Integral panel creep aging forming tool based on autoclave

A technology of creep aging forming and integral wall panels, which is applied in the field of sheet metal forming, can solve problems such as mold surface changes, and achieve the effects of ensuring sealing effects, saving time and economic costs, and facilitating adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

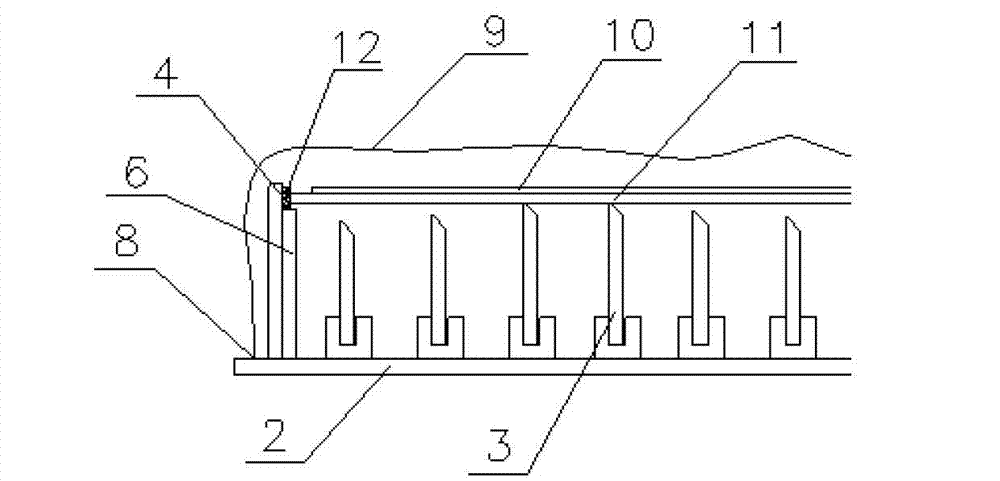

[0024] The present invention adopts some discrete and detachable clamps to form the mold surface, and the adjustment of the mold surface can be realized by replacing the clamps 3, which can meet the aging forming requirements of large-sized integral wall parts, and can greatly reduce the production time and economic cost .

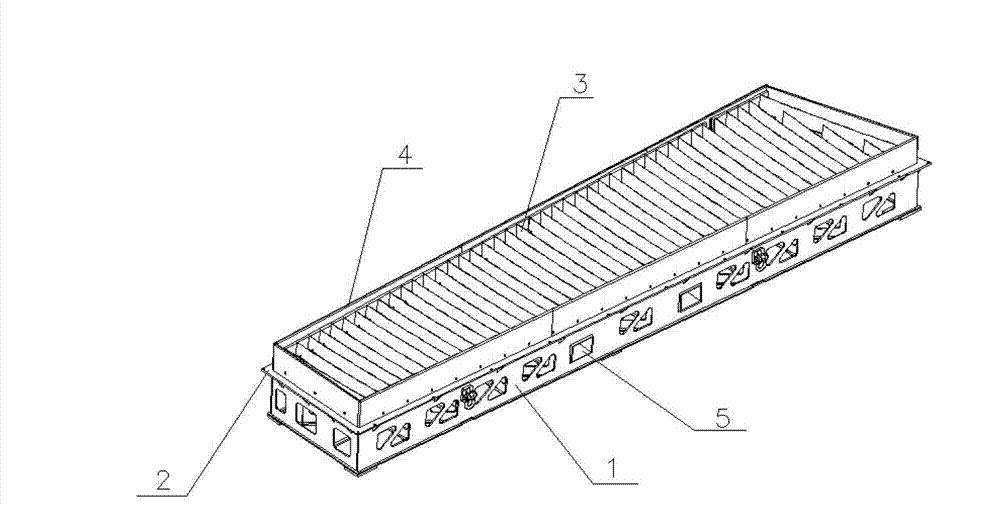

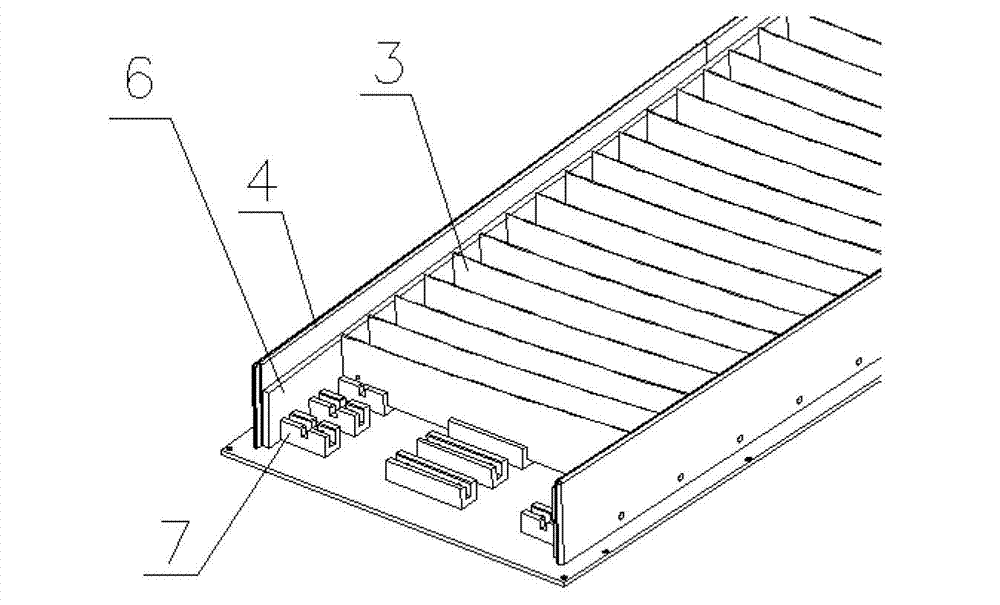

[0025] The present invention is a large-scale overall wall panel creep aging forming tool based on autoclave (such as figure 1 shown), including support structure 1, reference platform 2, clamping plate 3, outer wall 4, inner wall 6, limit base 7, backing plate 11 and sealing structure. The support structure 1 is a frame structure, the reference platform 2 is fixed on the plane of the support structure 1, and m*n limit bases 7 are placed on the reference platform 2 (such as figure 2 shown), n=length of part 10 / spacing of limit base 7, wherein the distance of limit base 7 is set along the length direction of part 10 according to 1.5-3% of the length of pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com