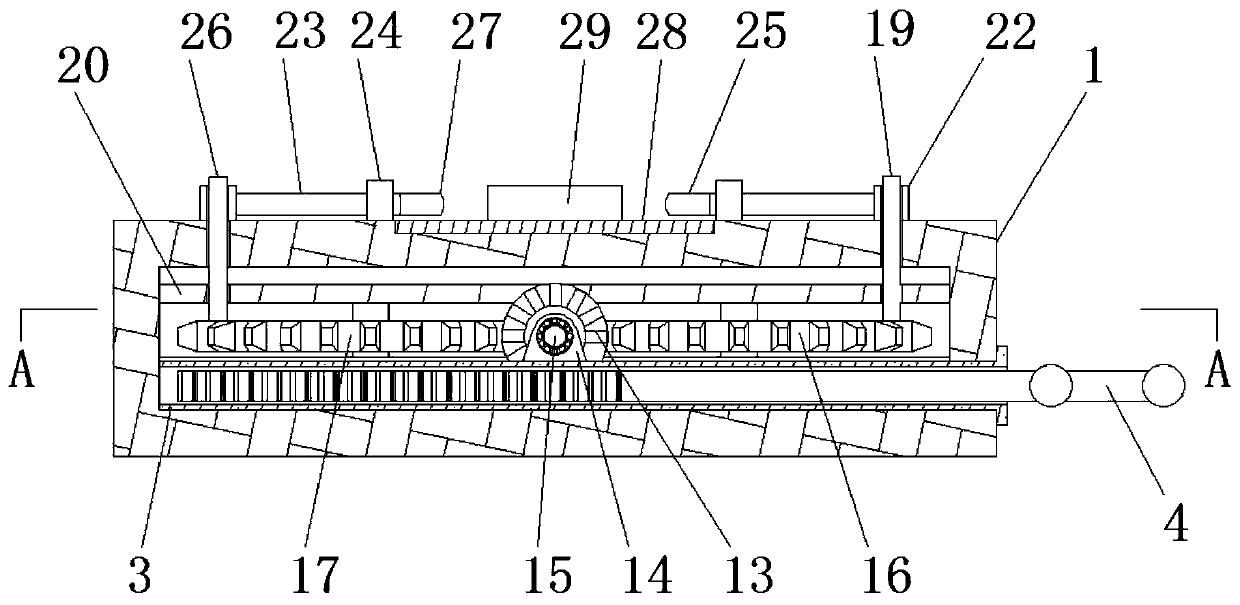

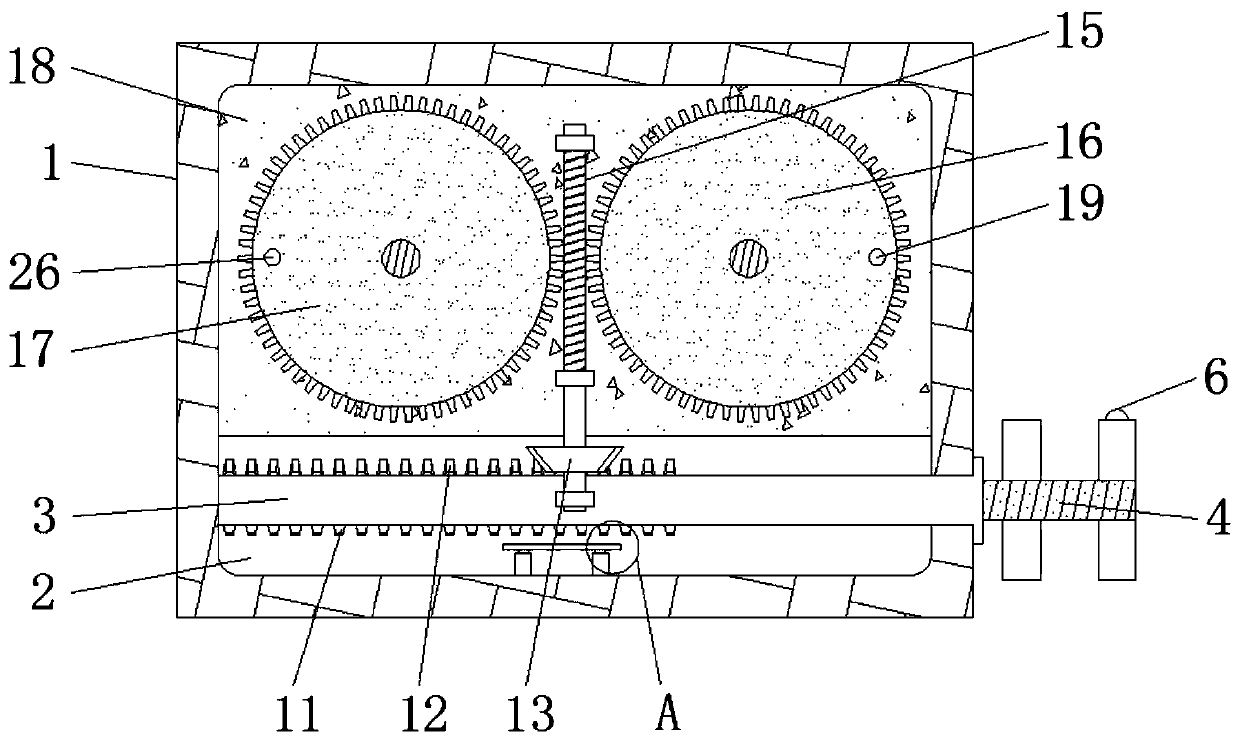

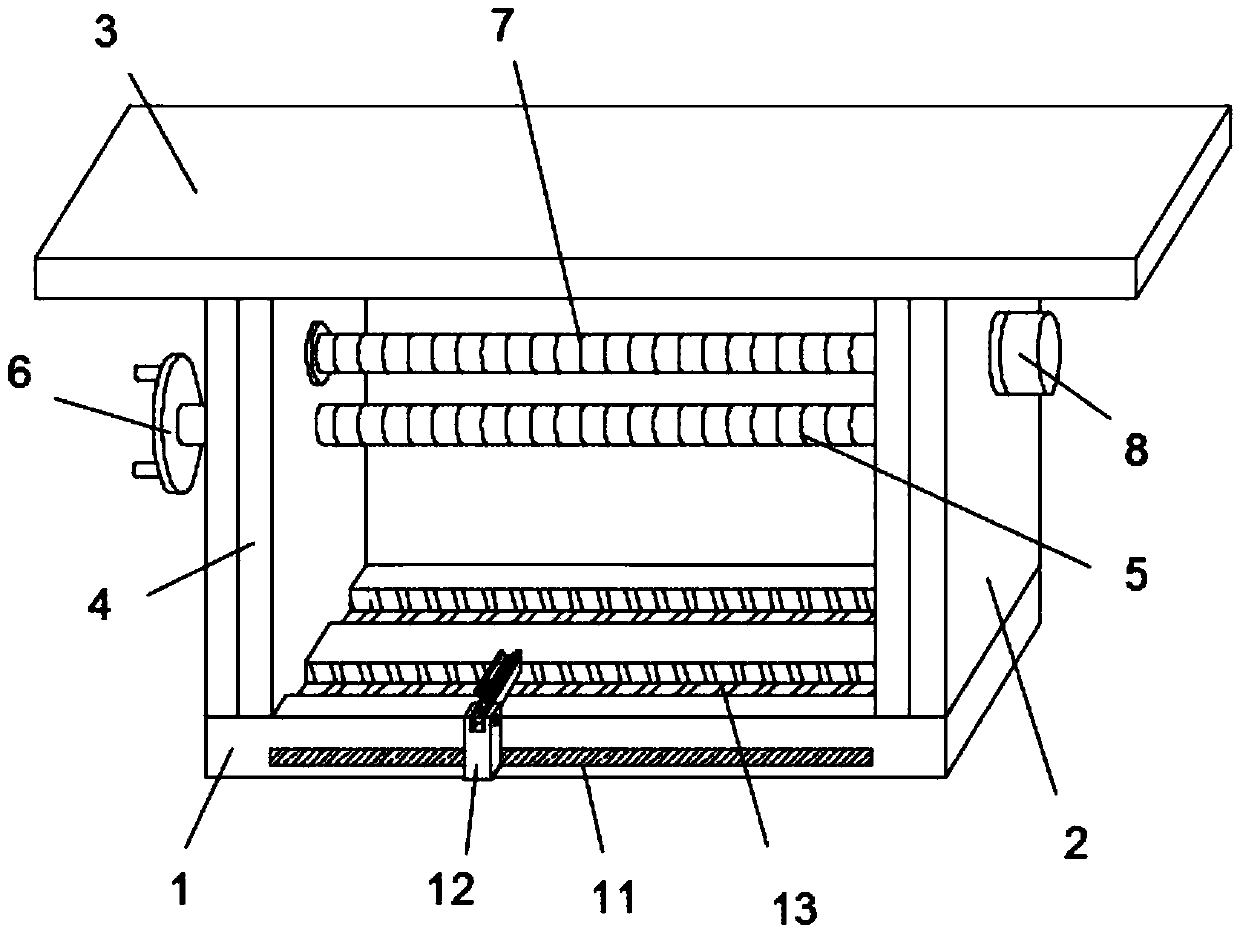

The invention discloses a portal crane capable of switching over clamps and used for a hardware pipe fitting, and relates to the field of hardware machining equipment. The portal crane capable of switching over clamps and used for the hardware pipe fitting comprises a crane frame, a clamp hoisting frame and clamp switchover rolls, wherein a winding reel arranged on a hoisting shaft on the crane frame is wound with traction ropes; the hoisting shaft is connected with the clamp hoisting frame through two traction ropes; the clamp hoisting frame is connected with two pairs of clamp switchover roll support columns through slide rods; one clamp switchover roll is rotationally connected between the lower ends of each pair of the clamp switchover roll support columns; a square pipe clamping groupis arranged at one side of each clamp switchover roll; and a circular pipe clamping group is arranged at the other side of each clamp switchover roll. According to the portal crane capable of switching over the clamps and used for the hardware pipe fitting, a rotary wheel is rotated, each pair of the clamp switchover roll support columns is controlled to move under the condition of adjusting thethread relationship of a screw rod and a screw rod seat, a distance between the clamp switchover rolls arranged at the lower ends of the two pairs of clamp switchover roll support columns is adjusted,the clamps arranged on the two groups of clamp switchover rolls clamp the pipe fitting, and the operation is convenient.

Owner:滨州高新材料产业园有限公司

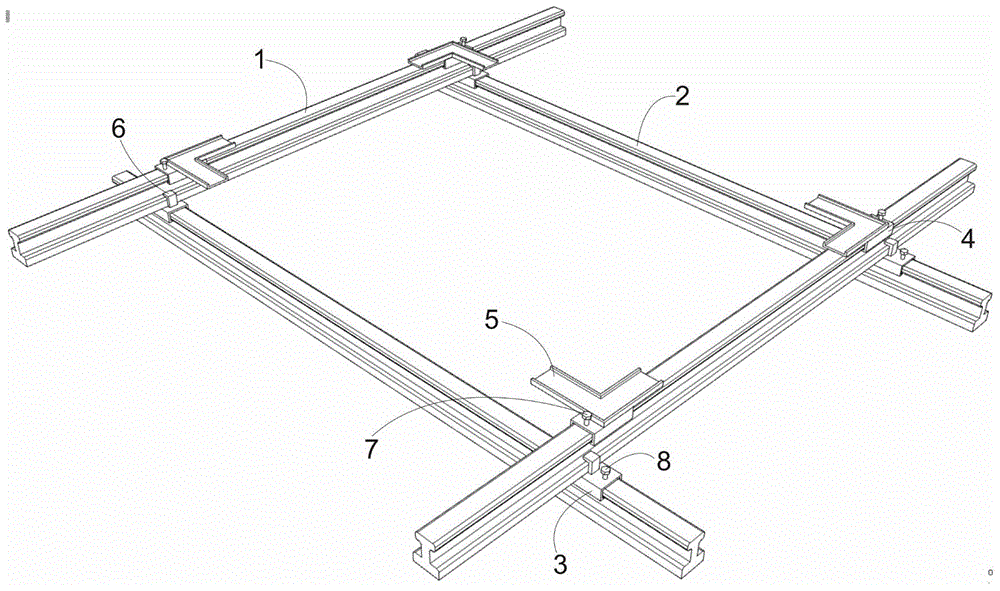

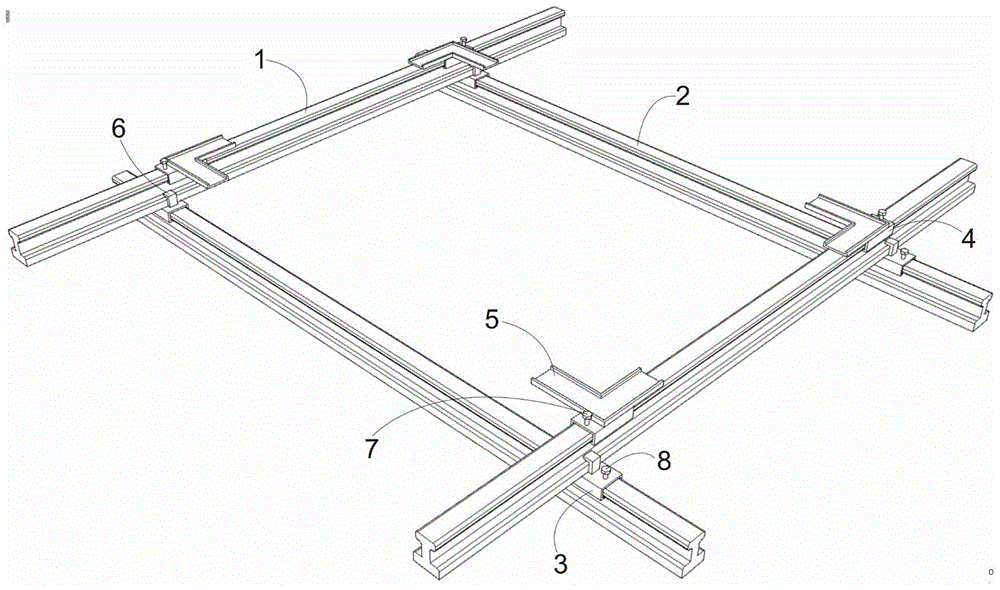

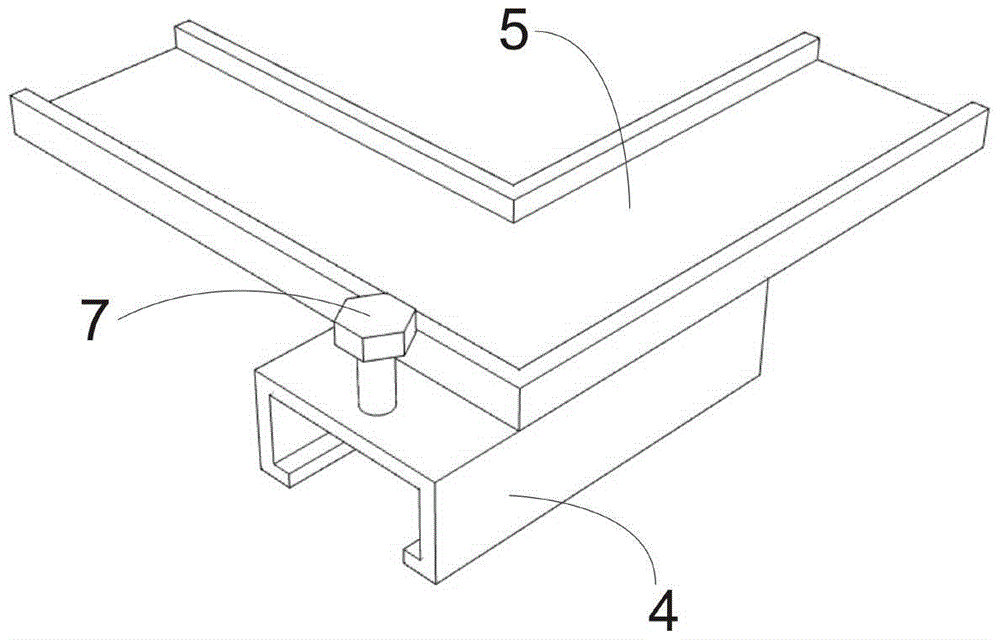

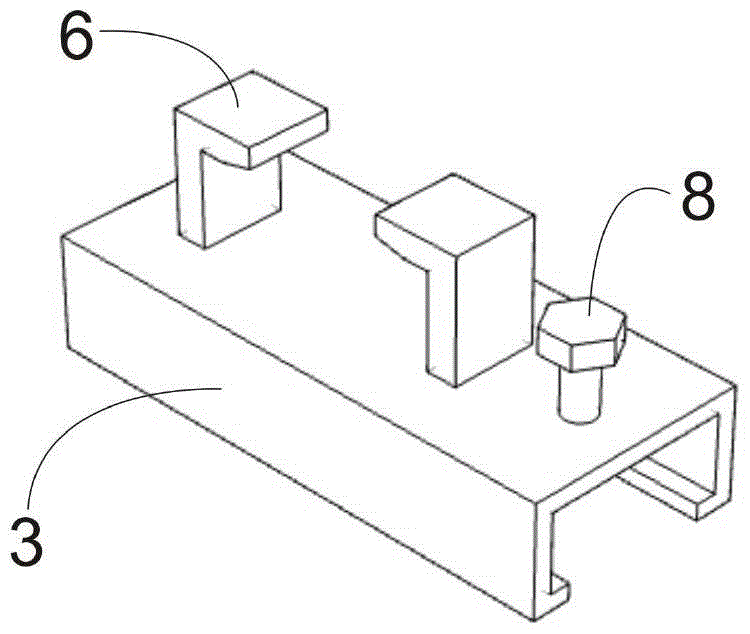

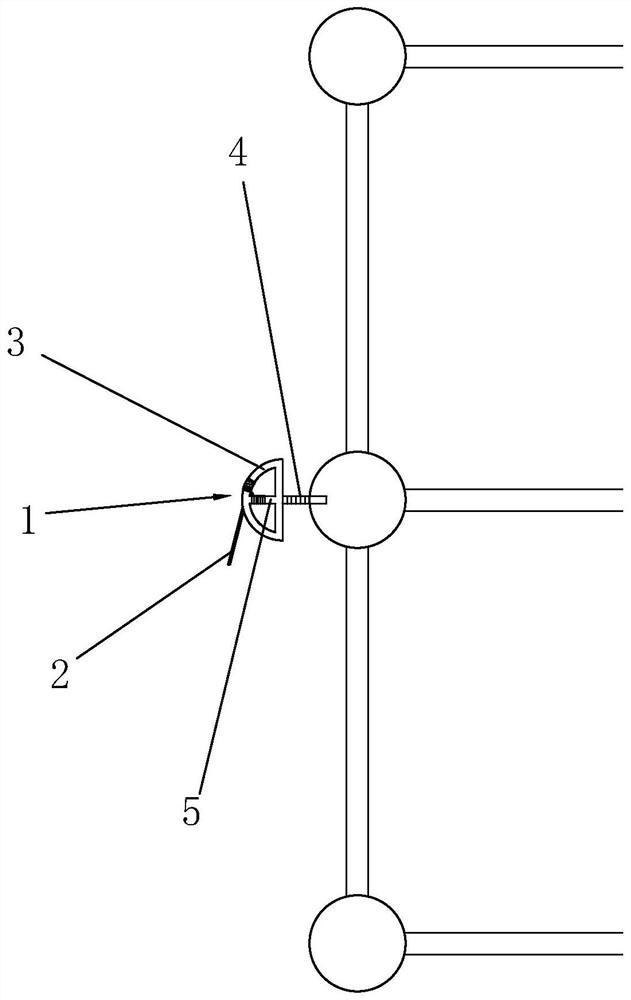

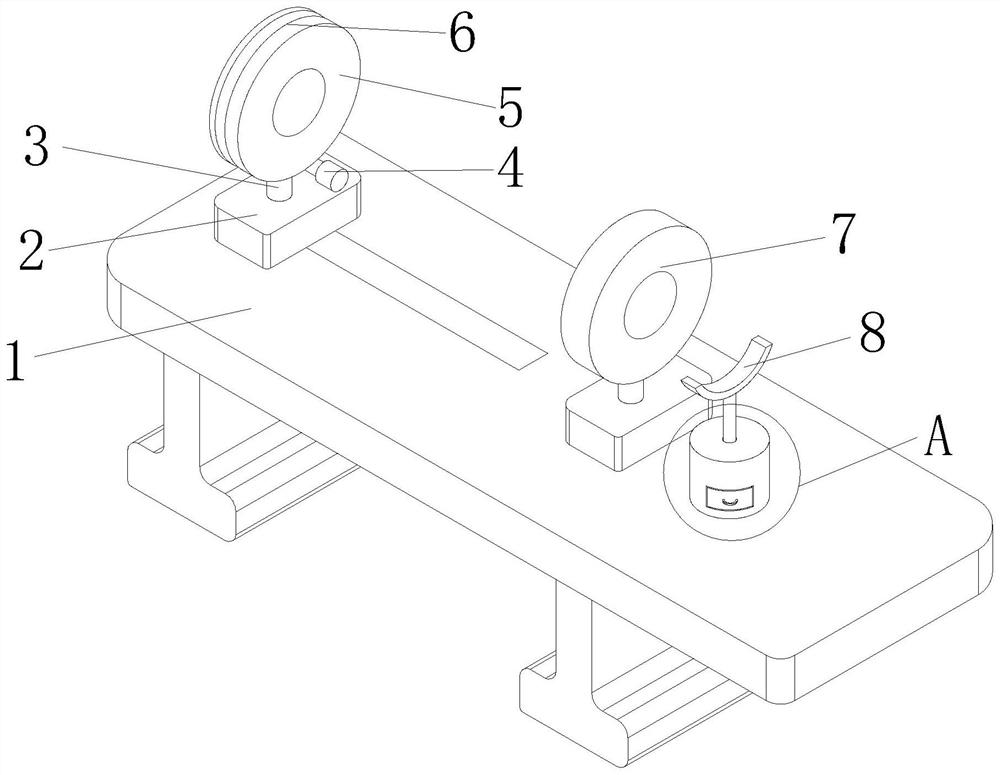

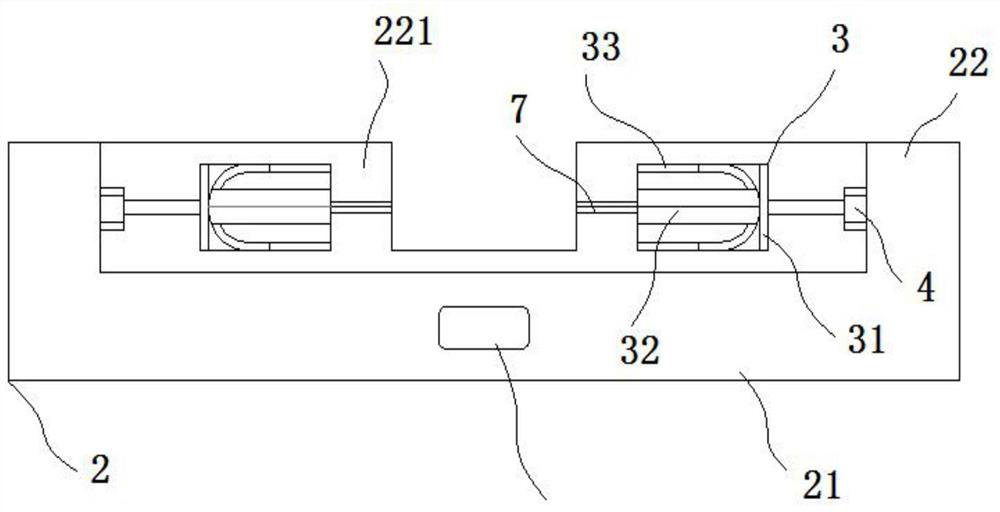

Welding clamp of extensible aluminum alloy window body

ActiveCN104526221ASimple and fast operationIncreased flexibility of useWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFastener

