Pipe supporting device for all-round laser cutting machine

A laser cutting machine and support device technology, applied in auxiliary devices, laser welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as inaccurate positioning of round pipes, improve processing quality, improve stability, and avoid shaking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

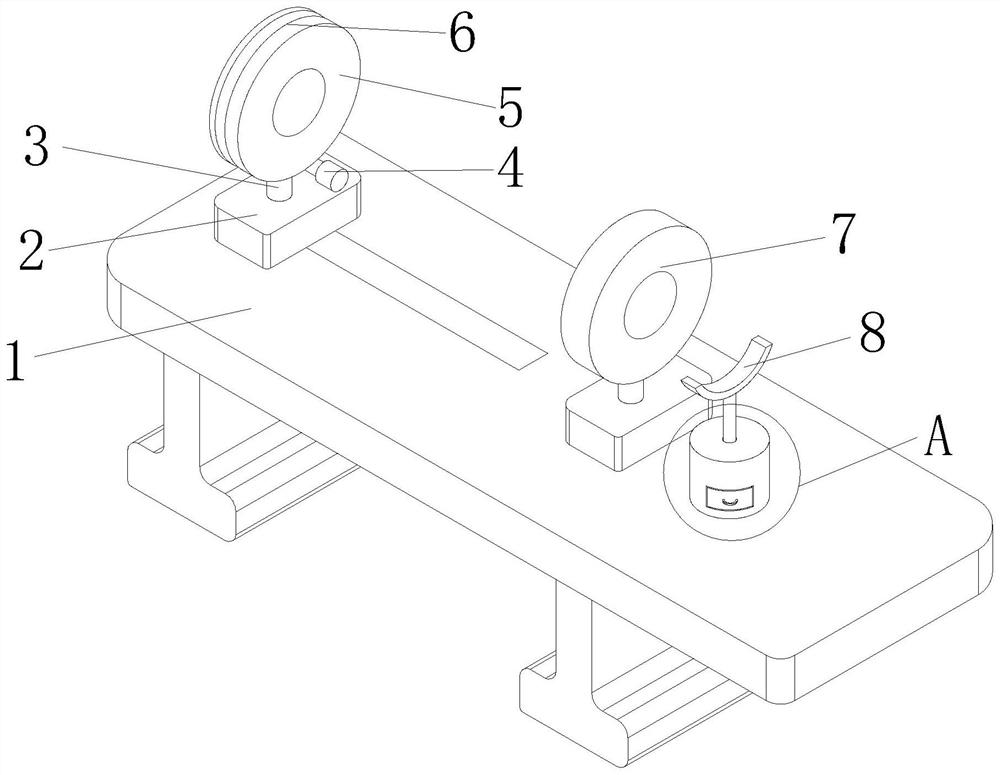

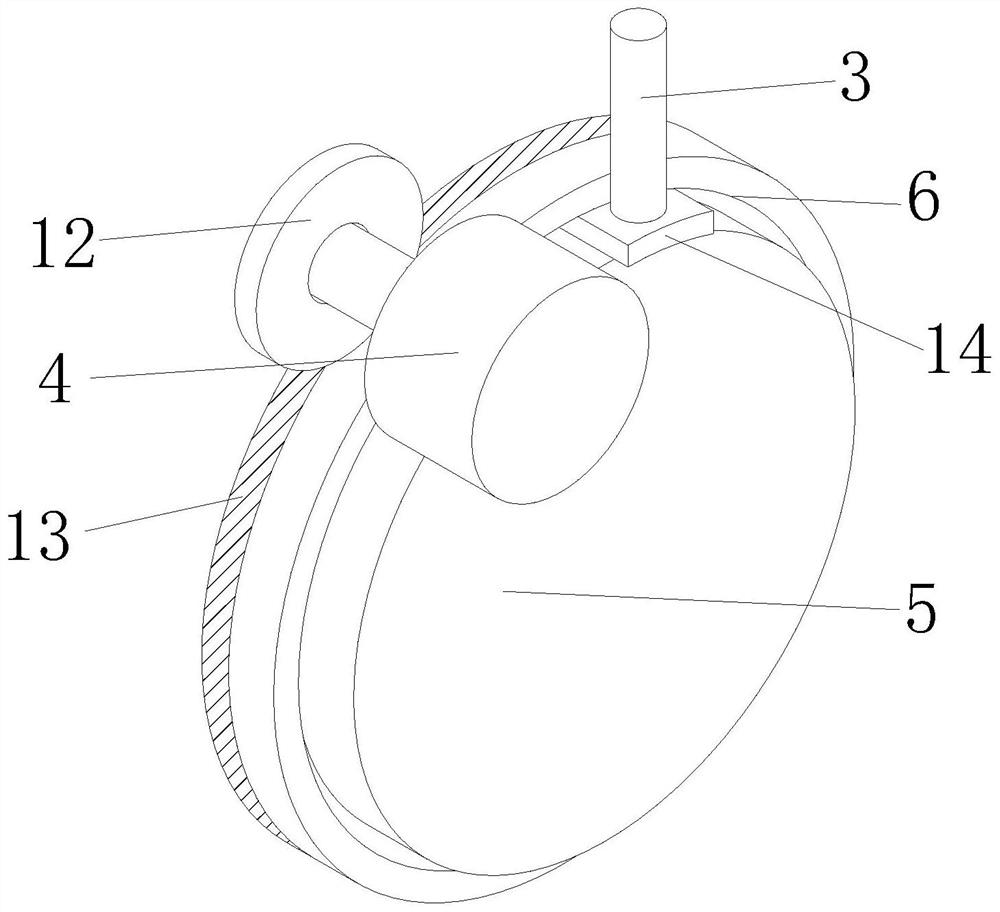

[0035] see Figure 1-8 , The present invention provides a technical solution: a pipe support device for an all-round laser cutting machine, comprising a support base 1, the surface of the support base 1 is slidably connected with a base 2, and the surface of the base 2 is fixedly connected with a connecting rod 3, The upper end of the connecting rod 3 is provided with a first fixing plate 5, the surface of the first fixing plate 5 is initially provided with a ring groove 6 with a convex cross-section, the inner wall of the ring groove 6 is slidably connected with the surface of the connecting rod 3, and the ring groove 6 is slidably connected. The inner wall is slidably connected with an arc-shaped first sliding block 14, and the surface of the first sliding block 14 is fixedly connected to the surface of the connecting rod 3, and then through the arc-shaped arrangement of the first sliding block 14, the first sliding block 14 and the ring The inner walls of the grooves 6 are ...

Embodiment 2

[0039] see Figure 1-8 , on the basis of the first embodiment, the surface of the first fixing plate 5 is provided with three chutes 20, and the cross-sections of the three chutes 20 are all elliptical, and a clamping mechanism is arranged inside the first fixing plate 5 to clamp The mechanism includes three second