Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Increase exhaust flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

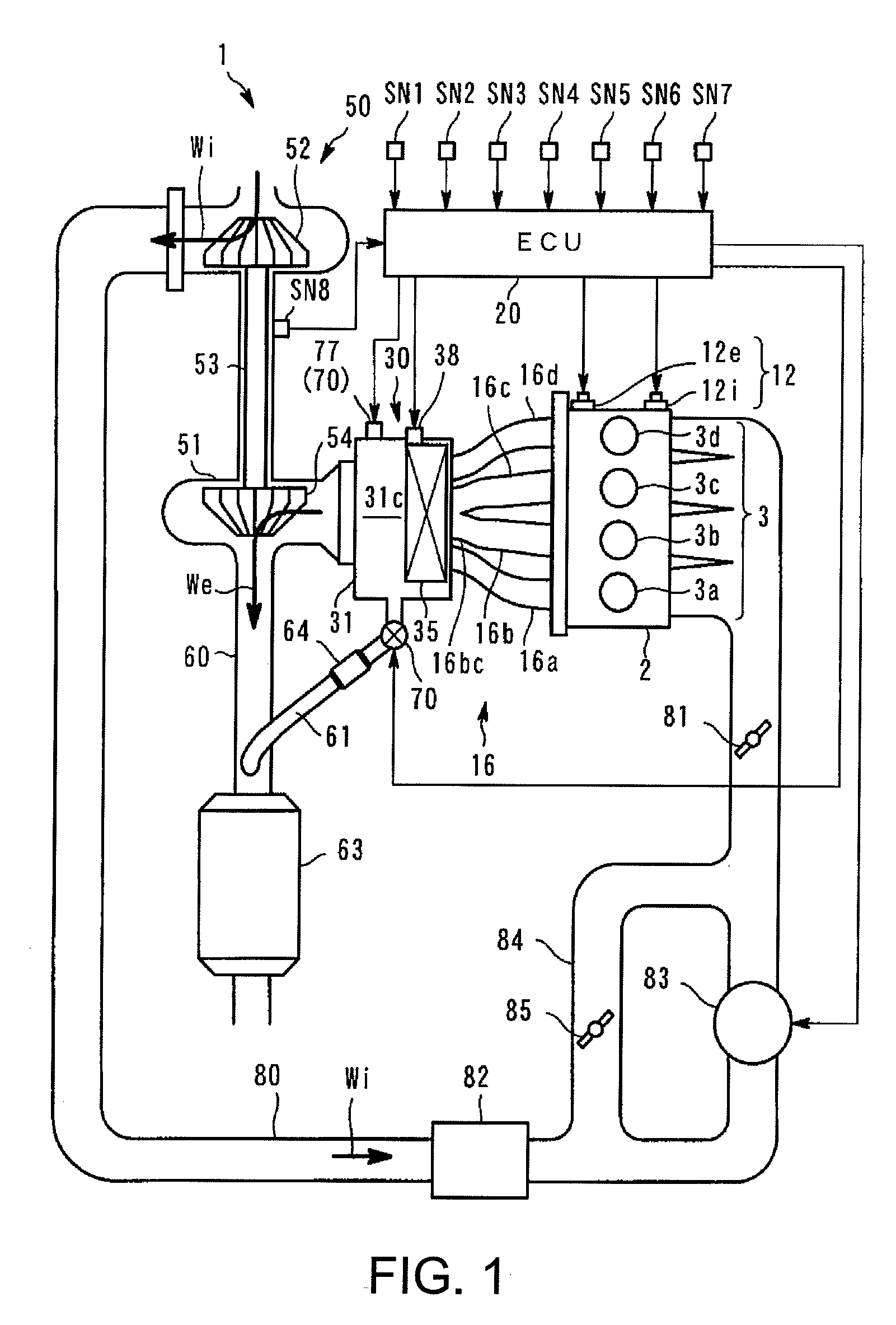

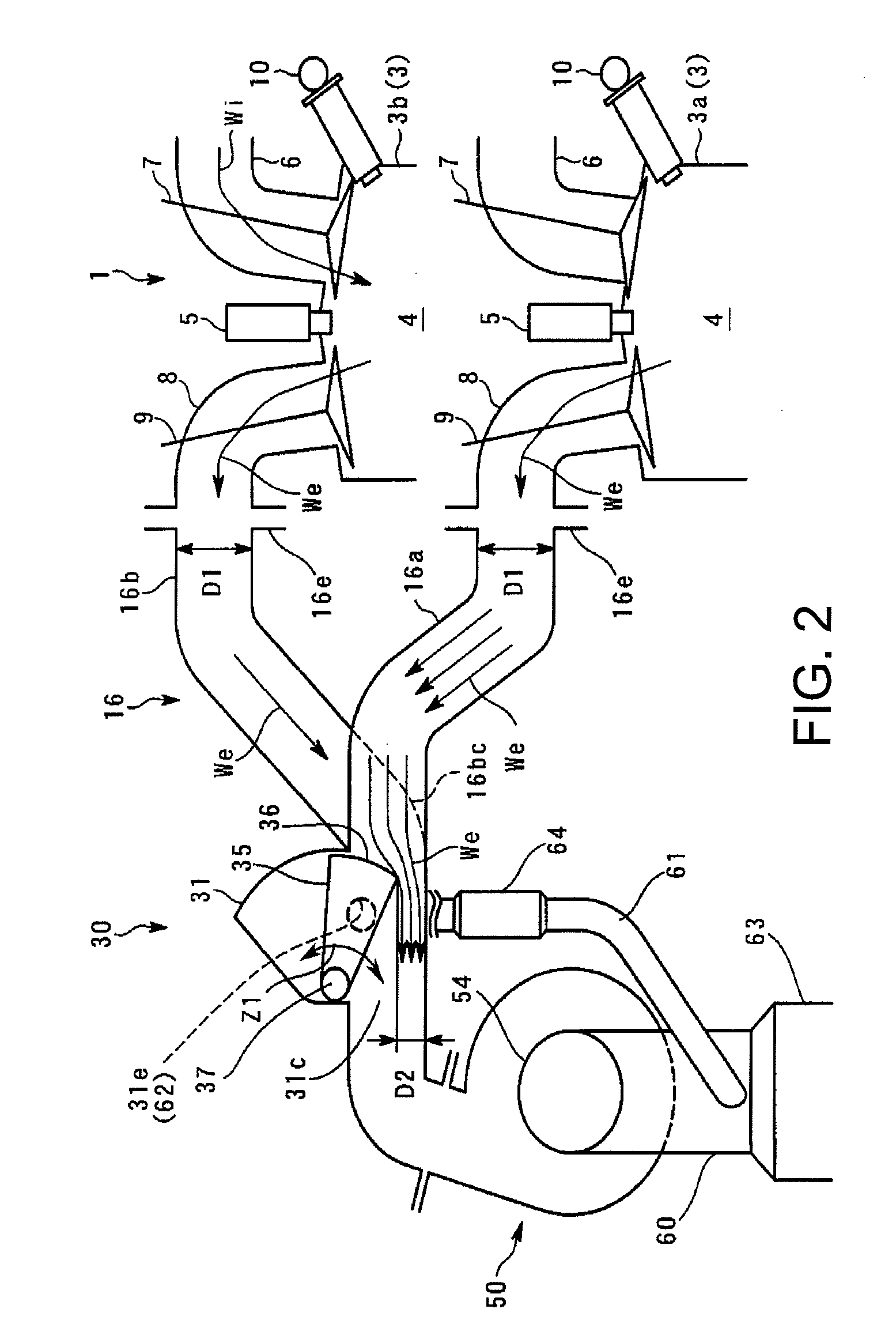

Supercharger for an engine

ActiveUS20090094978A1Improve performanceImprove charging effectInternal combustion piston enginesExhaust apparatusThrottle controlExhaust valve

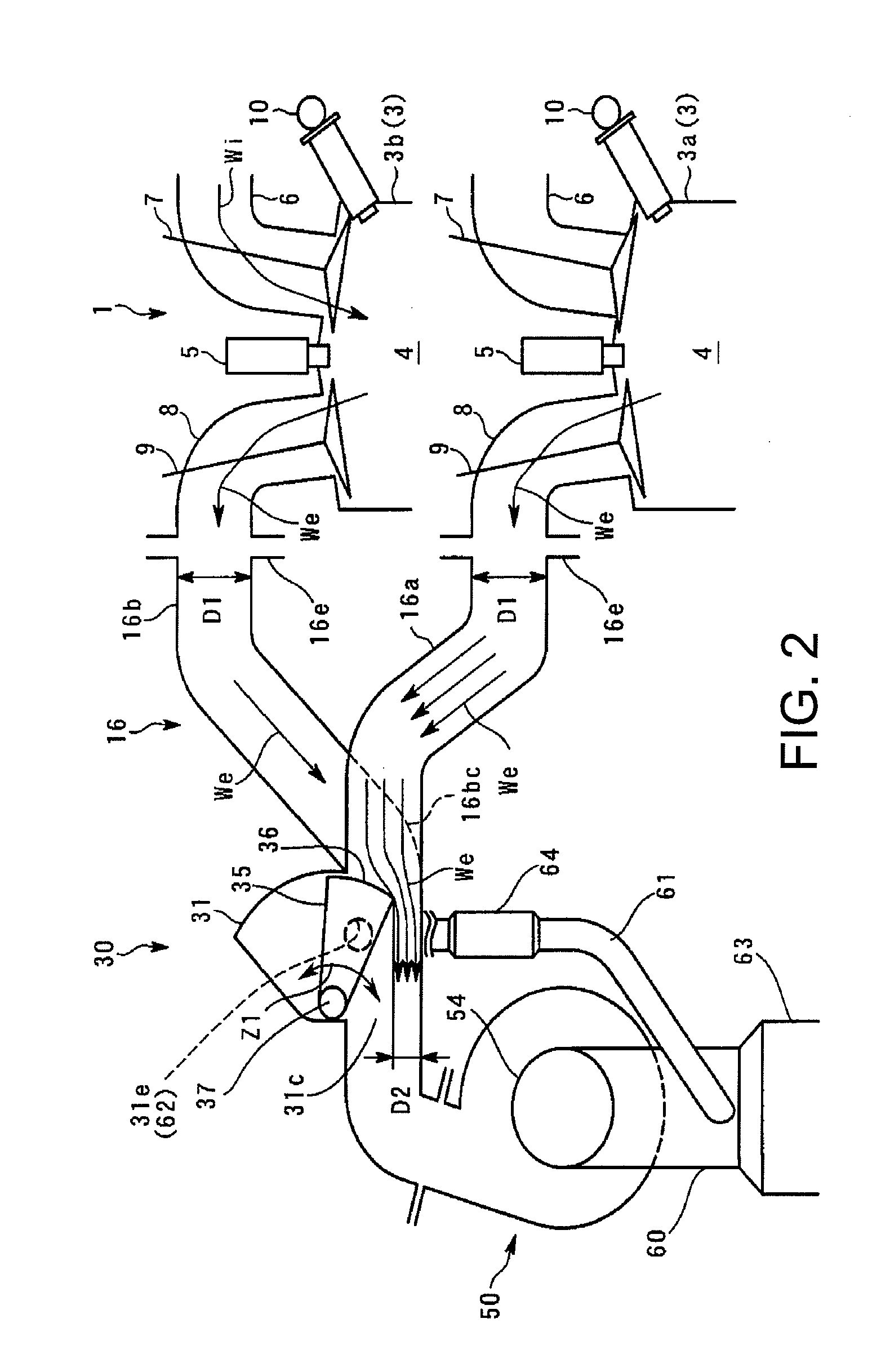

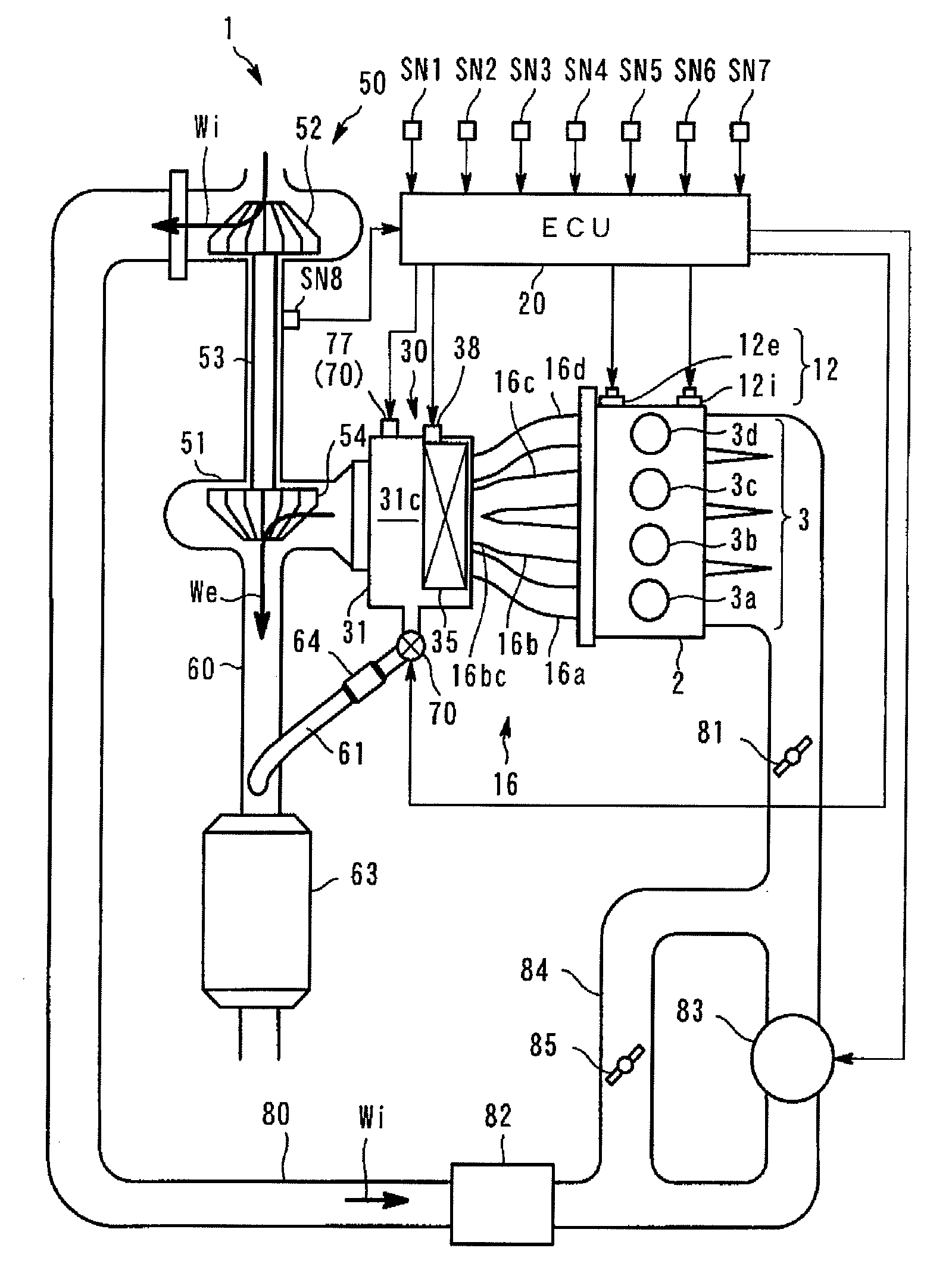

An engine system with a turbocharger is provided. The system may include an exhaust manifold having plural independent exhaust passages, each of the exhaust passages being connected to an exhaust port of a corresponding engine cylinder. The system may further include a collective part formed by gathering said independent exhaust passages in said exhaust manifold or on a downstream side of said exhaust manifold. The system may further include an exhaust turbocharger connected to a downstream side of said collective part. The system may further include a variable exhaust valve for changing each passage cross-sectional area of said independent exhaust passage at an upstream side of said collective part. The system may further include a controller for controlling said variable exhaust valve, wherein said controller is configured to perform independent exhaust throttle control for reducing a passage cross-sectional area of at least one of said independent exhaust passages.