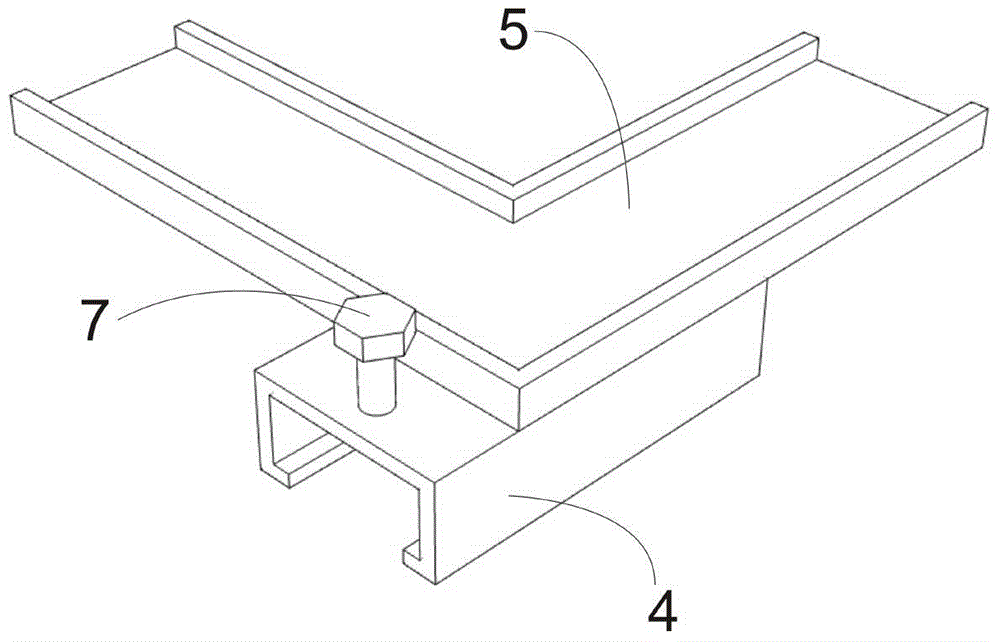

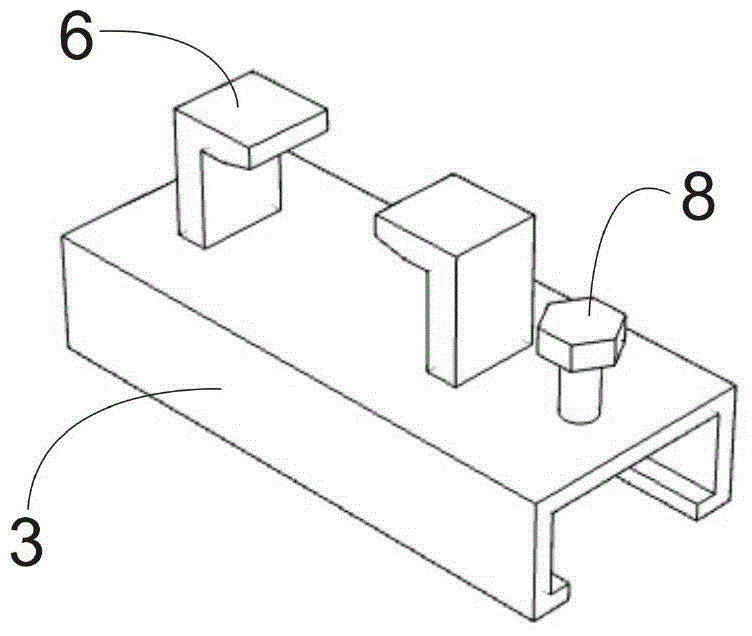

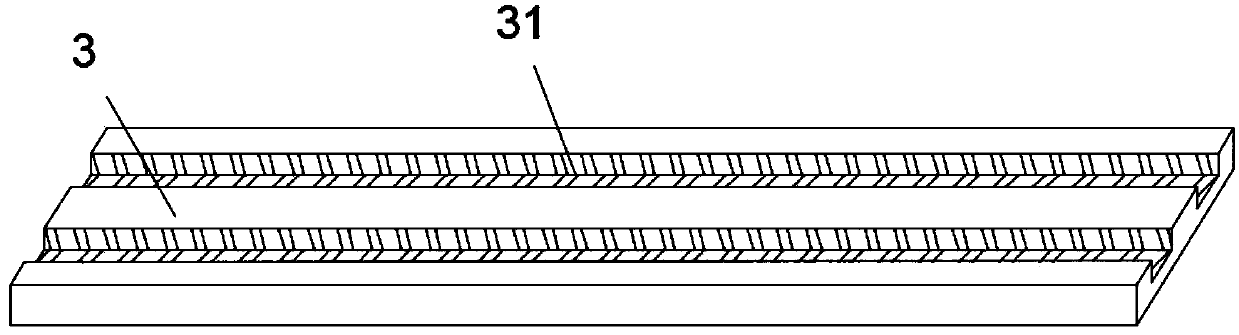

The invention discloses a welding clamp of an extensible aluminum alloy window body. The welding clamp comprises two parallel lower slide rails arranged at an interval, wherein the two lower slide rails are in sleeved connection with two lower slide seats, upper slide rails perpendicular to the lower slide rails are installed on the lower slide seats through fasteners, and the other end of each upper slide rail is installed on the lower slide seat in sleeved connection with another lower slide rail. Each upper slide rail is in sleeved connection with two upper slide seats, and limiting grooves are fixedly connected to the upper slide seats. Any adjustment on clamp size can be achieved, and the welding clamp can meet the welding requirements of different sizes of windows and has the advantages of being simple and convenient to operate, high in using flexibility, simple in structure and the like.

