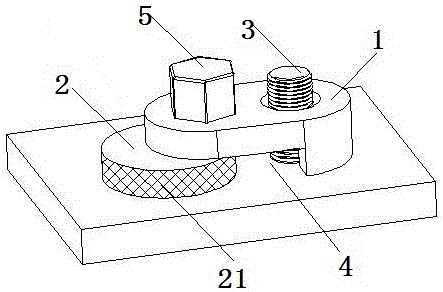

Screw twisting device

A screw and clamping piece technology, applied in the field of screw screwing tooling, can solve the problems of inconvenient operation and low efficiency of taking out the screw, and achieve the effect of solving the problem of low screw take-out efficiency, high take-out efficiency and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

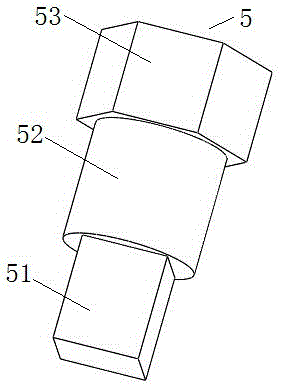

Examples

Embodiment 2

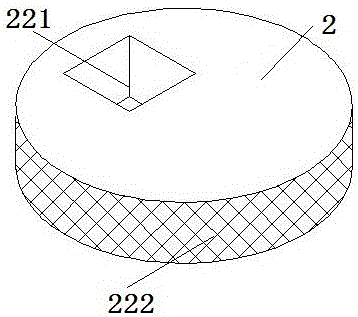

[0031] The specific embodiment 2 of the screw screwing device of the present invention, the difference between this embodiment and the above-mentioned embodiment is only that: the above-mentioned rotating shaft and the eccentric wheel rotate and cooperate, at this time, no power input section is provided on the rotating shaft, and a rotating shaft is provided on the eccentric wheel in addition. The handle drives the eccentric wheel to rotate by turning the handle.

[0032]In other embodiments, the above-mentioned through hole may not be provided, and the screw rod is only clamped through the cooperation of the first clamping part and the second clamping surface. The second clamping part cooperates with the second clamping surface to clamp the screw rod; the above-mentioned eccentric wheel is a kind of cam. In other embodiments, the eccentric wheel can be other cams that meet the requirements of the clamping screw rod. Of course, the above-mentioned second clamping member can al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com