Owner:MAZDA MOTOR CORP

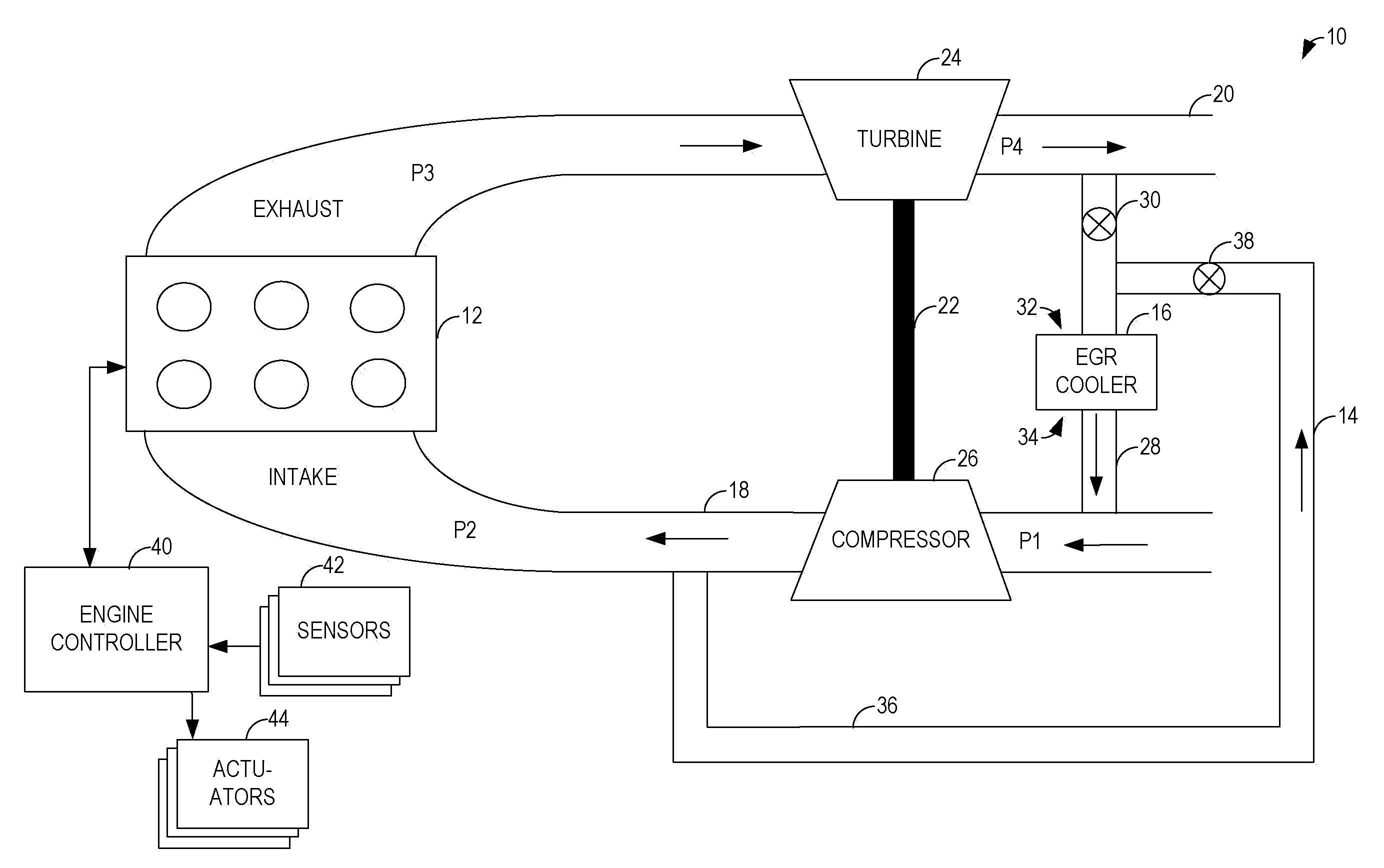

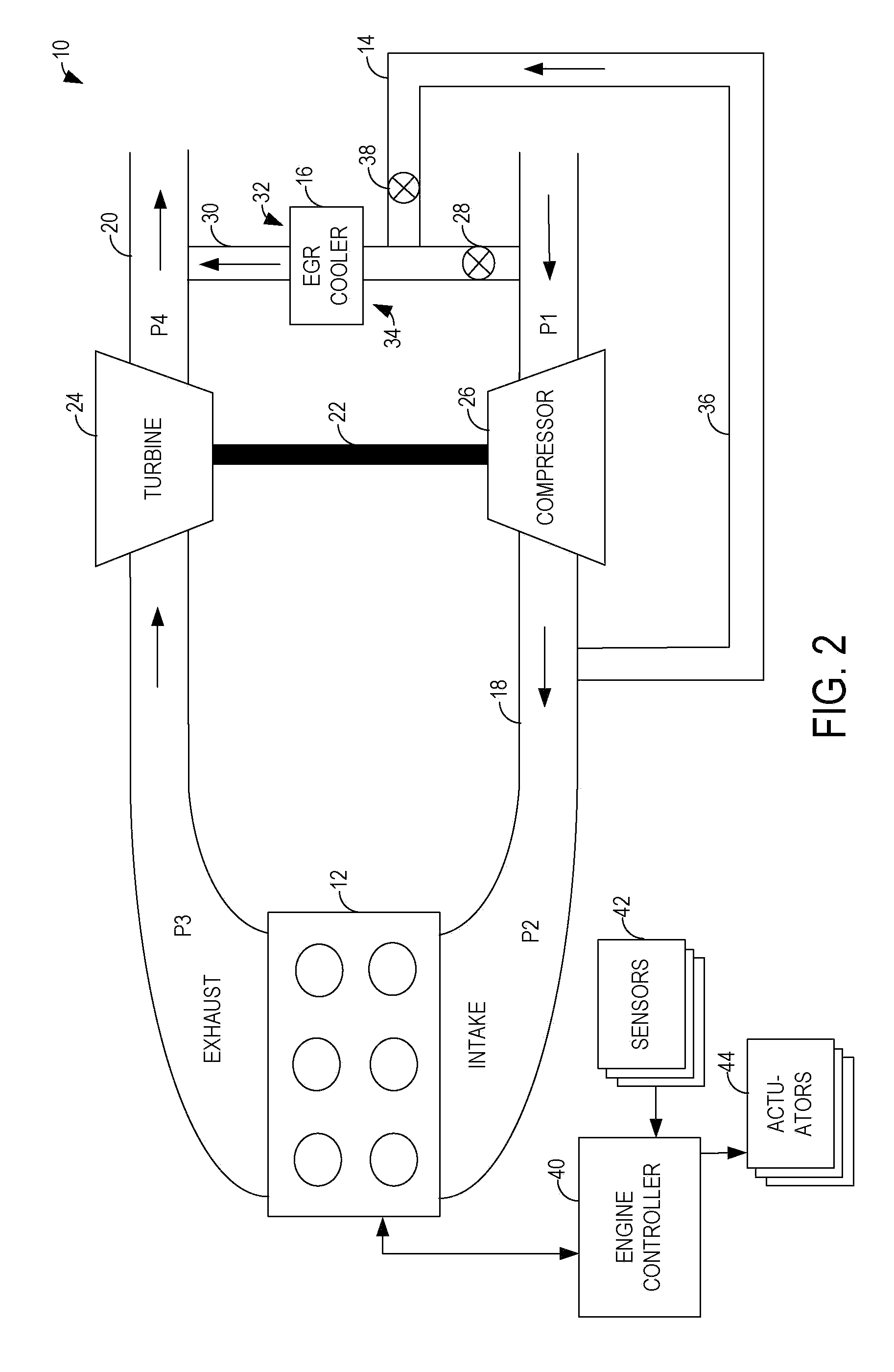

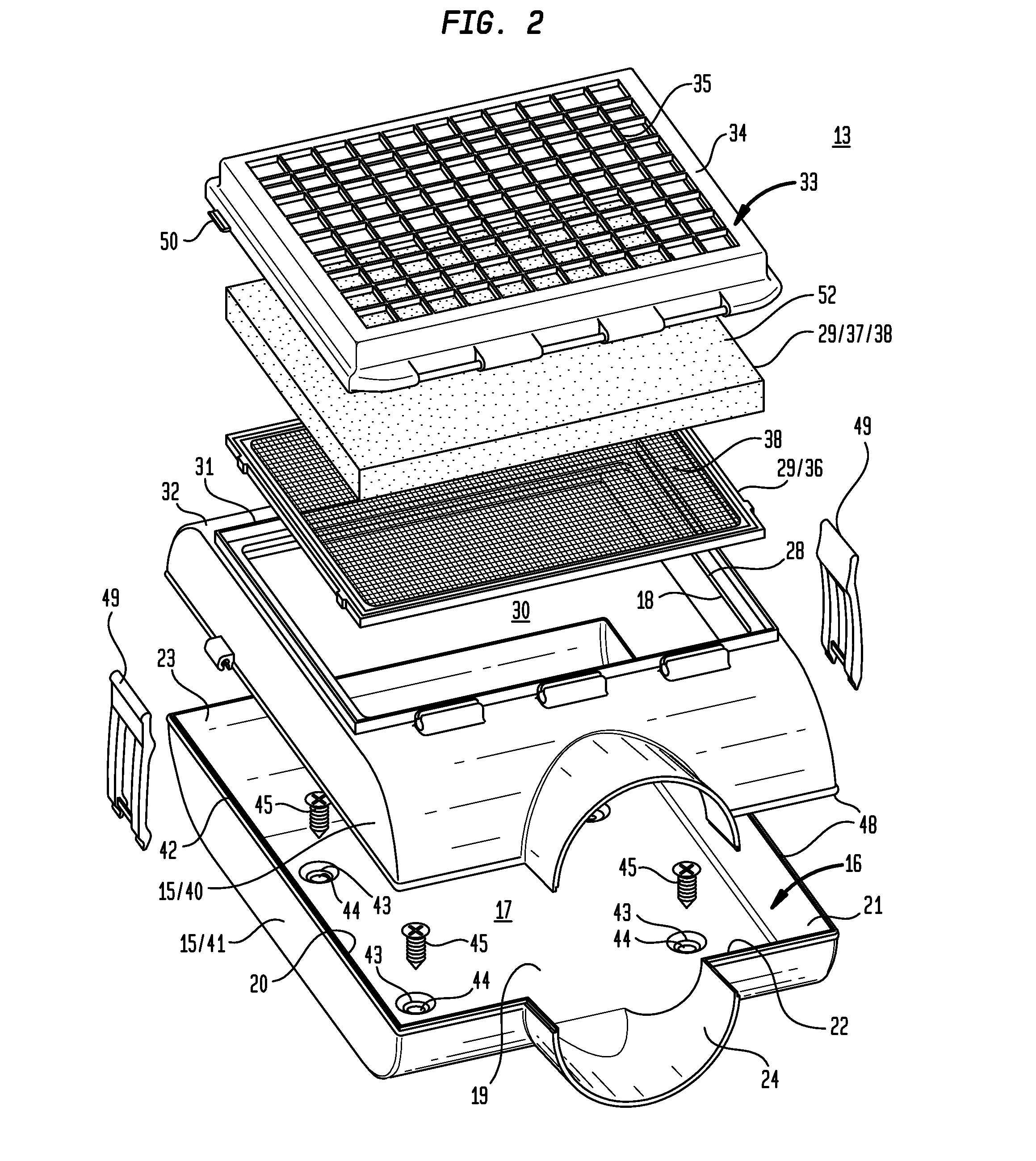

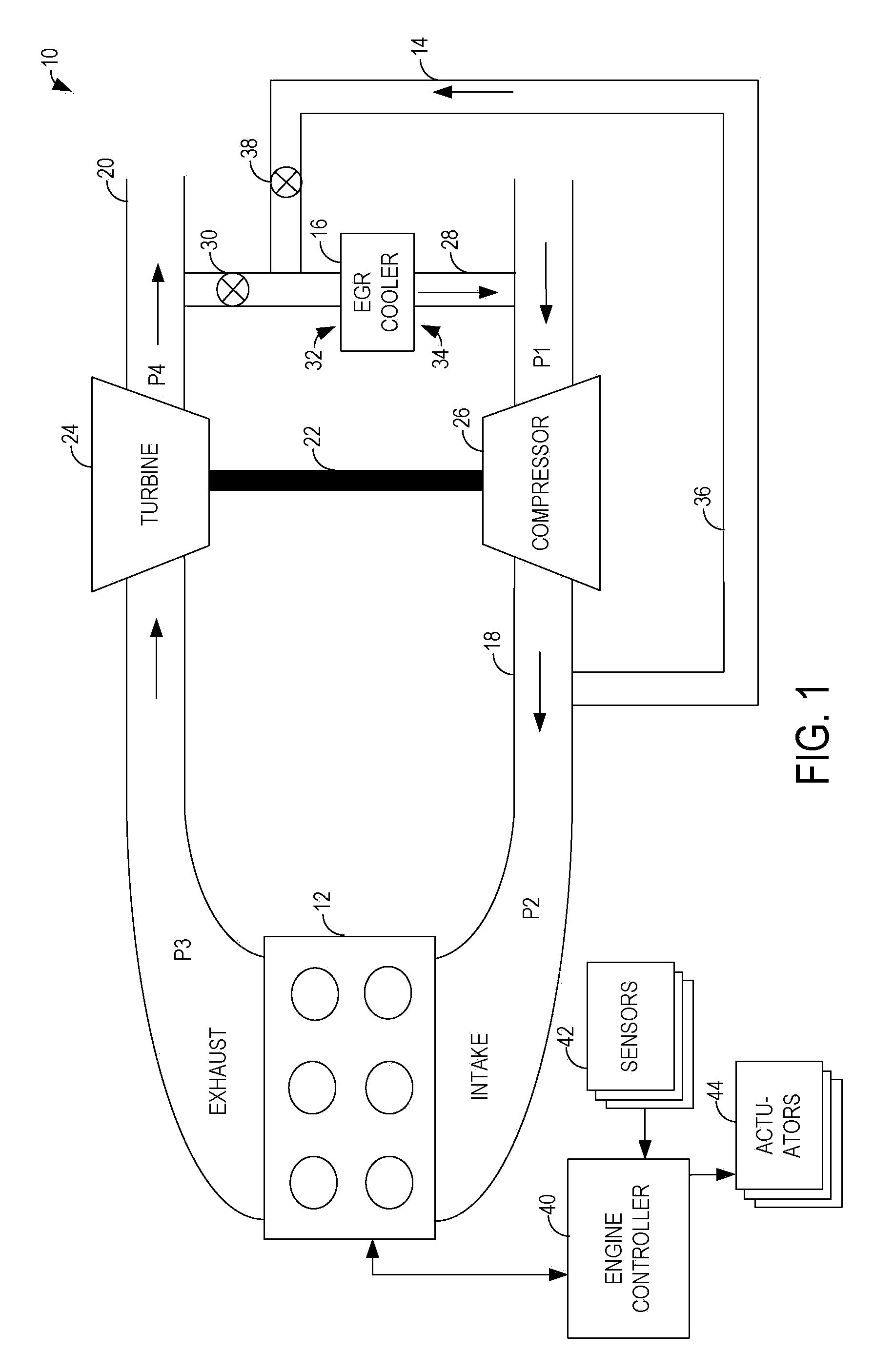

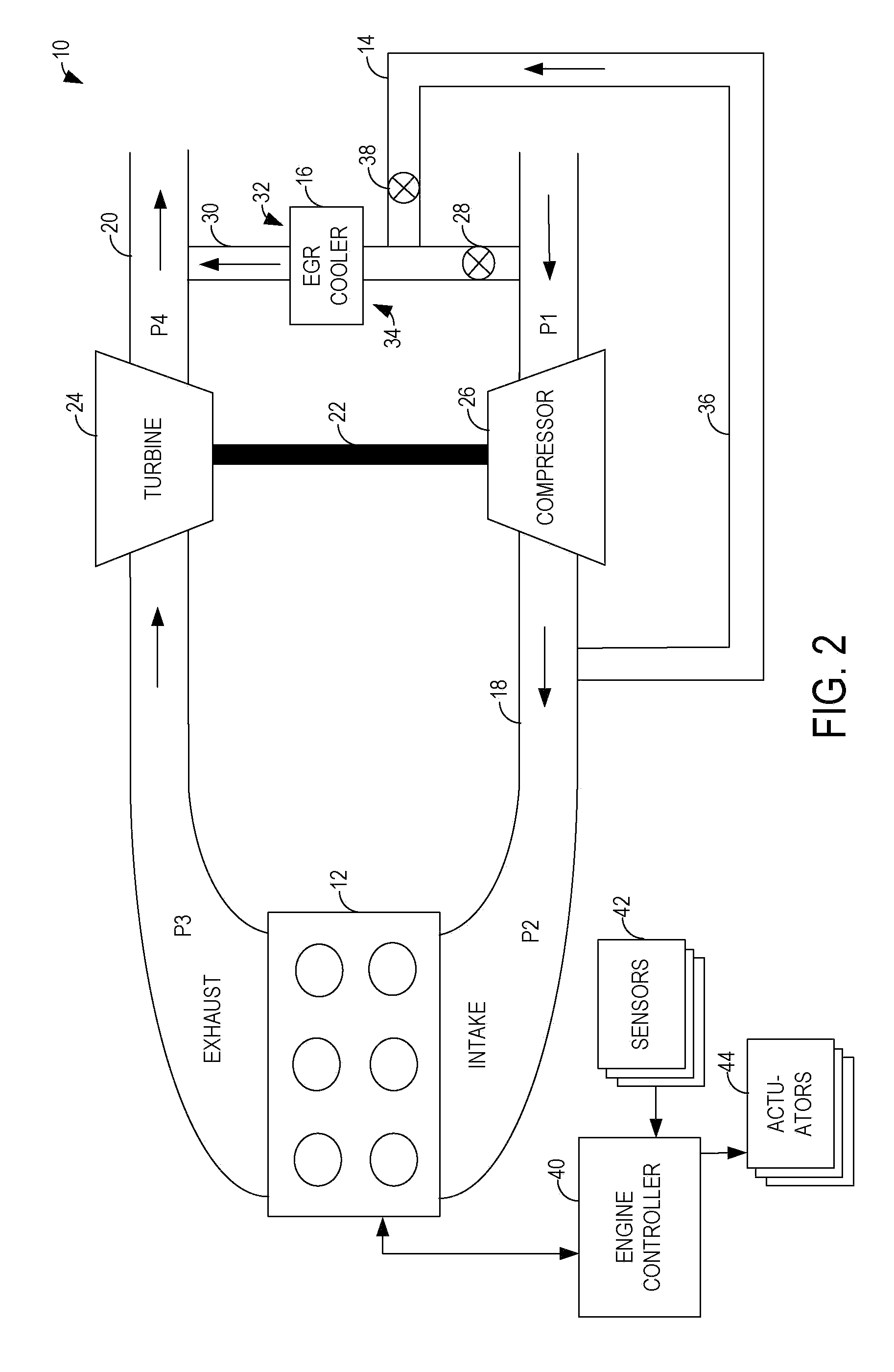

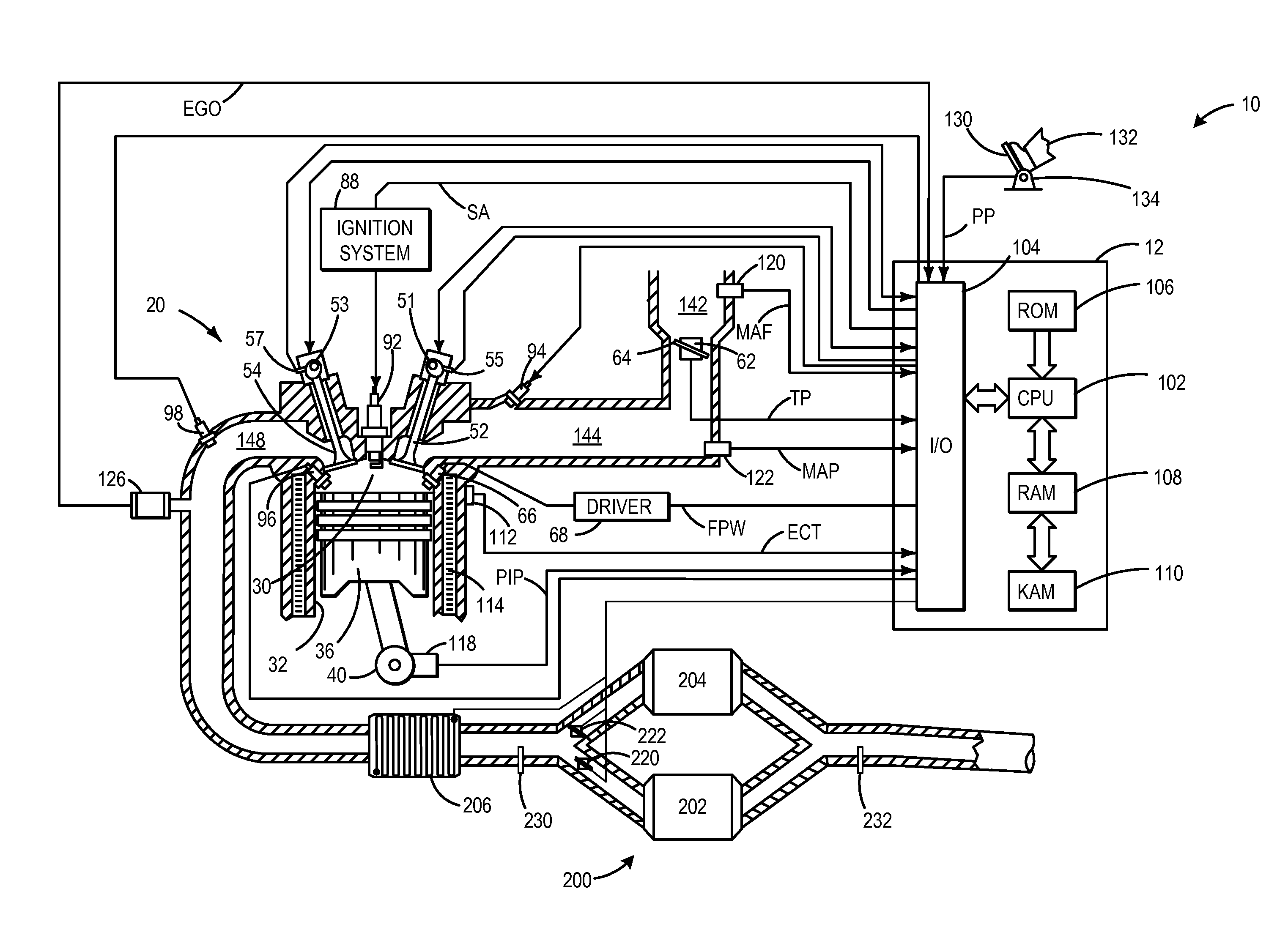

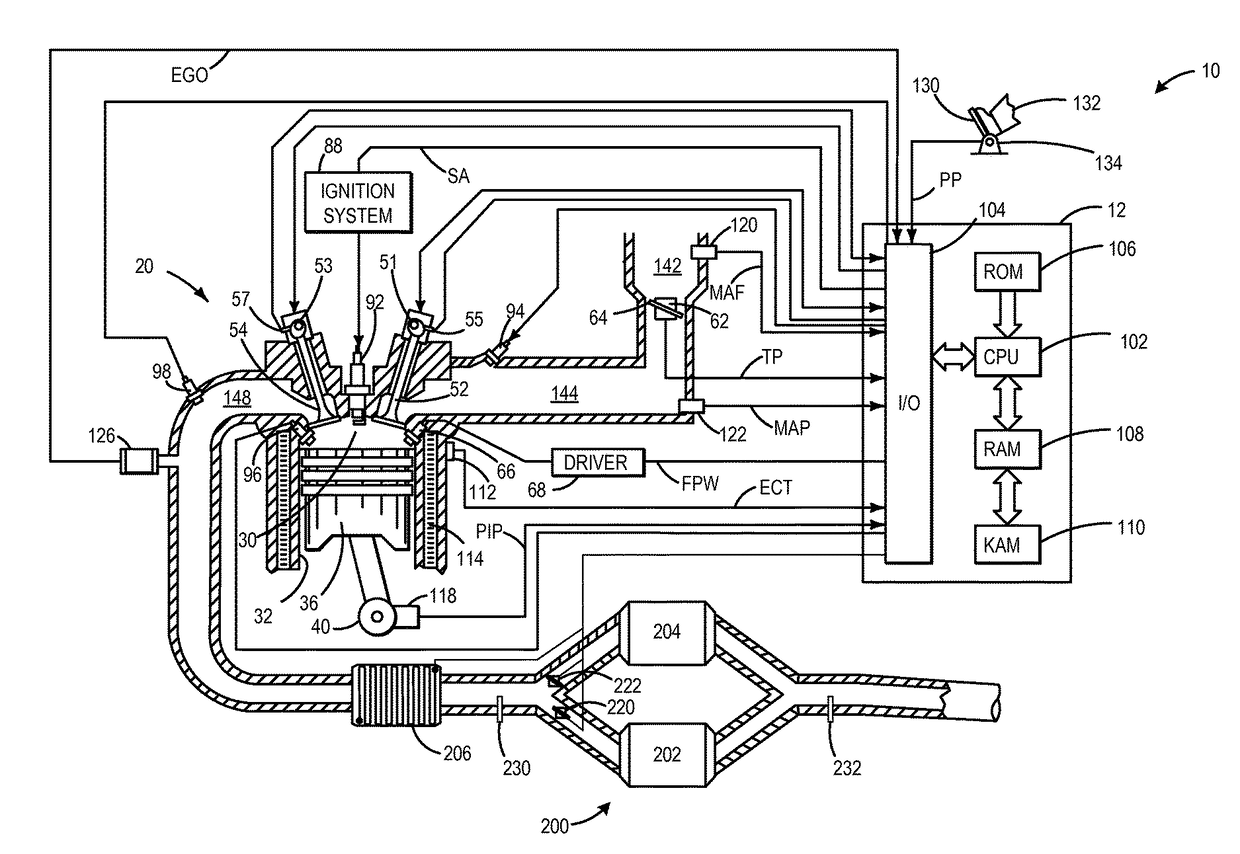