Owner:绥阳县覃兵门窗有限公司

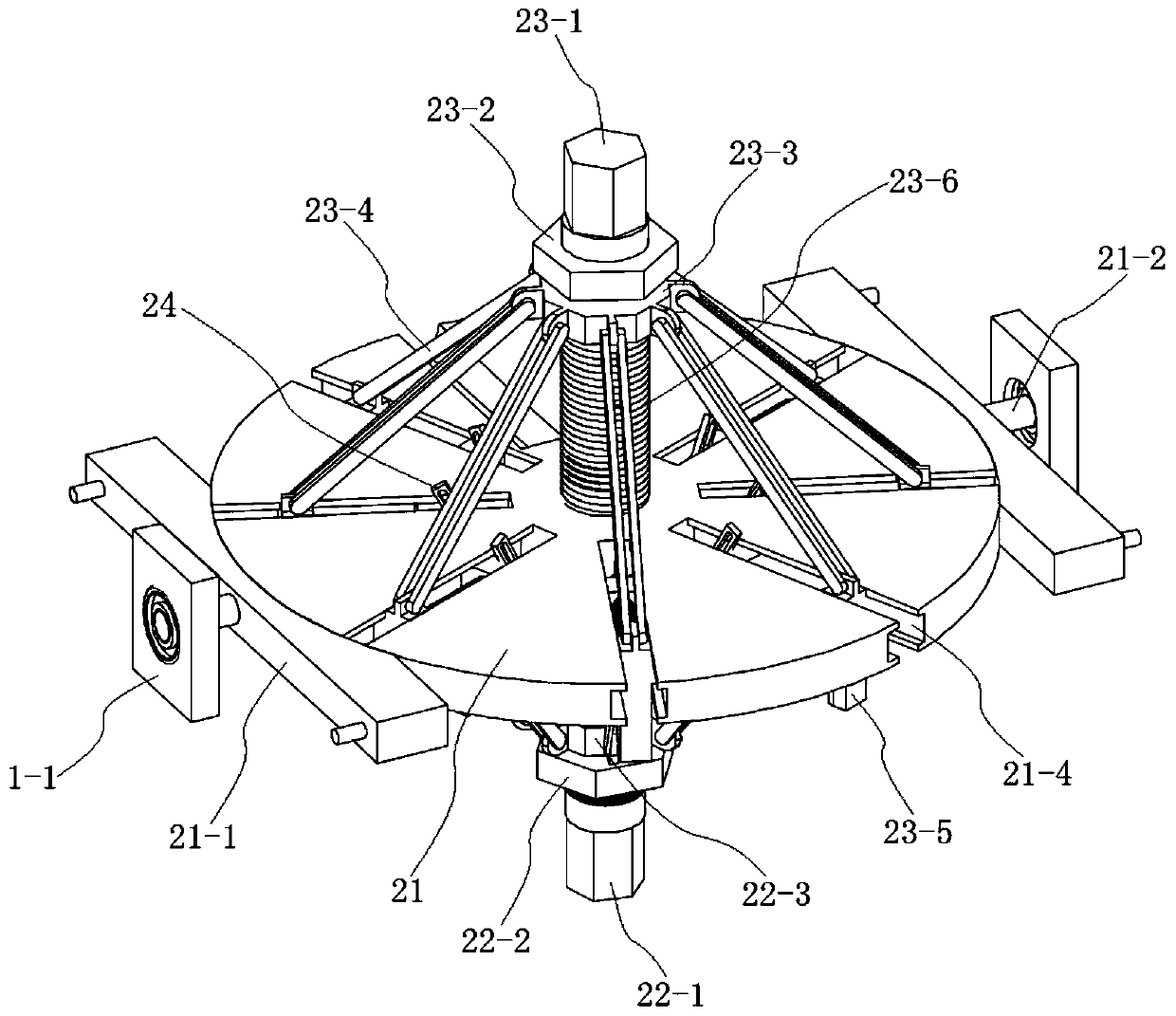

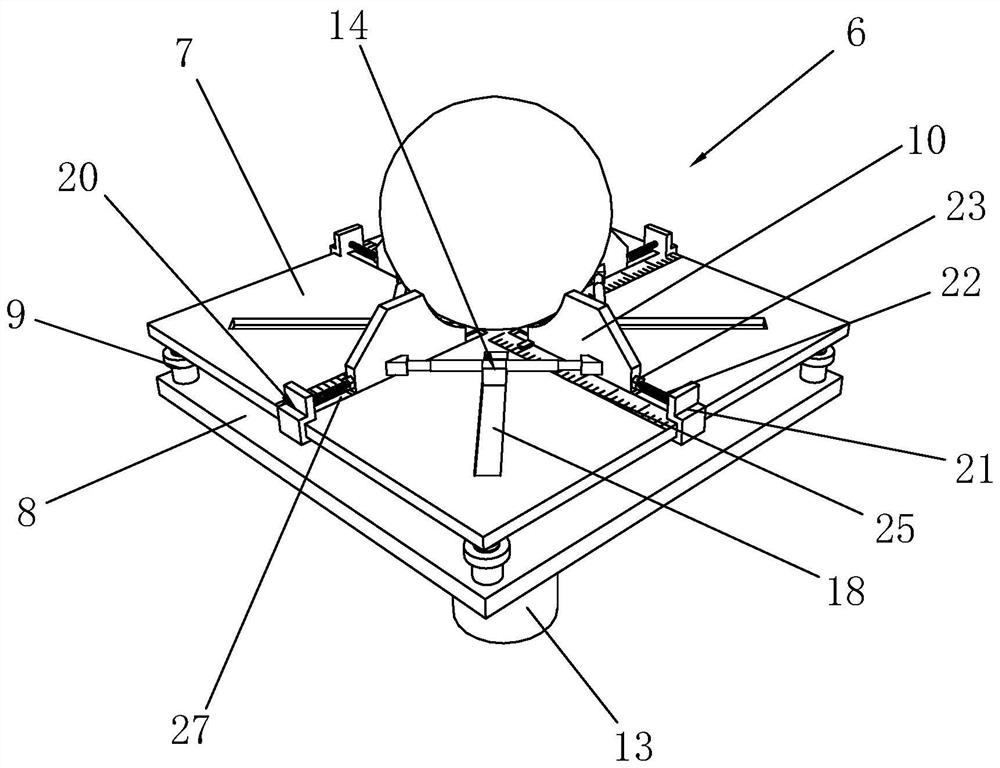

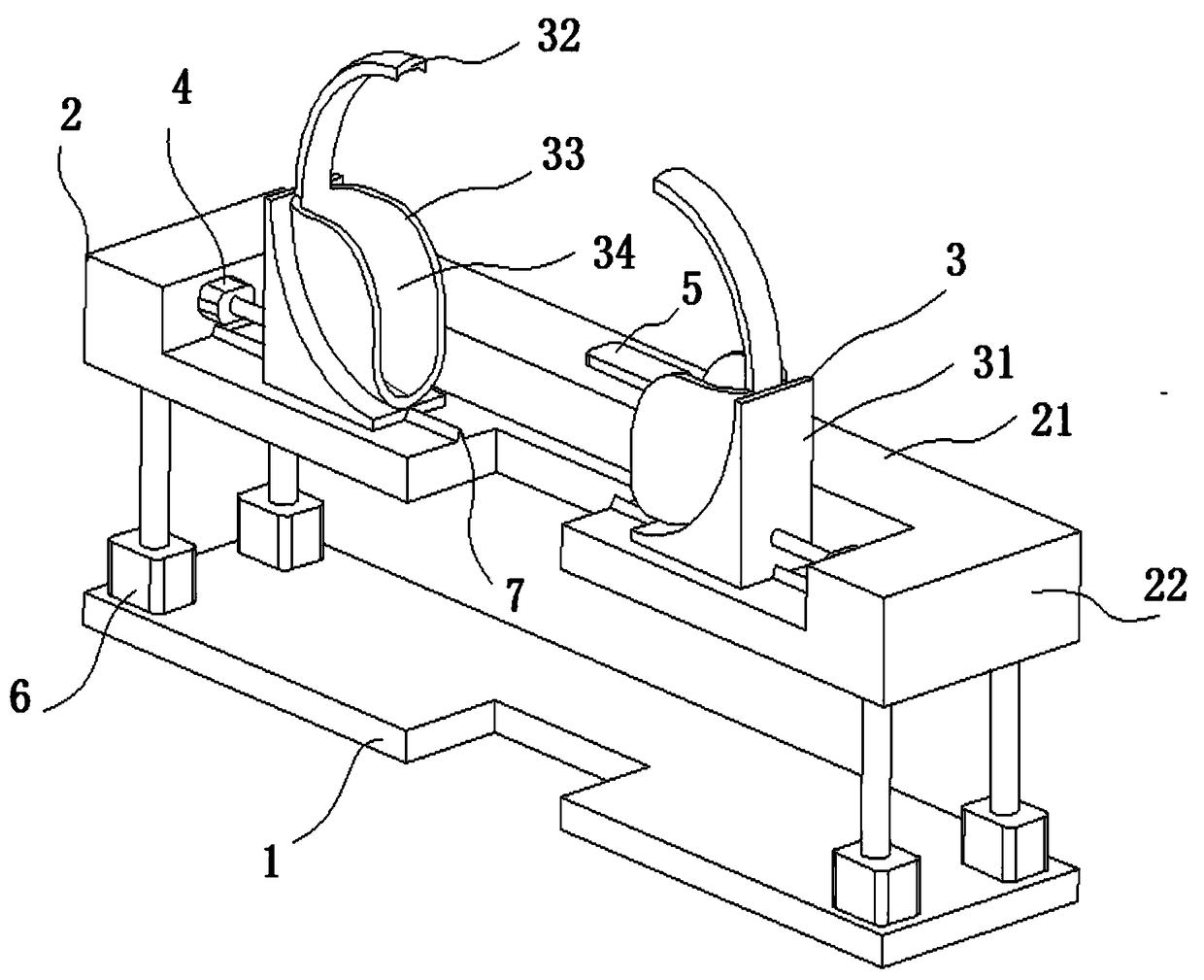

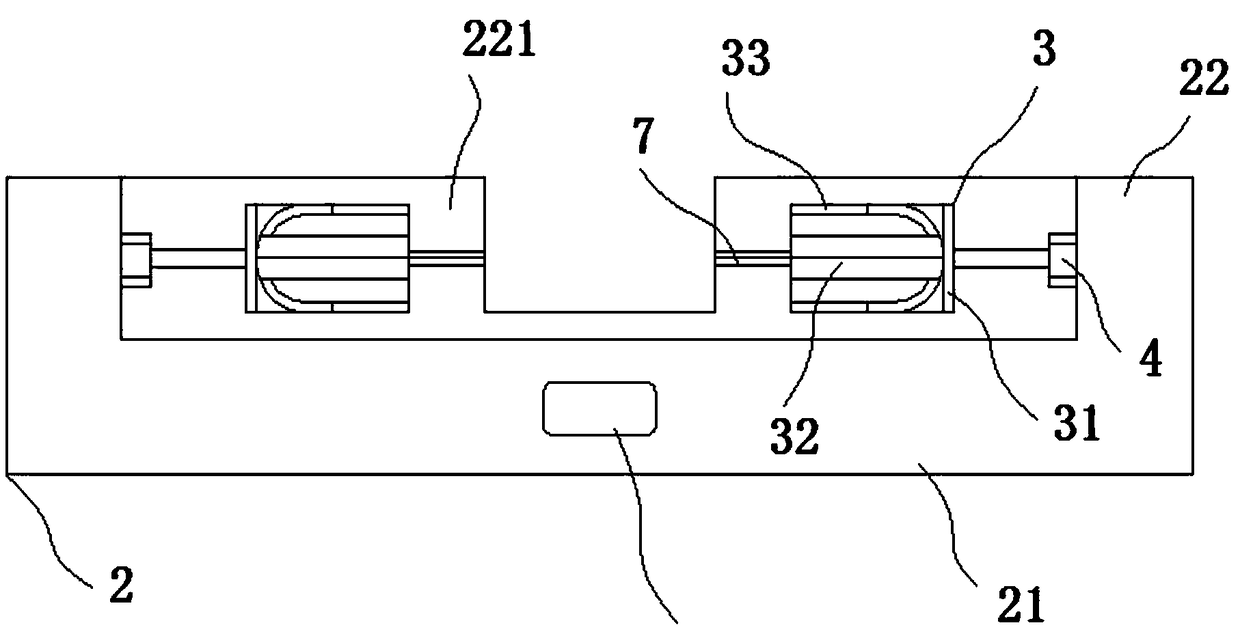

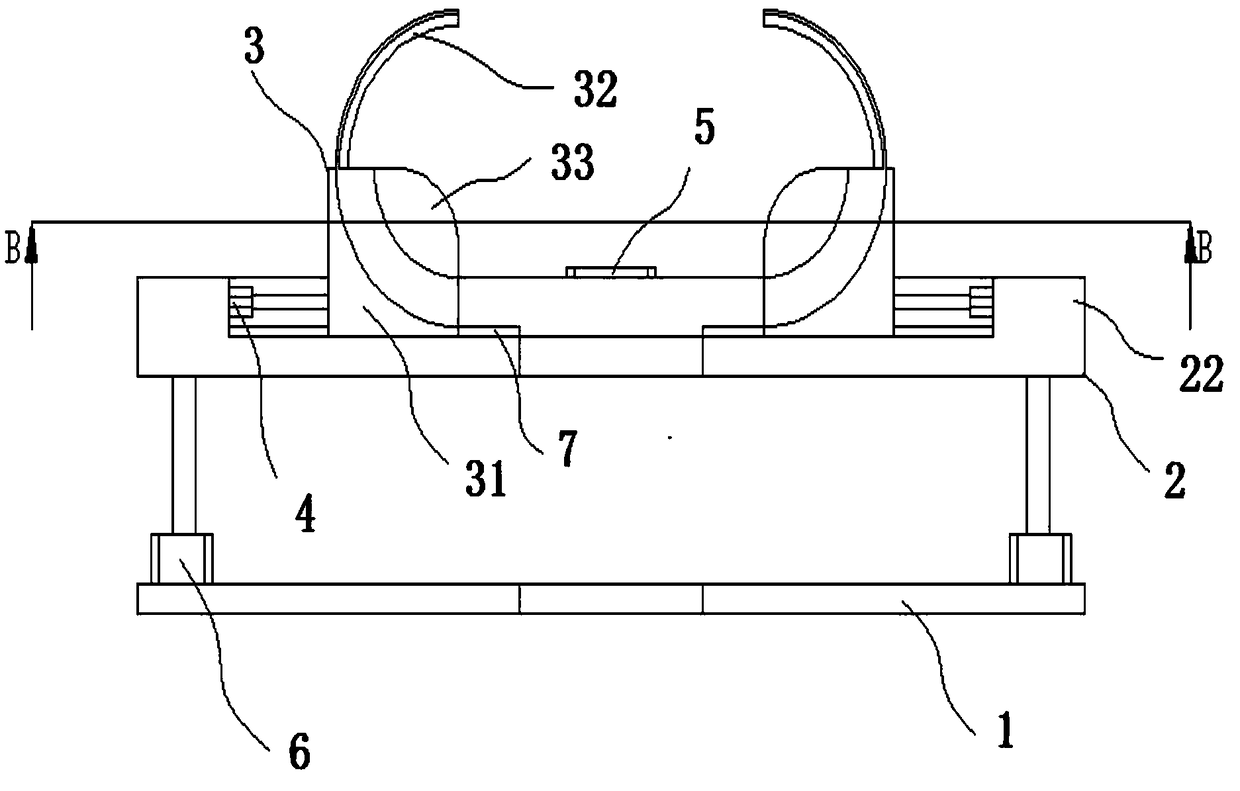

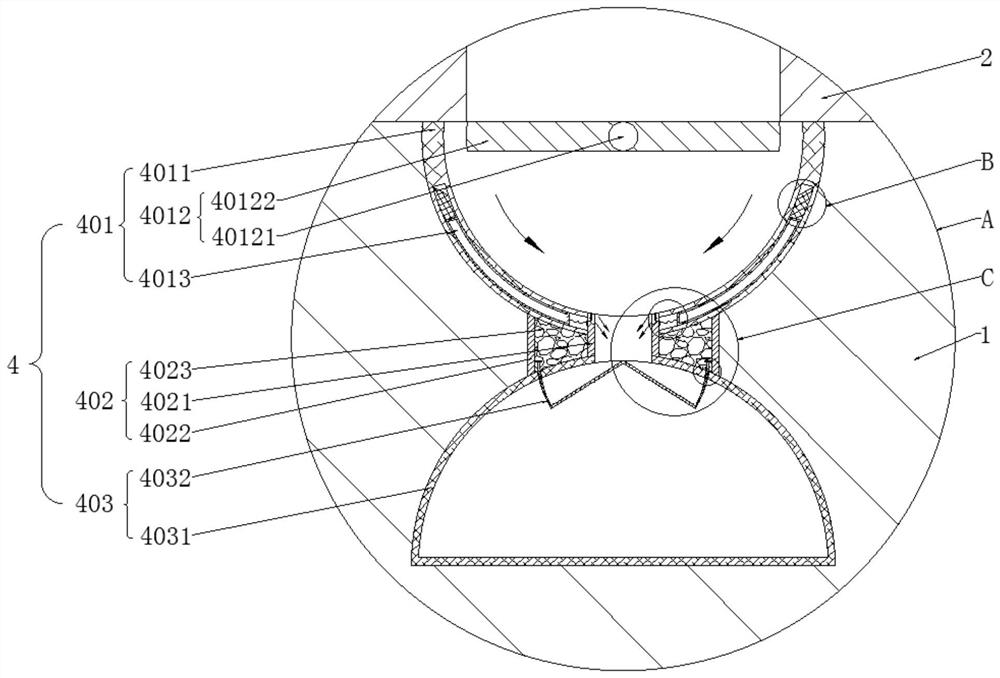

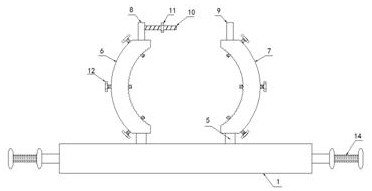

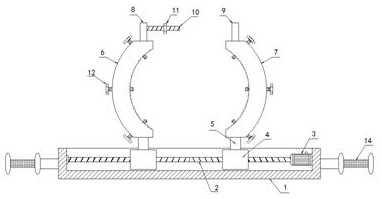

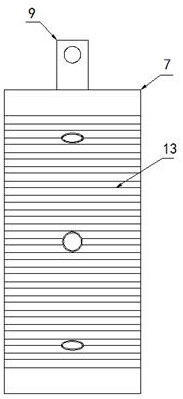

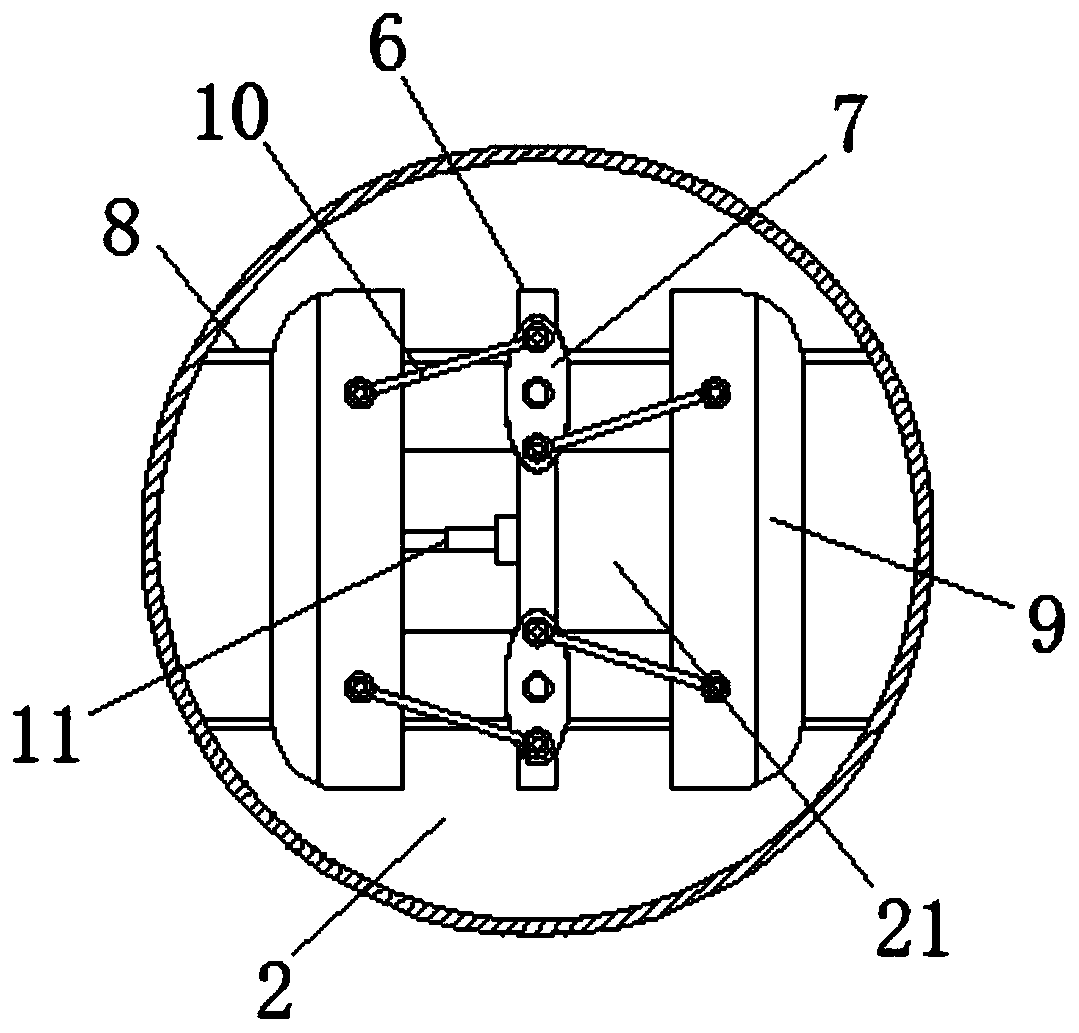

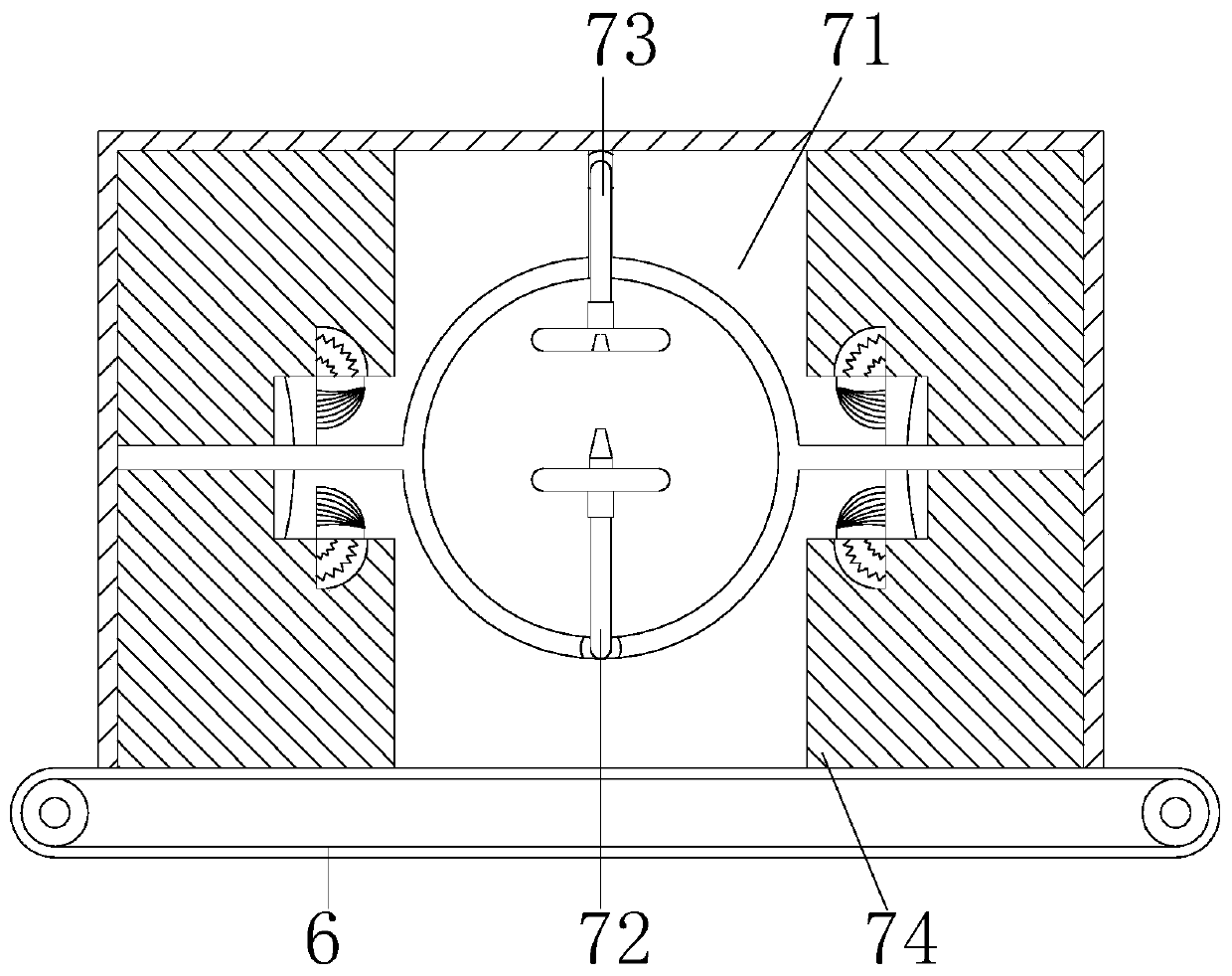

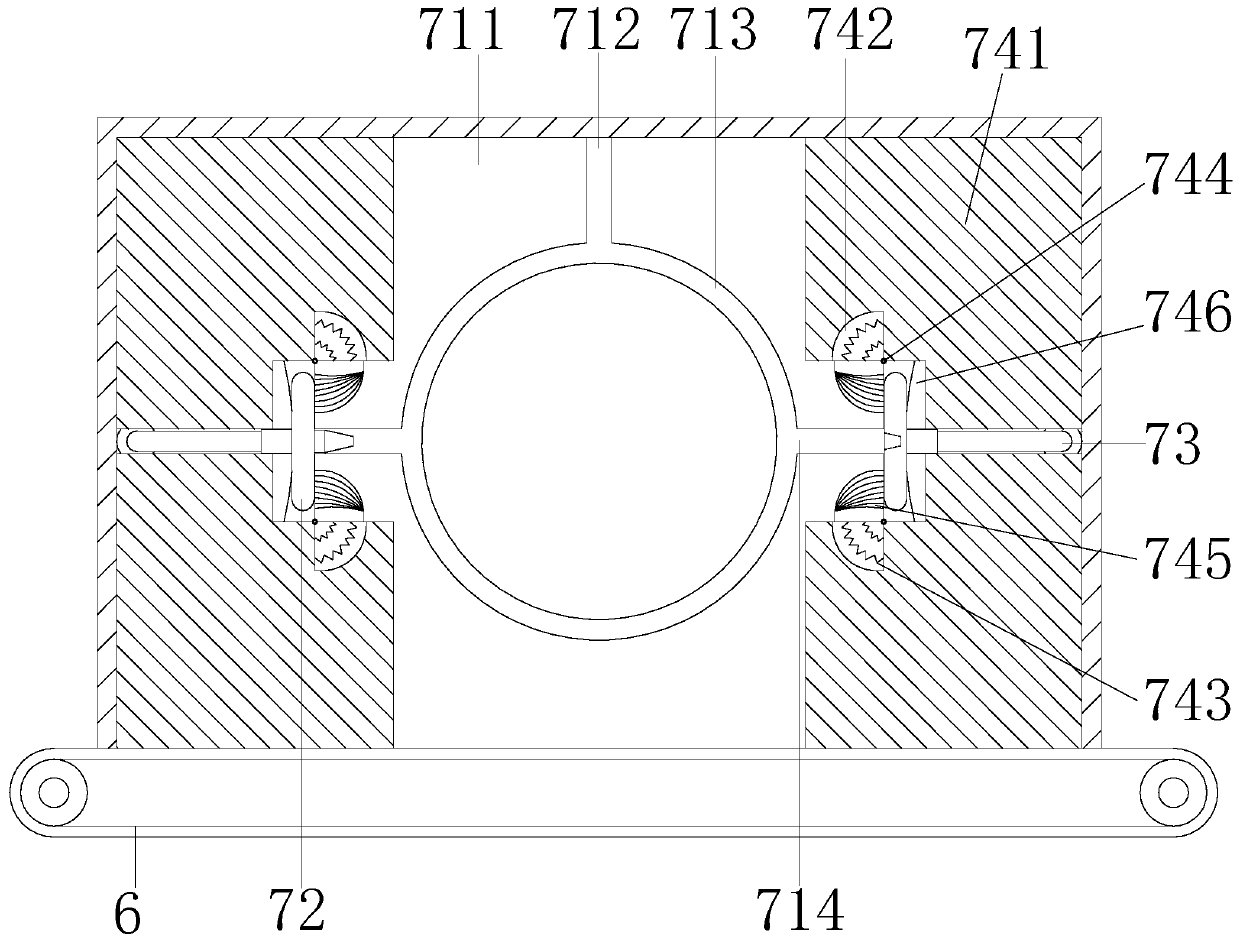

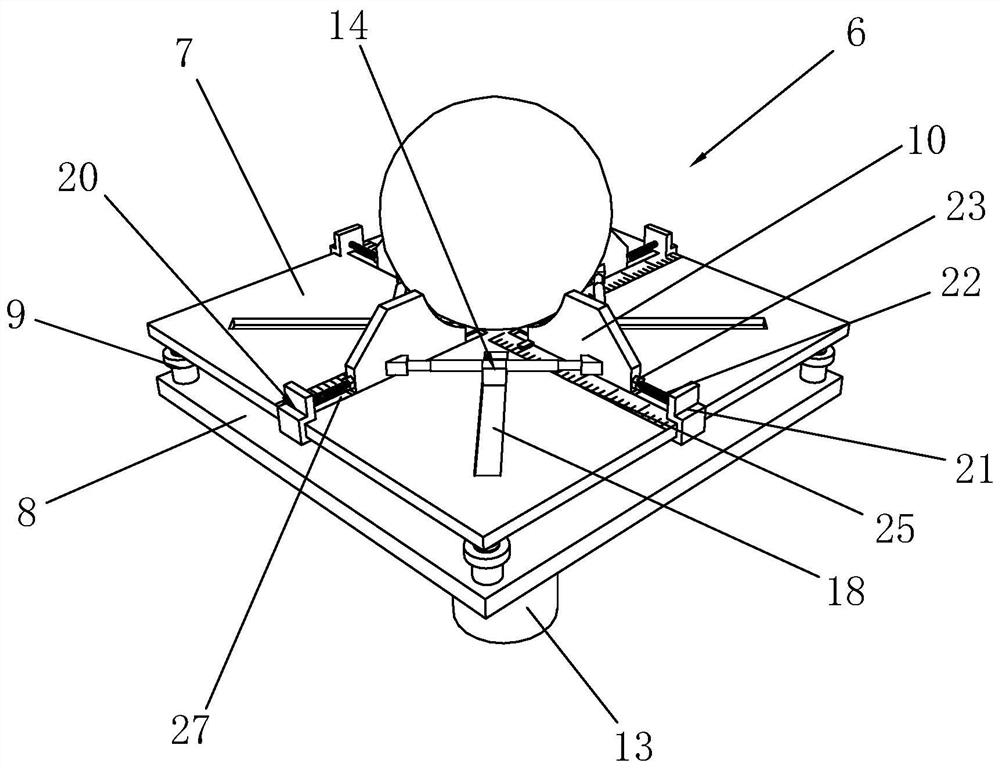

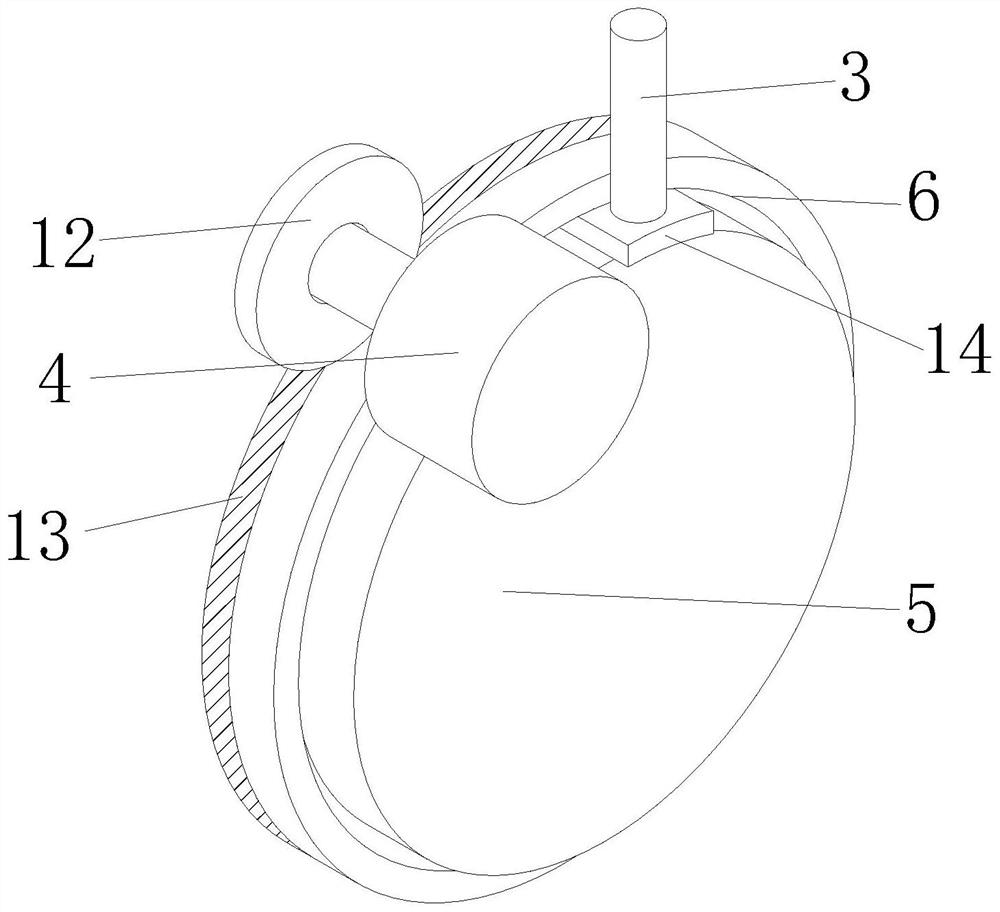

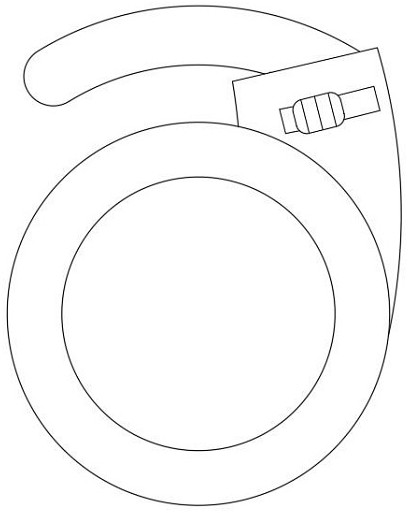

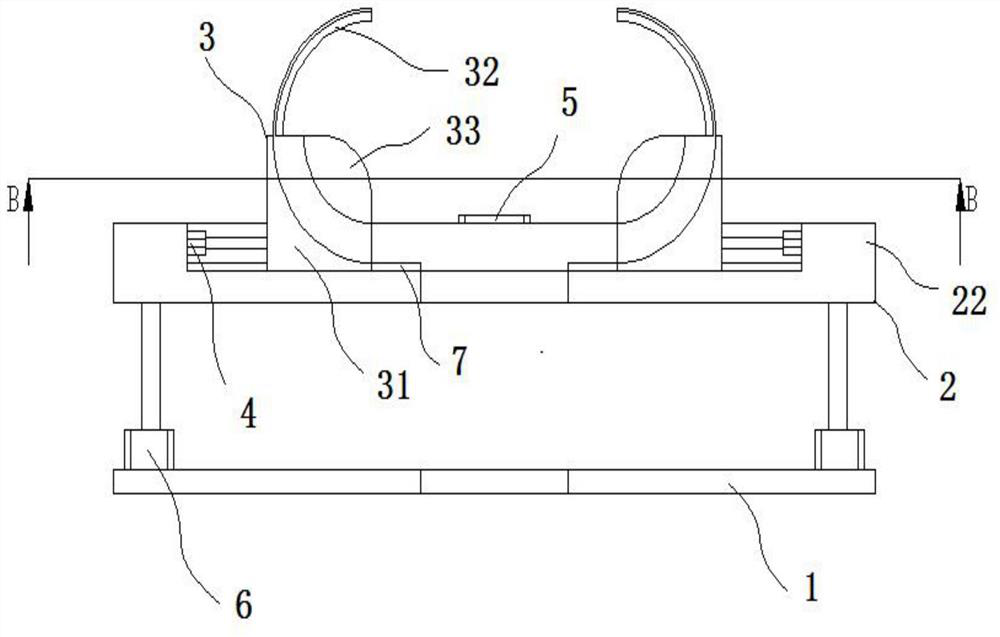

Auxiliary shape rectification welding tool for circular ring part quick clamping

InactiveCN111375965ACorrectiveMeet welding needsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPhysics

