Installing method for main pipeline of coolant system of nuclear power station

A technology of coolant system and installation method, which is applied in nuclear power generation, nuclear engineering, nuclear reactor monitoring and other directions, can solve the problems of large diameter and wall thickness of main pipeline, high welding quality requirements, and large construction period risks, so as to improve work efficiency and save money. material, effect of reducing the number of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

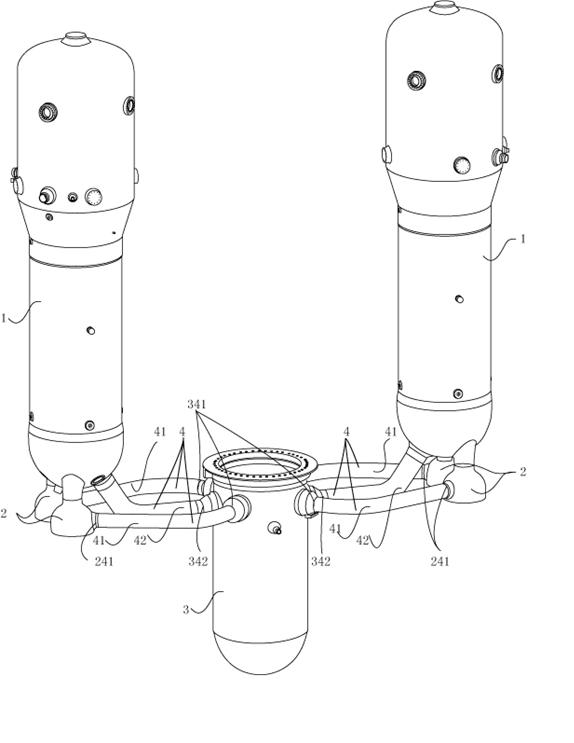

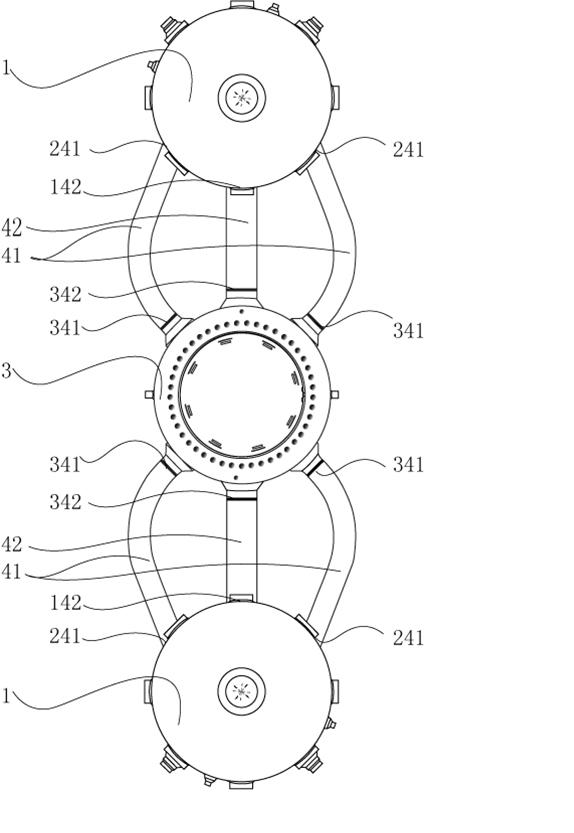

[0045] This embodiment first starts from the end of the pressure vessel 3 of the main pipeline 4 and installs towards the end of the steam generator 1, which is applicable to the situation that the steam generator 1 has not arrived and the pressure vessel 3 has arrived; the installation method is described in detail as follows:

[0046] 1) Install prerequisite check.

[0047] 2) The pressure vessel 3 is installed in place. If the steam generator 1 has not arrived, the steam generator and main pump will not be installed temporarily.

[0048] 3) Use laser tracking to measure pressure vessel 3, obtain nozzle data, and perform 3D modeling according to the data; if steam generator 1 has not arrived, you can directly refer to the measurement data provided by the supplier, or go to the supplier for inspection The data of steam generator 1 and main pump 2 are measured by laser tracking and 3D modeling is carried out.

[0049] 4) Laser tracking and measuring the cold and hot sections ...

Embodiment 2

[0067] This embodiment first starts from the steam generator 1 end of the main pipeline 4, and installs to the pressure vessel 3 end. It is suitable for the steam generator 1, the main pump 2 has arrived, and the pressure vessel 3 has not arrived. The installation method is described in detail as follows :

[0068] 1) Install prerequisite check.

[0069] 2) The steam generator 1 and the main pump 2 are installed in place. If the pressure vessel 3 has not arrived, it will not be installed temporarily.

[0070] 3) Use laser tracking to measure the nozzles of steam generator 1 and main pump 2. If the pressure vessel 3 has not arrived, you can directly refer to the data provided by the supplier; or go to the supplier for laser measurement of the nozzle data of pressure vessel 3 Track measurements and perform 3D modeling according to the data.

[0071] 4) Laser tracking and measuring the cold and hot sections of the main pipeline to obtain data, and perform 3D modeling and data f...

Embodiment 3

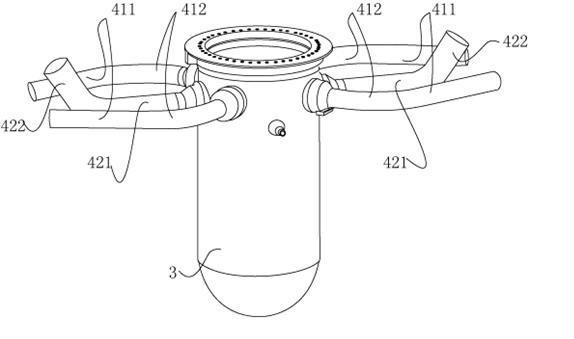

[0089] In this embodiment, the curved portion of the main pipe 4 is butt-welded first, and then the straight section is butt-welded, which is applicable when the steam generator 1 and the pressure vessel 3 have both arrived. Or measure the 3D data of the safety end nozzle and groove at the manufacturer, which is convenient to save on-site construction period. Its installation method is detailed as follows:

[0090] 1) Prerequisite checks.

[0091] 2) Laser tracking and measuring the nozzles of steam generator 1, main pump 2, and pressure vessel 3 to obtain data, and perform 3D modeling according to the data.

[0092] 3) Laser tracking and measuring the 4 cold and hot sections of the main pipeline to obtain data, and perform 3D modeling according to the data, and perform laser measurement on the groove characteristics of the main pipeline to be processed to obtain data confirmation, and perform 3D modeling and groove group pair fit. .

[0093] 4) Use the on-site CNC trackin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com