Double-steel-plate shear wall combined structure

A combined structure and double-steel technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of environmental protection, slow construction drawing speed, complex construction of concrete shear walls, etc., and achieve cost saving, material saving, design flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

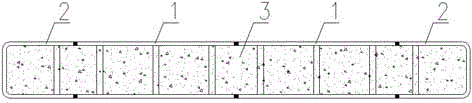

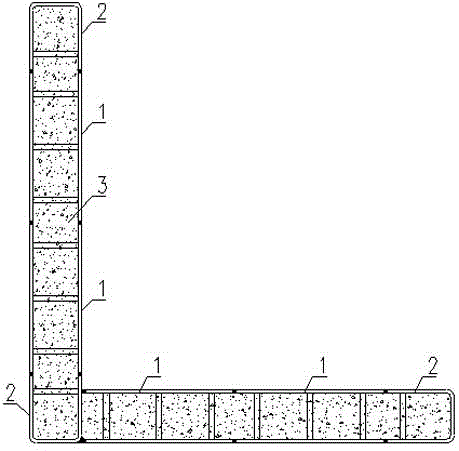

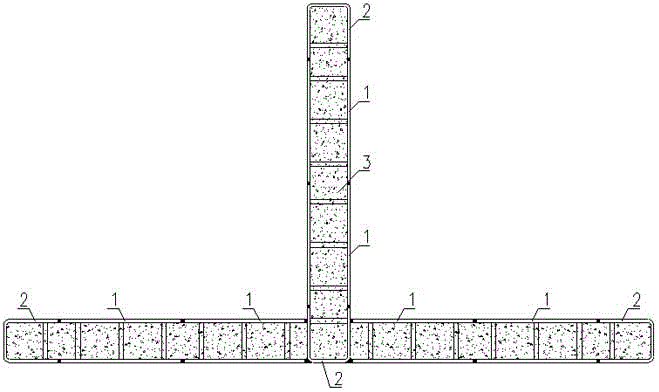

[0035] refer to Figures 1 to 11b , a double-steel plate shear wall composite structure, which is composed of at least one double-steel plate wall unit 1 and end member 2 welded, pouring concrete 3 in the cavity formed by the double-steel plate wall unit 1 and the end member 2, said The double steel plate wall unit 1 is welded by two steel plates 11 and a connecting piece 12 located in the middle of the two steel plates.

[0036] The section form of the composite structure of the double-steel plate shear wall can be in-line, or L-shaped, or T-shaped, or Z-shaped, or U-shaped.

[0037] The connecting piece 12 can be round steel, or steel bar, or steel pipe, or discontinuous steel plate, or section steel.

[0038] The end member can be a rectangular tube 21, or a U-shaped steel tube 22, or a steel plate 23, or other shaped steel, and the connecting piece 12 can be arranged inside the U-shaped steel tube 22.

[0039] The ends of the steel plates 11 in the double steel plate wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com