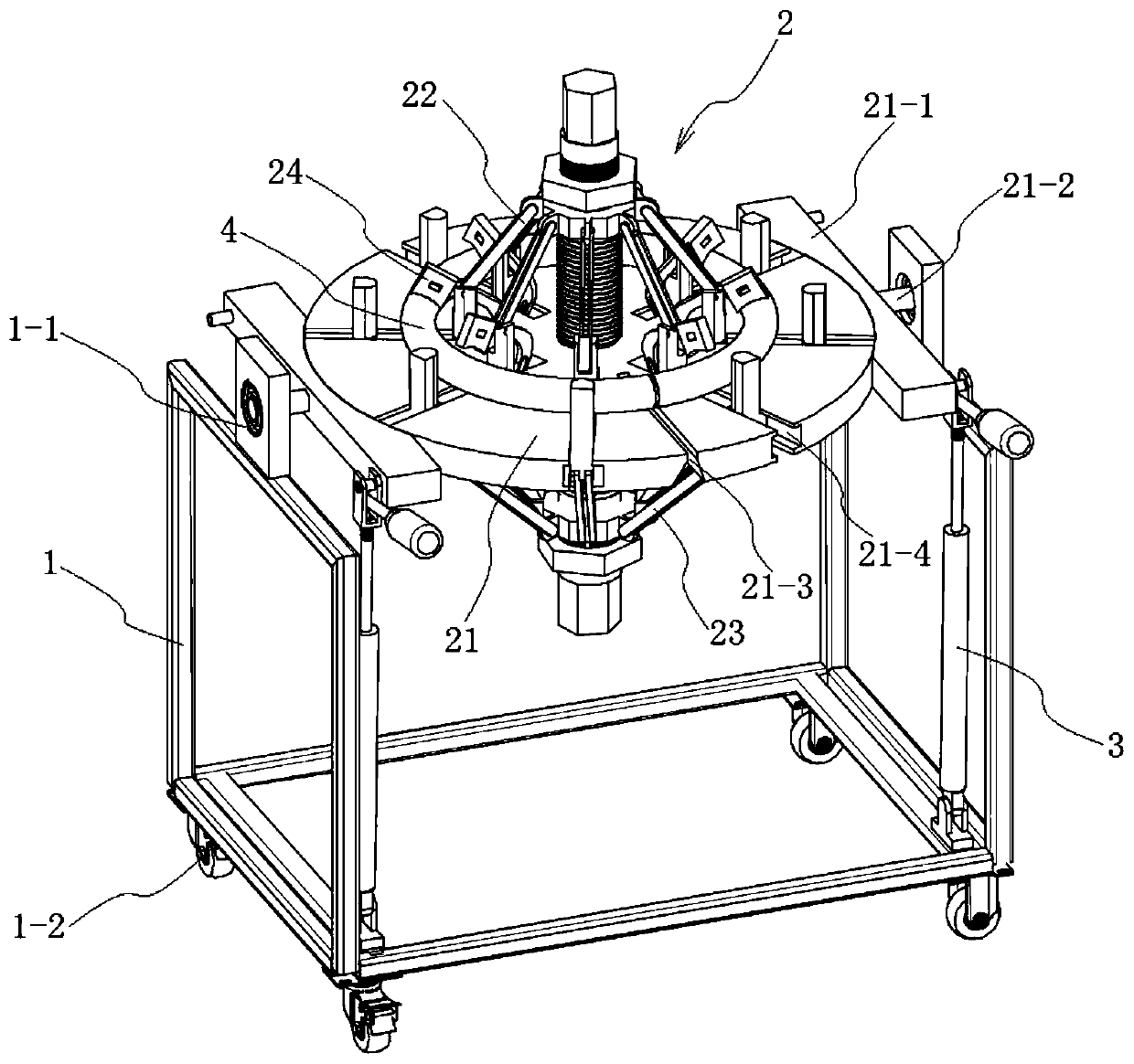

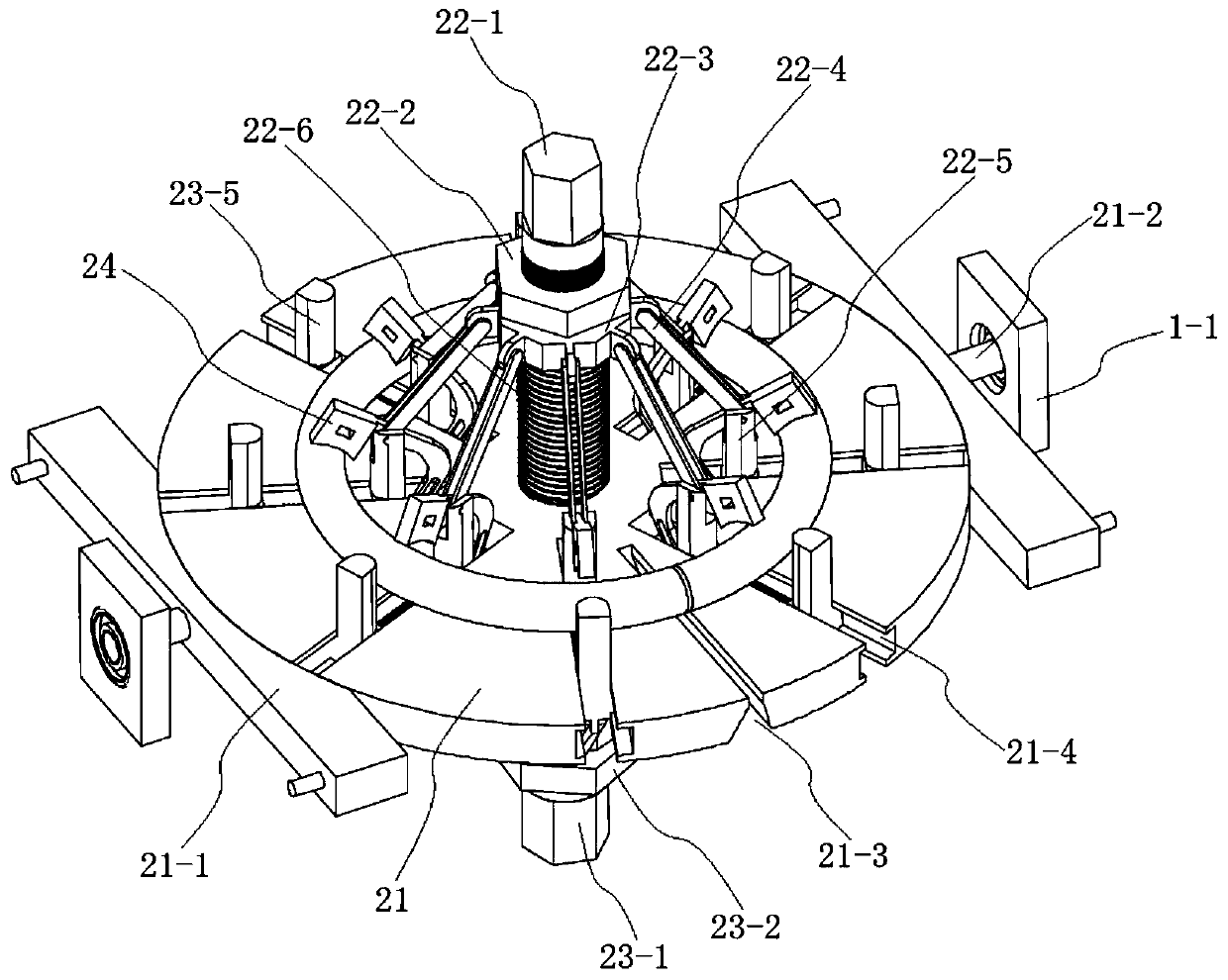

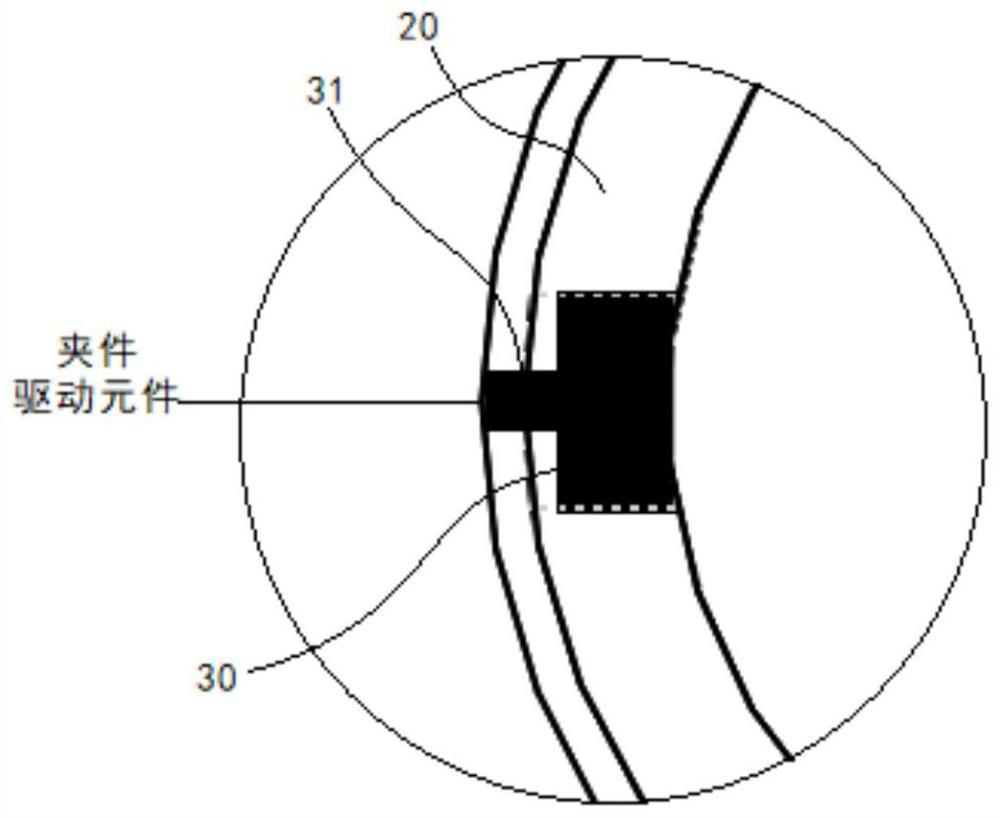

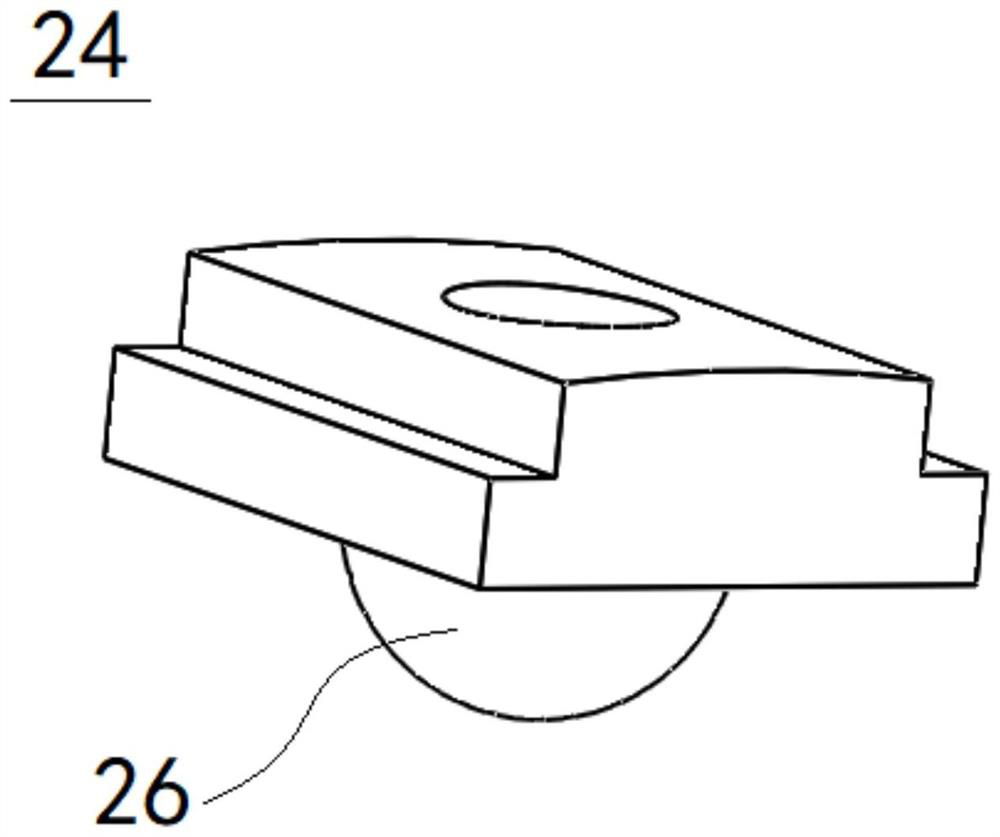

The invention discloses an auxiliary shape rectification welding tool for circular ring part quick clamping, and belongs to the field of welding tools. The auxiliary shape rectification welding tool comprises a bracket and a shape rectification fixing device rotationally erected on the bracket. The shape rectification fixing device comprises a base, an inner wall positioning mechanism, an outer wall positioning mechanism and a pressing mechanism. A welded circular ring part is fixed at multiple points by using multiple groups of mutually matched inner wall clamping blocks and outer wall clamping blocks, so that clamping and fixing are stable and reliable; and the inner wall clamping blocks and the outer wall clamping blocks synchronously stretch and retract inside and outside, so that a certain rectification function can be achieved on the welded circular ring part. In addition, in the clamping process of the inner wall clamping blocks and the outer wall clamping blocks, the pressing mechanism can be synchronously driven for linkage and downward pressing, and the upper portion of the welded circular ring part is pressed and fixed, so that clamping is more rapid and convenient, andthe clamping efficiency and stability are improved. Meanwhile, the inner wall clamping blocks and the outer wall clamping blocks can be moved and adjusted inside and outside radially in the circumferential direction, welding requirements of welded circular ring parts in different sizes can be met, and the product adaptability is high.

Owner:CHANGZHOU INST OF TECH

Installation method of curved steel latticed shell structure with gradually varied gable starting span

ActiveCN111809893AGuarantee the stability of the pullPrevent slidingBuilding material handlingArchitectural engineeringBall joint

The invention discloses an installation method of a curved steel latticed shell structure with a gradually varied gable starting span. The installation method comprises the following steps of a, construction preparation; b, splicing block by block and segment by segment; and c, installing a purline system and a roof panel structure. Connection between a steel wire rope and a ball joint is achievedthrough a steel wire rope pulling device, the pulling stability of the steel wire rope is guaranteed, the steel wire rope is prevented from sliding, the perpendicularity of a vertical gable structureis guaranteed, and damage to a rod piece of the latticed shell structure in the steel wire rope pulling process is avoided; and meanwhile, temporary fixing devices are used for supporting the ball joints on the inner sides of the gable latticed shell units, the construction safety performance is improved, and the temporary fixing devices can eliminate the influence of site flatness errors on themounting precision, mounting construction between the ball joints and the temporary fixing devices is better facilitated, construction operation is convenient, field construction is flexible and convenient, precision errors are easy to adjust, construction efficiency is high, installation quality is guaranteed, potential safety hazards of aloft work are reduced, and construction cost is reduced.