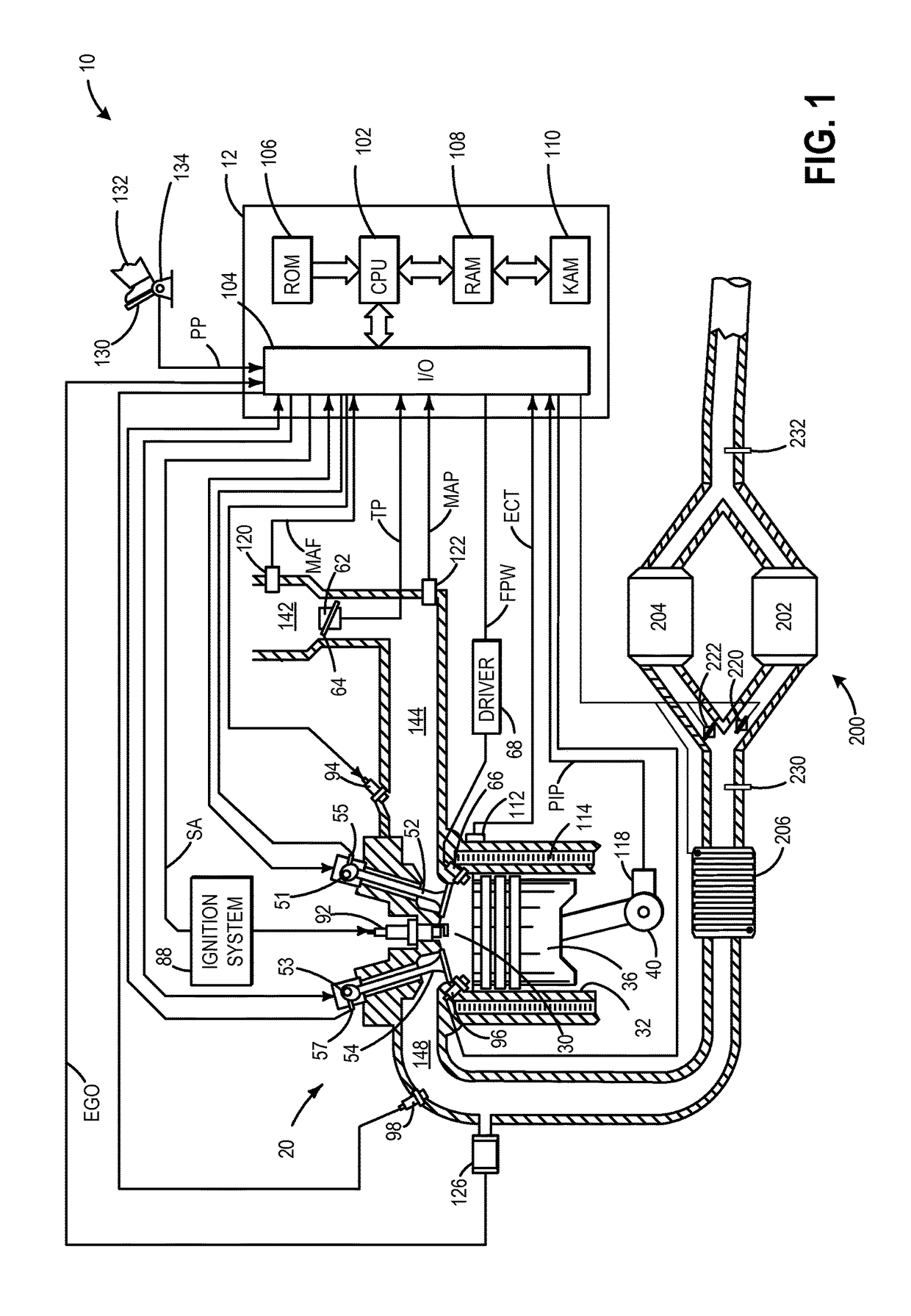

Using compressed intake air to clean engine exhaust gas recirculation cooler

InactiveUS20100107631A1Improve emission effectReduce heat transferNon-fuel substance addition to fuelSuction cleanersExternal combustion engineTurbocharger

