Method of welding printed circuit board containing mixed lead components and leadless components

A printed circuit board and welding method technology, which is applied in the direction of assembling printed circuits with electrical components, welding media, welding equipment, etc. The effect of avoiding the decrease of solder joint reliability, avoiding the deformation of printed circuit boards, and reducing the difficulty of material control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] 1. Basic components:

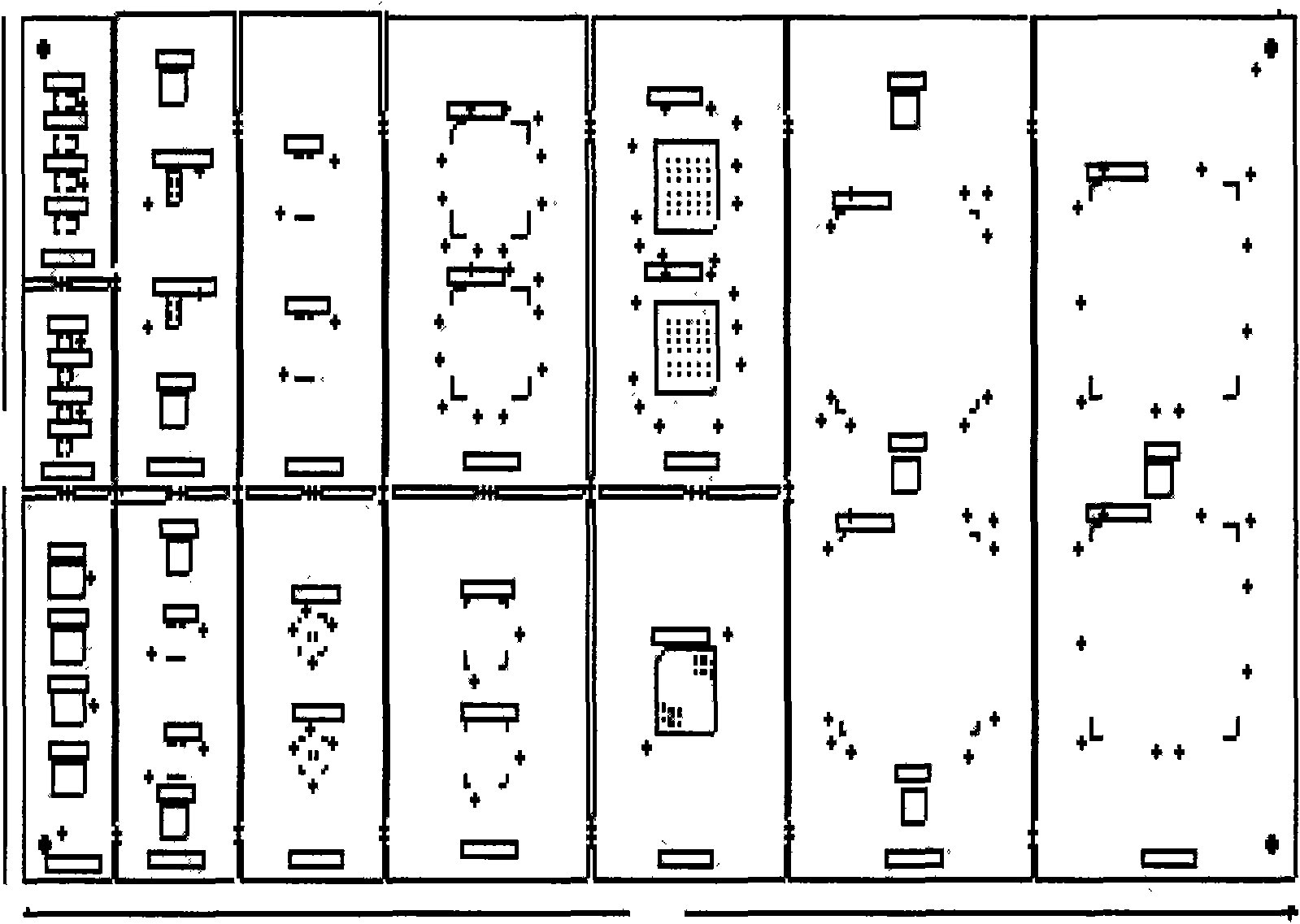

[0055] 1) Printed circuit board

[0056] The main factors affecting the quality of solder joints are: welding process parameters, printed board materials and coating materials, pin coatings of lead-free components, welding times, environmental tests, etc. In order to compare and analyze the influence trend of various influencing factors on soldering quality, in this embodiment, two types of printed boards are designed to install various types of lead-free devices and chip components, wherein: the board is epoxy glass laminated board (FR4 ), the surface coating is a lead-tin alloy printed board, numbered board A1-01; the board is epoxy glass laminated board (FR4), and the surface coating is electroless nickel-plated immersion gold 1 printed board, numbered Plate A2-01. In order to avoid the influence of other factors on the test results, the design of the test circuit board is simplified as far as possible, and the device density is low. The tes...