Owner:浙江中南绿建科技集团有限公司

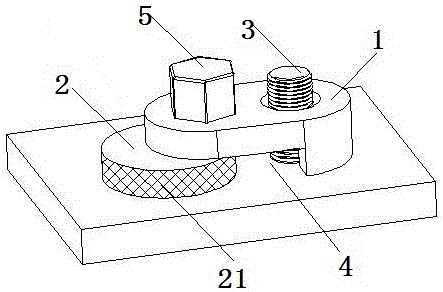

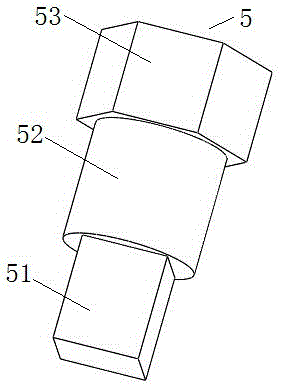

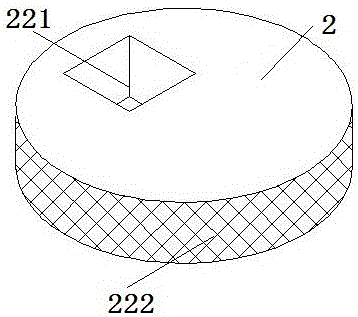

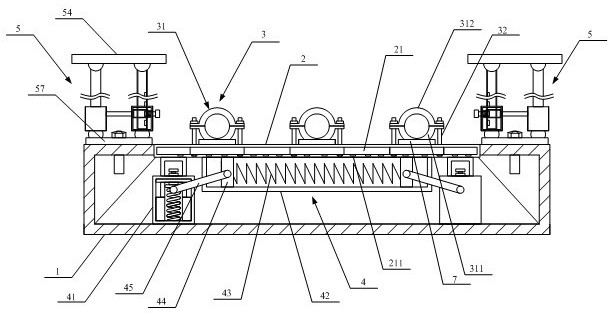

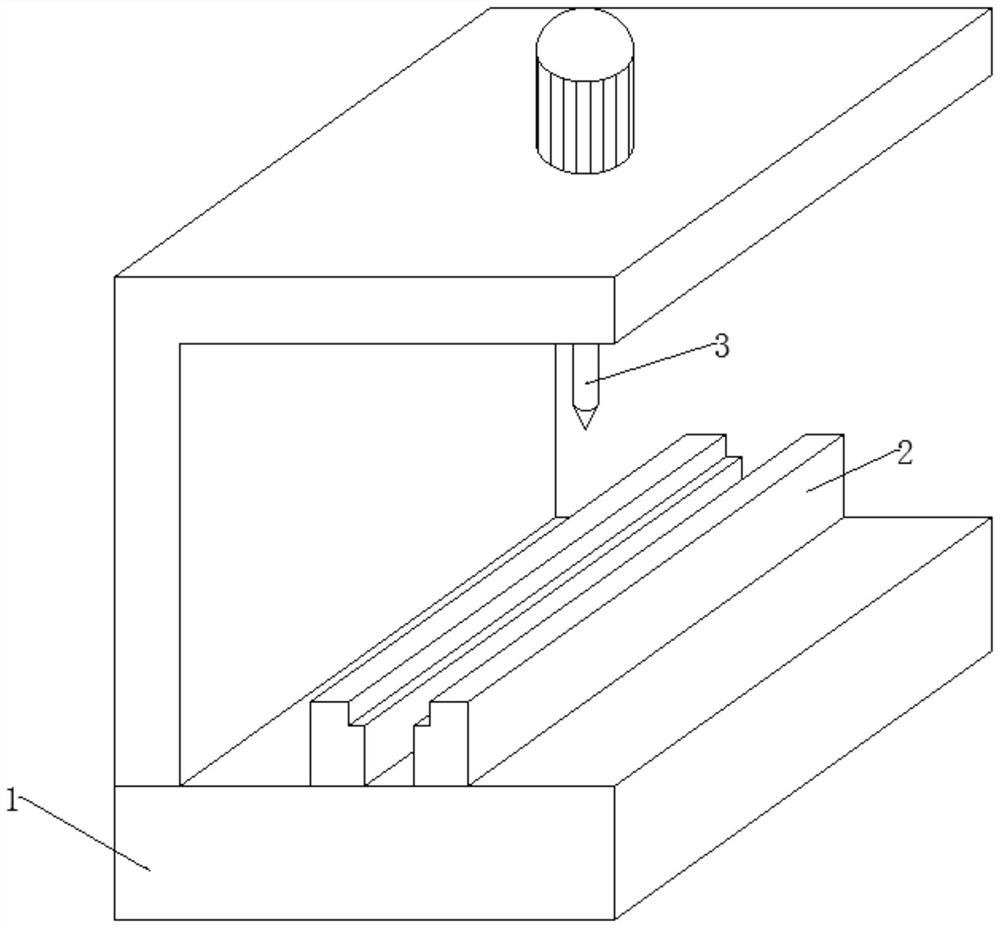

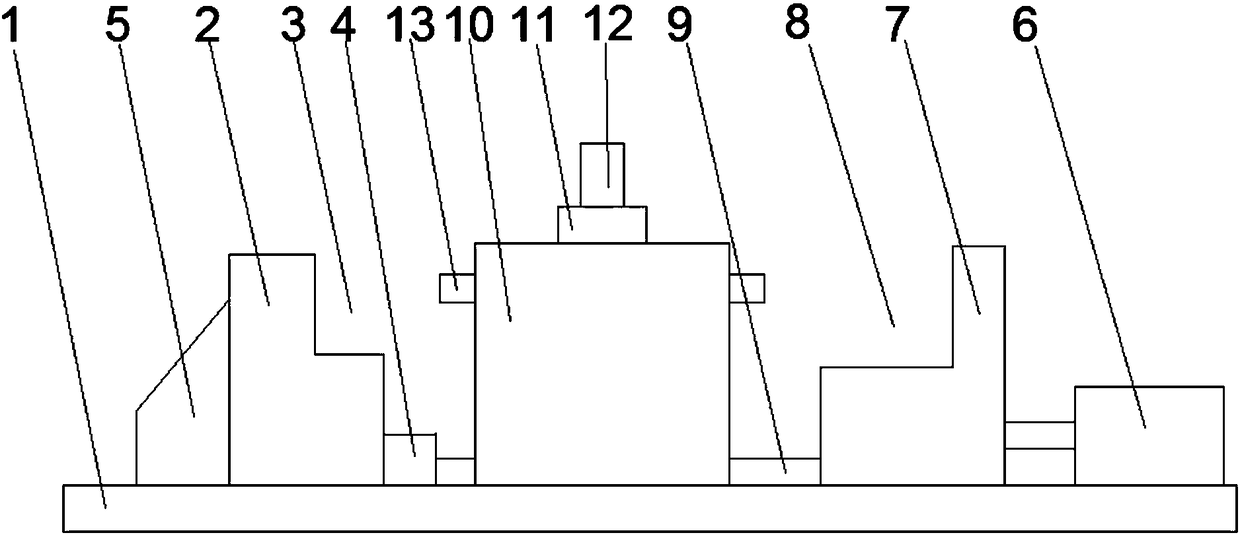

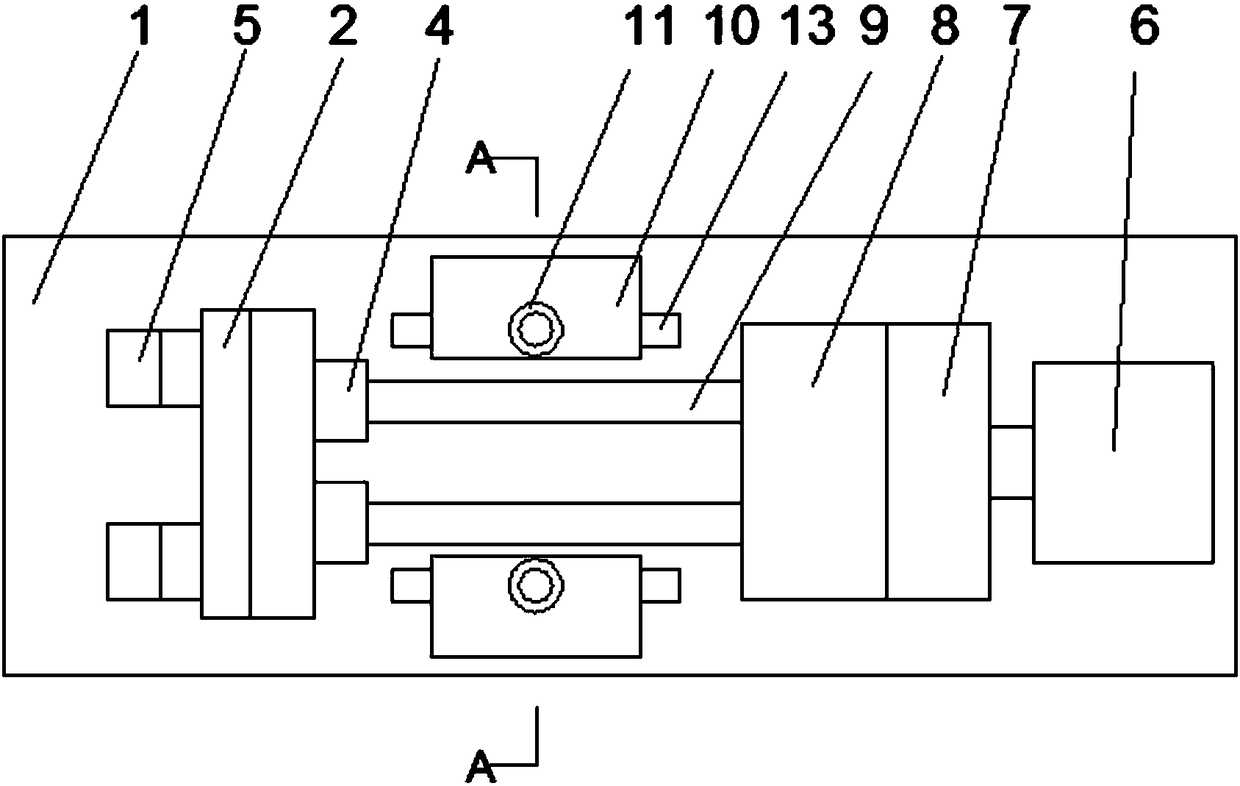

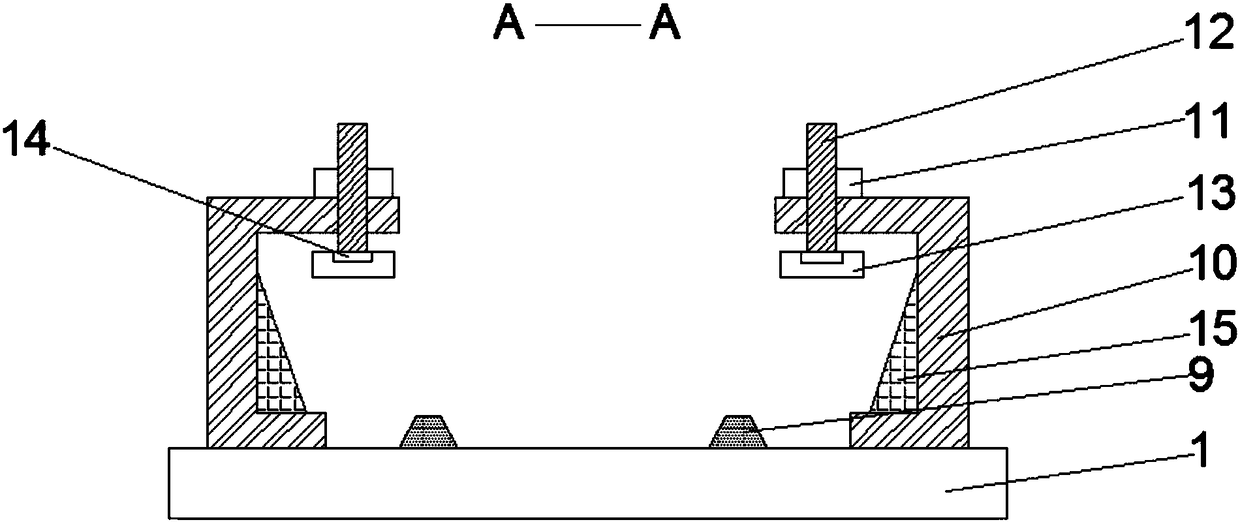

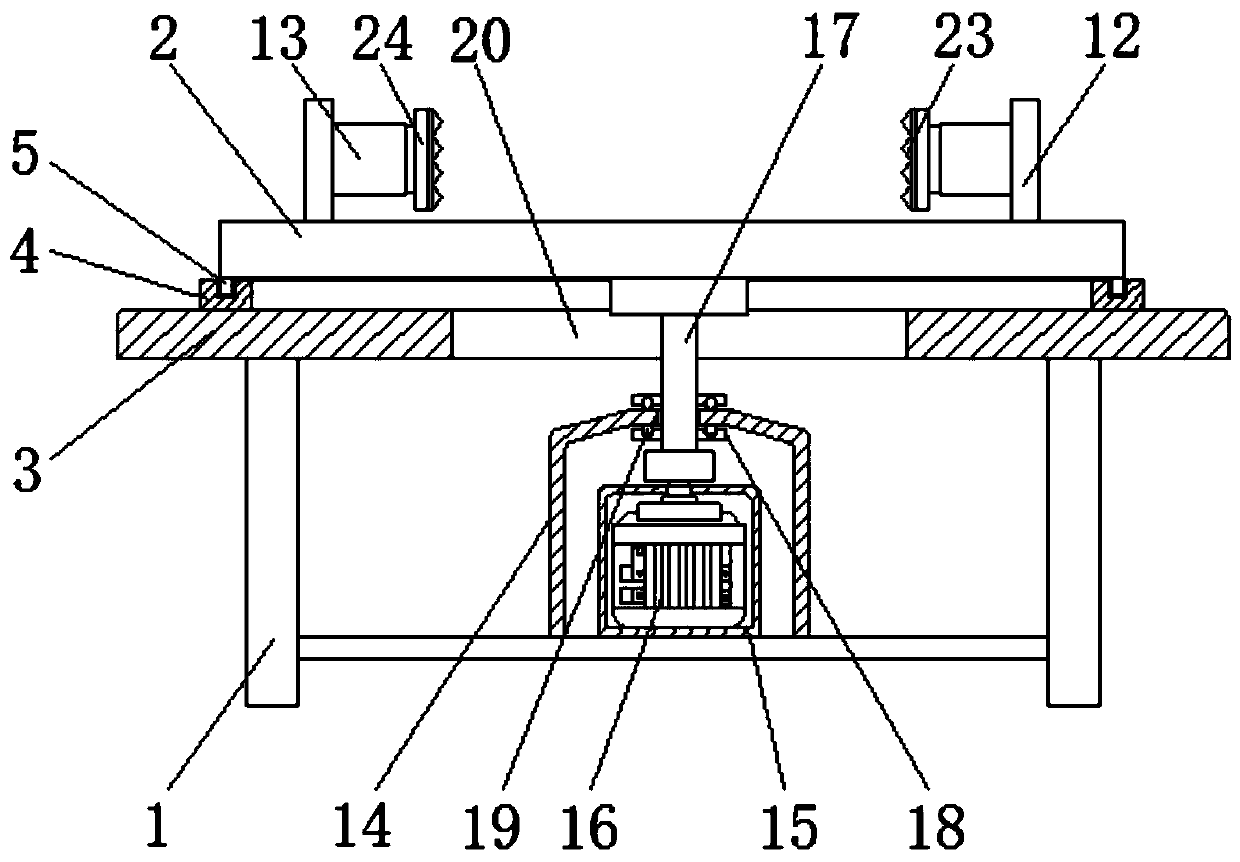

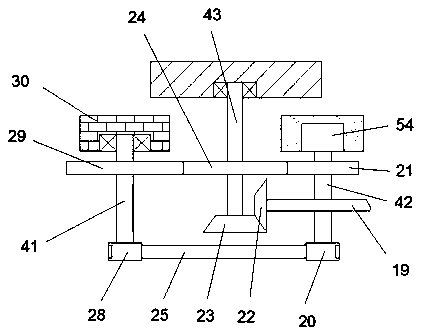

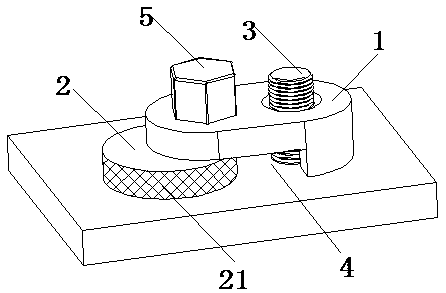

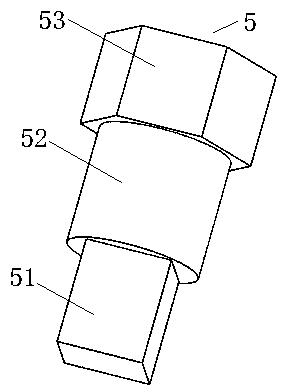

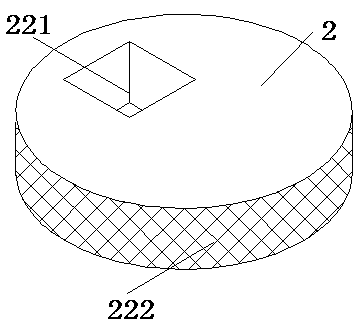

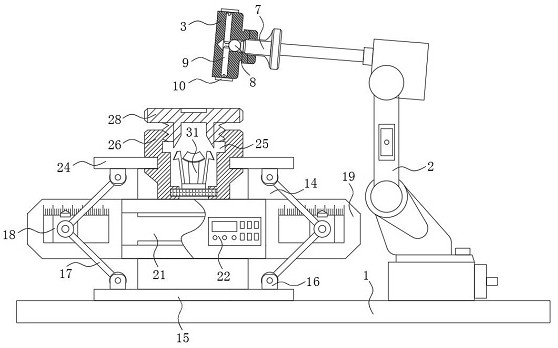

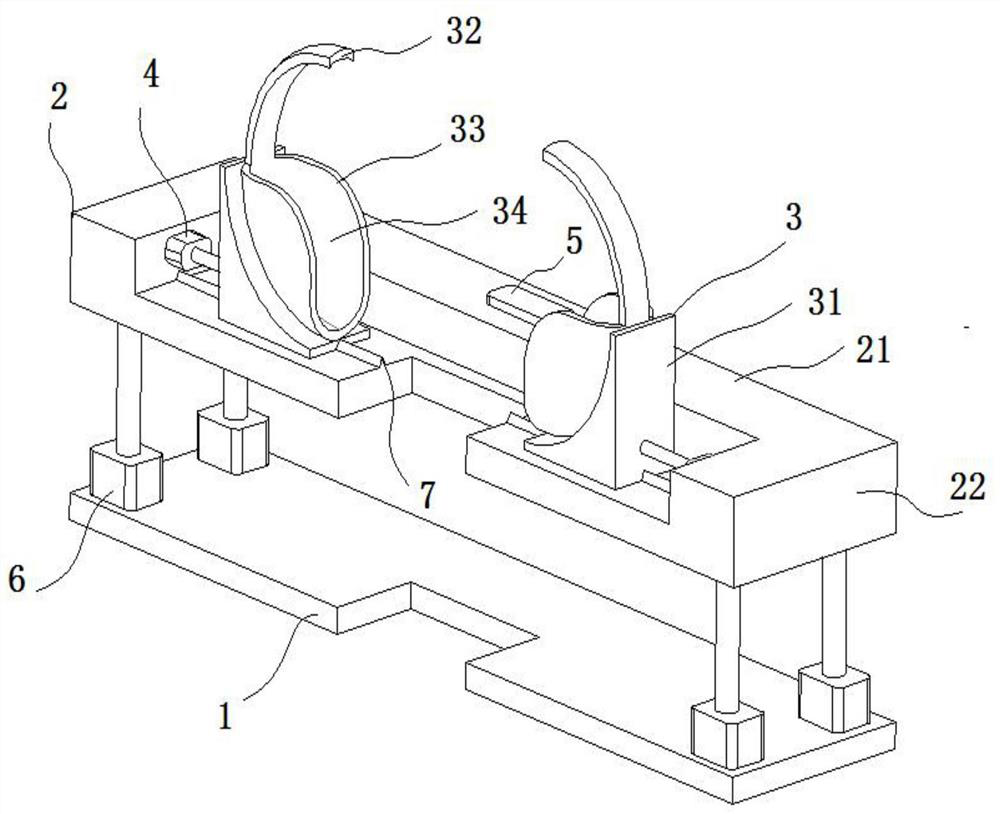

Rapid positioning and clamping device for metal cutting machining

InactiveCN113352115AEnsure stabilityGuaranteed stable clampingPositioning apparatusMetal-working holdersMachine partsEngineering

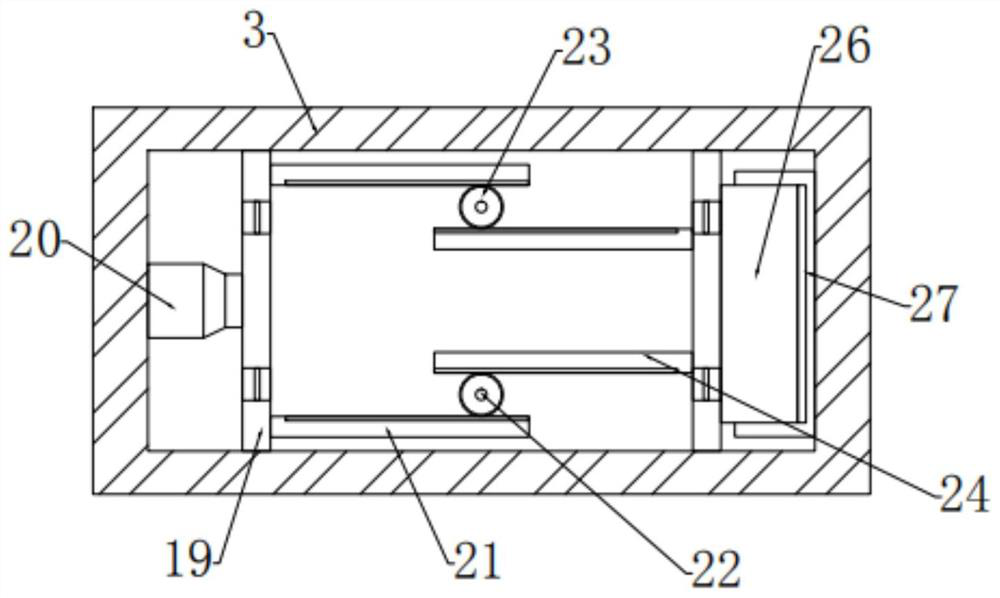

The invention provides a rapid positioning and clamping device for metal cutting machining. The rapid positioning and clamping device for metal cutting machining comprises a base, wherein a clamping mechanism for clamping the front and rear sides of a to-be-machined part is fixed on the upper surface of the base, and a positioning mechanism for jacking the left and right sides of the to-be-machined part is further fixed on the upper surface of the base; the upper surface of the base is connected with a fixed part of a lead screw sliding table through a transverse sliding mechanism, a sliding part of the lead screw sliding table is fixedly connected with an outer shell of a first electric push rod, and the telescopic end of the first electric push rod is connected with a supporting nail and used for supporting the lower side of the to-be-machined part; a first plate body is further fixed to the base, a transverse sliding groove is formed in the first plate body, the sliding groove is in sliding connection with a sleeve, the sleeve is in threaded connection with a first screw rod, and a pressing head used for pressing the upper part of the to-be-machined part is fixed to the lower end of the first screw rod; The rapid positioning and clamping device for metal cutting machining is suitable for universal clamping of complex parts, and the clamping mechanism, the positioning mechanism, a supporting mechanism and a pressing mechanism are matched to limit the six degrees of freedom of the parts so as to guarantee stable clamping of the parts.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

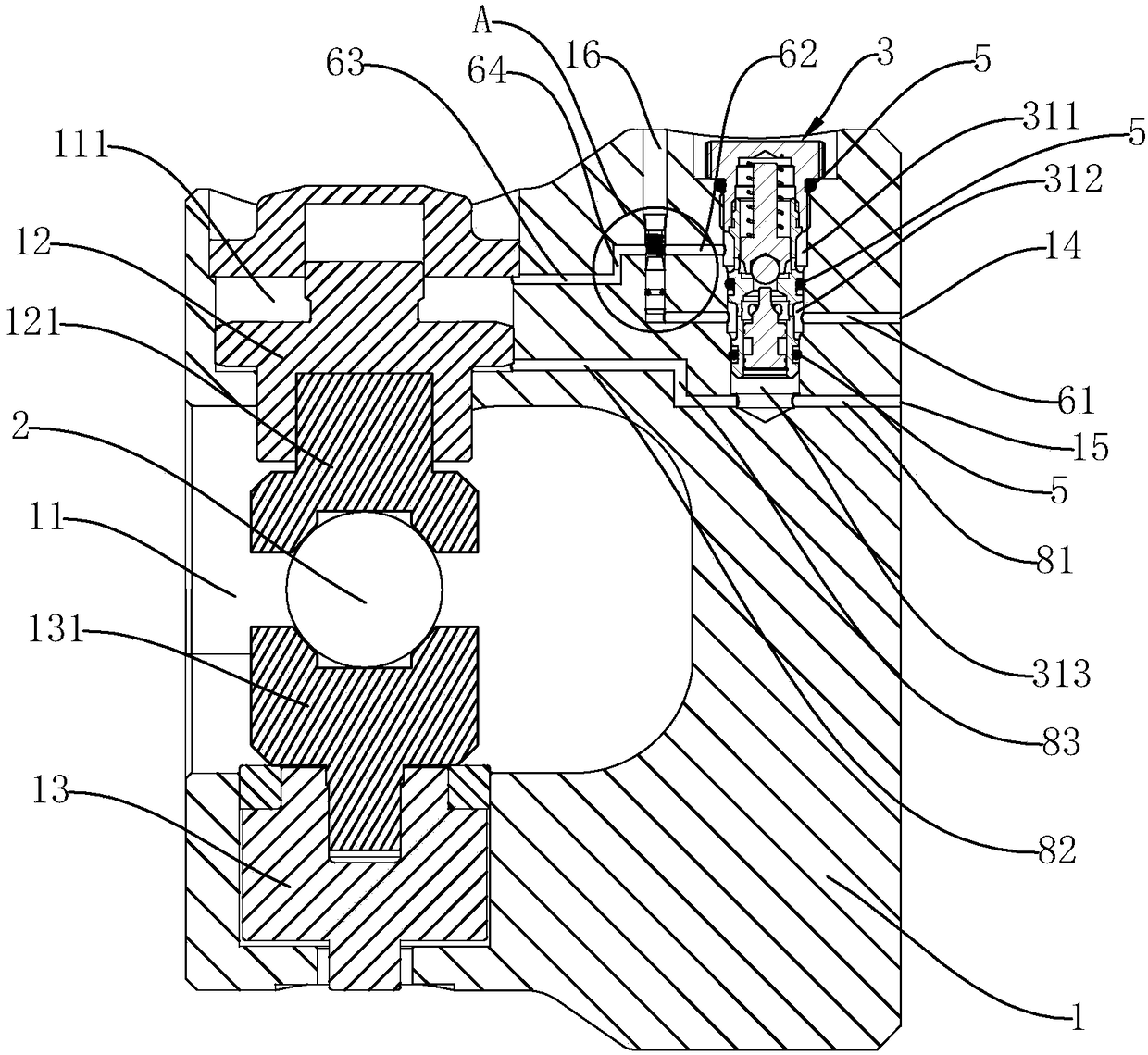

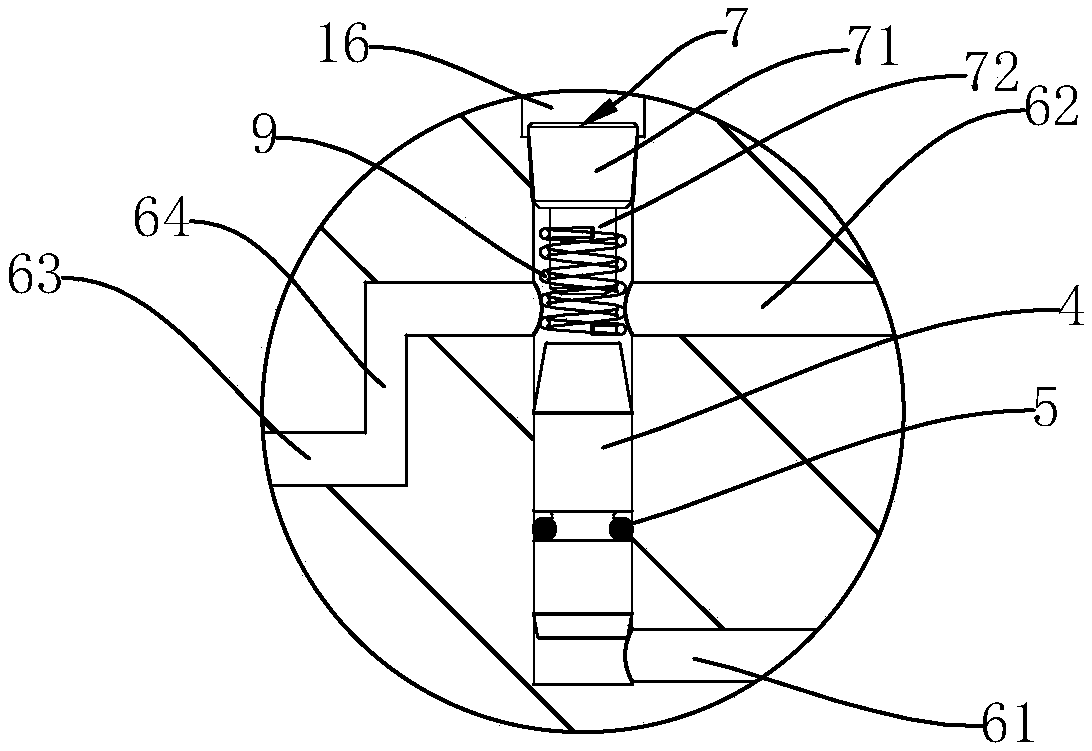

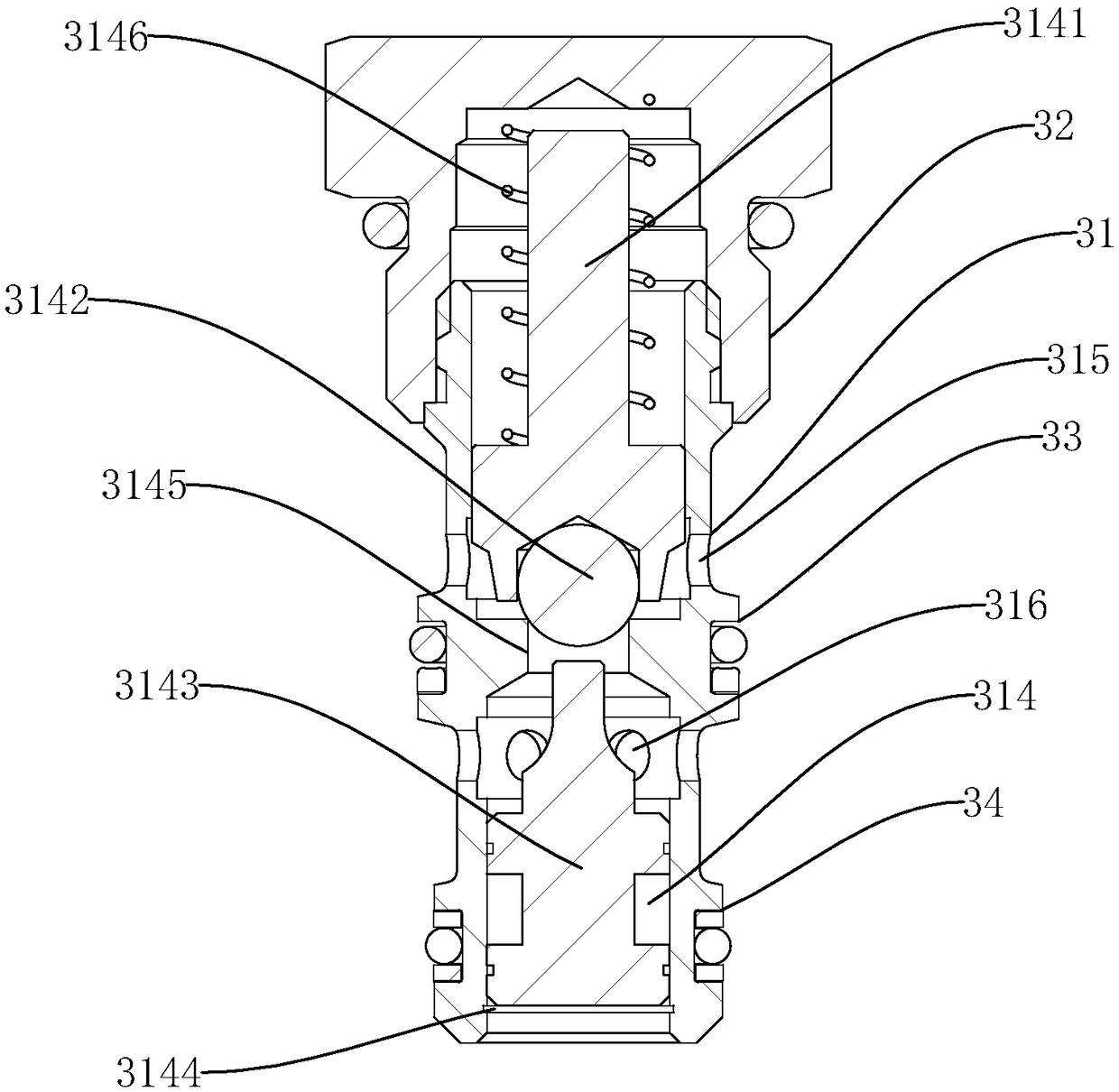

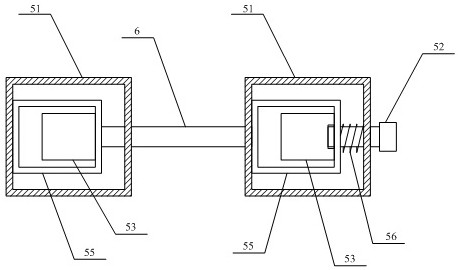

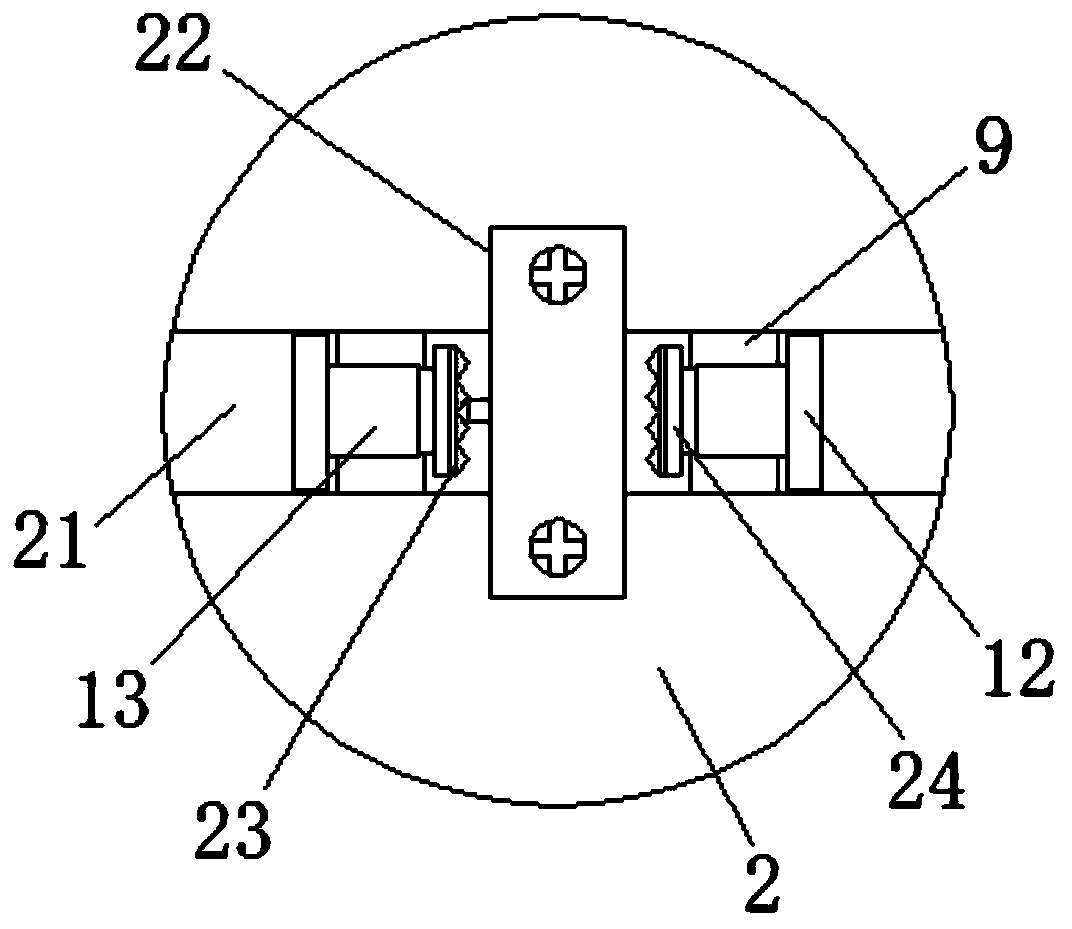

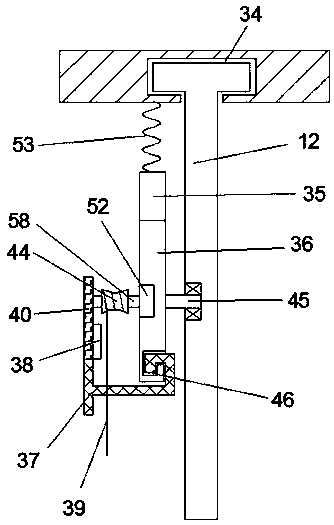

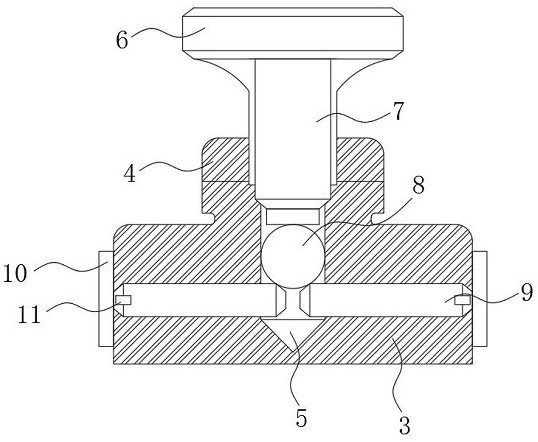

Hydraulic index chuck

PendingCN108421995AGuaranteed stable clampingAvoid loss of clamping forcePrecision positioning equipmentChucksHydraulic circuitEngineering

The invention discloses a hydraulic index chuck which comprises a chuck body. A clamping cavity is formed in the front end of the chuck body, an upper clamping seat and a lower clamping seat are arranged in the clamping cavity and vertically opposite, an upper clamp and a lower clamp for clamping workpieces are arranged in the upper clamping seat and the lower clamping seat, the upper clamping seat is vertically and movably arranged in the clamping cavity, the lower clamping seat is fixedly arranged in the clamping cavity, and a hydraulic circuit for controlling the upper clamping seat to clamp workpieces downwards or release the workpieces upwards is arranged on the chuck body. The hydraulic index chuck is characterized in that a pressure compensation mechanism is arranged on the hydraulic circuit. The hydraulic index chuck has the advantages that the pressure compensation mechanism arranged on the hydraulic circuit provides a reverse centrifugal force, pressure compensation for the upper clamping seat is realized, loss of clamping force caused by the centrifugal force of the clamping seats and the clamps can be avoided, stable clamping of the workpieces is ensured, and the hydraulic index chuck is simple in structure and good in safety.

