T-shaped steel assembly machine

A technology of erecting machine and T-beam, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficult to clean, difficult to pin, affecting the production progress, etc., to reduce the labor intensity of workers, The effect of reducing the number of hoisting and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

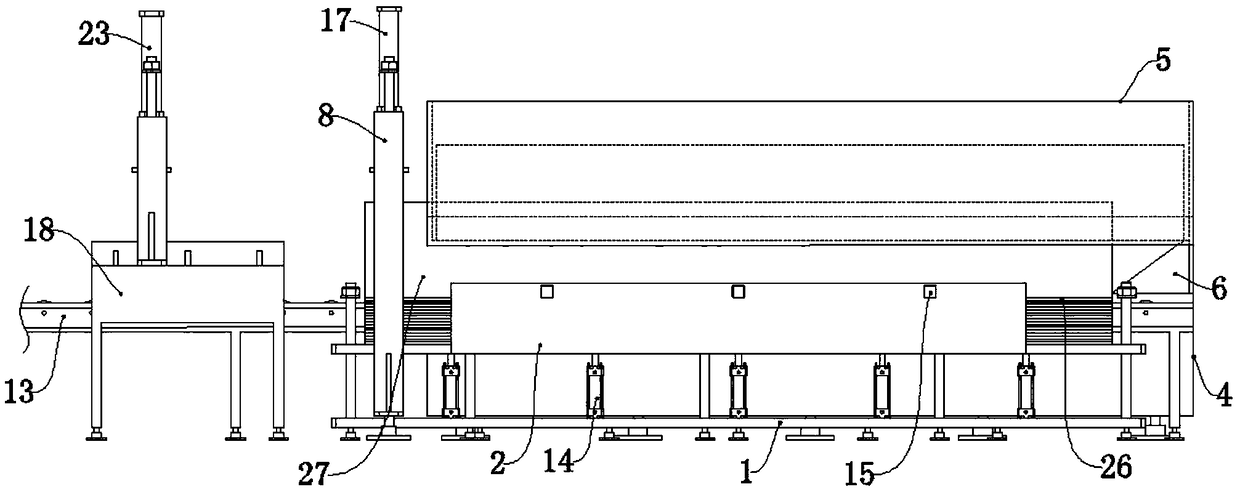

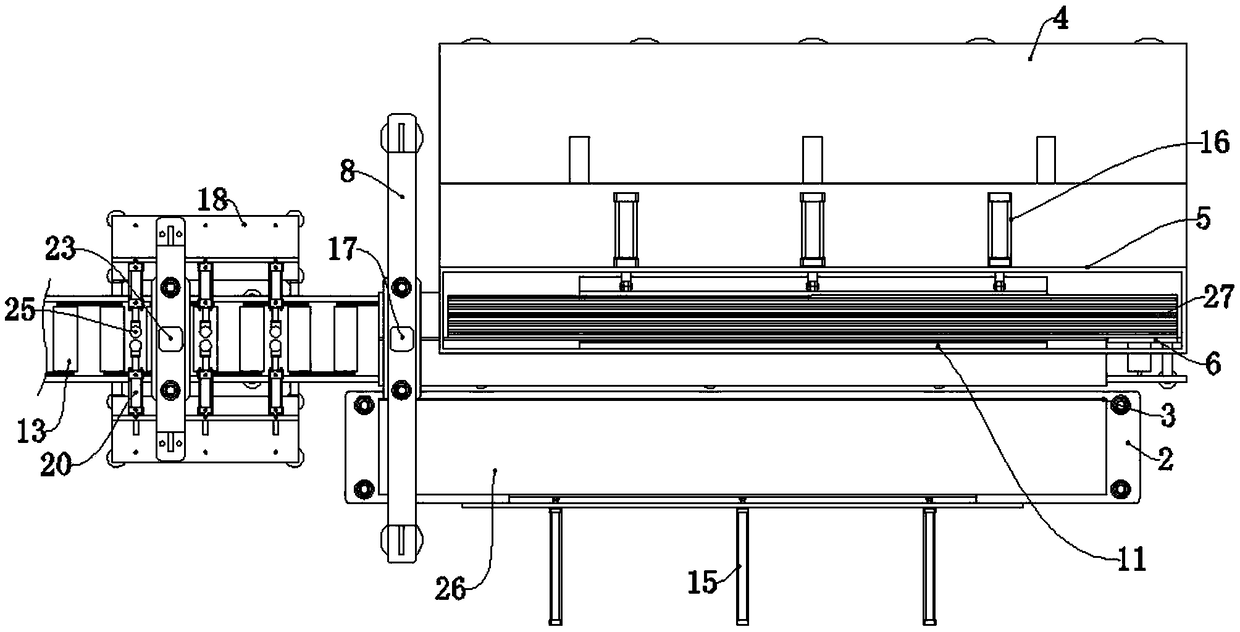

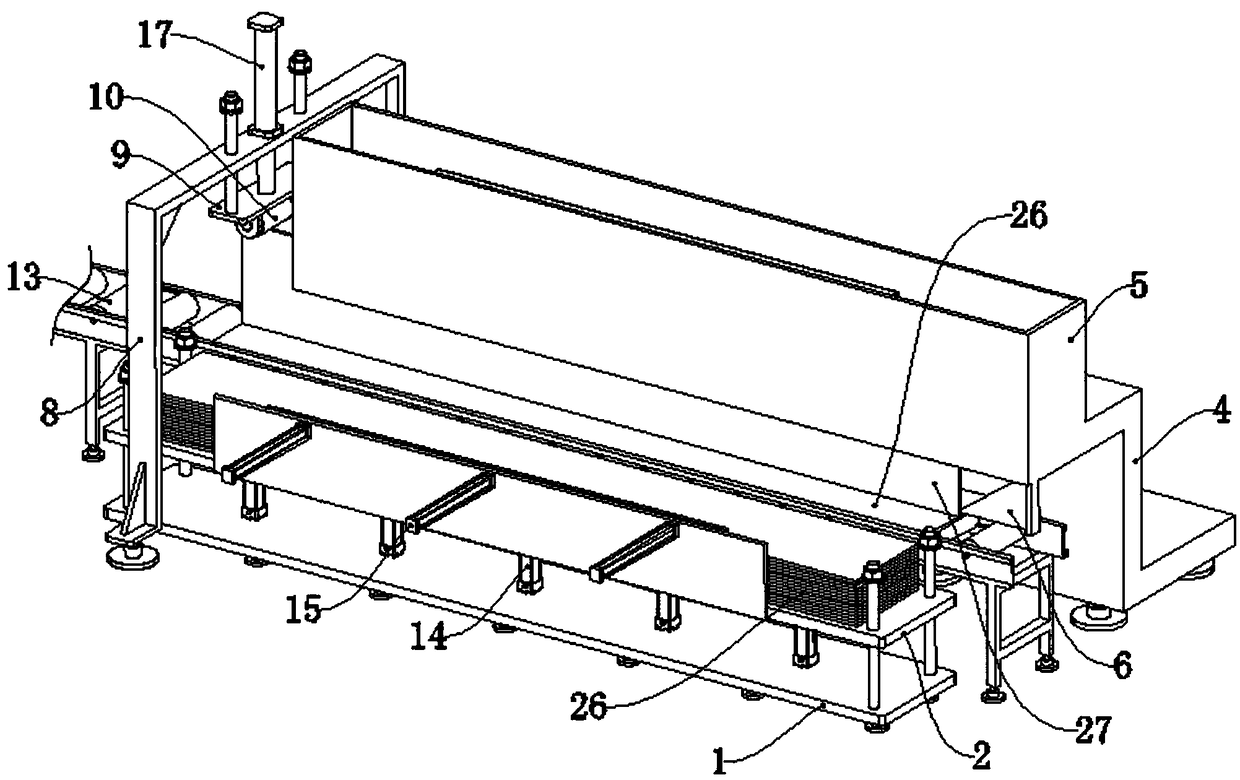

[0021] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below according to the accompanying drawings.

[0022] Figure 1 to Figure 8 It shows the T-shaped steel erecting machine of the present invention, a T-shaped steel erecting machine, which includes an electric roller table 13, a wing plate feeding device, a web feeding device, a vertical pre-compression device and a centering device.

[0023] The wing plate feeding device comprises a wing plate feeding device support 1, a wing plate supporting bracket 2, a wing plate supporting bracket lifting hydraulic cylinder 14 and a wing plate horizontally pushing hydraulic cylinder 15. The blade feeding device bracket 1 is located on one side of the electric roller table 13, and the blade supporting bracket 2 can be vertically slidably mounted on the blade feeding device bracket 1. A baffle plate 3 is provided on the side of the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com