Systems and methods for using compressed intake air that is free of soot particles to clean the EGR cooler of an internal combustion engine having a turbocharger are provided herein. One example system includes an EGR valve for selectively diverting a portion of exhaust gas through an EGR conduit to an intake side of the internal combustion engine, an EGR cooler disposed in the EGR conduit, the EGR cooler having an exhaust side and an intake side, and a compressed intake air delivery system including a compressed air conduit, the compressed intake air delivery system being configured to selectively divert a portion of compressed intake air compressed by the turbocharger through the EGR cooler to remove soot particles deposited in the EGR cooler.

Owner:FORD GLOBAL TECH LLC

Supercharger for an engine

ActiveUS8141357B2Engine torque may be increasedIncrease rangeInternal combustion piston enginesExhaust apparatusThrottle controlExhaust valve

An engine system with a turbocharger is provided. The system may include an exhaust manifold having plural independent exhaust passages, each of the exhaust passages being connected to an exhaust port of a corresponding engine cylinder. The system may further include a collective part formed by gathering said independent exhaust passages in said exhaust manifold or on a downstream side of said exhaust manifold. The system may further include an exhaust turbocharger connected to a downstream side of said collective part. The system may further include a variable exhaust valve for changing each passage cross-sectional area of said independent exhaust passage at an upstream side of said collective part. The system may further include a controller for controlling said variable exhaust valve, wherein said controller is configured to perform independent exhaust throttle control for reducing a passage cross-sectional area of at least one of said independent exhaust passages.