Owner:宁波迈途机械科技有限公司

Aircraft tire clamping and lifting device and control system thereof

ActiveCN108751059AGuaranteed stable clampingImprove stabilityLifting devicesAircraft assemblyControl systemRelative motion

The invention discloses an aircraft tire clamping and lifting device, and relates to the technical field of aircraft tire clamping and lifting devices. The aircraft tire clamping and lifting device comprises a U-shaped supporting plate, a U-shaped base and clamping devices. The U-shaped base comprises a straight plate. Two side plates are symmetrically fixed to the two ends of the straight plate.Each clamping device comprises an arc seat. One side face of each arc seat is an arc face. An arc clamp plate is fixed to each arc face. Arc protection plates are fixed to the two side faces of each arc clamp plate. A tire groove channel is defined by each arc clamp plate and the corresponding two arc protection plates. The invention further provides a control system of the aircraft tire clampingand lifting device. According to the aircraft tire clamping and lifting device, the two symmetric clamping devices are fixed to the two side plates, meanwhile, the two clamping devices are controlledby first telescopic devices to move relatively to clamp aircraft wheels, each tire groove channel defined by the corresponding arc clamp plate and the corresponding two arc protection plates is matched with aircraft tires, and clamping stability is improved; and meanwhile, second telescopic devices are used for lifting the clamping devices, and mounting and repairing of the aircraft wheels are facilitated.

Owner:安徽翰邦科技咨询有限公司

Screw twisting device

ActiveCN106272250ASolve operational problemsSolve efficiency problemsMetal-working hand toolsEngineeringMechanical engineering

Owner:PINGGAO GRP +2

Building construction support

PendingCN113585712AStable clampingAvoid offsetVibration suppression adjustmentsScaffold accessoriesArchitectural engineeringPipe

The invention provides a building construction support. The support comprises a hollow shell, a supporting plate, a clamping mechanism, a damping mechanism and a distance adjusting mechanism, wherein an opening is formed in the top of the shell, and the supporting plate is movably arranged on the side wall, which corresponds to an opening, of the shell and covers the opening; the distance adjusting mechanism is arranged on the top of the shell, is connected with a wall body and is also used for adjusting the distance between the shell and the wall body; the clamping mechanism is arranged on the supporting plate, is arranged outside the shell and is used for clamping a steel pipe; and the damping mechanism is arranged in the shell and is used for damping when the supporting plate vibrates. According to the building construction support, the distance between the shell and the wall body is adjusted through the distance adjusting mechanism, the shell and the wall body are relatively fixed after adjustment, the steel pipe is clamped through the clamping mechanism, when vibration occurs on the wall body or in other places, the supporting plate can move up and down relative to the shell, and the supporting plate is damped through the damping mechanism, so that the steel pipe is prevented from deviating, the stability in clamping the steel pipe is guaranteed, the steel pipe does not need to be fixed again, and the construction efficiency is improved.

Owner:CHINA MCC 2 GRP CO LTD

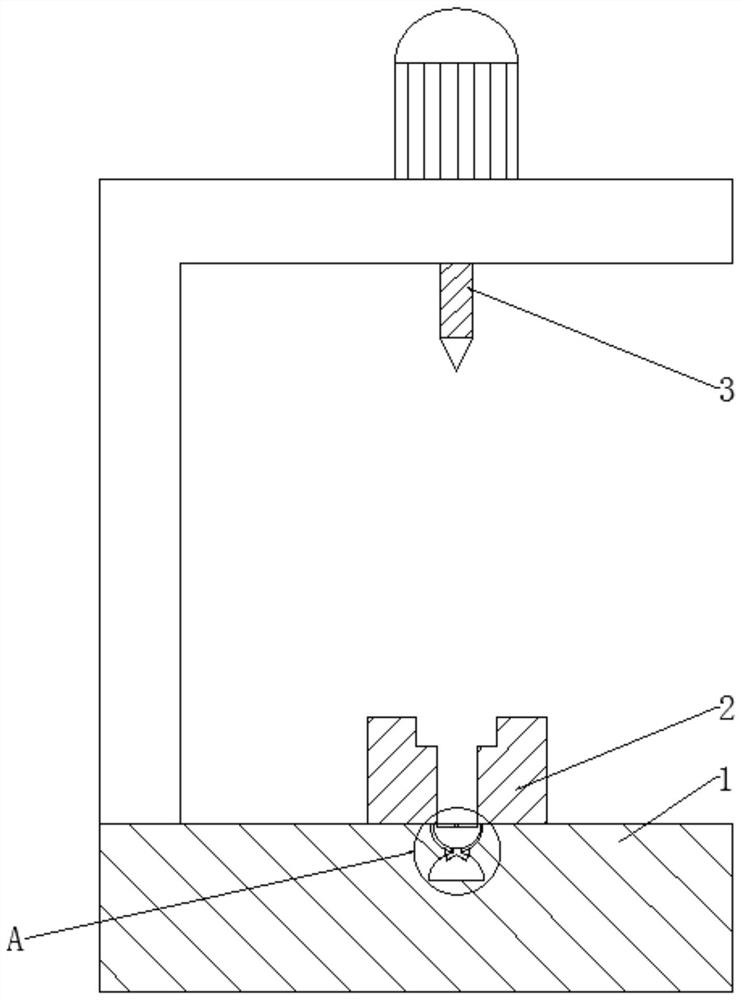

Drilling equipment for network transformer

InactiveCN113182924AGuaranteed cleanlinessRealize the collectionMaintainance and safety accessoriesBoring/drilling machinesProcess engineeringDrill bit

The invention provides drilling equipment for a network transformer. The drilling equipment comprises a workbench, two limiting bases and a drill bit, wherein a plurality of cleaning assemblies capable of cleaning a workbench top are installed at the position, close to a groove between the two limiting bases, of the inner surface of the top side of the workbench in the front-back horizontal direction in an equally adjacent and sliding mode, and each cleaning assembly comprises a dust control assembly capable of controlling entering and exiting of dust, a water storage assembly capable of storing clear water and a dust collection assembly capable of collecting and absorbing the dust. According to the drilling equipment for the network transformer, the workbench can have a self-cleaning function, in a drilling process of the network transformer, the dust is prevented from being left and accumulated in the groove between the two limiting bases for a long time, the dust can be cleared in time, stable clamping of the network transformer is guaranteed, the drilling error is reduced, and the accuracy is improved.

Owner:江西顺群电子科技有限公司

Quick and convenient clamp device for mechanical machine tool

InactiveCN108544279APrevent lateral movementMobile will notWork clamping meansPositioning apparatusEngineeringMachine tool

The invention discloses a quick and convenient clamp device for a mechanical machine tool, and belongs to the technical field of mechanical clamps. A fixing clamping block is arranged on the left sideof the top of a base, a limiting block is arranged at the bottom of the right side wall of the fixing clamping block, a powerful telescopic cylinder is arranged on the right side of the top of the base, and a guiding nut is arranged on the top of a supporting frame; an adjusting screw rod is arranged in an inner cavity of the guiding nut in a nested mode, the adjusting screw rod penetrates through the supporting frame to be connected with a pressing plate, and a reinforcing vertical plate is arranged on the side, close to a sliding rail, of the supporting frame; and reinforcing plates are evenly arranged in an inner cavity of a pressing plate body in the length direction, clamping protruding blocks are evenly arranged at the bottom of the pressing plate body in the length direction, and abrasion-resisting rubber sleeves are arranged at the bottoms of the clamping protruding blocks. The quick and convenient clamp device is reasonable in structural design, the reliability of the deviceis improved, it can be ensured that a workpiece is clamped stably, the workpiece does not move, machining consistency is ensured, and the reliability of product quality is indirectly improved.

Owner:章静

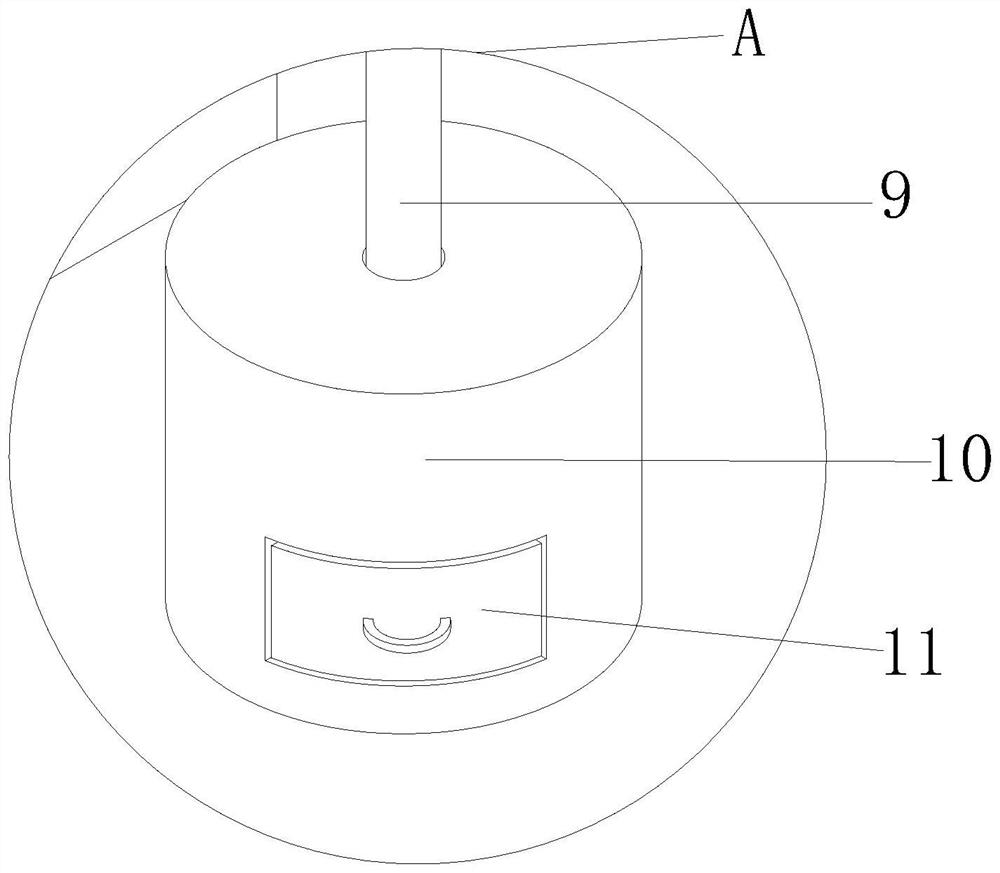

Electric wrench for engraving machine tool rod

InactiveCN112025583ALarge clamping forceIncrease frictional resistanceWork holdersRolling-element bearingElectric machinery

The invention relates to the technical field of wrenches, and discloses an electric wrench for an engraving machine tool rod. The electric wrench comprises a fixing plate, a strip-shaped groove is transversely formed in the upper side of the fixing plate, a bidirectional screw rod is transversely arranged in the strip-shaped groove, the left end of the bidirectional screw rod is rotationally connected with the left side of the strip-shaped groove through a rolling bearing, a motor is fixedly arranged on the right side wall of the strip-shaped groove, the output end of the motor is fixedly connected with the right end of the bidirectional screw rod through a coupler, two moving blocks are symmetrically arranged in the strip-shaped groove in a sliding mode, the side walls of the two moving blocks are in threaded connection with the two sides of the rod wall of the bidirectional screw rod through a first threaded hole and a second threaded hole respectively, and connecting rods are fixedly arranged on the upper sides of the two moving blocks. According to the electric wrench, the operation intensity of workers is reduced, and a first arc-shaped clamping plate and a second arc-shaped clamping plate can be guaranteed to stably clamp the tool rod, so that the dismounting and mounting efficiency of the tool rod is improved.

Owner:西安致开工业自动化工程有限公司

Computer hardware processing fixing device

InactiveCN109866131AEasy to processGuaranteed stabilityWork holdersRotating discComputer engineering

The invention discloses a computer hardware processing fixing device, and relates to the technical field of computer processing devices. The computer hardware processing fixing device comprises a supporting frame and a rotating disc box; the top of the supporting frame is fixedly connected with supporting plates, and the tops of the supporting plates are fixedly connected with annular groove plates; the bottom of the rotating disc box is fixedly connected with annular plates, and the outer surfaces of the annular plates are slidably connected with the inner surfaces of the annular groove plates; and the bottom of an inner cavity of the rotating disc box is fixedly connected with a fixing plate, the top of the fixing plate is sequentially and fixedly connected with swinging blocks from topto bottom, and a sliding groove is formed in the bottom of the rotating disc box. According to the computer hardware processing fixing device, the positions of clamping telescopic rods can be changed,thus forming of hydraulic telescopic rods is reduced, stable clamping of the computer hardware processing fixing device is also guaranteed, using is convenient, and the problems that the stroke of the hydraulic telescopic rods is limited, consequently certain slightly larger parts cannot be clamped during processing, and using is affected are solved.

Owner:合肥清若科技有限公司

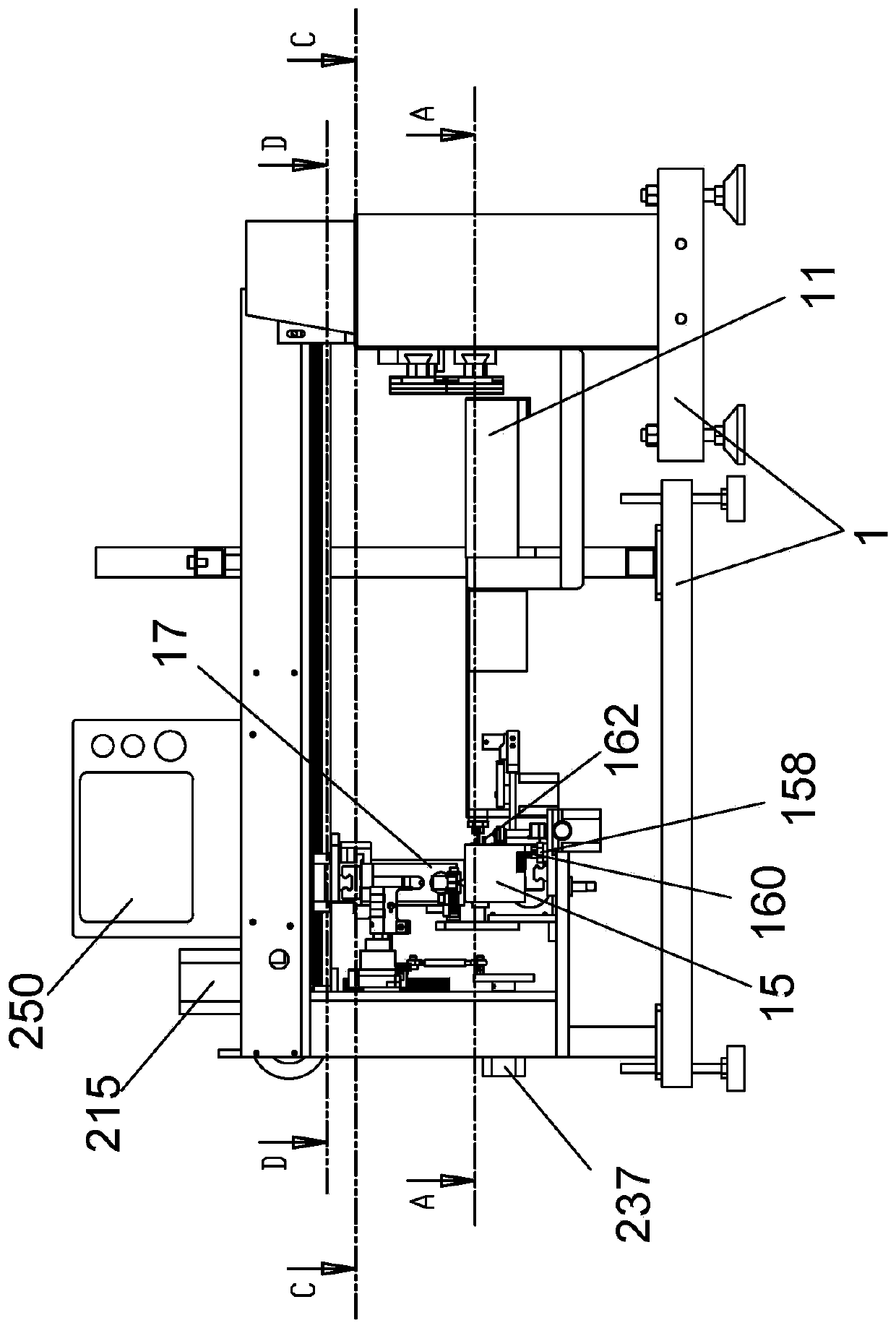

Automatic sealing equipment

PendingCN110615147AThe sealing position is consistentGood conditionWrapper twisting/gatheringEngineeringElectrical and Electronics engineering

