Hydraulic large plate leveling device

A hydraulic and hydraulic station technology, applied in the field of hydraulic metal sheet leveling machinery, can solve the problems of complex welding process, poor surface quality of side wall panels, and many welding seams, achieve good economic and social benefits, improve work efficiency, The effect of the reduction in the number of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structure of the hydraulic slab leveling device of the present invention will be further described in detail in the following embodiments in conjunction with the accompanying drawings.

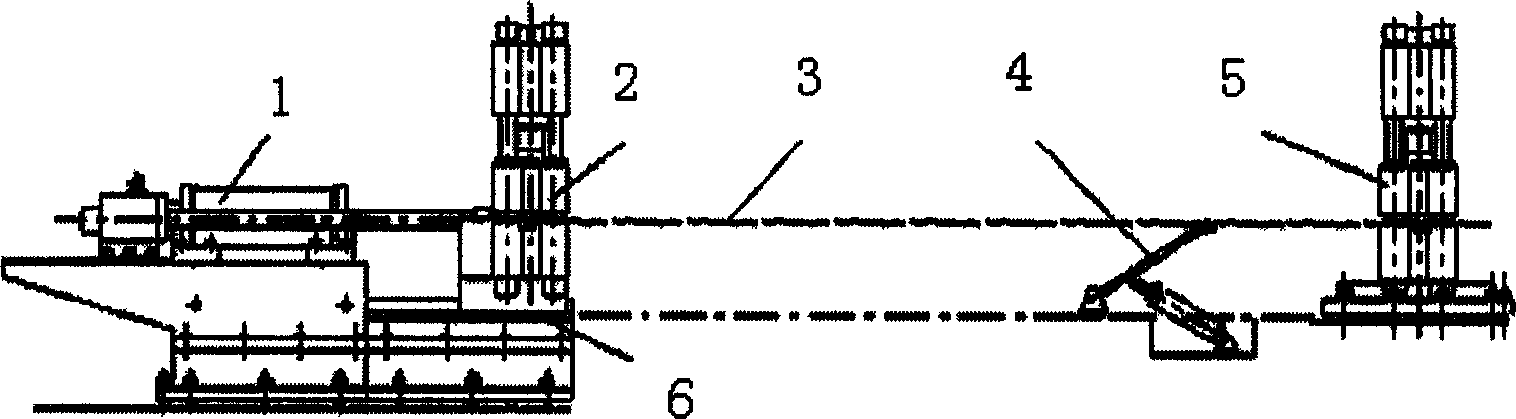

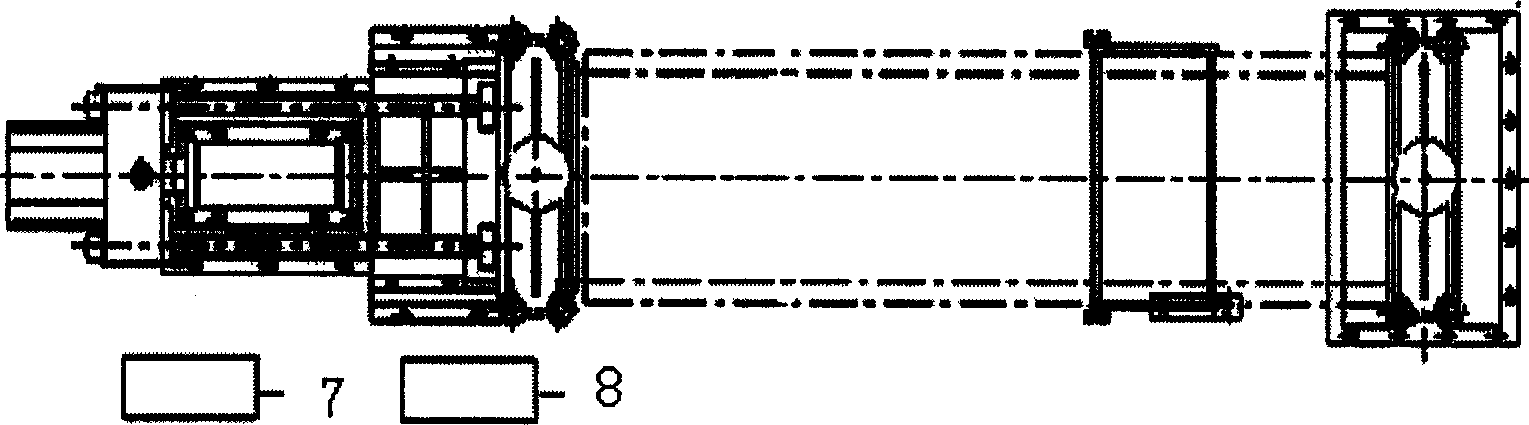

[0022] refer to Figures 1 to 6 , the hydraulic slab leveling device is composed of a stretching mechanism 1, a sliding clamping mechanism 2 and a fixed clamping mechanism 5, a working platform 3, a feeding and returning mechanism 4, a sliding table mechanism 6, a hydraulic station 7, and a control console 8. , the control console 8 is connected with the hydraulic station 7 by a circuit, and the motor, oil pump, and solenoid valve in the hydraulic station 7 are controlled to work. The hydraulic station 7 communicates with the stretching mechanism 1, the sliding clamping mechanism 2, and the fixed clamping mechanism 5 through the oil circuit connected to drive the stretching mechanism and the clamping mechanism;

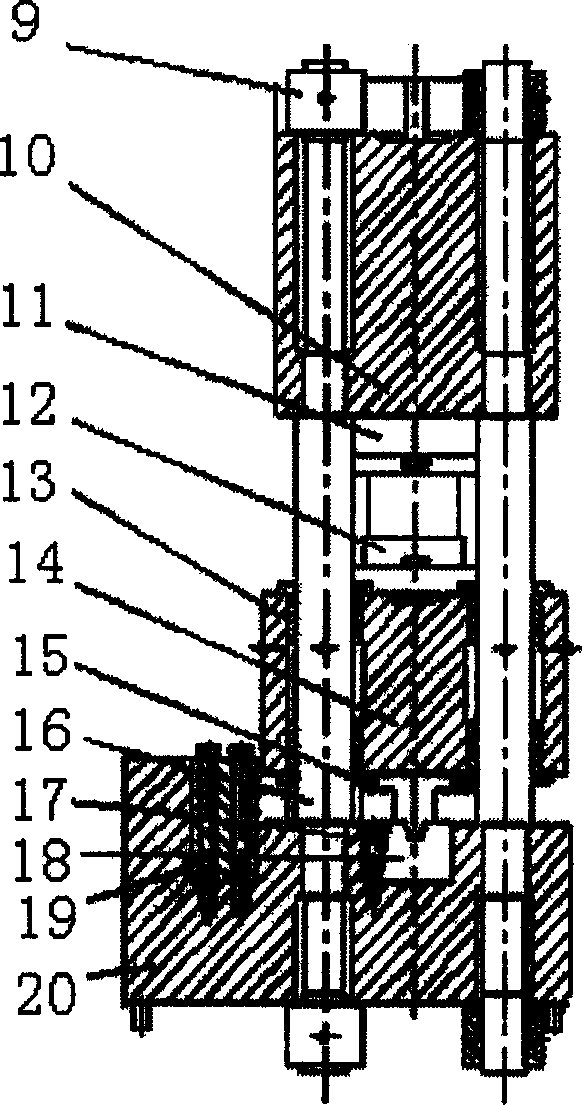

[0023] The sliding clamping mechanism 2 and the fixed clamping mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com