Owner:MAZDA MOTOR CORP

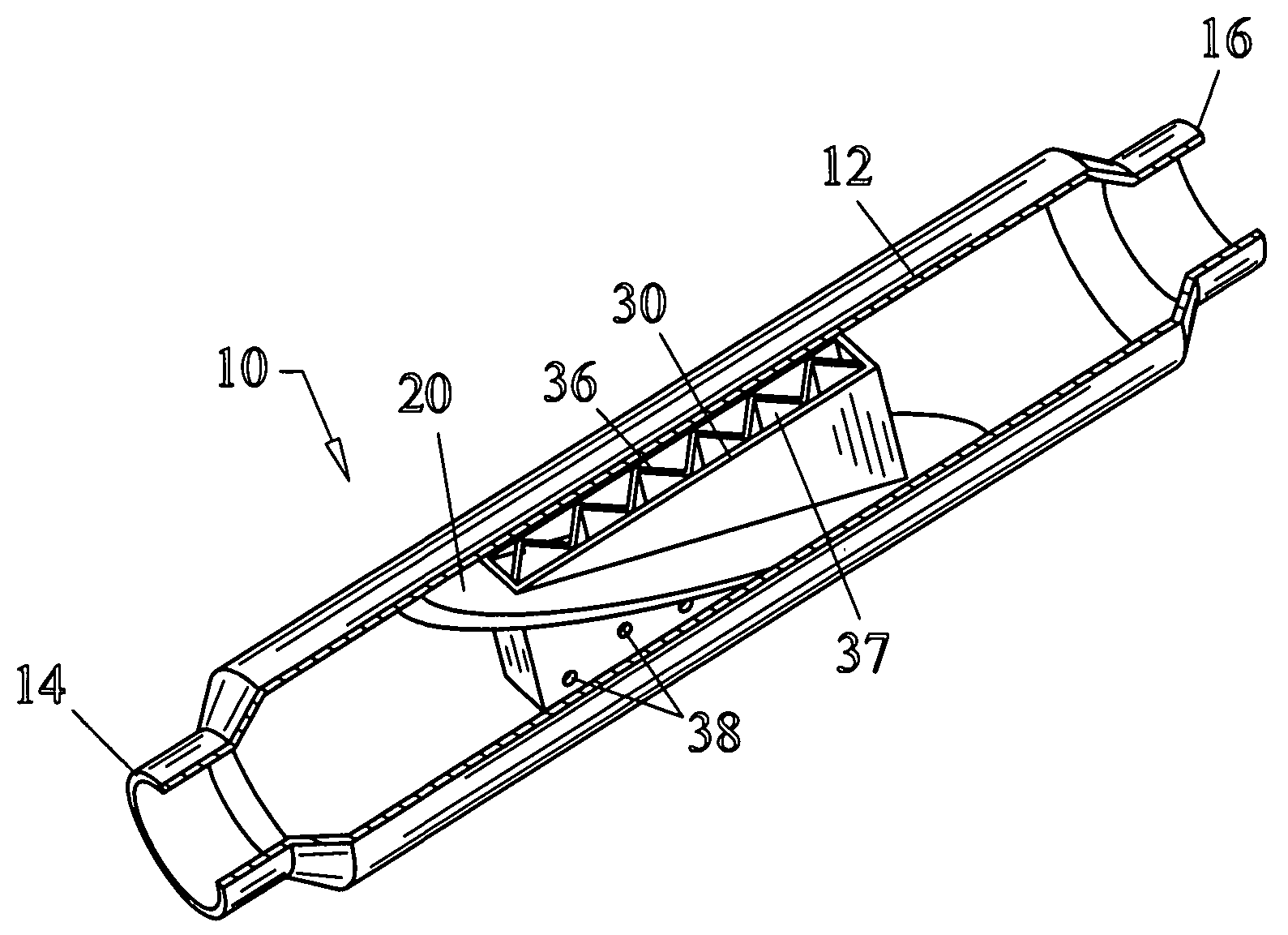

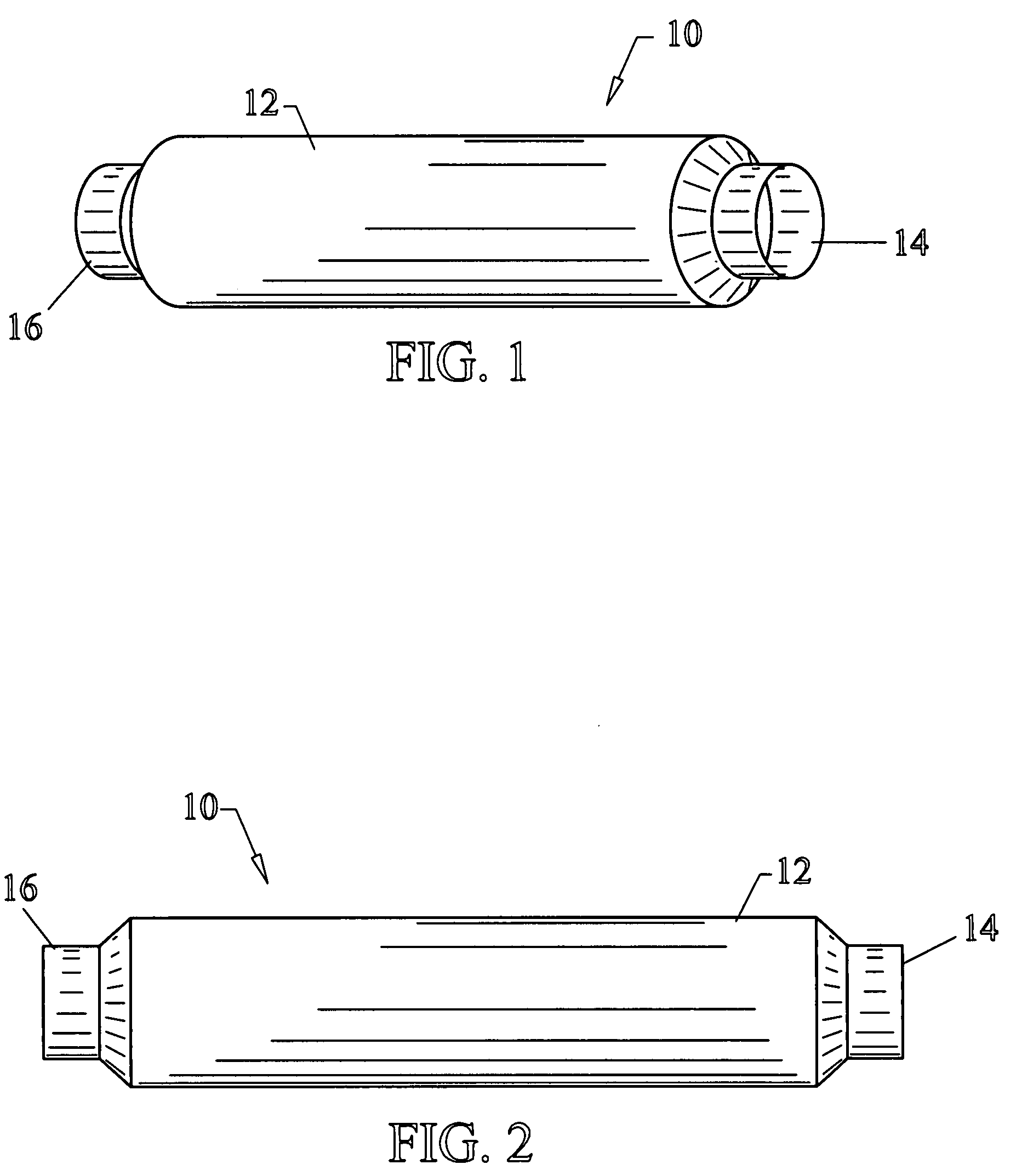

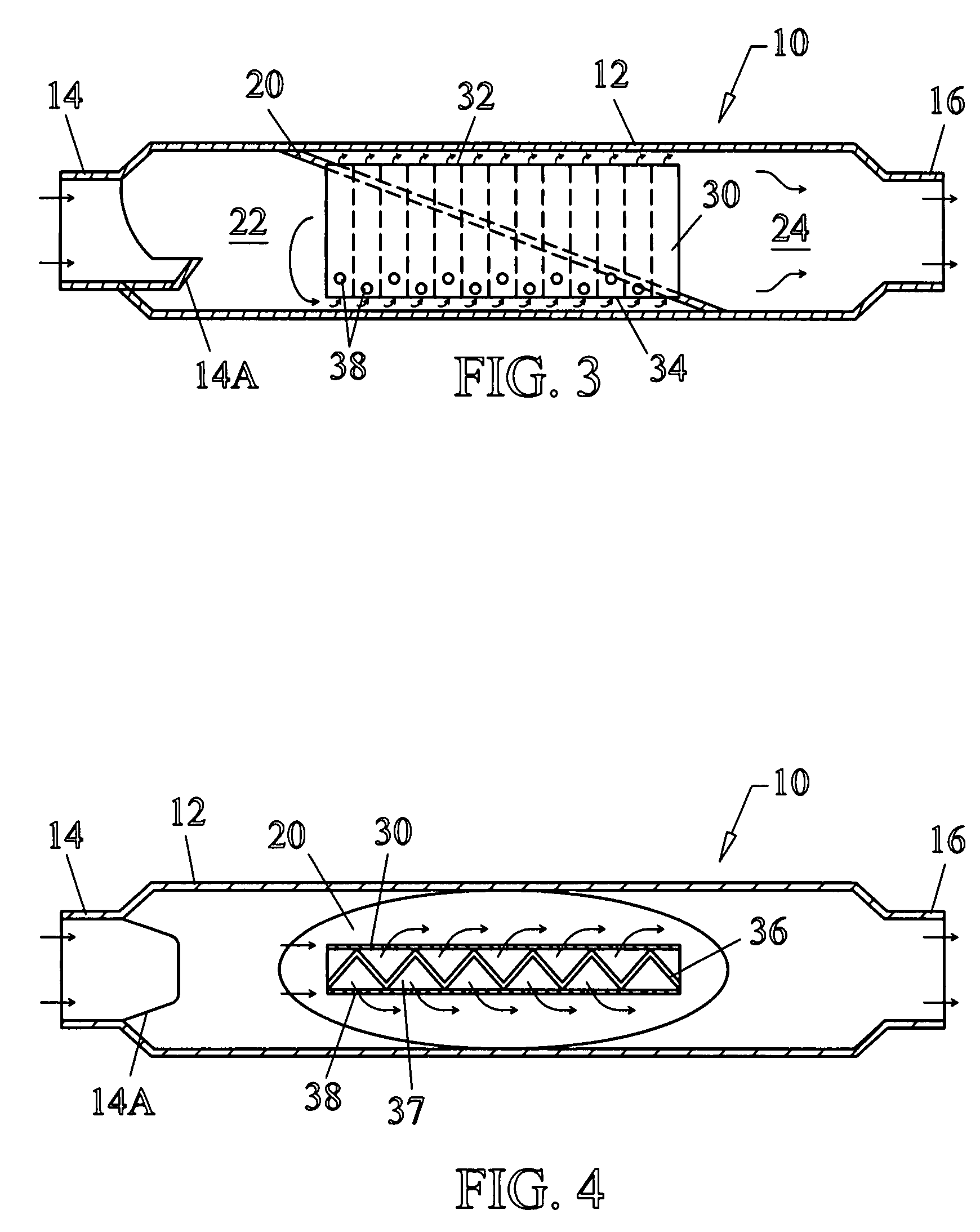

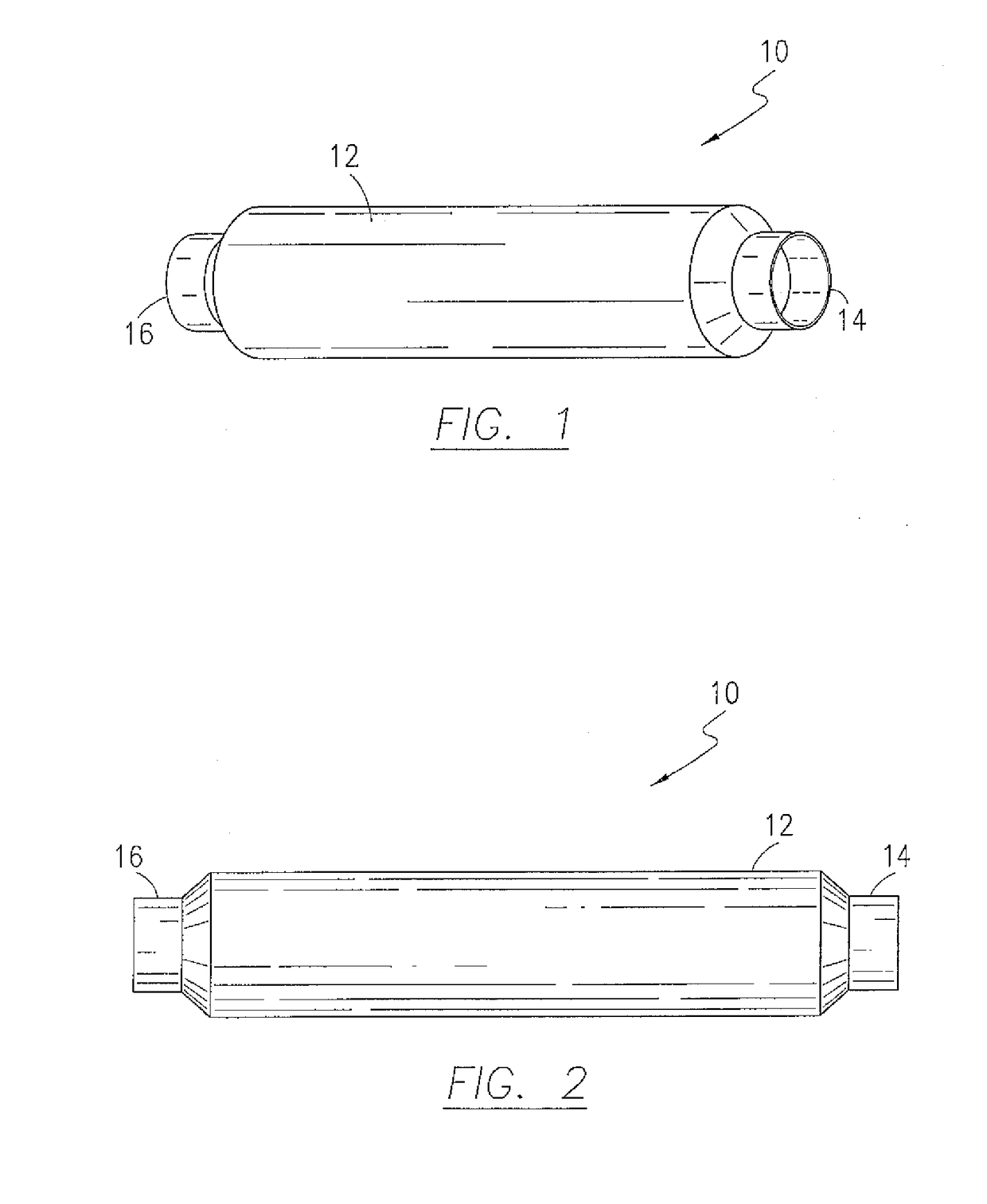

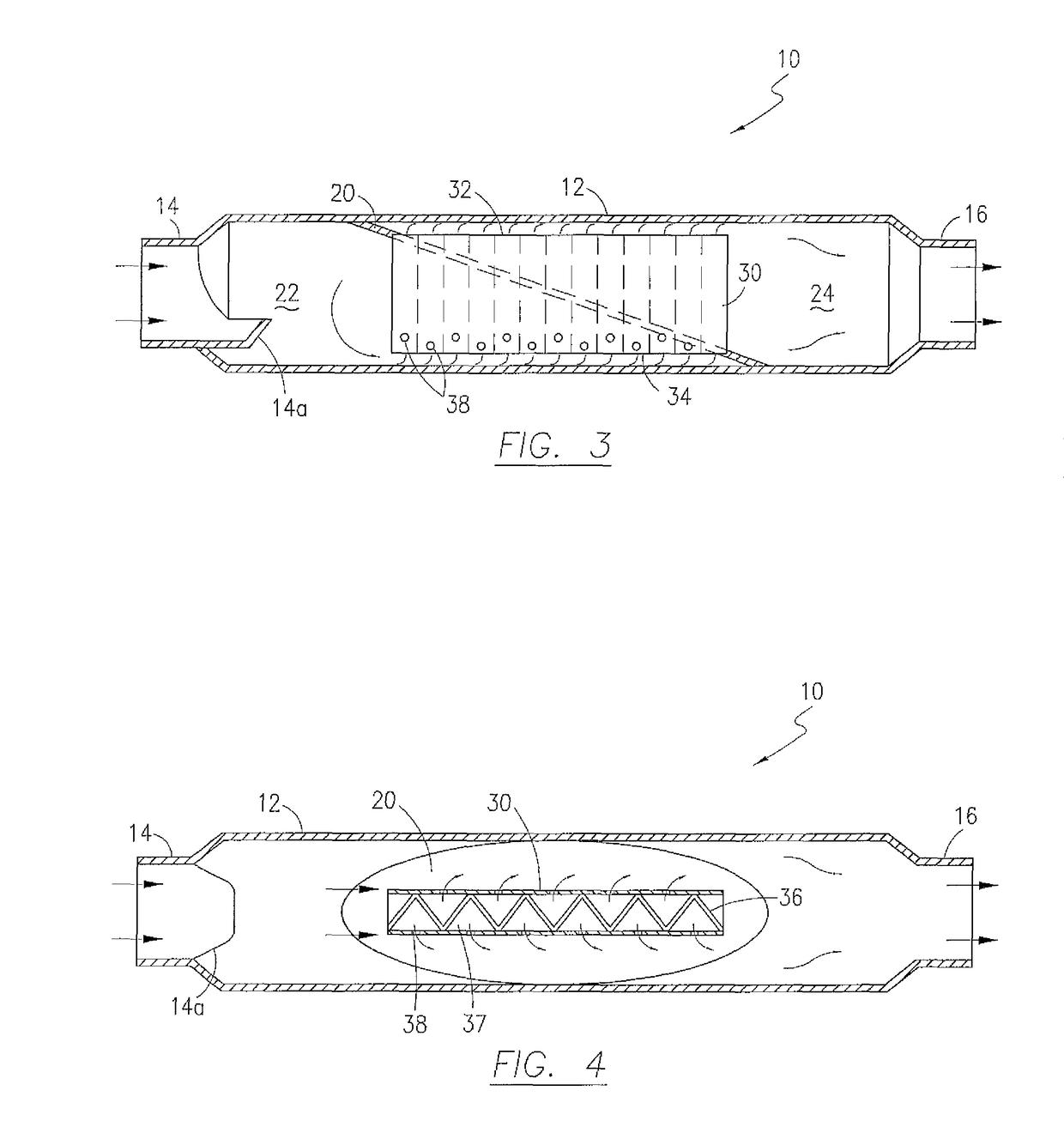

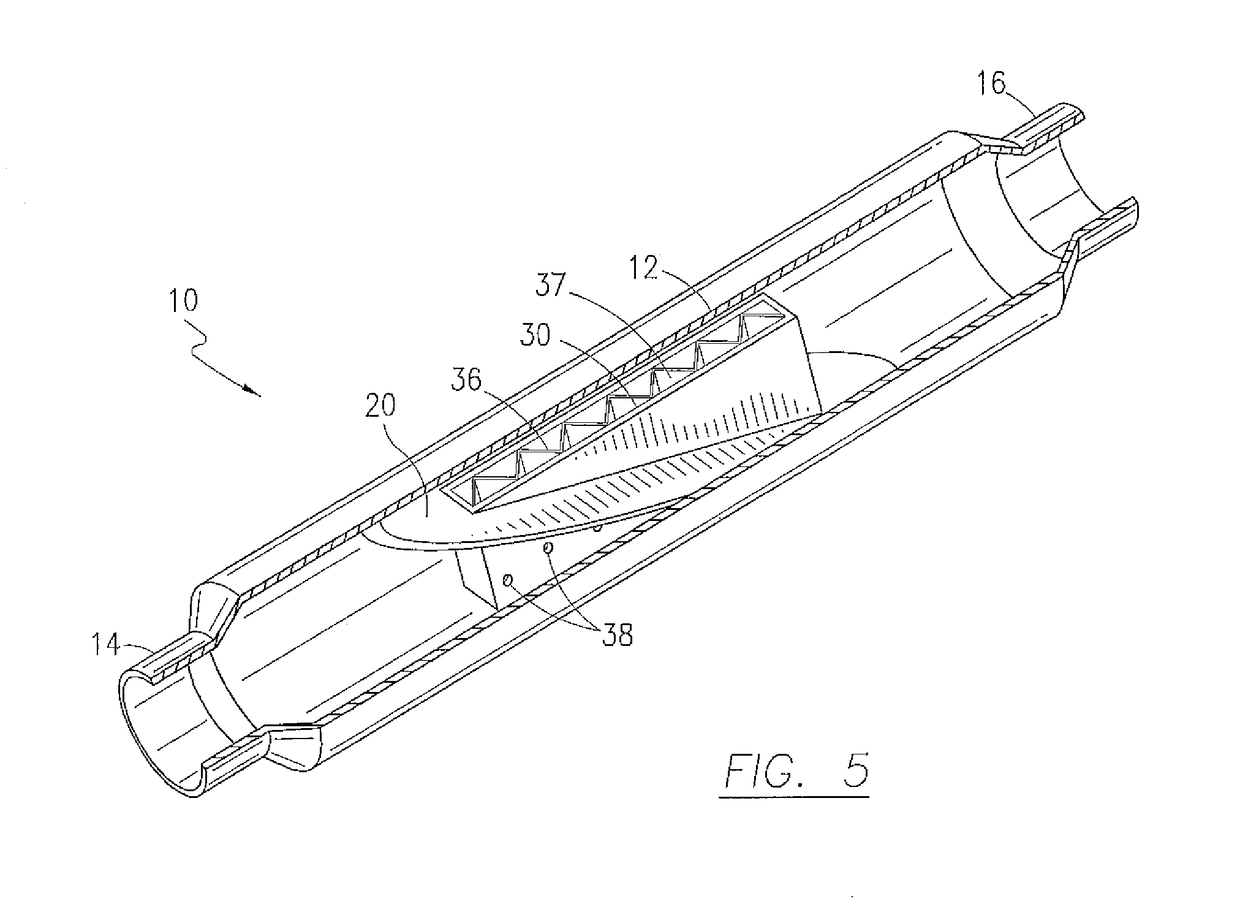