Owner:漳浦金盛智能科技有限公司

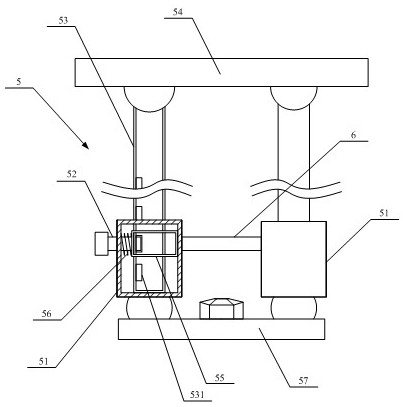

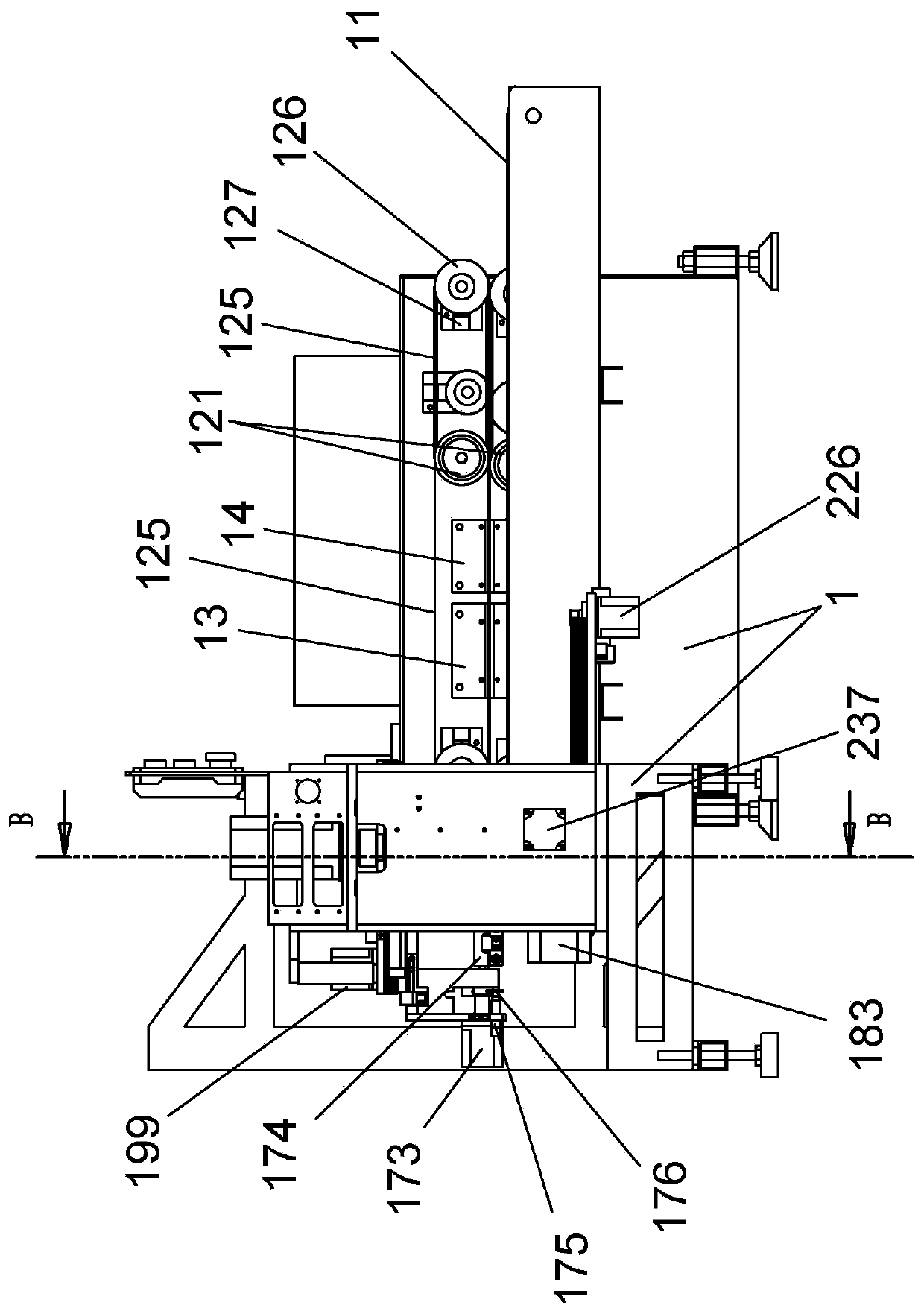

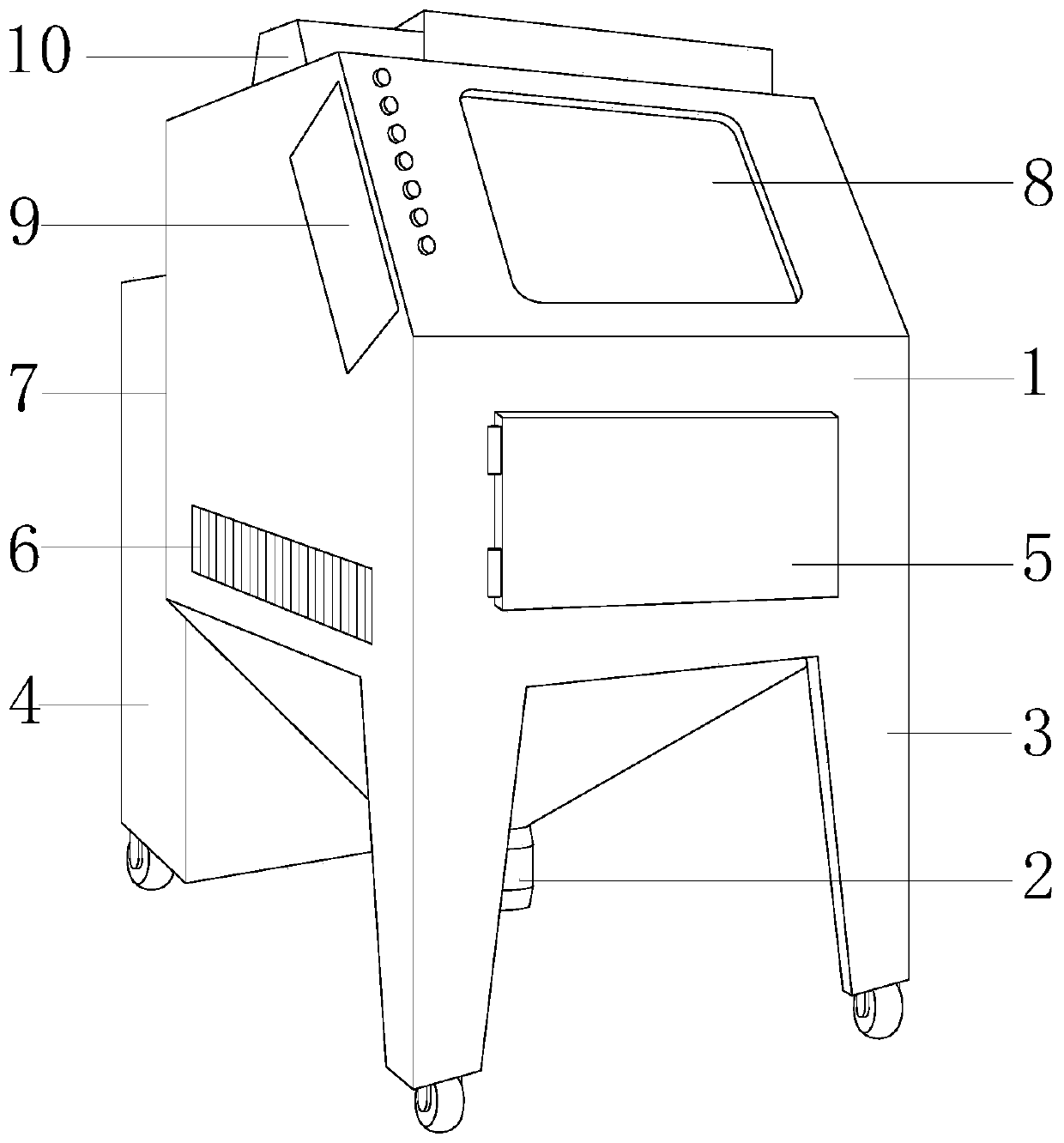

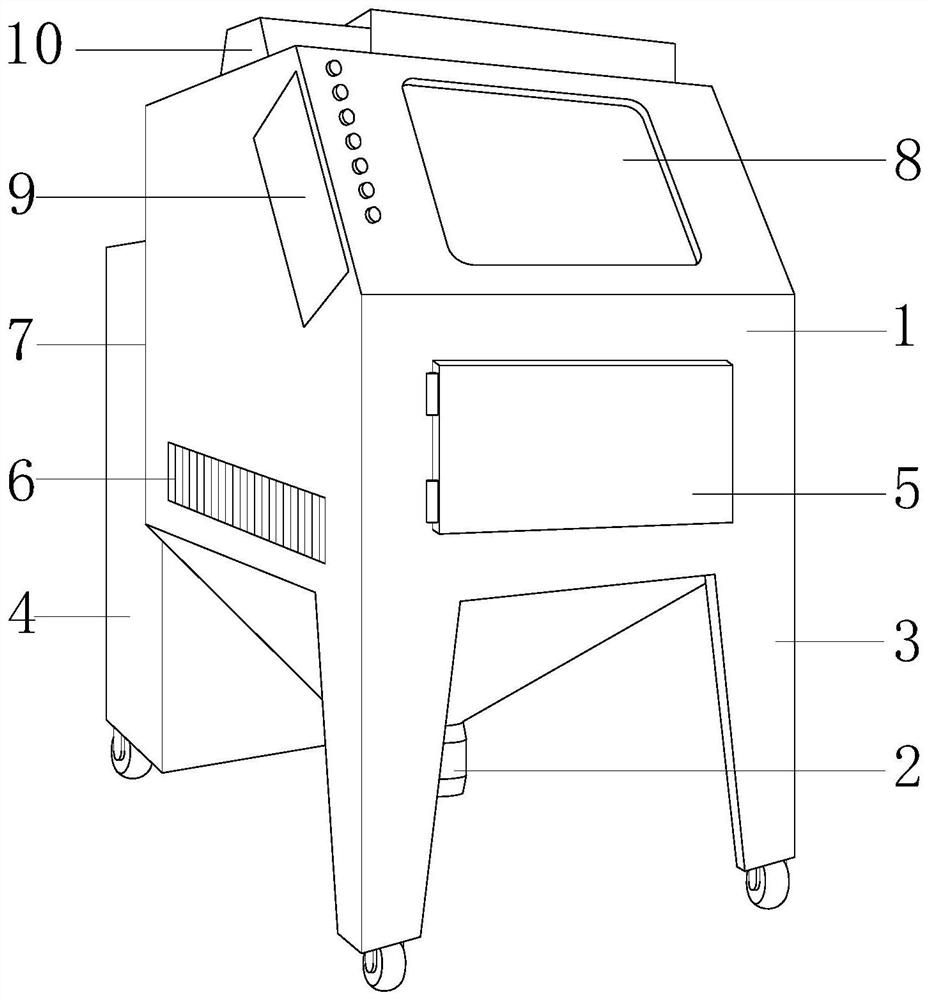

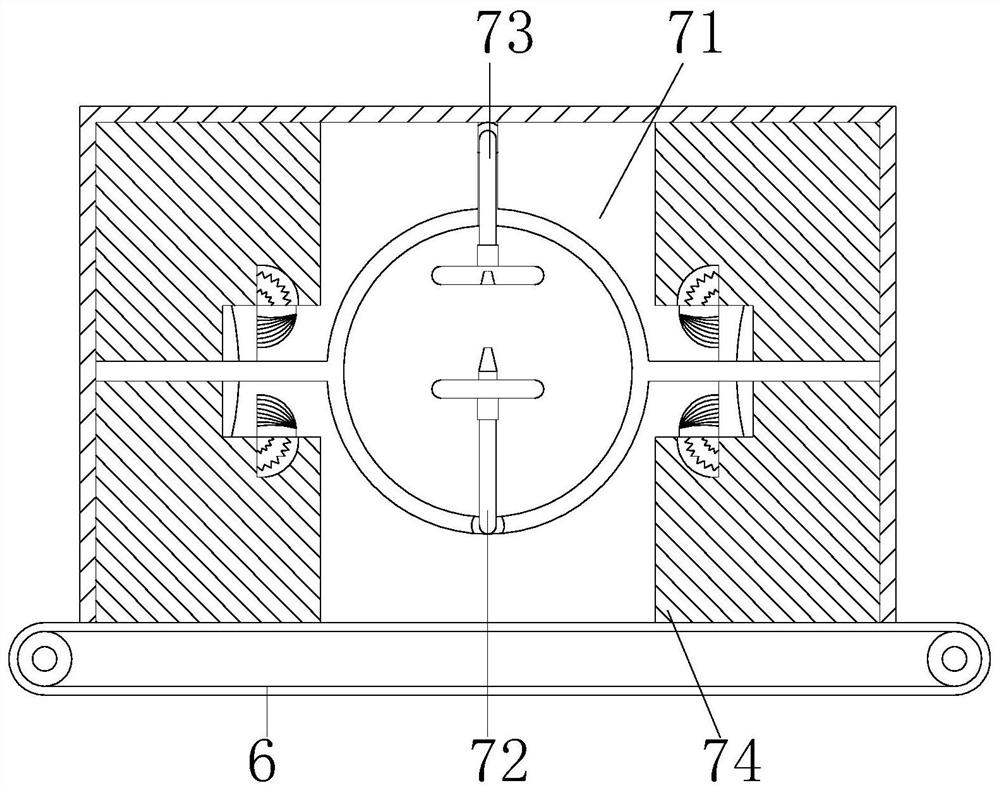

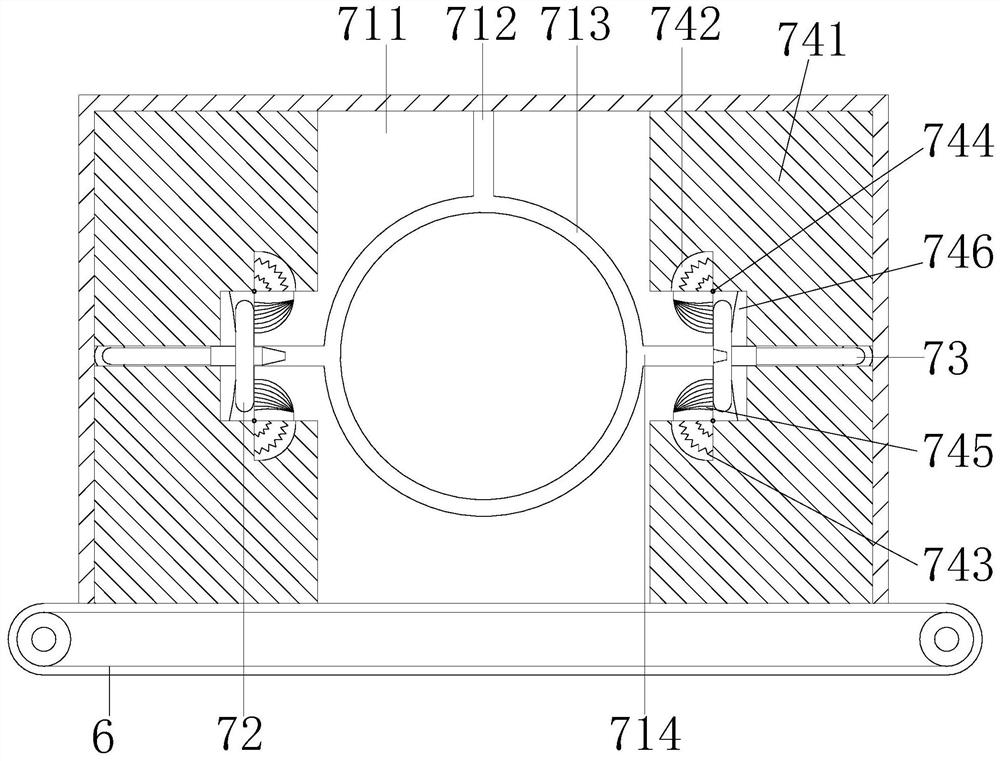

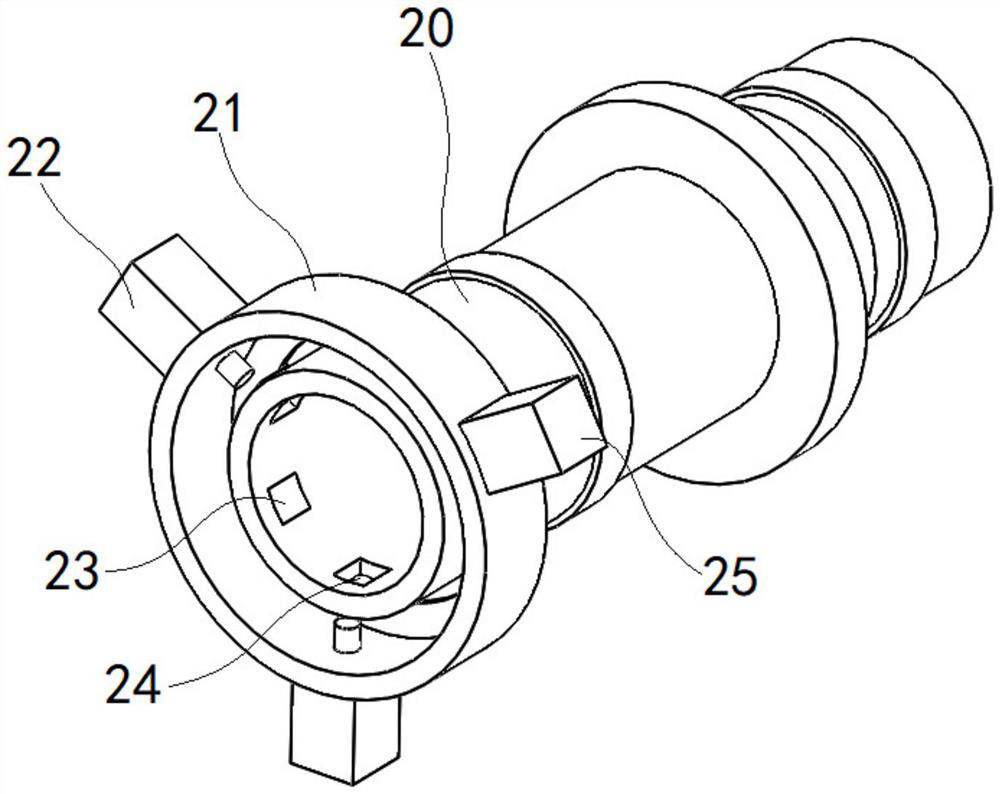

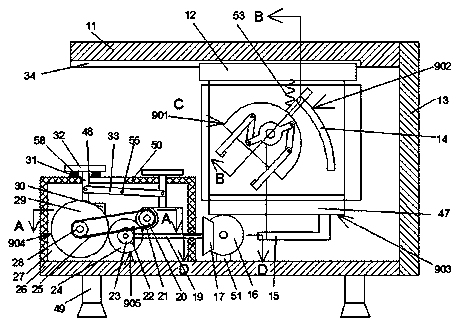

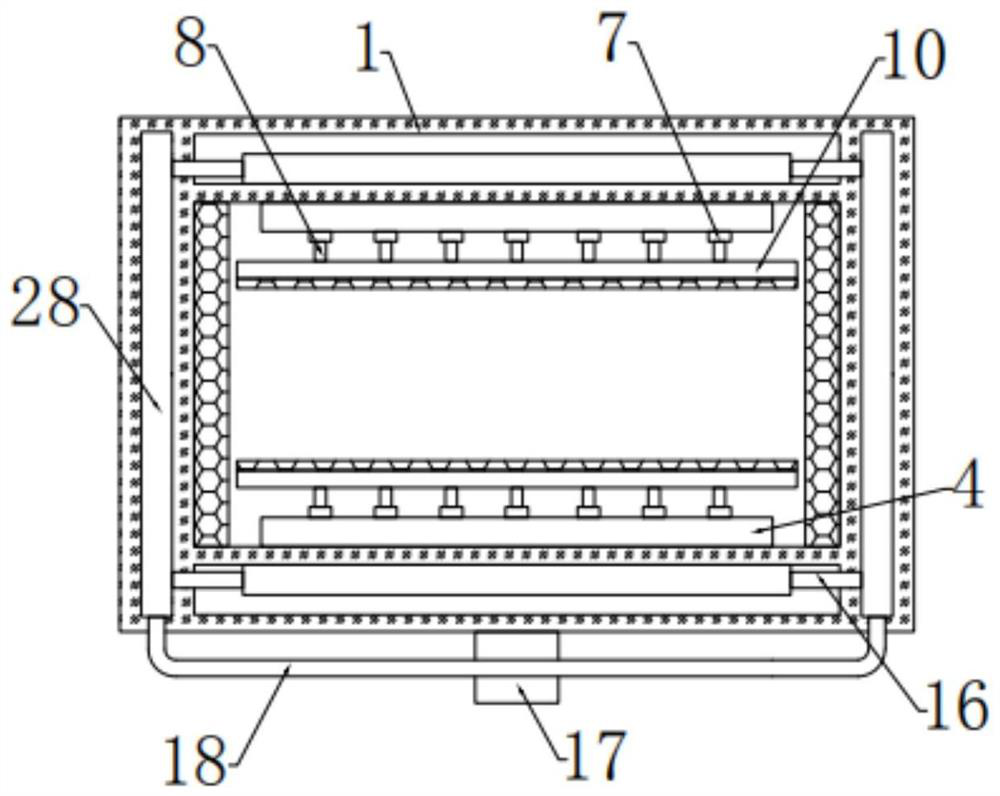

Automotive part automatic turnover sand blasting device

ActiveCN110340809AAvoid affecting the turning abilityImplement loop operationAbrasive machine appurtenancesAbrasive blasting machinesSand blastingEngineering

The invention discloses an automotive part automatic turnover sand blasting device. The automotive part automatic turnover sand blasting device structurally comprises a sand blasting machine body, a recovery hopper, supporting legs, a raw material box, a part inlet, a part output device, an intermittent type self-sand-removal turnover device, a visible window, an electric control cabinet and a waste gas treatment device. The sand blasting machine body is of a rectangular structure. The recovery hopper is arranged at the bottom of the sand blasting machine body and is of an integrally formed structure. The supporting legs are arranged at the four ends of the bottom of the sand blasting machine body. The raw material box is arranged behind the sand blasting machine body. By the adoption of the automotive part automatic turnover sand blasting device, clamping plates are timely cleaned by the arranged intermittent type self-sand-removal turnover device after the sand blasting machining ofeach automotive part is accomplished, and the orderly cyclic operation of sand blasting, turnover, part discharging and self cleaning is achieved. In addition, as the purpose that the double sides aresubjected to uniform sand blasting is achieved, the phenomena that due to the facts that after the clamping plates are subjected to sand blasting along with the automotive parts, the clamping platesare not timely cleaned, and the accumulation of sand materials happens, the mass of the sand materials is increased, and the turnover capacity of the clamping plates is affected are avoided, and the stable clamping operation of the clamping plates is guaranteed.

Owner:唐山斯坦博科技有限公司

An automatic flipping sandblasting device for auto parts

ActiveCN110340809BAvoid affecting the turning abilityImplement loop operationAbrasive machine appurtenancesAbrasive blasting machinesSand blastingStructural engineering

The invention discloses an automotive part automatic turnover sand blasting device. The automotive part automatic turnover sand blasting device structurally comprises a sand blasting machine body, a recovery hopper, supporting legs, a raw material box, a part inlet, a part output device, an intermittent type self-sand-removal turnover device, a visible window, an electric control cabinet and a waste gas treatment device. The sand blasting machine body is of a rectangular structure. The recovery hopper is arranged at the bottom of the sand blasting machine body and is of an integrally formed structure. The supporting legs are arranged at the four ends of the bottom of the sand blasting machine body. The raw material box is arranged behind the sand blasting machine body. By the adoption of the automotive part automatic turnover sand blasting device, clamping plates are timely cleaned by the arranged intermittent type self-sand-removal turnover device after the sand blasting machining ofeach automotive part is accomplished, and the orderly cyclic operation of sand blasting, turnover, part discharging and self cleaning is achieved. In addition, as the purpose that the double sides aresubjected to uniform sand blasting is achieved, the phenomena that due to the facts that after the clamping plates are subjected to sand blasting along with the automotive parts, the clamping platesare not timely cleaned, and the accumulation of sand materials happens, the mass of the sand materials is increased, and the turnover capacity of the clamping plates is affected are avoided, and the stable clamping operation of the clamping plates is guaranteed.

Owner:唐山斯坦博科技有限公司

Clamping equipment and method

PendingCN114226774AHigh clamping accuracyPrecise control of spatial attitudeAuxillary equipmentChucksEngineeringPhysics

Owner:GUANGZHOU ROVMA AUTO PARTS

A Fixing Device for Bearing Production Favorable to Avoid Springback

ActiveCN109940423BRapid productionAccurate locationWork holdersPositioning apparatusDrive wheelEngineering

The invention discloses a fixing device for bearing production in favour of avoiding springback. The fixing device comprises a housing and a pushing frame, wherein an adjusting cavity is arranged in the housing; the rear end face of an adjusting rod is connected with driving teeth, and the outer side of the driving teeth is connected with a driving wheel; a driving rod is arranged in the driving wheel; the pushing frame is arranged outside a first pushing rod, the inner side of the pushing frame is provided with a connecting arm, and the outer side of the top of the connecting arm is providedwith a fixing seat; and the top end of the connecting arm is connected with a first clamping plate. The fixing device for bearing production in favour of avoiding the springback is easy to operate, isconducive to ensuring the accurate position of a bearing and is convenient to feed and discharge at the same time, is conductive to producing the bearing rapidly, and can ensure that a clamping device cannot spring back after adjusting and clamping, so that the stable clamping of the bearing part is ensured, and thus the stable machining and using of the bearing part is facilitated.

Owner:新昌县黄达机械有限公司

Gantry crane for hardware pipe fittings with switchable clamps

ActiveCN110329903BFlexible deletionMulti-job environmentBase supporting structuresBraking devices for hoisting equipmentsPipe fittingControl engineering

The invention discloses a portal crane capable of switching over clamps and used for a hardware pipe fitting, and relates to the field of hardware machining equipment. The portal crane capable of switching over clamps and used for the hardware pipe fitting comprises a crane frame, a clamp hoisting frame and clamp switchover rolls, wherein a winding reel arranged on a hoisting shaft on the crane frame is wound with traction ropes; the hoisting shaft is connected with the clamp hoisting frame through two traction ropes; the clamp hoisting frame is connected with two pairs of clamp switchover roll support columns through slide rods; one clamp switchover roll is rotationally connected between the lower ends of each pair of the clamp switchover roll support columns; a square pipe clamping groupis arranged at one side of each clamp switchover roll; and a circular pipe clamping group is arranged at the other side of each clamp switchover roll. According to the portal crane capable of switching over the clamps and used for the hardware pipe fitting, a rotary wheel is rotated, each pair of the clamp switchover roll support columns is controlled to move under the condition of adjusting thethread relationship of a screw rod and a screw rod seat, a distance between the clamp switchover rolls arranged at the lower ends of the two pairs of clamp switchover roll support columns is adjusted,the clamps arranged on the two groups of clamp switchover rolls clamp the pipe fitting, and the operation is convenient.

Owner:滨州高新材料产业园有限公司

A Welding Fixture for Telescopic Aluminum Alloy Window

ActiveCN104526221BSimple and fast operationIncreased flexibility of useWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFastener

The invention discloses a welding clamp of an extensible aluminum alloy window body. The welding clamp comprises two parallel lower slide rails arranged at an interval, wherein the two lower slide rails are in sleeved connection with two lower slide seats, upper slide rails perpendicular to the lower slide rails are installed on the lower slide seats through fasteners, and the other end of each upper slide rail is installed on the lower slide seat in sleeved connection with another lower slide rail. Each upper slide rail is in sleeved connection with two upper slide seats, and limiting grooves are fixedly connected to the upper slide seats. Any adjustment on clamp size can be achieved, and the welding clamp can meet the welding requirements of different sizes of windows and has the advantages of being simple and convenient to operate, high in using flexibility, simple in structure and the like.

Owner:绥阳县覃兵门窗有限公司

An installation method for a curved steel reticulated shell structure with a gradual change in the starting span of the gable wall

ActiveCN111809893BGuarantee the stability of the pullPrevent slidingBuilding material handlingPurlinControl theory

The invention discloses a method for installing a curved steel reticulated shell structure with a gable starting span gradually changing, comprising the following steps: a. construction preparation; b. assembling block by block; c. installing a purlin system and a roof panel structure. The invention realizes the connection between the steel wire rope and the ball joint through the steel wire rope pulling device, ensures the stability of the steel wire rope pulling and setting, prevents the steel wire rope from sliding, ensures the verticality of the vertical gable structure, and avoids the rods of the reticulated shell structure during the steel wire rope pulling. At the same time, in the present invention, the ball joints inside the gable reticulated shell unit are supported by the temporary fixing device to increase the construction safety performance, and the temporary fixing device can also eliminate the influence of the site flatness error on the installation accuracy, which is more conducive to the ball joints The installation and construction between temporary fixtures are convenient for construction and operation, flexible and convenient for on-site construction, easy to adjust accuracy errors, high construction efficiency, guaranteed installation quality, reduced safety hazards for high-altitude operations, and reduced construction costs.

Owner:浙江中南绿建科技集团有限公司

Pipe supporting device for all-round laser cutting machine

PendingCN114871602AFixed effectEasy to processWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingMachine

The invention discloses a pipe supporting device for an all-round laser cutting machine, and relates to the technical field of laser cutting, the pipe supporting device for the all-round laser cutting machine comprises a supporting base, the surface of the supporting base is slidably connected with a base, and the surface of the base is fixedly connected with a connecting rod; a first fixing disc is arranged at the upper end of the connecting rod, a clamping mechanism is arranged in the first fixing disc, and through the arrangement of the clamping mechanism, a worker only needs to rotate a worm, the circle center of a round pipe can coincide with the circle center of the first fixing disc, machining of the round pipe is facilitated, meanwhile, use of a spring is avoided as much as possible, and the machining efficiency is improved. The situation that when the round pipe is heavy, the spring is extruded, and consequently the round pipe is located inaccurately is avoided as much as possible, the machining quality of the round pipe is improved, meanwhile, meshing of the worm gear and the worm has self-locking performance, shaking generated in the round pipe machining process is avoided as much as possible, the influence on fixing of the round pipe is avoided as much as possible, and the fixing stability of the round pipe is improved.

