Storage-tank cylindrical-section integral wallboard creep aging forming method

A technology of creep aging forming and cylindrical section, applied in forming tools, metal processing equipment, manufacturing tools, etc. To avoid problems such as degree deviation, achieve high dimensional accuracy, good formability, and small size deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method for integral creep aging forming of the wall plate of the tank cylinder section according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] A method for integral creep aging forming of a tank cylinder section wall plate according to the present invention comprises the following steps:

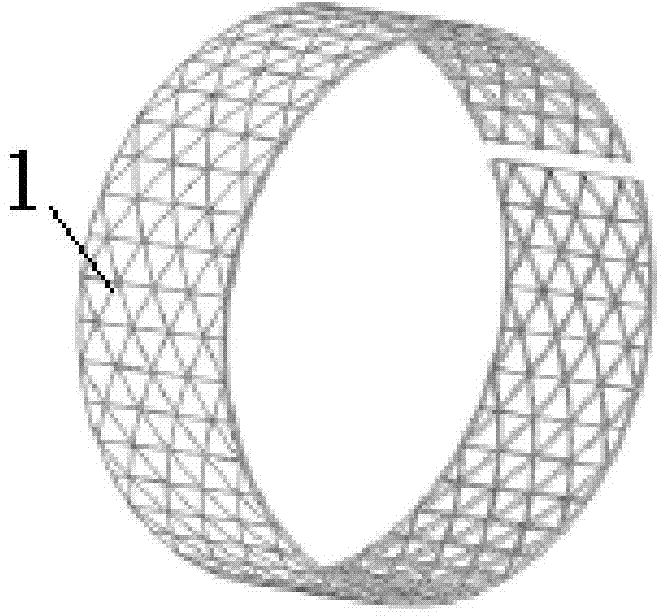

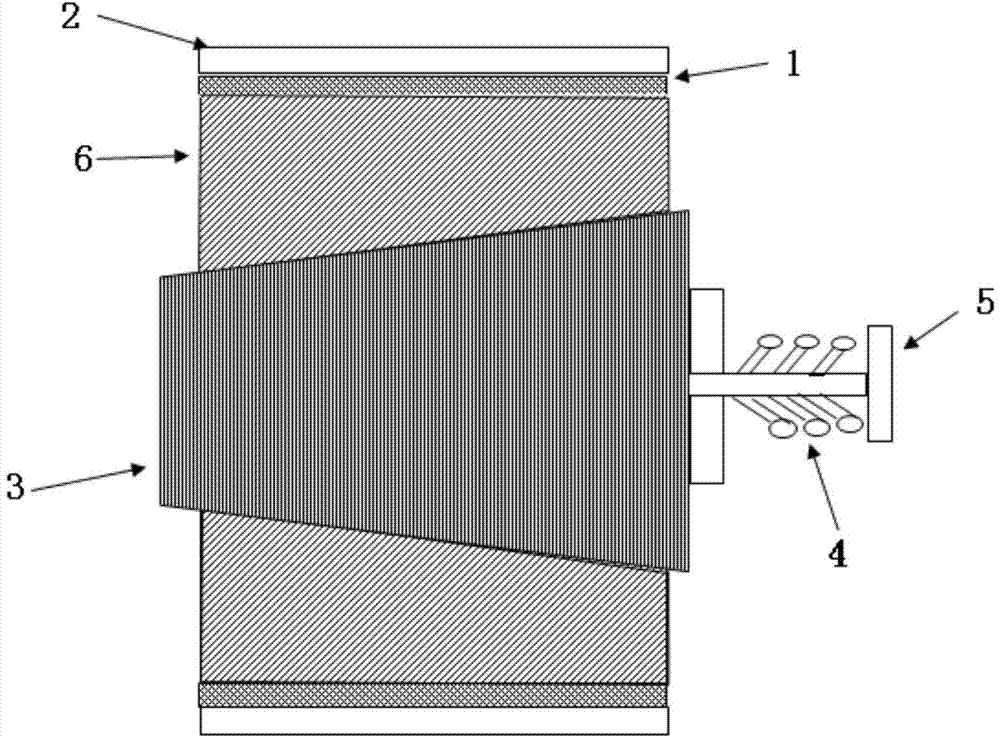

[0025] (a) if figure 1 As shown, the wall plate of the cylindrical section of the storage tank is processed according to the drawing size, and the inner grid or outer grid of the wall plate is milled to meet the size requirements; then the wall plate 1 is pre-rolled on the rolling bending equipment;

[0026] (b) welding the wall plate 1 obtained in step (a) along the longitudinal seam into an integral cylindrical wall plate; the cylindrical wall plate has only one welding seam;

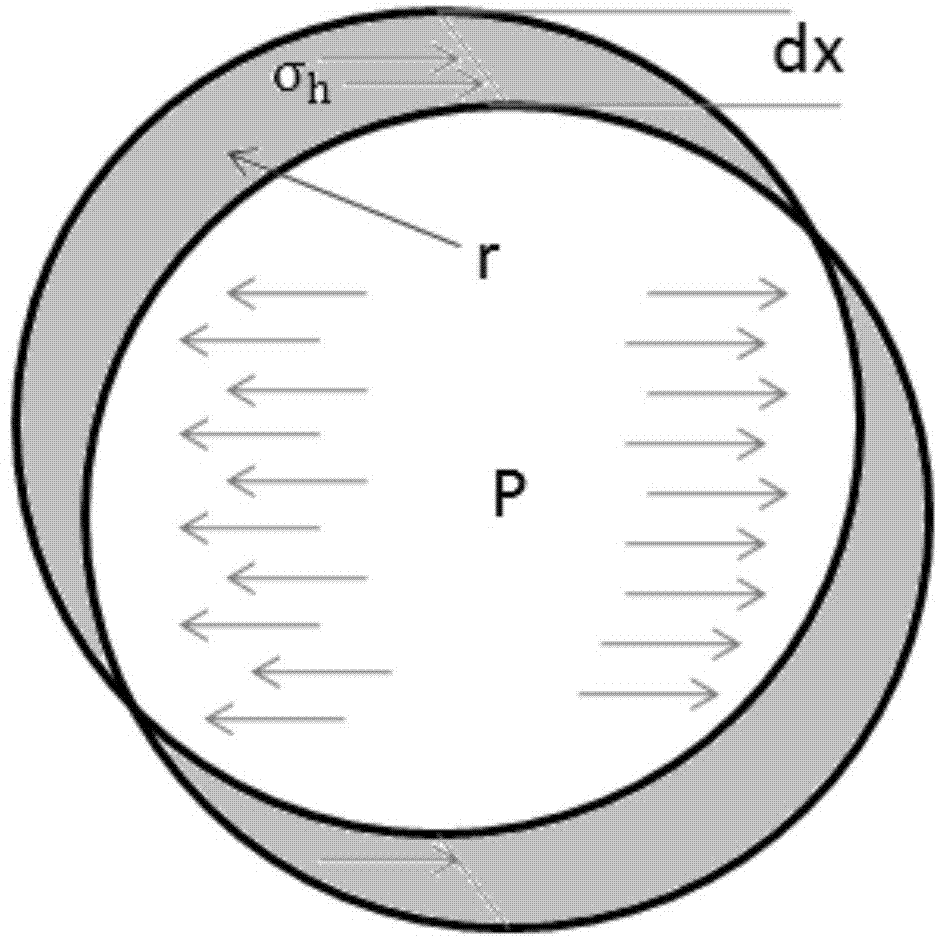

[0027] (c) Carry out finite element simulation of creep aging forming (using existing technology, such as: ABAQ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com