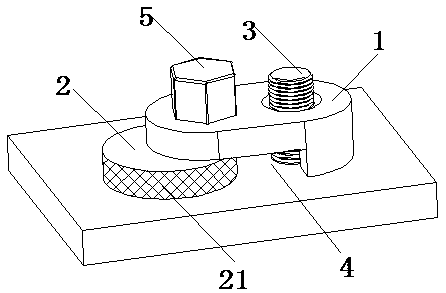

screw screw device

A screw and shaft mounting hole technology, which is applied in the manufacture of tools, hand-held tools, etc., can solve the problems of low efficiency and inconvenient operation of taking out the screw, and achieve high take-out efficiency, solve the effect of low take-out efficiency of the screw and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

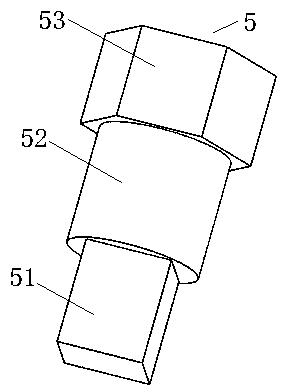

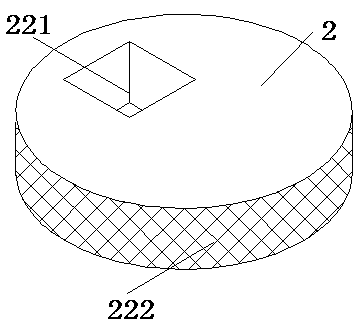

Examples

Embodiment 2

[0031] Specific embodiment 2 of the screw screw device of the present invention. The difference between this embodiment and the above-mentioned embodiment is only that: the above-mentioned rotating shaft and the eccentric wheel are rotationally matched. At this time, the power input section is not provided on the rotating shaft, and the eccentric wheel is provided with rotation The handle, by turning the handle to drive the eccentric wheel to rotate.

[0032] In other embodiments, the above-mentioned through hole may not be provided, and the screw can only be clamped by the first clamping portion and the second clamping surface. Of course, the receiving groove may not be provided, and only the through hole may be provided. The two clamping parts cooperate with the second clamping surface to clamp the screw; the above-mentioned eccentric wheel is a kind of cam. In other embodiments, the eccentric wheel may be another cam that meets the requirements of the clamping screw. Of course,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com