Screwing positioning tool, screwing structure and screwing method

A technology for positioning tooling and screwing, which is applied to workpiece clamping devices, manufacturing tools, hand-held tools, etc., and can solve problems such as time-consuming, low efficiency, and inaccurate alignment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

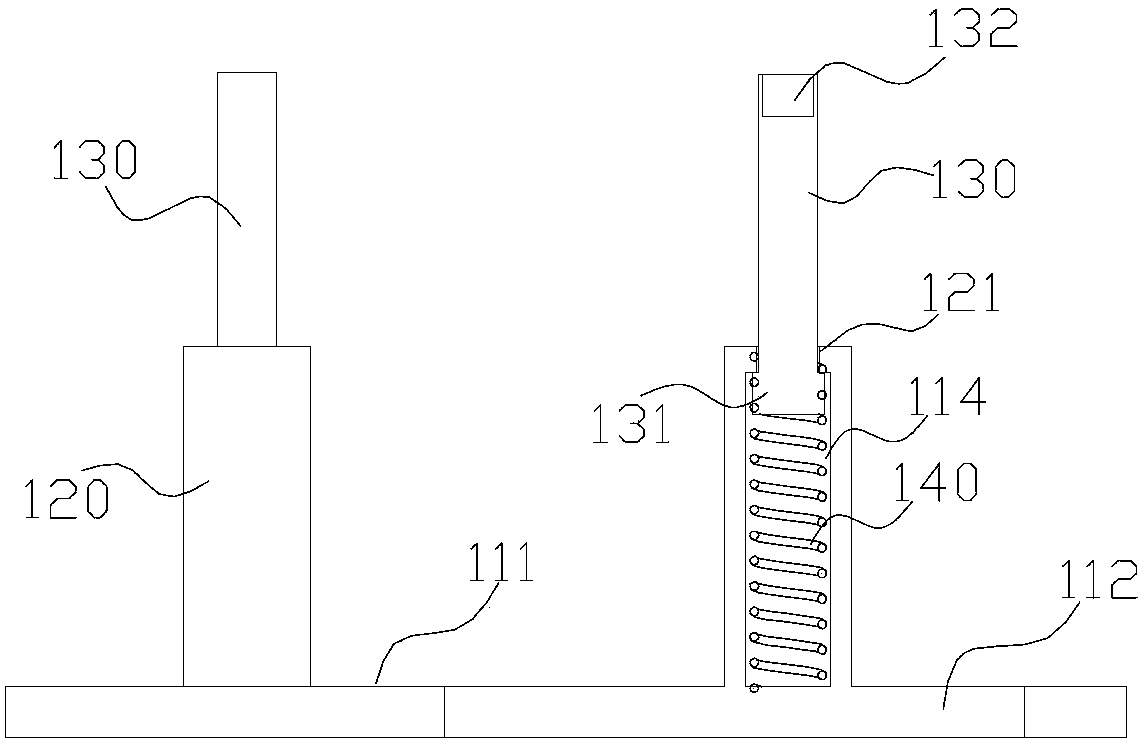

[0029] A screw positioning tool 100 such as figure 1 As shown, it includes a base 110 (the base 110 includes a seat body 112 and a sleeve 113), a positioning column 130 and an elastic member 140 (in this embodiment, the elastic member 140 is a coil spring), the upper part of the base 110 forms a placing platform 111, and the sleeve The tube 113 is fixed upright on the placement table 111 of the base 110, the sleeve 113 is provided with a sliding hole 114, the upper end of the sliding hole 114 is a limiting hole 121, the lower end of the positioning column 130 is provided with a limiting head 131, and an elastic member 140 Located between the positioning post 130 and the base 110 , under the action of the elastic member 140 , the position-limiting head 131 of the positioning post 130 is limited by the position-limiting hole 121 , and the upper end of the positioning post 130 protrudes from the position-limiting hole 121 . A counterbore 132 is defined at the upper end of the pos...