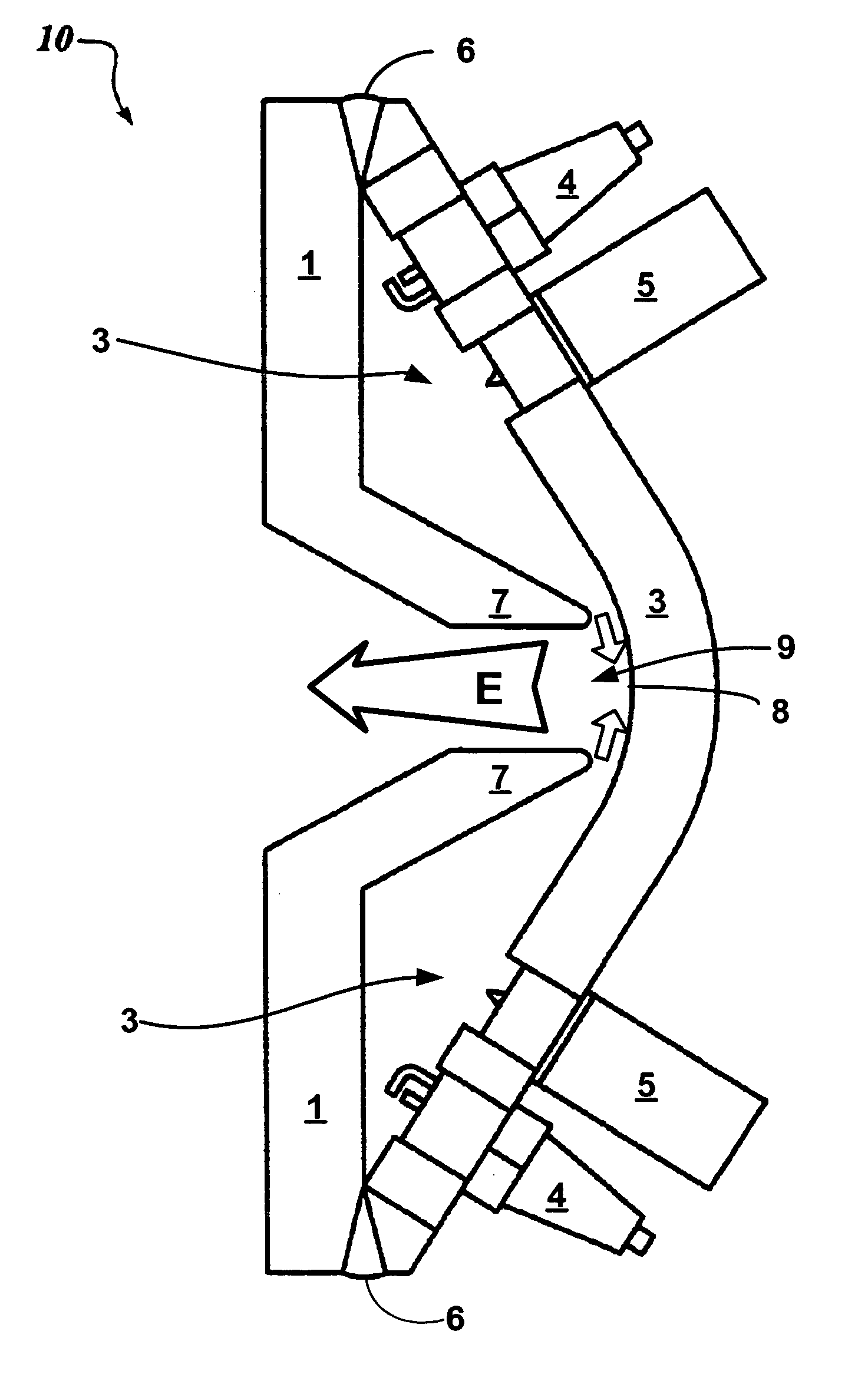

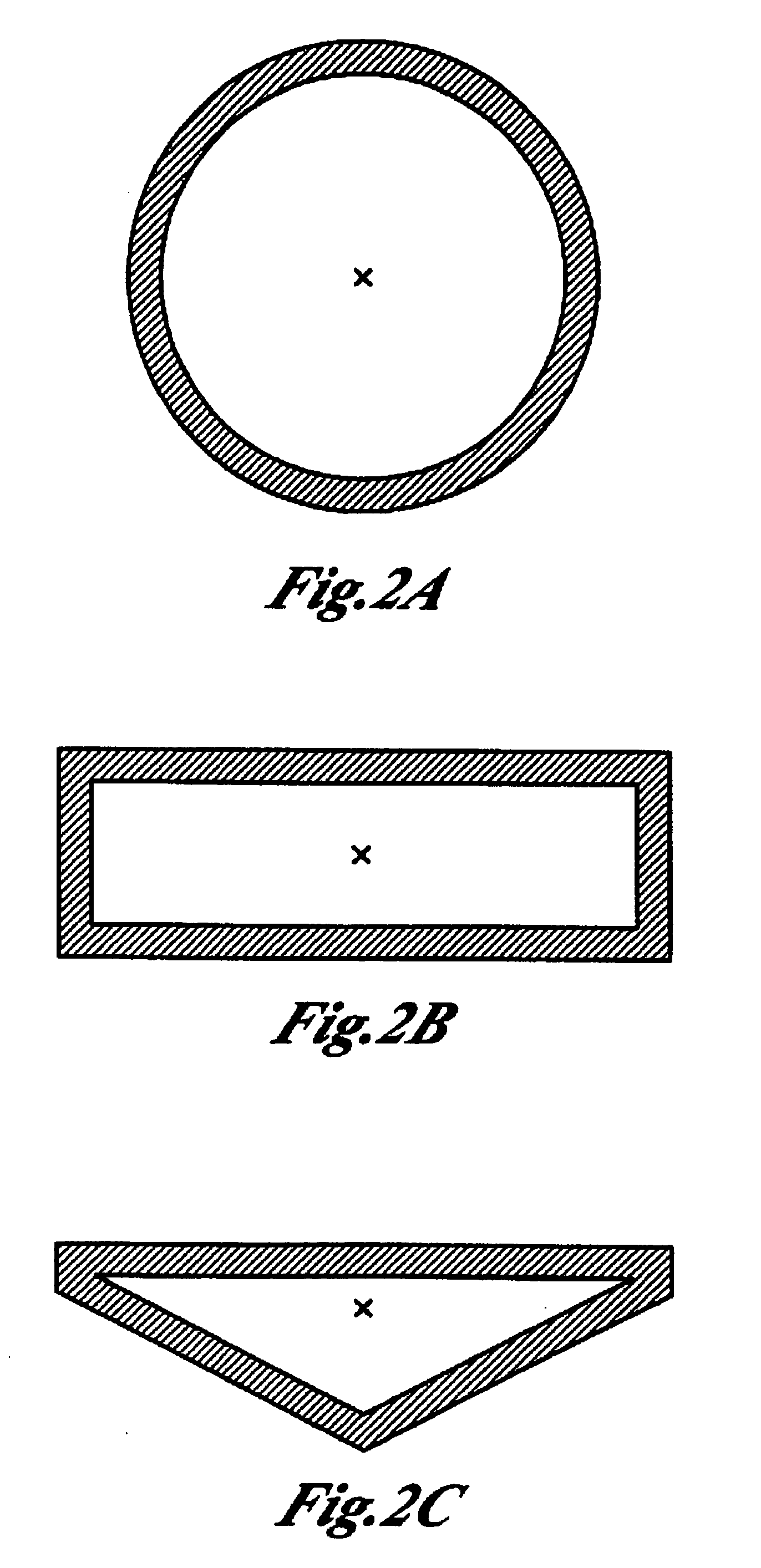

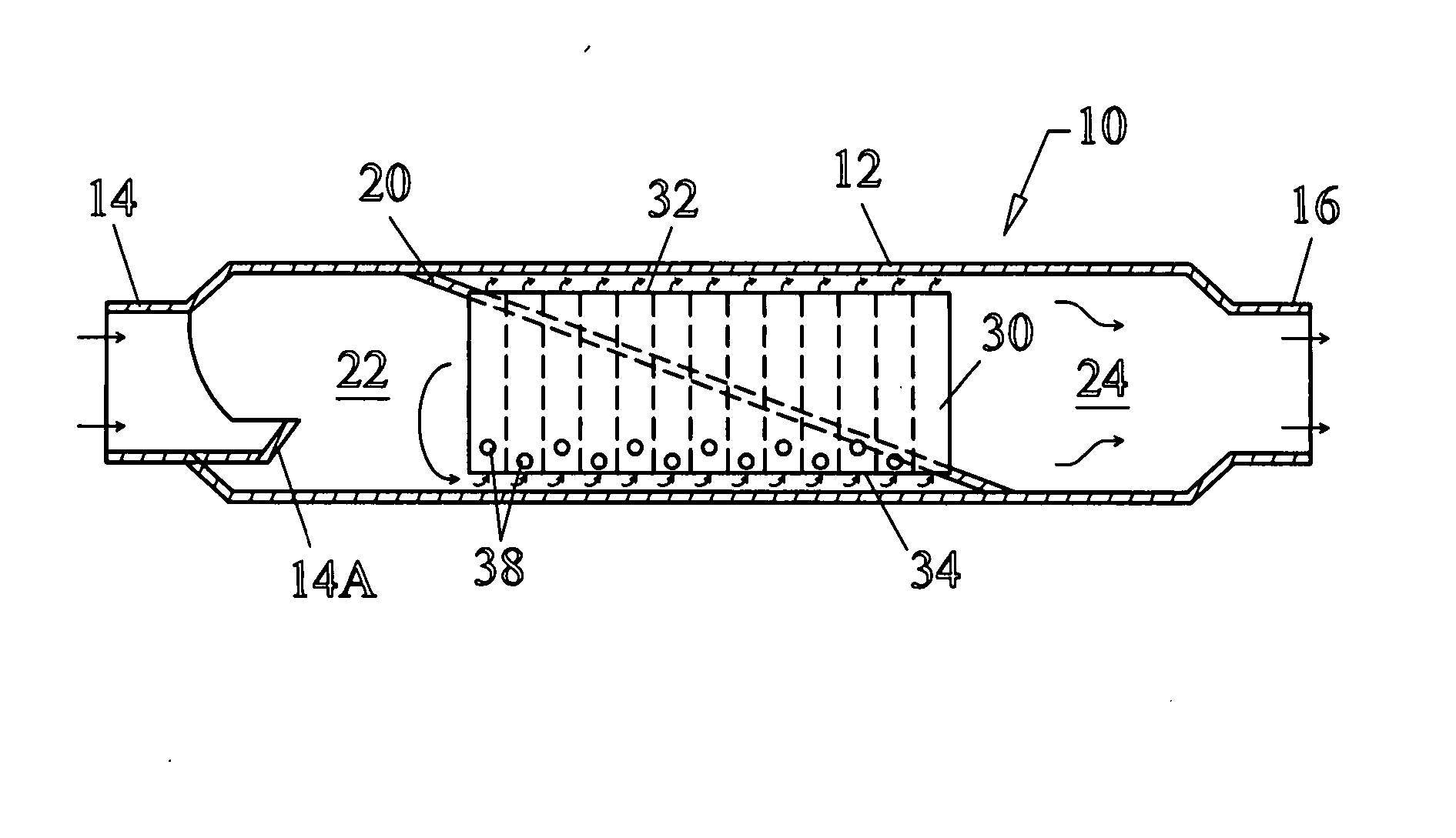

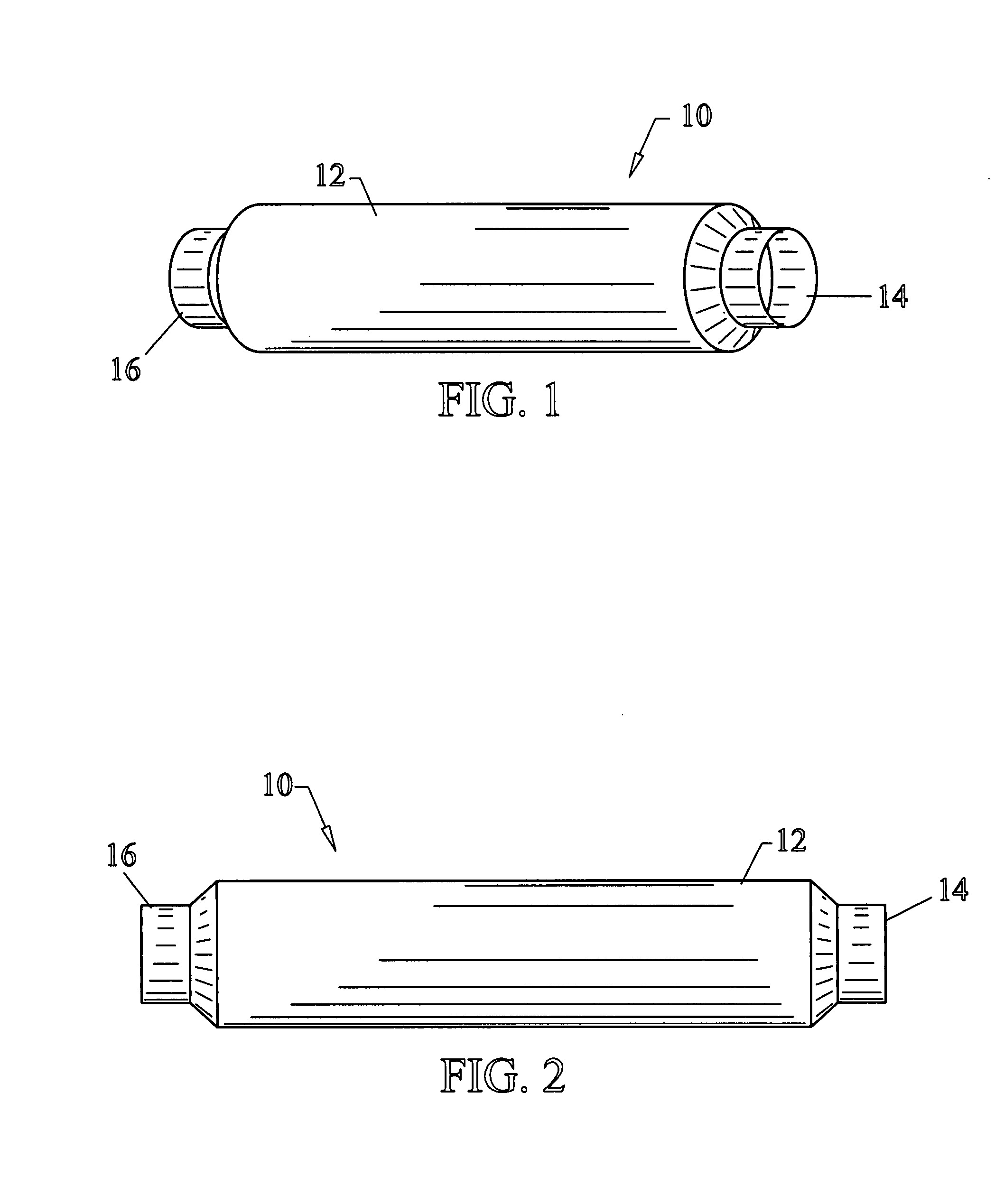

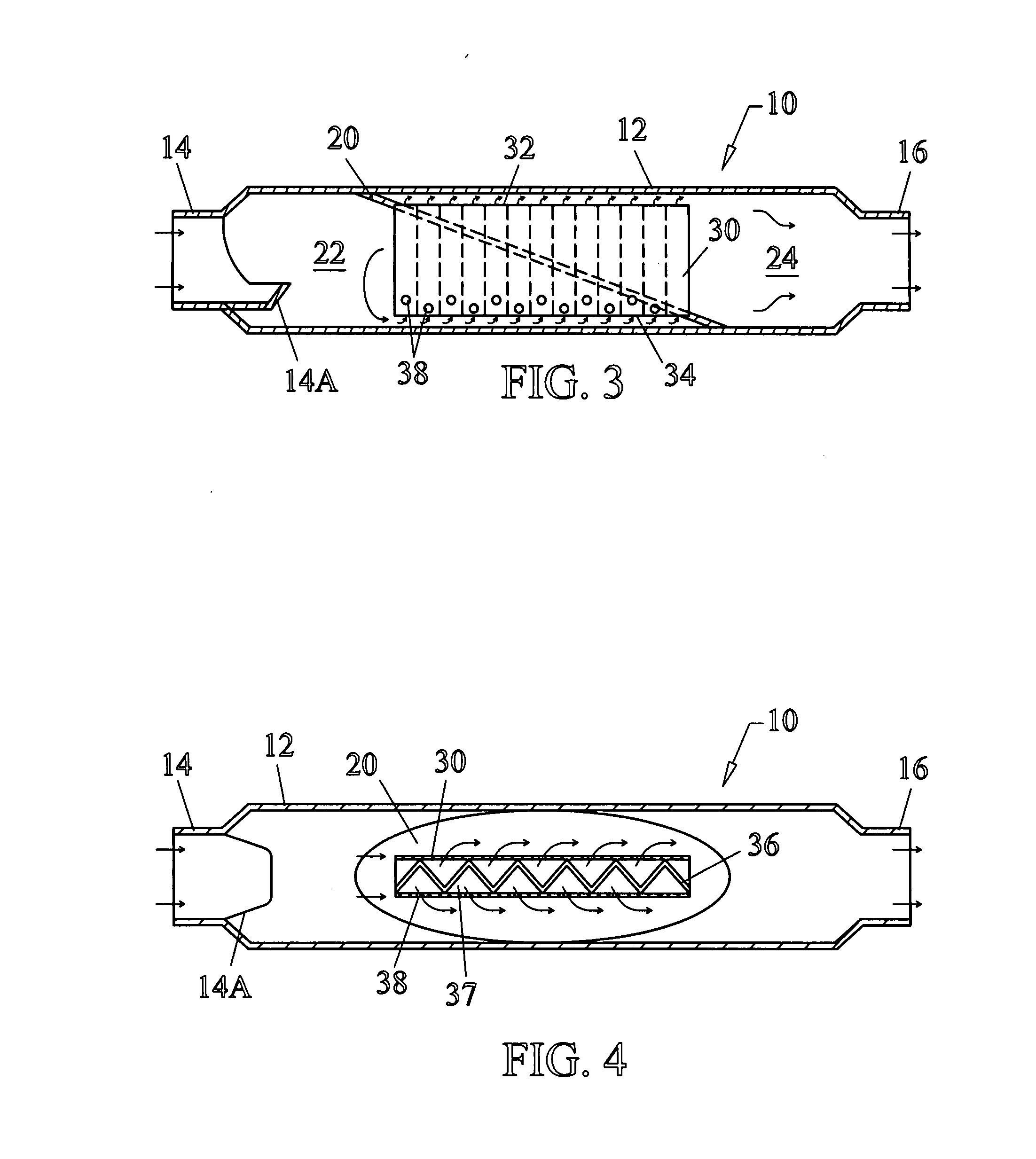

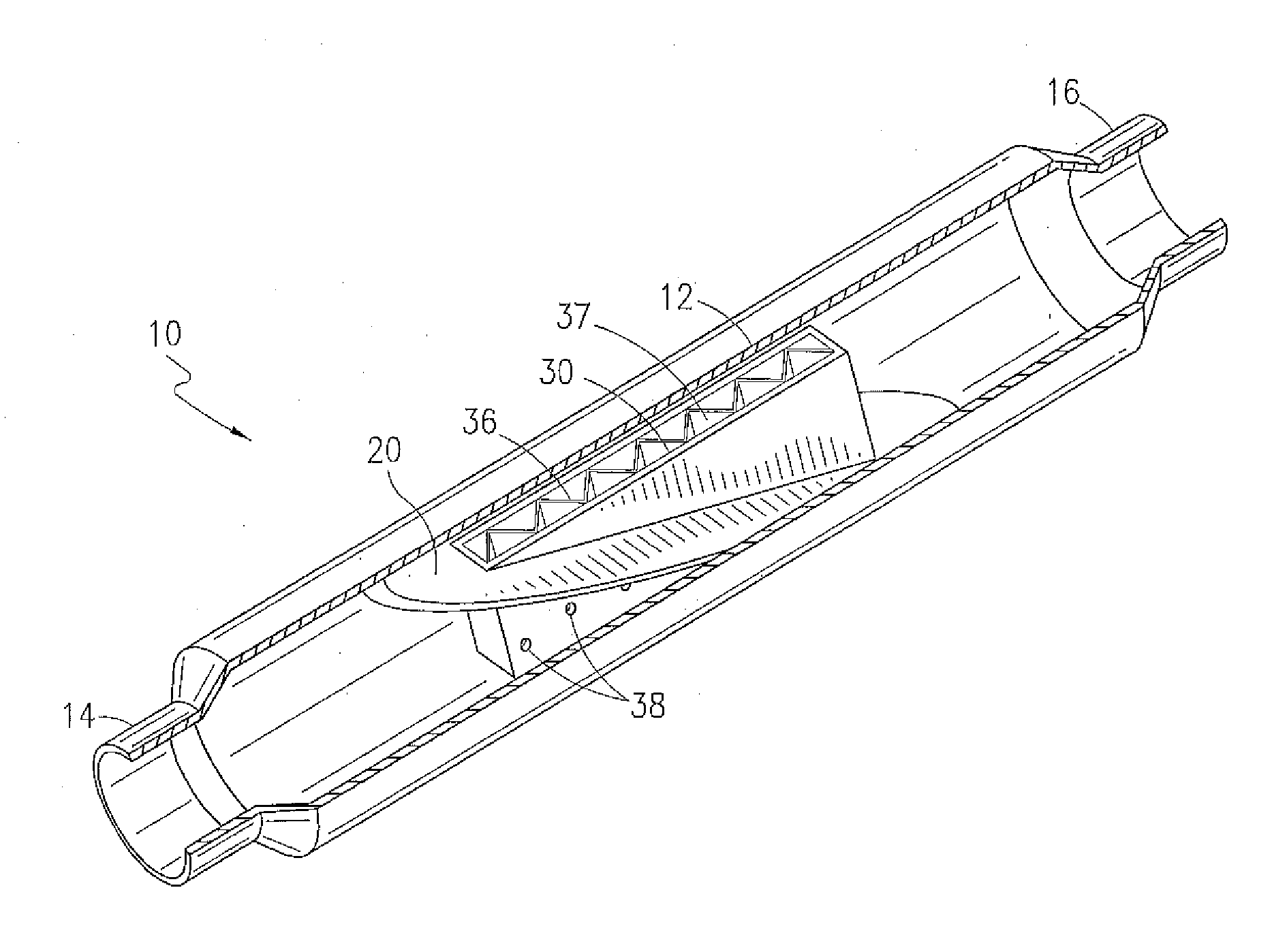

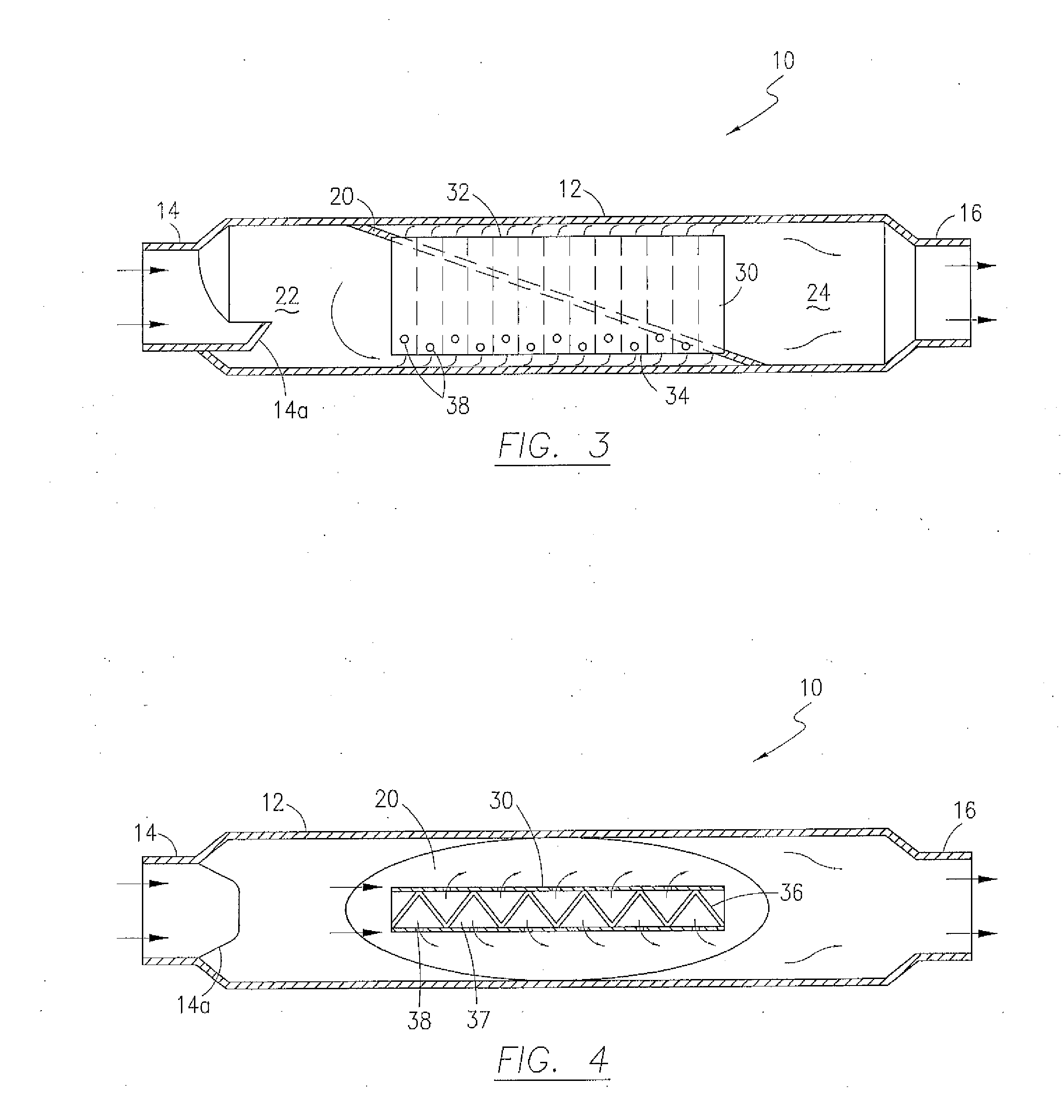

