Creep age forming method for wallboard and pre-pressing mold

A creep aging forming and creep aging technology, applied in the manufacturing field, can solve the problems of slow speed and poor quality of large-curvature wall panels, and achieve the effect of improving surface quality, large load and uniform load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

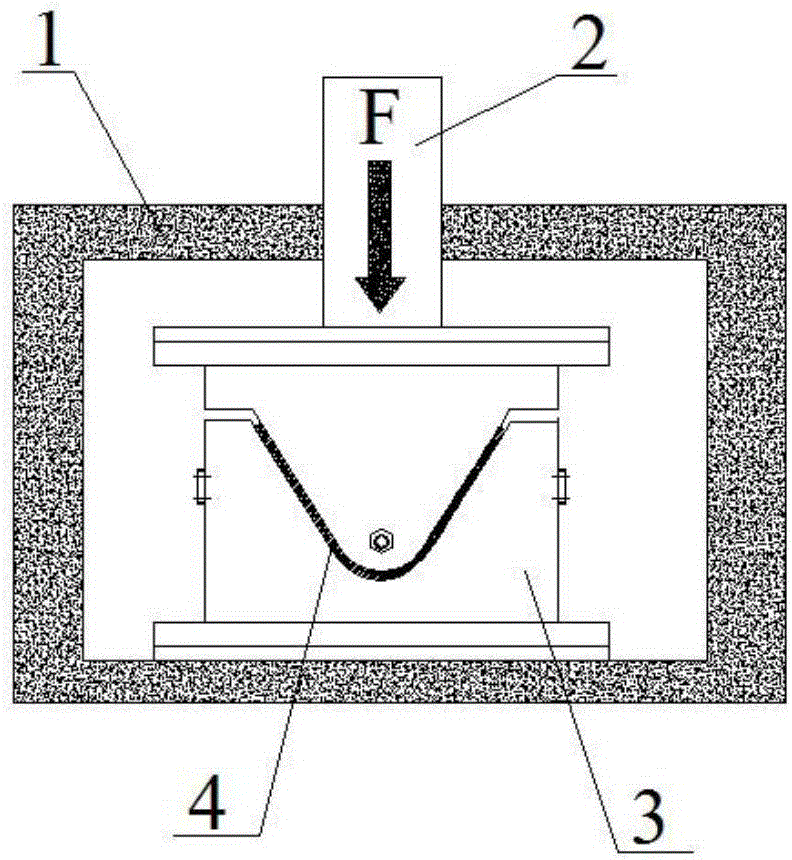

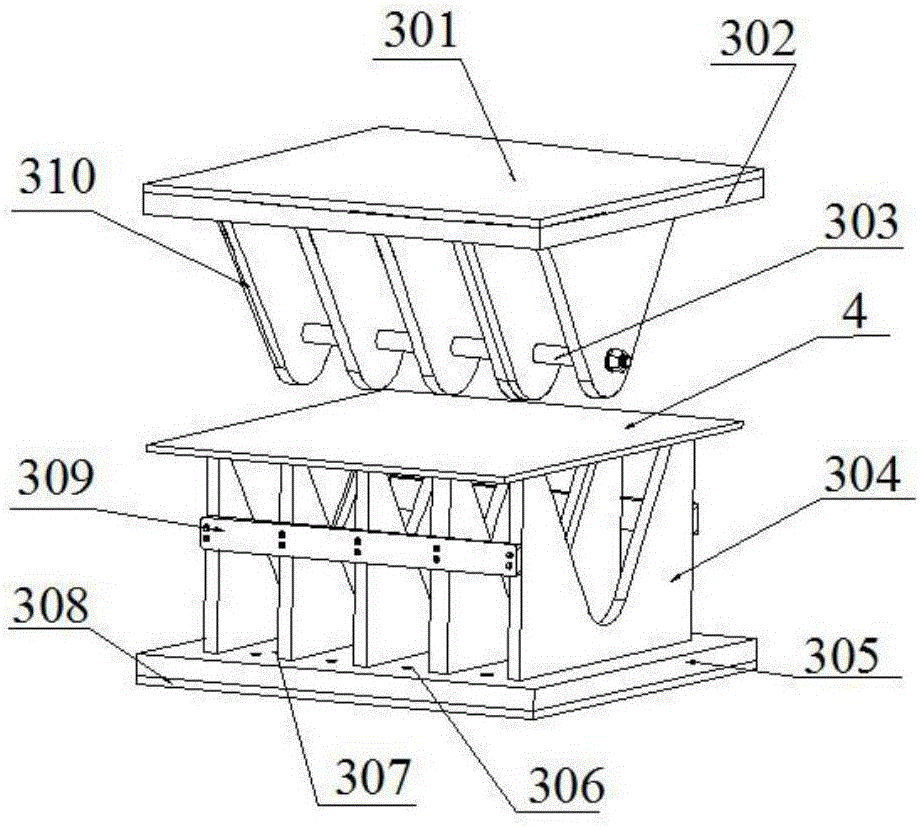

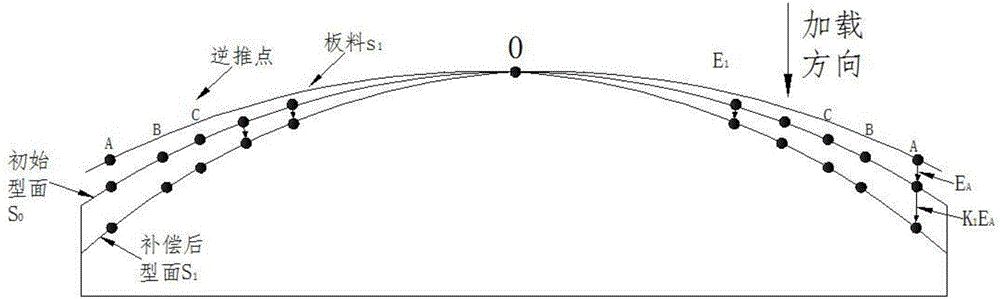

[0032] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0033] Such as figure 1 and figure 2 As shown, the present invention discloses a pre-compression mold for creep aging forming of wall panels, which includes an upper backing plate, an upper fixing plate, a lower fixing plate, a lower backing plate, several upper clamping plates, and several numbers of the same number as the upper clamping plates the lower pallet;

[0034] The positions between the upper fixing plate and the upper backing plate, and between the lower fixing plate and the lower backing plate are all positioned and fixed by several pins and bolts;

[0035] The top of the upper clamping plate is fixedly connected with the upper fixing plate;

[0036] The lower clamping plate is arranged under its corresponding upper clamping plate, and the bottom is fixedly connected with the lower fixing plate;

[0037] The upper clamping plate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com