sliders 16 , the surfaces of the three second sliders 16 are respectively slidably connected with the inner walls of the three chutes 20 , and the shapes of the three second sliders 16 match the shapes of the three chutes 20 . , and then through the elliptical arrangement of the three second sliders 16 and the three chute 20, the frictional force when the second slider 16 slides in the chute 20 is reduced, the smoothness of the device is improved, and the The movement track of the second sliding block 16 is restricted, so that the second sliding block 16 can only slide smoothly in the chute 20 without shifting, thereby ensuring smooth operation.

[0040] The opposi...

Embodiment 3

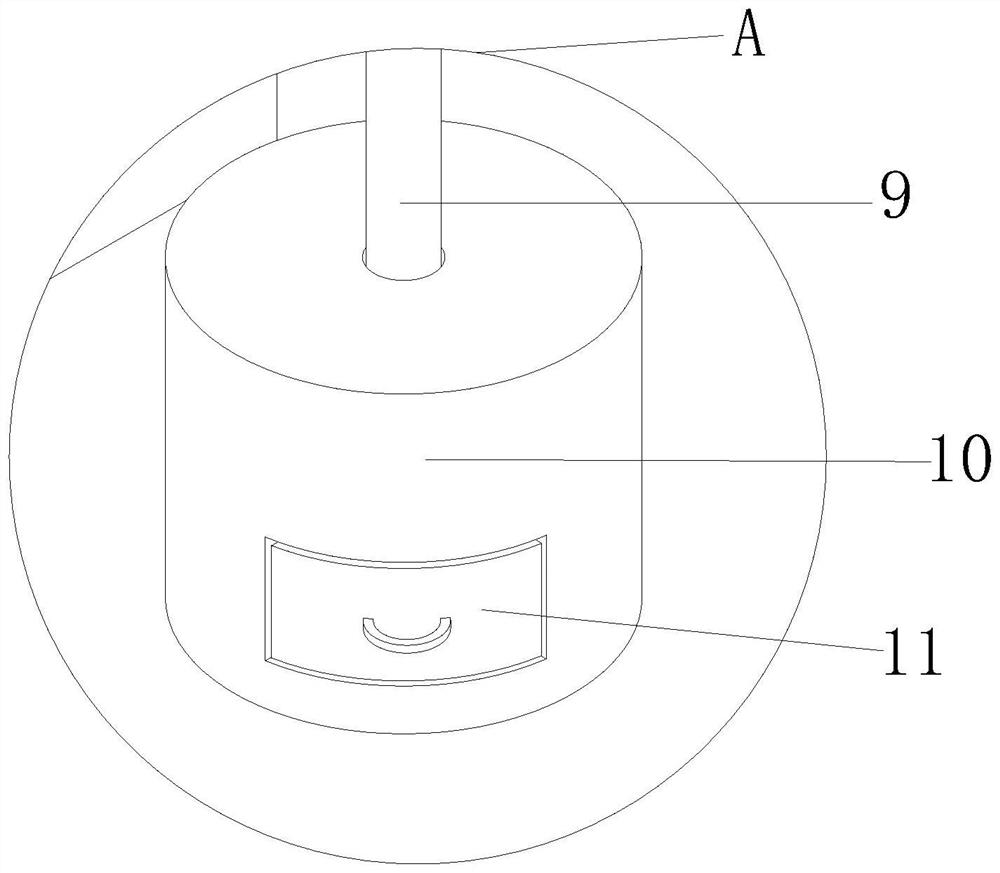

[0045] see Figure 1-8 , On the basis of Embodiment 1 and Embodiment 2, the surface of the support base 1 is fixedly connected with a collection cylinder 10, the interior of the collection cylinder 10 is slidably connected with a collection box 11, and the upper end of the collection cylinder 10 is slidably connected with a support cylinder 9, supporting The surface of the cylinder 9 is movably sleeved with a tension spring 25, and the two ends of the tension spring 25 are respectively fixedly connected to the inner wall of the collecting cylinder 10 and the surface of the supporting cylinder 9, and the upper end of the supporting cylinder 9 is fixedly connected with an arc-shaped support plate 8, It is used to support the circular pipe, and the arc-shaped support plate 8 enables the support plate 8 to fit more closely with the surface of the round pipe. At the same time, the tension spring 25 is set so that the height of the support plate 8 can be adjusted, and then The suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com