Multi-point forming method for whole aluminum alloy wall plate of aircraft

A technology of integral wallboard and multi-point forming, which is applied in metal processing, forming tools, metal processing equipment, etc., to achieve the effect of improving forming accuracy and improving forming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

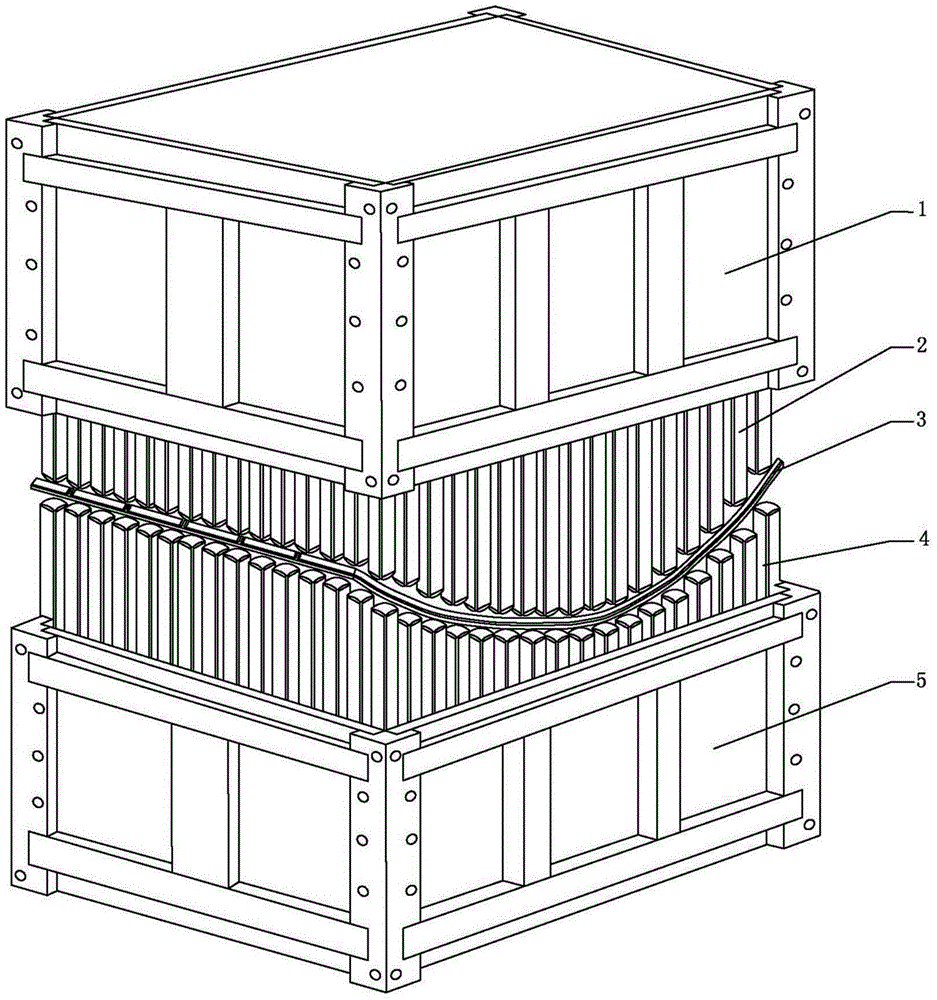

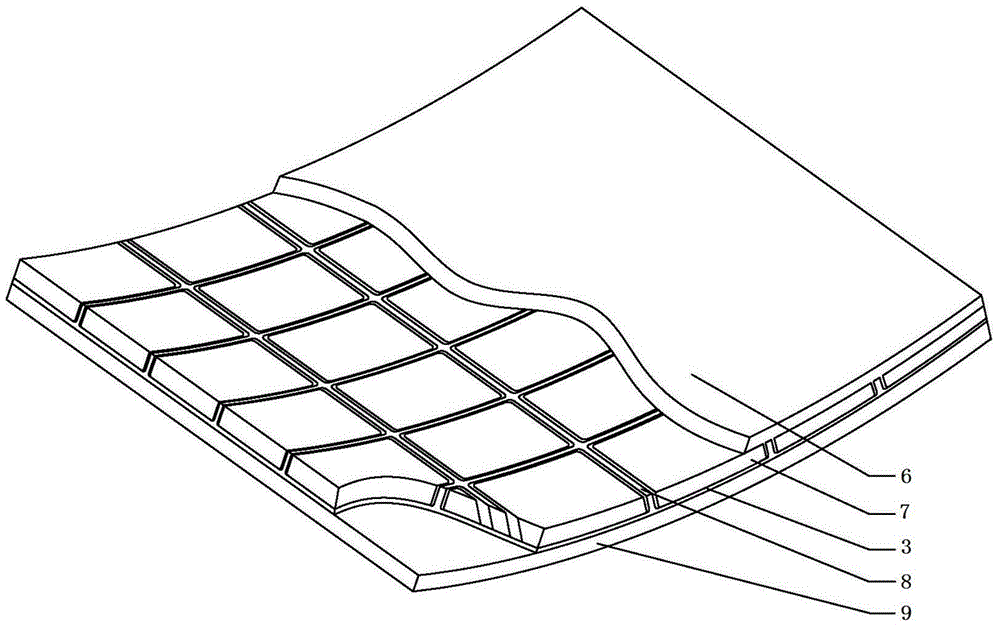

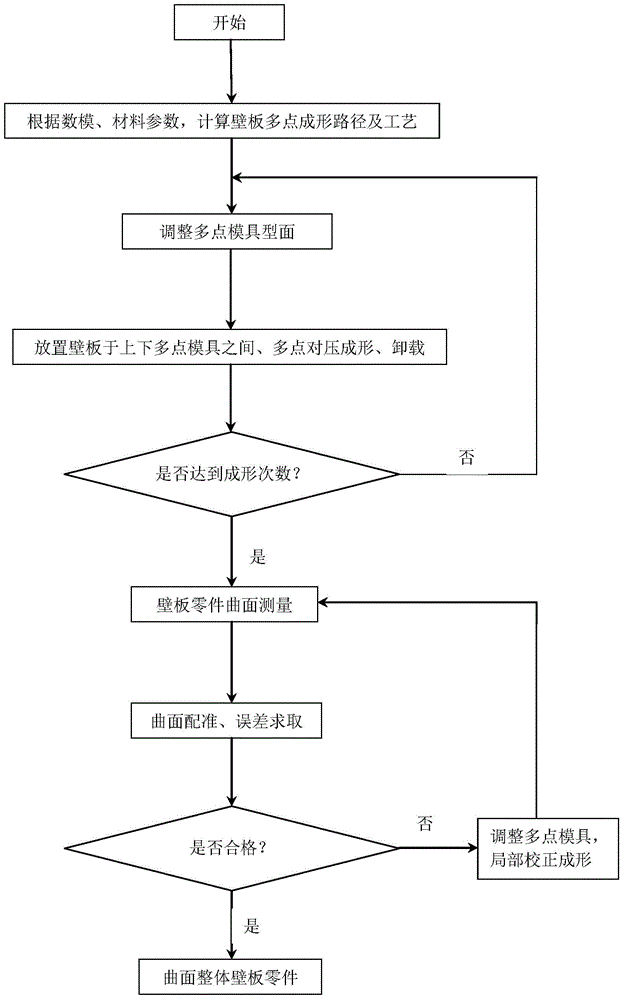

[0020] refer to image 3 It is a process flow chart of the multi-point forming method for an aluminum alloy aircraft integral wall panel of the present invention. The aluminum alloy aircraft integral panel is an aluminum alloy integral panel with I-shaped, T-shaped or J-shaped high ribs, and the structure of the ribs is Unidirectional distribution, grid structure or rice-shaped structure, the upper and lower multi-point molds 1 and 5, which can be quickly reconstructed, are used to form aluminum alloy aircraft with rib structure according to the planned deformation path Integral panel 3 divides the large target deformation into multiple steps non-uniformly, gradually changes the shape of the forming surface of the multi-point mold, and performs gradual counter-press forming, and finally obtains the required large-deformed aluminum alloy aircraft through the gradual accumulation of small deformations Integral wallboard 3, this method comprises the following steps:

[0021] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com