Construction method for enabling water-cooling walls of refuse incineration power generation waste heat boiler to integrally penetrate from top

A waste heat boiler and waste incineration technology, applied in the direction of combustion methods, boiler water pipes, combustion chambers, etc., can solve the problems of being stored near the installation location, welding quality cannot be guaranteed, and the working surface cannot be expanded, so as to facilitate control and reduce high waste. The effect of empty pipe arrangement on the quantity of welding, improving work efficiency and engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further illustrated below by specific examples.

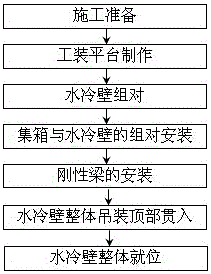

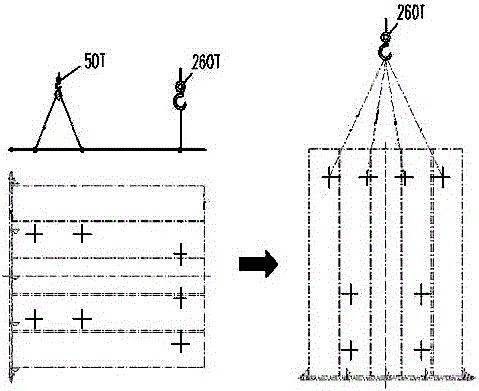

[0030] A construction method for the overall top penetration of the water-cooled wall of the waste heat boiler for waste incineration power generation, including

[0031] Step 1. Fabrication of water wall tooling platform:

[0032] Two I-beams are used to meet the simultaneous assembly of four sets of water-cooled walls. The height of the tooling platform from the ground is at least 1 meter. Each leg of the tooling platform is supported on a concrete pier or concrete road to prevent the platform from sinking and deforming. Adjust the elevation of the tooling platform to ensure levelness;

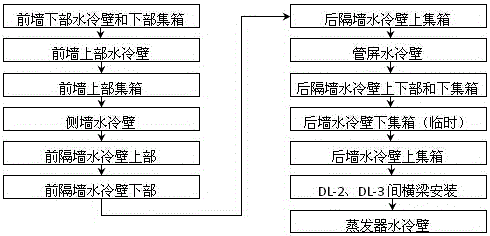

[0033] Step 2. Assemble the water-cooled wall ground in sections:

[0034] Weld the limit device on the water-cooled wall tooling platform, the limit device is 4 meters apart, and is used for the assembly and adjustment of the water-cooled wall; when assembling the water-cooled wall, mainly adjust its length,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com