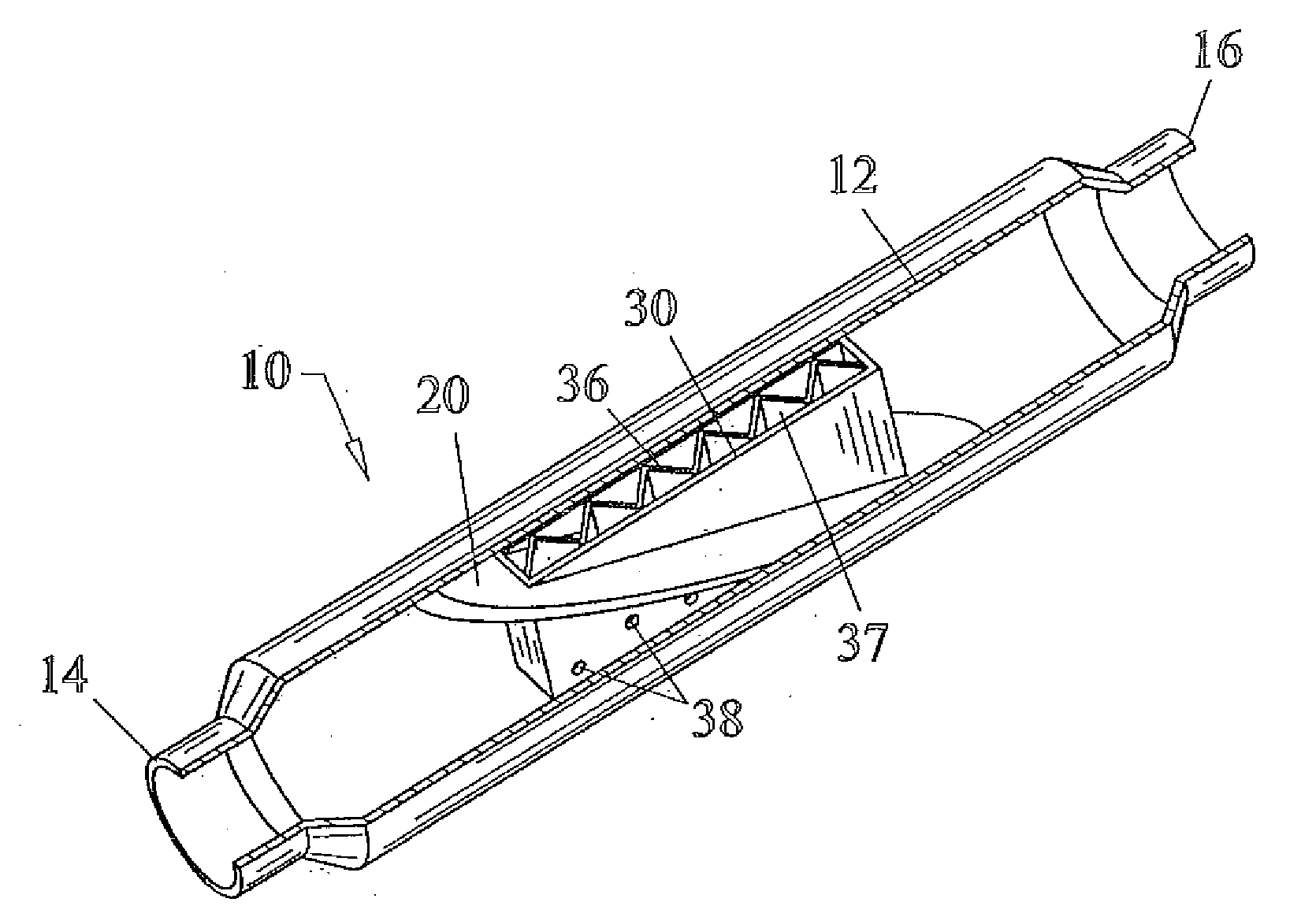

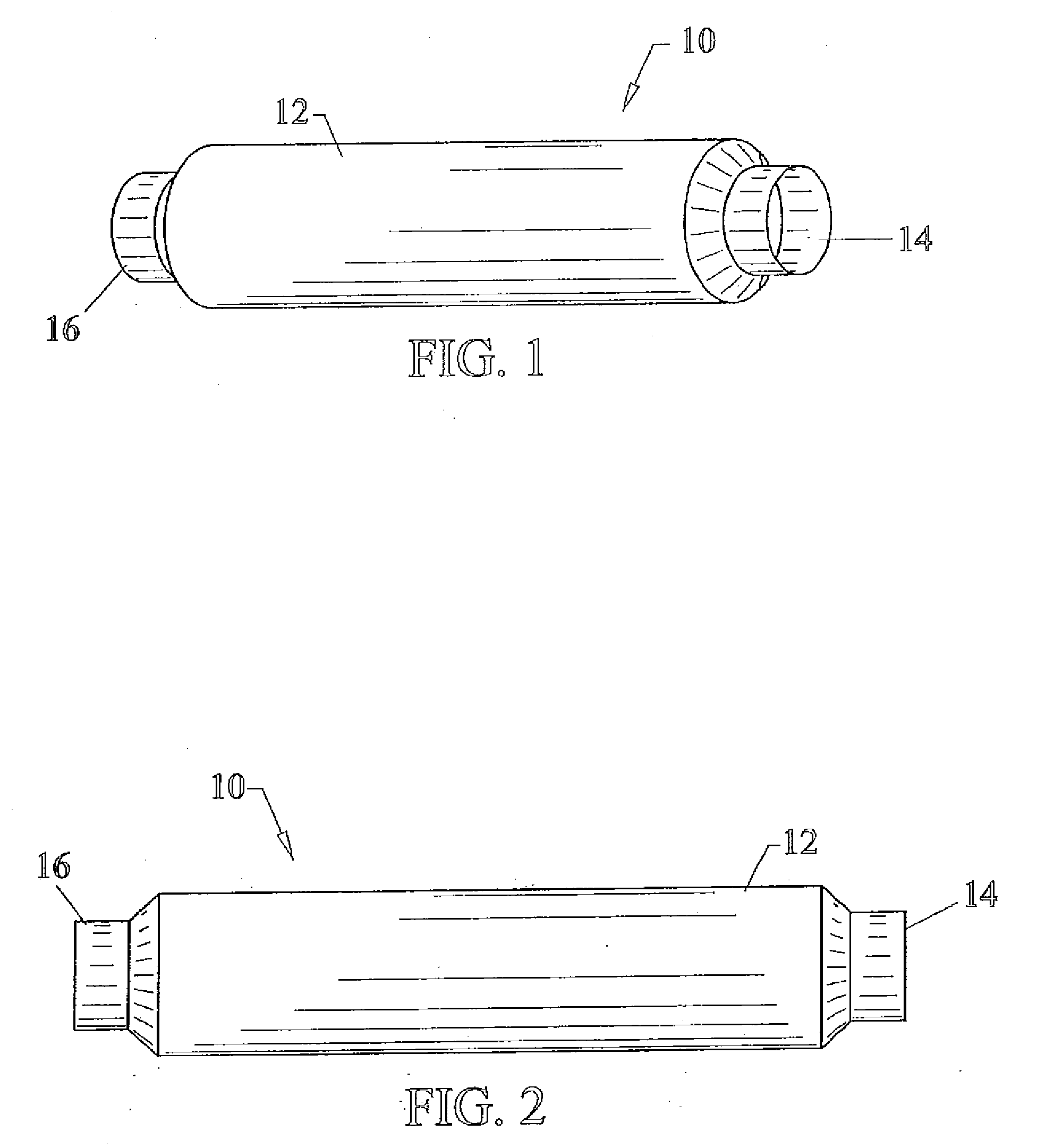

Marine muffler with angularly disposed internal baffle

ActiveUS7581620B2Solve the quick installationPerformance in of easeExhaust apparatusValve members for absorbing fluid energyClosed chamberEngineering