Embodiment 2

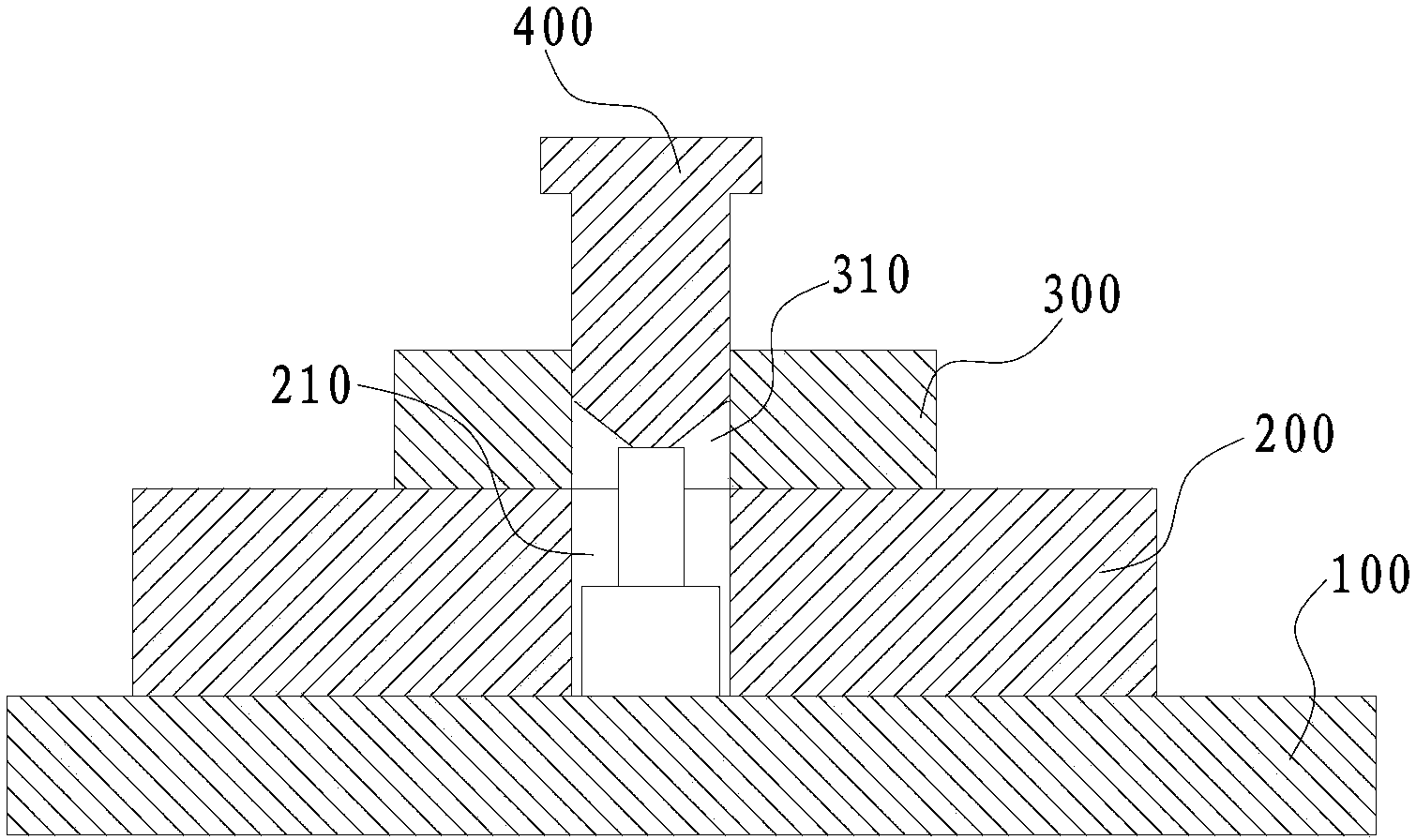

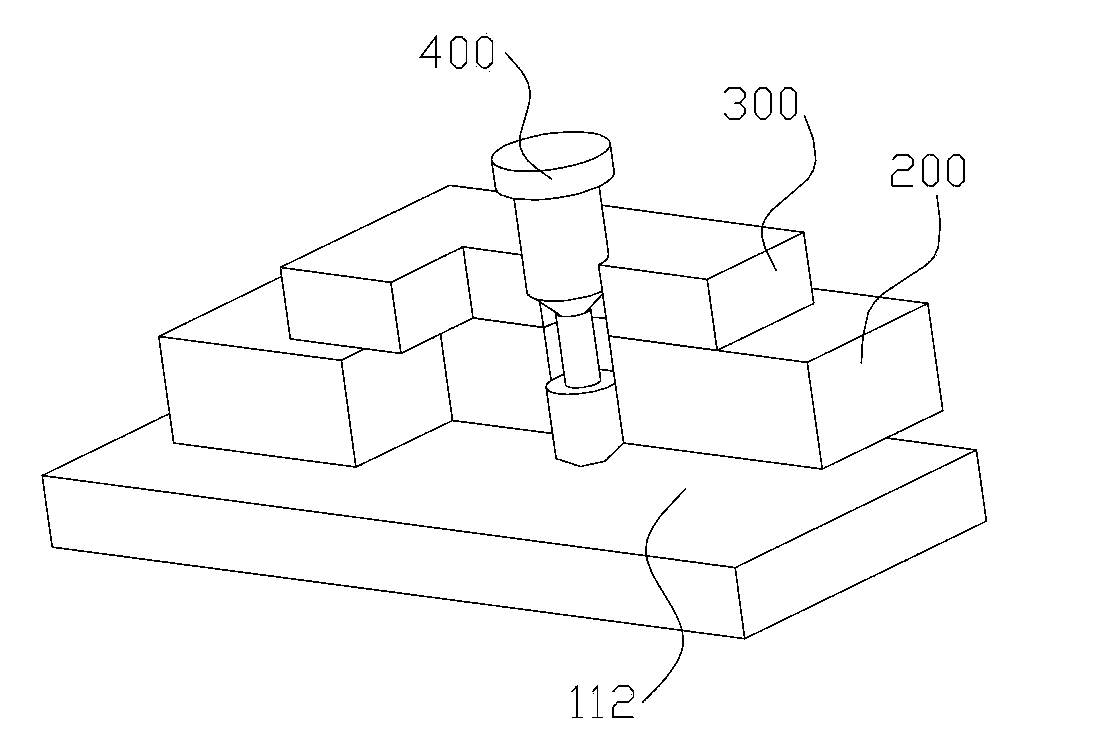

[0039] Such as Figure 4 As shown, the difference between the present embodiment and the first embodiment is that the base 110 has a certain thickness, and the sliding hole 114 is directly provided in the base 110 , the principle is the same as that of the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com