Owner:JINAN G WEIKE SCI & TECH

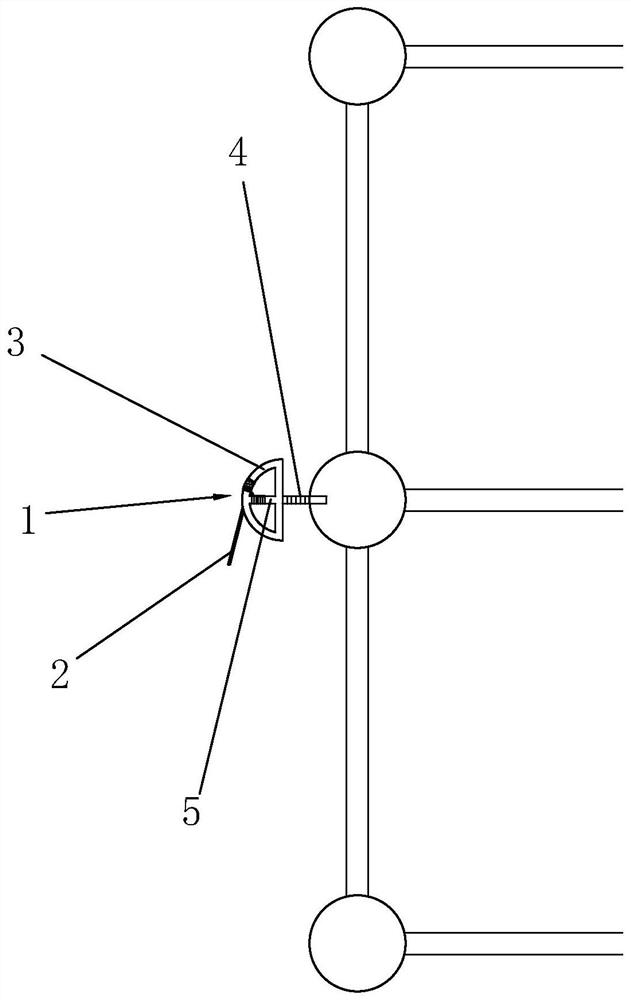

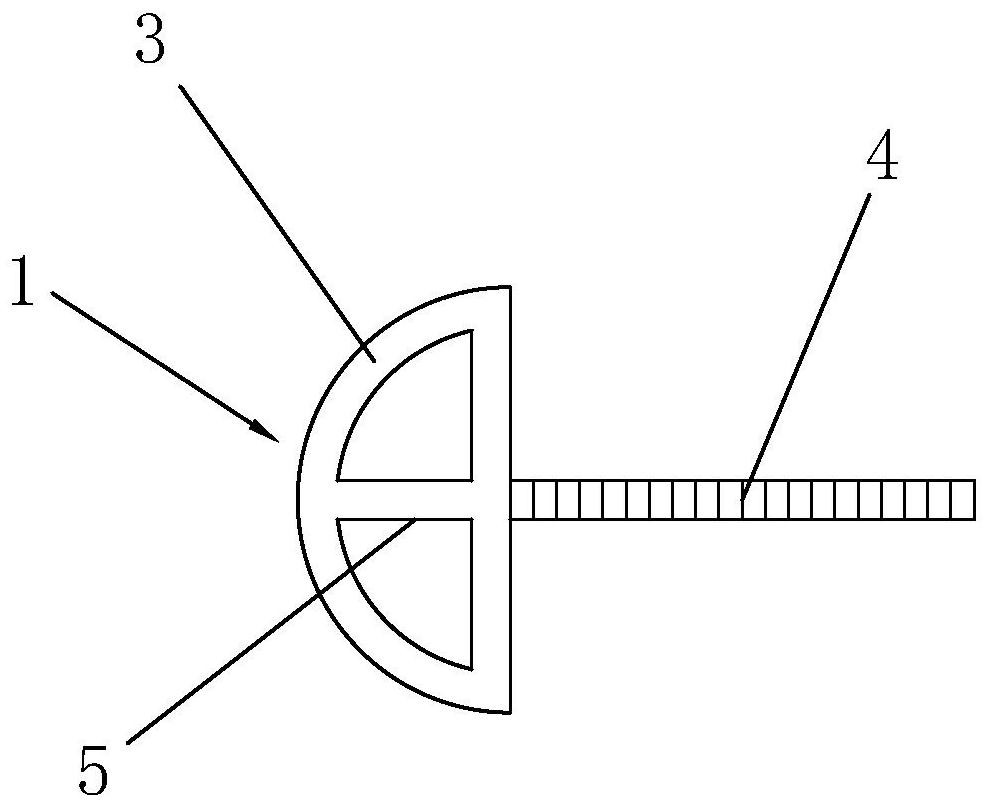

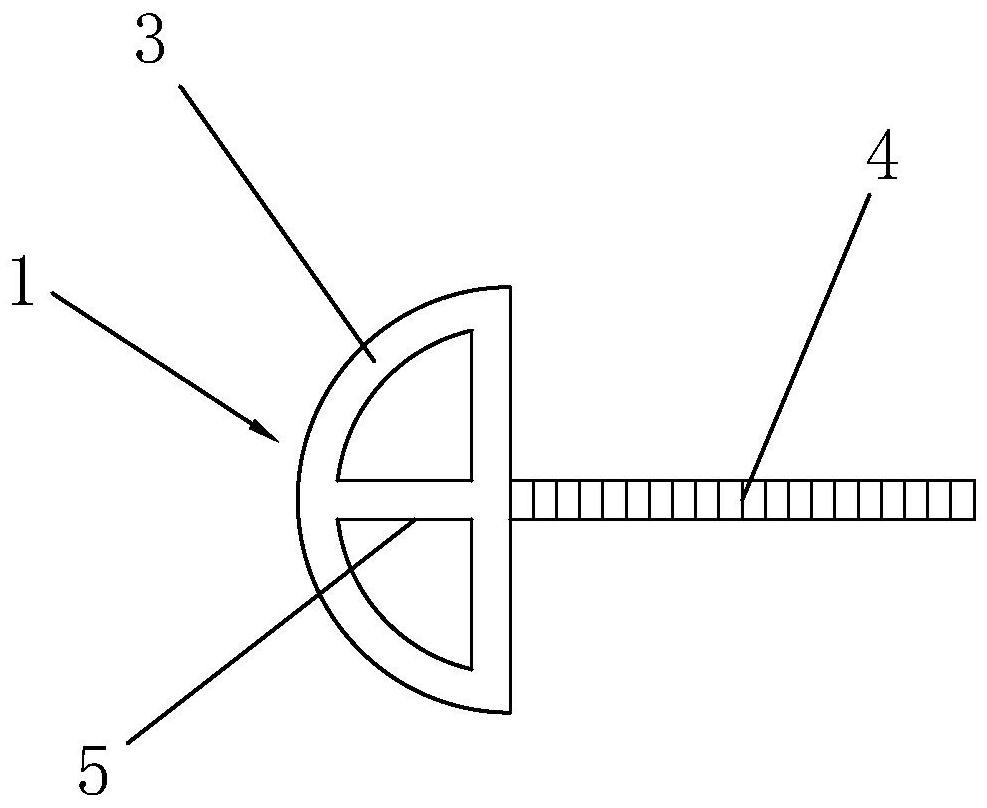

Positioning and installation device for computer CPU

ActiveCN110587531AGuaranteed stable clampingGuaranteed Position AdjustmentWork holdersMetal-working hand toolsCircular discDrive shaft

The invention discloses a positioning and installation device for a computer CPU. The positioning and installation device comprises a base, the right end of the base is provided with a bracket, the upper end of the bracket is provided with a top plate, a T-shaped slider is slidably connected into the top plate, a first transmission shaft is rotatably connected to the T-shaped slider, a semicircular disc is arranged on the first transmission shaft, and a clamping component is arranged on the semicircular disc. The clamping component includes a judging spring in rotary connection with the semicircular disc. The judging spring is adopted in the positioning and installation device to ensure that the CPU running distances are different when a mainboard is on different mainboard pallets, symmetrically-designed adjustment sliders are adopted for ensuring stable clamping of the CPU, the design of a winding barrel and a motor ensures position adjustment after the CPU is in place, the design ofan adjustment spring is adopted to ensure that the device returns to the initial state after one-time working, and the current conditions that the process of installing the CPU is too tedious, the construction cost is high, and the CPU cannot be quickly and easily positioned and installed are changed.

Owner:浙江利恩工程设计咨询有限公司

screw screw device

ActiveCN106272250BEasy to operateImprove removal efficiencyMetal-working hand toolsEngineeringMechanical engineering

Owner:PINGGAO GRP +2

Limb protection device for clinical use in pediatric surgery

ActiveCN112826610BAchieve clampingIncrease painDiagnosticsInstruments for stereotaxic surgeryPhysical medicine and rehabilitationEngineering

The invention relates to the technical field of medical devices, in particular to a limb protection device for clinical use in pediatric surgery, which includes a fixed frame, a clamping mechanism is arranged inside the fixed frame, a support frame is arranged outside the fixed frame, and a support frame is used between the support frame and the fixed frame. Mechanism connection, the lower side of the support frame is provided with a mounting seat, and the mounting seat and the support frame are connected by a lifting mechanism. In the present invention, by setting a clamping mechanism, the clamps on both sides of the upper and lower sides can be used under the action of the driving mechanism to realize the treatment of children with different sizes. The clamping of the limbs makes the device more applicable. By setting the clamp and using the pressure sensor, it is possible to avoid increasing the pain of the child patient due to excessive extrusion force during the fixation process. On the premise of ensuring stable clamping , so that the comfort of children patients is improved.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

Passenger car frame clamp

PendingCN107790942AQuick gripGuaranteed stable clampingWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameCar passenger

The invention discloses a passenger car frame clamp. A positioning device is arranged on the front surface of a base in a sliding mode, a top plate is fixedly arranged at the upper ends of supportingplates on the upper surface of the base, two clamping plates are arranged between first sliding grooves and second sliding grooves in a sliding mode, a first lead screw penetrates through the left supporting plate and the left clamping plate, and a second lead screw penetrates through the upper end of the right supporting plate and the right clamping plate. The positioning device can quickly clampa car frame, and controls the position of the right clamping plate through the positioning device, so that the stable clamping of the car frame is guaranteed, the clamping mode is suitable for various situations, real-time adjustment can be carried out according to the field specific conditions, the welding requirement of complex conditions is met, and the welding efficiency is guaranteed.

Owner:苏州友邦汽车底盘科技有限公司

Processing equipment capable of replacing lug wings and having anti-falling test function

PendingCN113654775AGuaranteed stable clampingAvoid affecting the accuracy of the experimentMachine part testingWork holdersControl engineeringStructural engineering

The invention discloses processing equipment capable of replacing lug wings and having an anti-falling test function, and relates to the technical field of special-shaped component processing detection, in particular to a base, an internal expansion clamping mechanism, a puncture detection mechanism, an expansion locking mechanism and an alicyclic ring, and the alicyclic ring is connected to the bottom end of an expansion sleeve. In the processing equipment capable of replacing lug wings and having an anti-falling test function, the internal expansion clamping mechanism is arranged, the mechanism is specially designed according to material characteristics and annular structural characteristics of replaceable lug wing material elastic rubber, by rotating the adjusting handle, the screw meshed with the adjusting handle is subjected to downward driving force relative to the adjusting handle component, the spherical pin is driven to extrude the three sliding columns arranged at the bottom end of the guide groove, the shape of the supporting pieces arranged at the output ends of the tops of the sliding columns is matched with the shape of the end face of an inner hole of the to-be-detected replaceable lug wing material, it is guaranteed that the to-be-detected replaceable lug wing material is clamped stably, and it is avoided that the experiment precision is affected by loosening and slipping in the detection process.

Owner:东莞市天楚机电科技有限公司

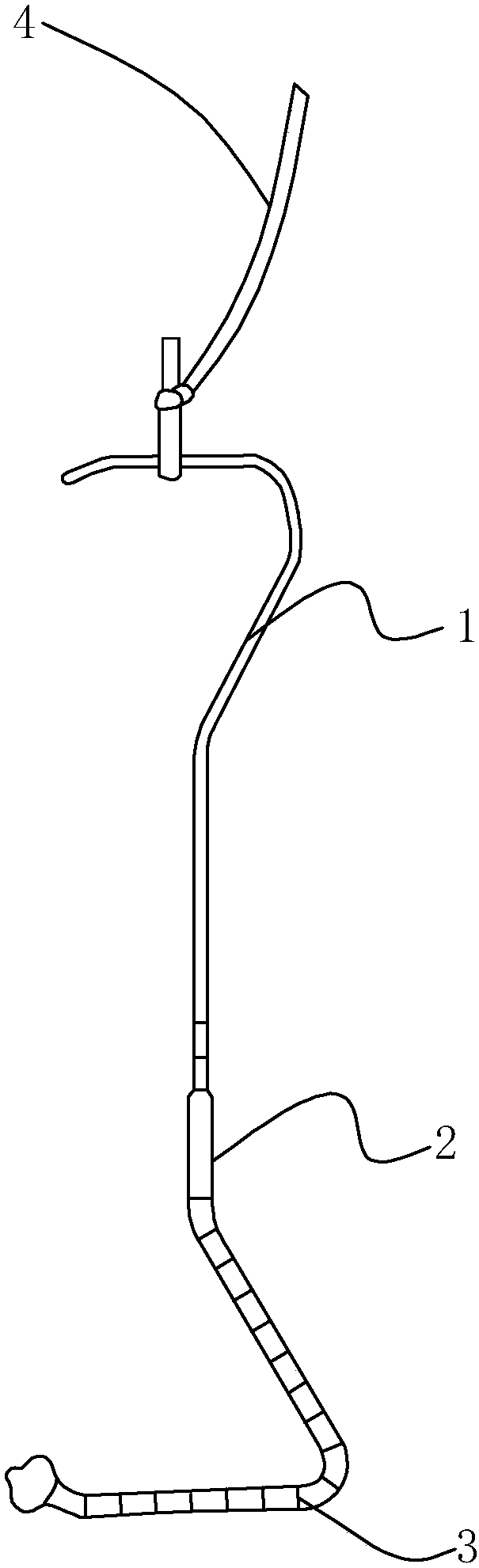

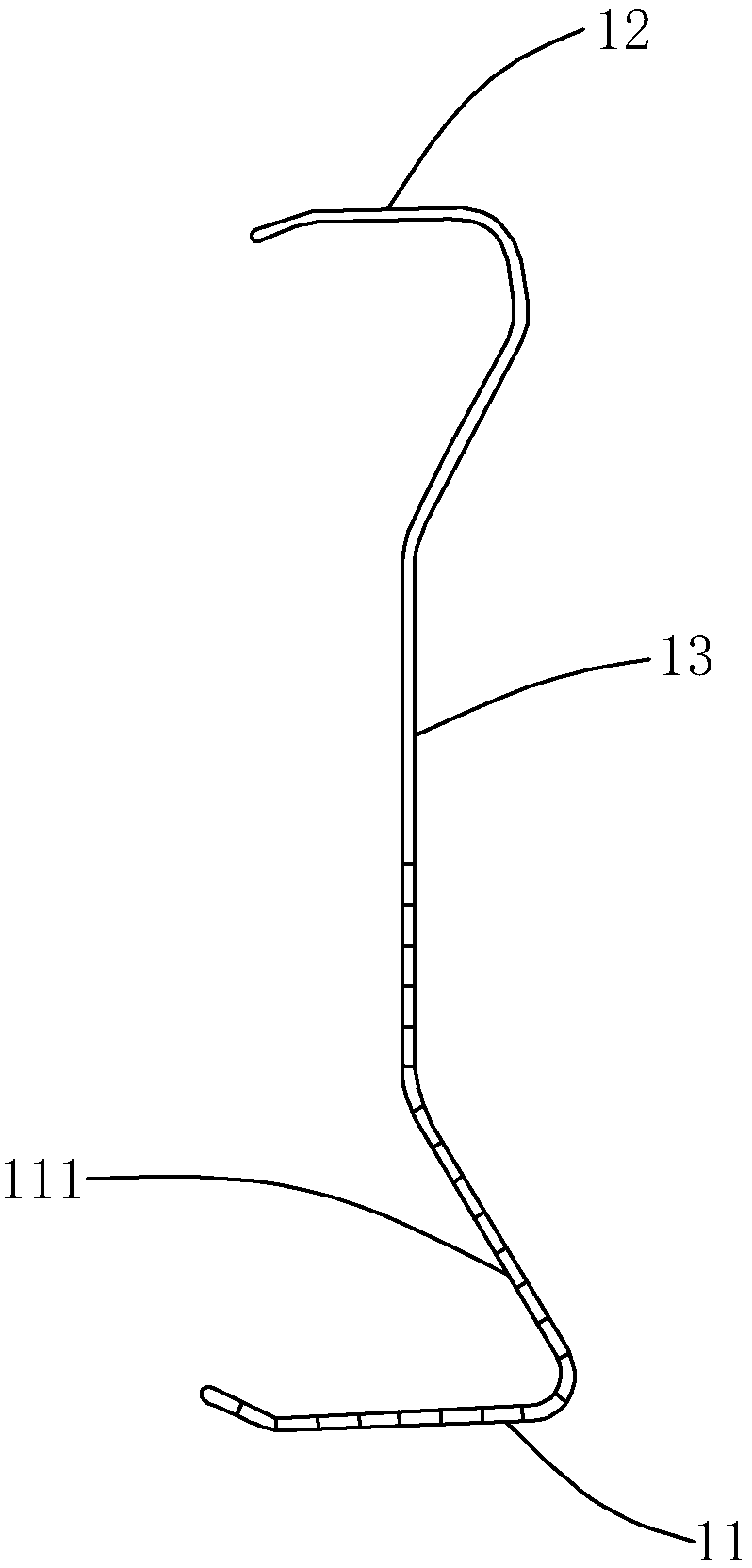

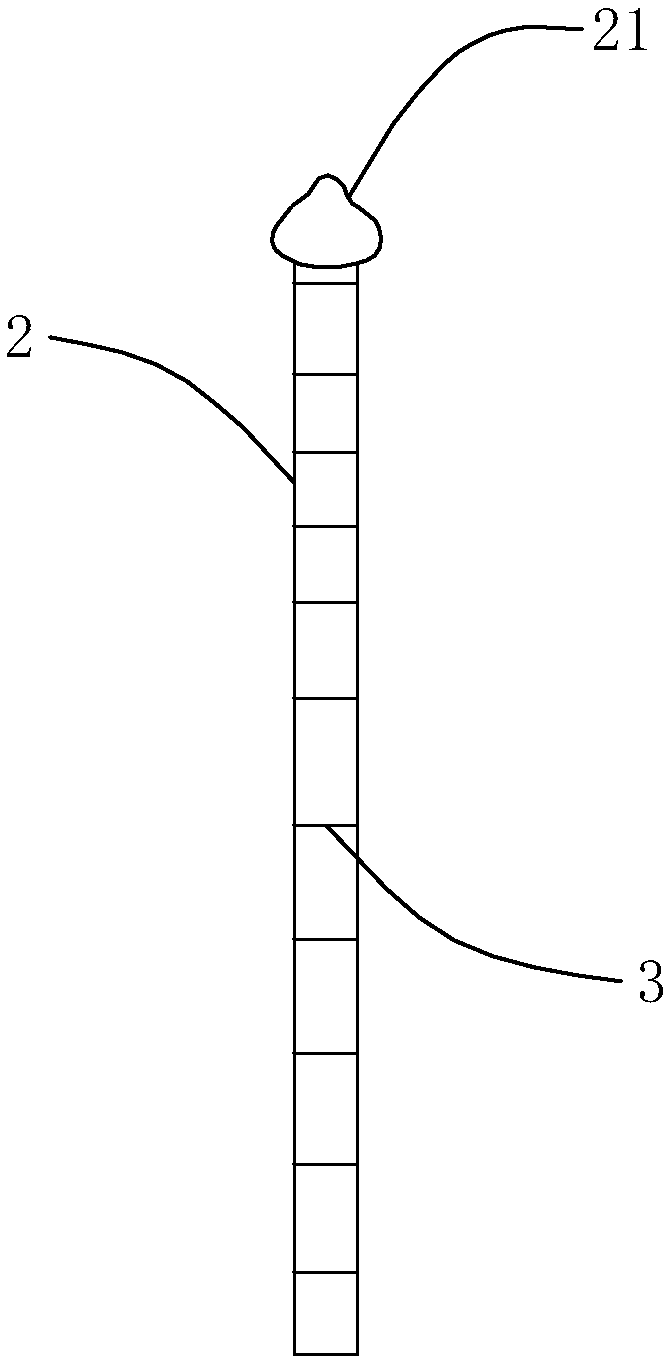

Endoscope retractor with measuring function and using method thereof

PendingCN107582114AGuaranteed stable clampingAvoid damageDiagnosticsSurgeryOperative instrumentEngineering

The invention provides an endoscope retractor with a measuring function. An integral bent structure is adopted. A needed opening is small in diameter, other trocar cannulas are not needed, and therefore apparatuses are saved; a locking assembly is arranged, a wire retractor can be locked on other equipment during an operation to keep clamping organs stably, no specialized personnel are needed to hold the wire retractor in the whole process, so that manpower is saved; scale is formed in the wire retractor and can effectively measure the operation depth and operation scale of operative instruments, therefore, a quantitative concept is provided for an operator, and the problems are avoided that due to imaging differences, operation difficulty is high and the organs and tissues are easy to crash and injure. The invention further provides a using method of the endoscope retractor. Combined with the specific shape characteristics and structure characteristics of the retractor, a bent sequential inserting and step-by-step assembly mode is adopted, and therefore the incision size is reduced; by the supplementary means of the scale, relative sizes of an operative region can be precisely controlled, and the probability of body tissue and organ injuries is significantly reduced.

Owner:钟朝辉

An aircraft tire clamping and lifting device and its control system

ActiveCN108751059BGuaranteed stable clampingImprove stabilityLifting devicesAircraft assemblyControl systemMechanical engineering

The invention discloses an aircraft tire clamping and lifting device, and relates to the technical field of aircraft tire clamping and lifting devices. The aircraft tire clamping and lifting device comprises a U-shaped supporting plate, a U-shaped base and clamping devices. The U-shaped base comprises a straight plate. Two side plates are symmetrically fixed to the two ends of the straight plate.Each clamping device comprises an arc seat. One side face of each arc seat is an arc face. An arc clamp plate is fixed to each arc face. Arc protection plates are fixed to the two side faces of each arc clamp plate. A tire groove channel is defined by each arc clamp plate and the corresponding two arc protection plates. The invention further provides a control system of the aircraft tire clampingand lifting device. According to the aircraft tire clamping and lifting device, the two symmetric clamping devices are fixed to the two side plates, meanwhile, the two clamping devices are controlledby first telescopic devices to move relatively to clamp aircraft wheels, each tire groove channel defined by the corresponding arc clamp plate and the corresponding two arc protection plates is matched with aircraft tires, and clamping stability is improved; and meanwhile, second telescopic devices are used for lifting the clamping devices, and mounting and repairing of the aircraft wheels are facilitated.

Owner:安徽翰邦科技咨询有限公司

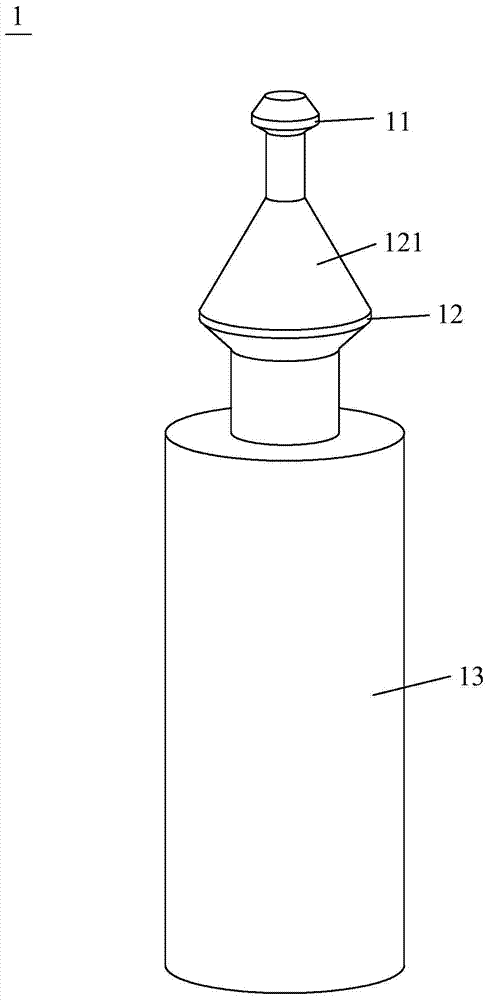

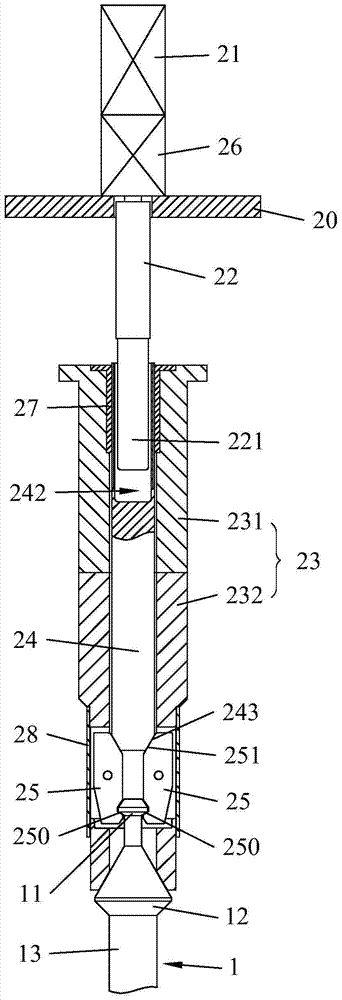

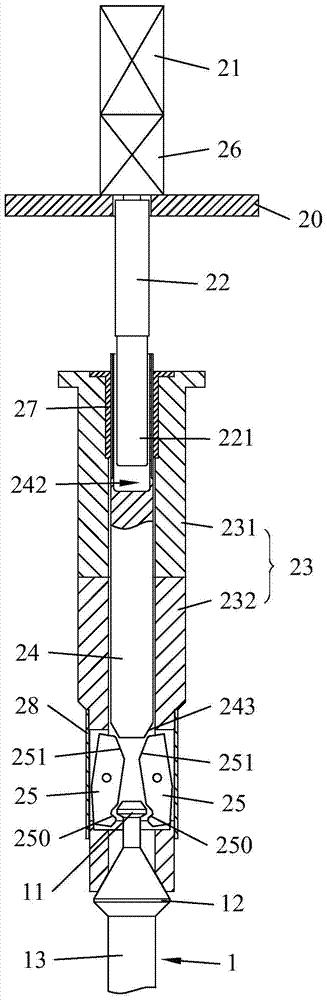

Control rod drive mechanism and its connection with control rods

ActiveCN104183280BGuaranteed stable clampingReduces the risk of accidental trippingNuclear energy generationNuclear reaction controlEngineeringScrew thread

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com