Embodiment 2

[0100] 1. Basic components

[0101] 1) Printed circuit board

[0102] Select a printed board with epoxy glass laminate (FR4) and lead-tin alloy as the surface coating, numbered board A1-02; the plate is epoxy glass laminate (FR4), and the surface coating is electroless nickel plating 1 printed board of gold, numbered board A2-02, the rest are the same as "embodiment 1".

[0103] 2) Leaded components and lead-free components

[0104] Same as Example 1

[0105] 3) Solder and flux

[0106] Same as Example 1

[0107] 4) Instruments and equipment

[0108] Same as Example 1

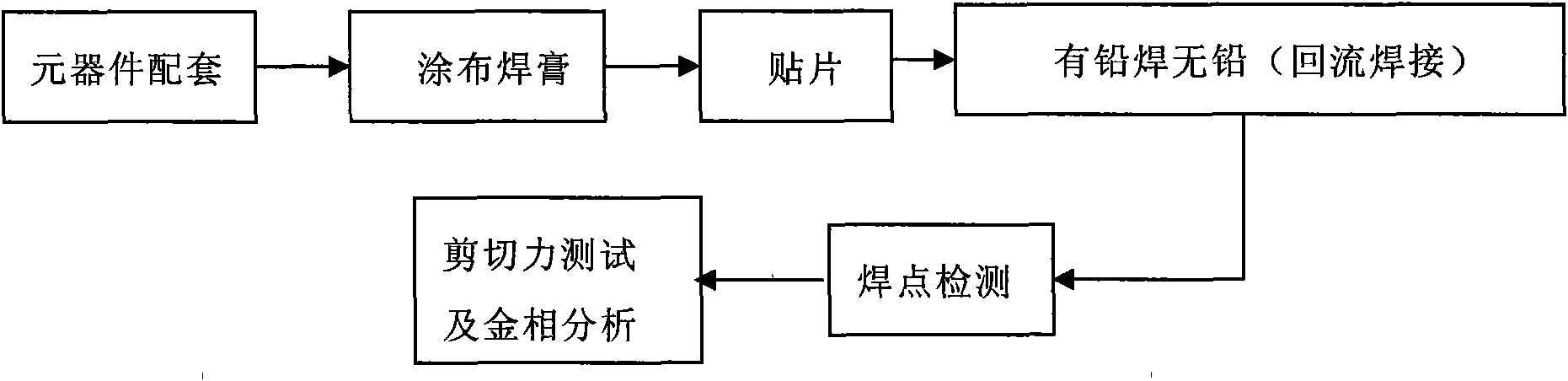

[0109] 2. Test steps

[0110] 1) Inspection and matching of components

[0111] Same as Example 1

[0112] 2) Coating solder paste

[0113] Same as Example 1

[0114] 3) patch

[0115] Same as Example 1

[0116] 4) Reflow soldering

[0117] Put the printed circuit board into the reflow furnace with 9 temperature zones for soldering, and control the peak temperature to 215°C, such as Figure 5 Sho...

Embodiment 3

[0123] 1. Basic components

[0124] 1) Printed circuit board

[0125] Select a printed board with epoxy glass laminate (FR4) and lead-tin alloy as the surface coating, numbered board A1-03; the plate is epoxy glass laminate (FR4), and the surface coating is electroless nickel plating 1 printed board of gold, numbered board A2-03, the rest are the same as "embodiment 1".

[0126] 2) Leaded components and lead-free components

[0127] Same as Example 1

[0128] 3) Solder and flux

[0129] Same as Example 1

[0130] 4) Instruments and equipment

[0131] Same as Example 1

[0132] 2. Test steps

[0133] 1) Inspection and matching of components

[0134] Same as Example 1

[0135] 2) Coating solder paste

[0136] Same as Example 1

[0137] 3) patch

[0138] Same as Example 1

[0139] 4) Reflow soldering

[0140] Put the printed circuit board into the reflow furnace with 9 temperature zones for soldering, and control the peak temperature at 225°C, such as Figure 6 Sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com