A marine muffler comprises an elongate cylindrical housing having an inlet and an outlet and defining an internal volume partitioned, by an angularly disposed internal baffle, into a lower chamber in communication with the inlet and an upper chamber in communication with the outlet. A vertically disposed duct is insertably secured to the baffle to allow exhaust gas and exhaust cooling water to flow from the lower inlet chamber to upper outlet chamber. The exhaust duct may preferably be further adapted with internal structure forming a plurality of individual flow conduits or passages. The duct is preferably positioned such that a plurality of flow passage inlets are positioned in proximity to the lower cylindrical housing wall, with flow passage outlets positioned in proximity to the upper housing wall. The lower duct wall may further be adapted with sidewall apertures for improving exhaust flow dynamics therethrough.

Owner:WOODS WOODROW

Marine muffler with angularly disposed internal baffle

ActiveUS7905322B2Solve the quick installationPerformance in of easeExhaust apparatusValve members for absorbing fluid energyClosed chamberEngineering

A marine muffler comprises an elongate cylindrical housing having an inlet and an outlet and defining an internal volume partitioned, by an angularly disposed internal baffle, into a lower chamber in communication with the inlet and an upper chamber in communication with the outlet. A vertically disposed duct is insertably secured to the baffle to allow exhaust gas and exhaust cooling water to flow from the lower inlet chamber to upper outlet chamber. The exhaust duct may preferably be further adapted with internal structure forming a plurality of individual flow conduits or passages. The duct is preferably positioned such that a plurality of flow passage inlets are positioned in proximity to the lower cylindrical housing wall, with flow passage outlets positioned in proximity to the upper housing wall. The lower duct wall may further be adapted with sidewall apertures for improving exhaust flow dynamics therethrough.

Owner:WOODS WOODROW

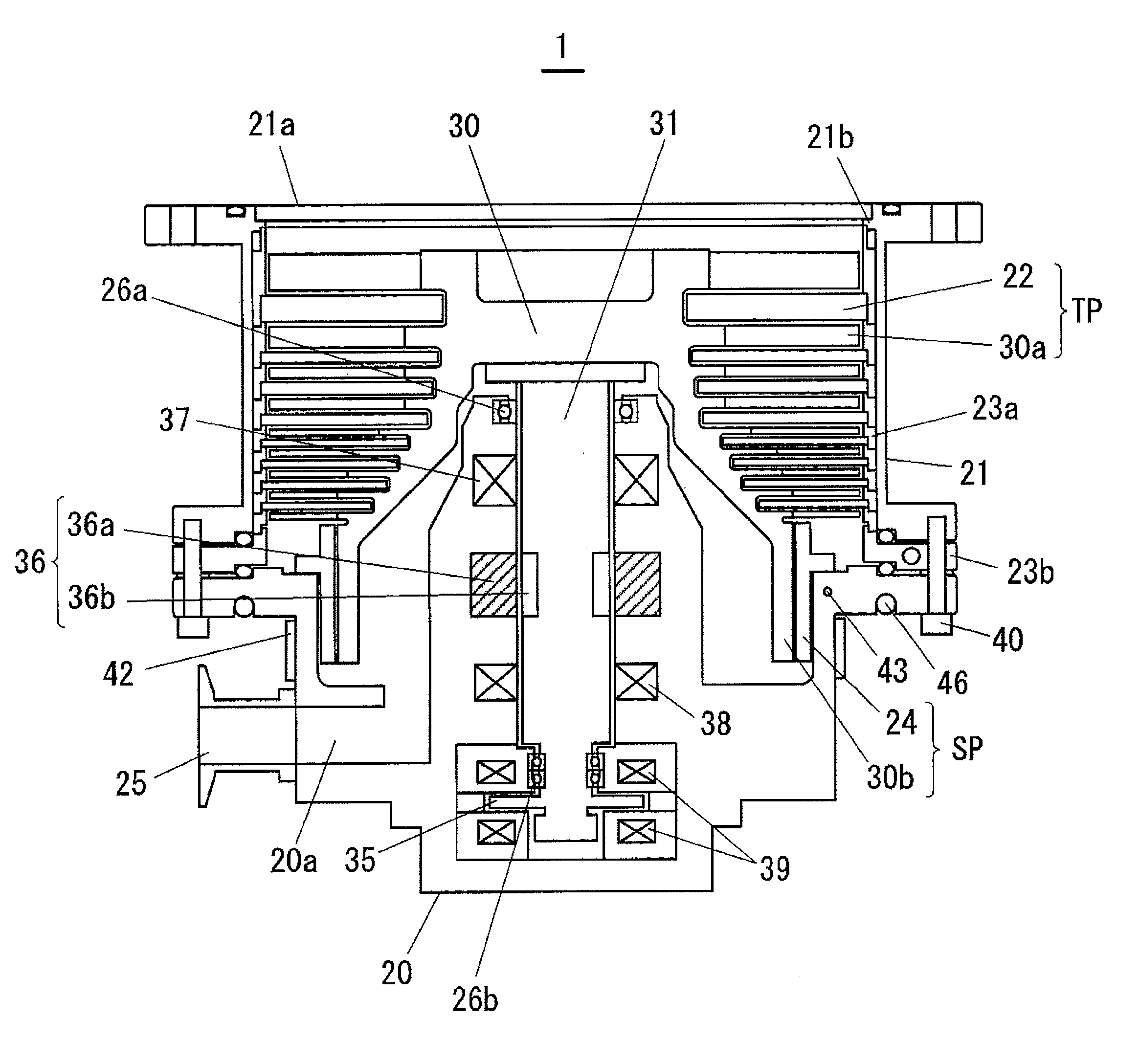

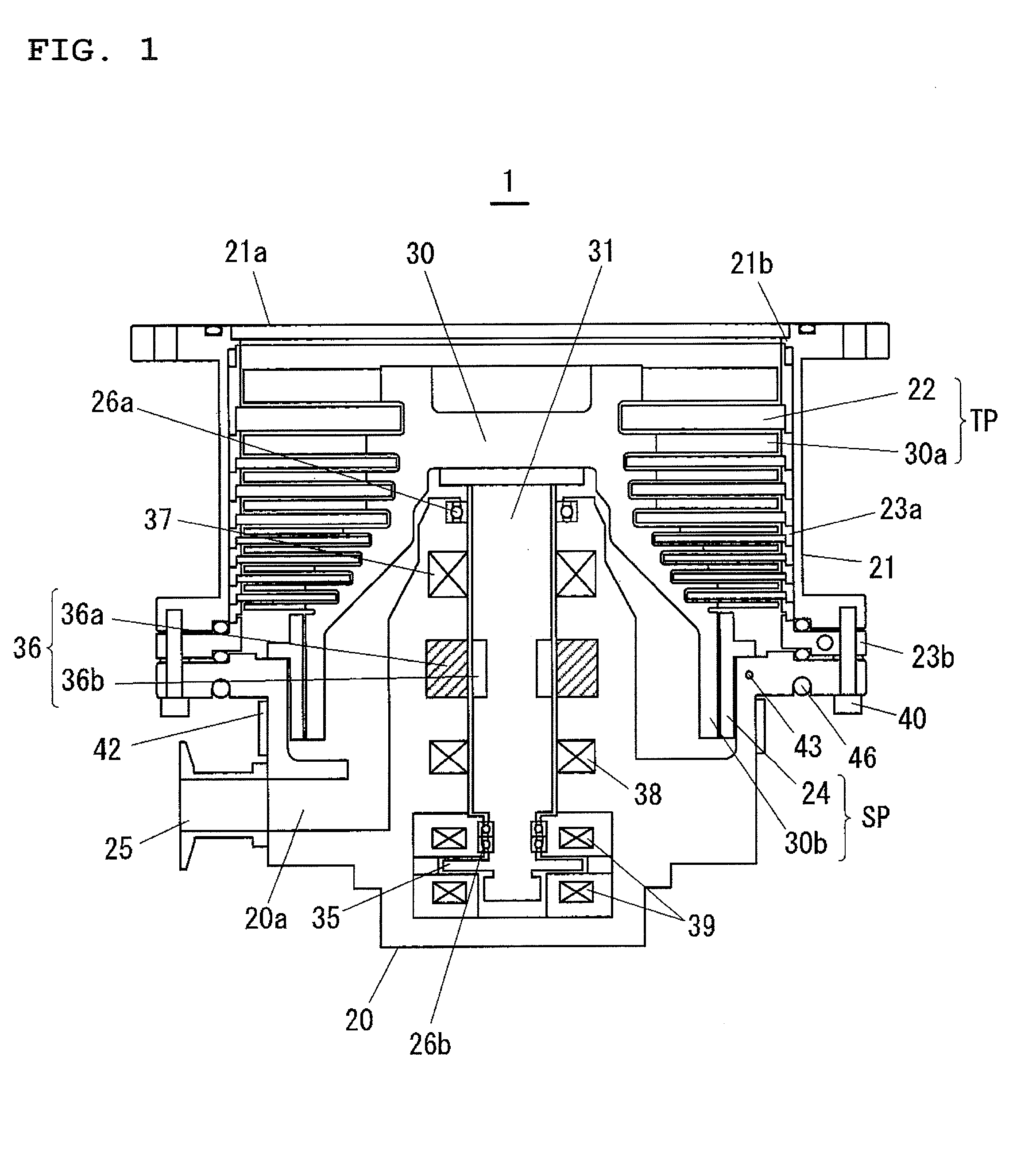

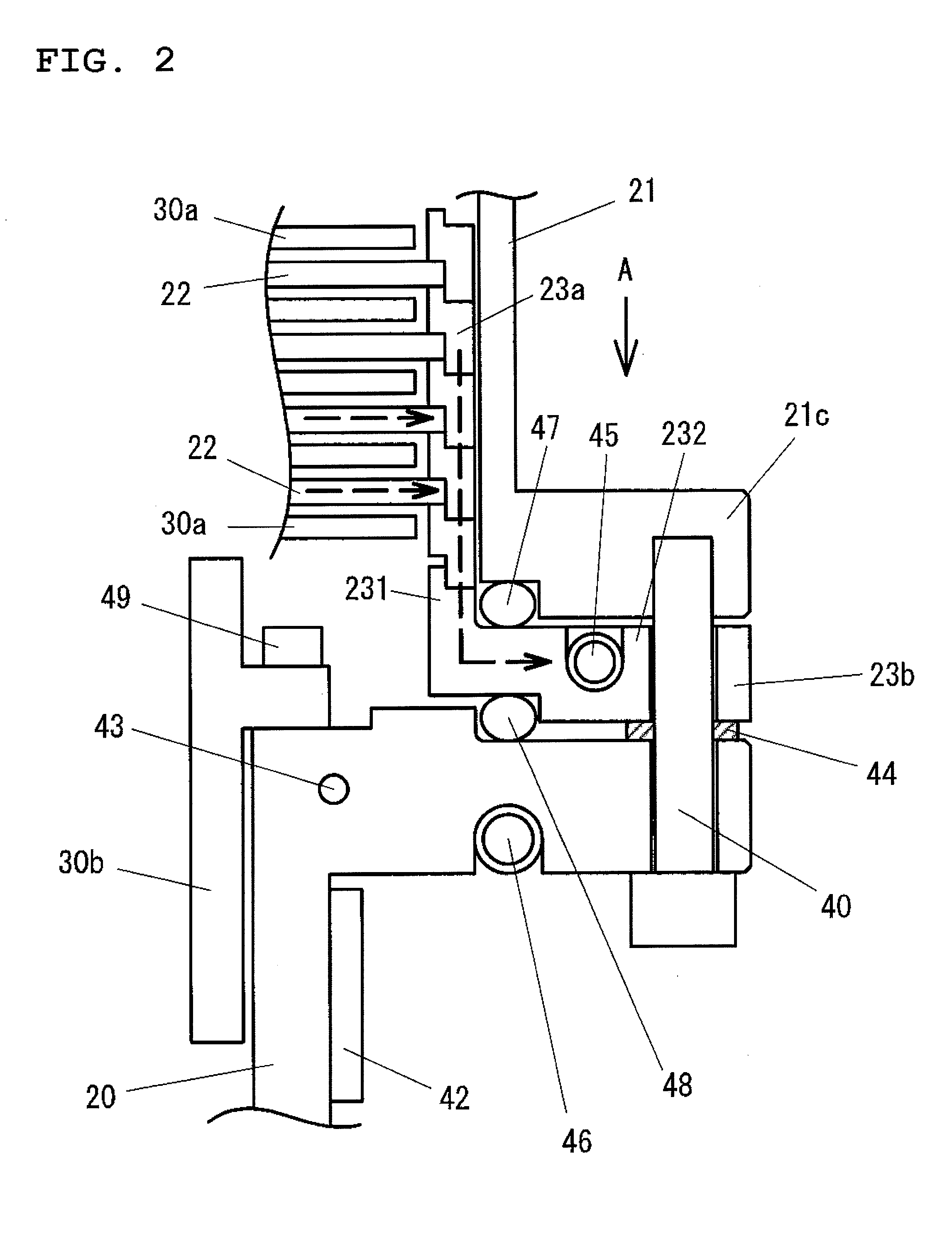

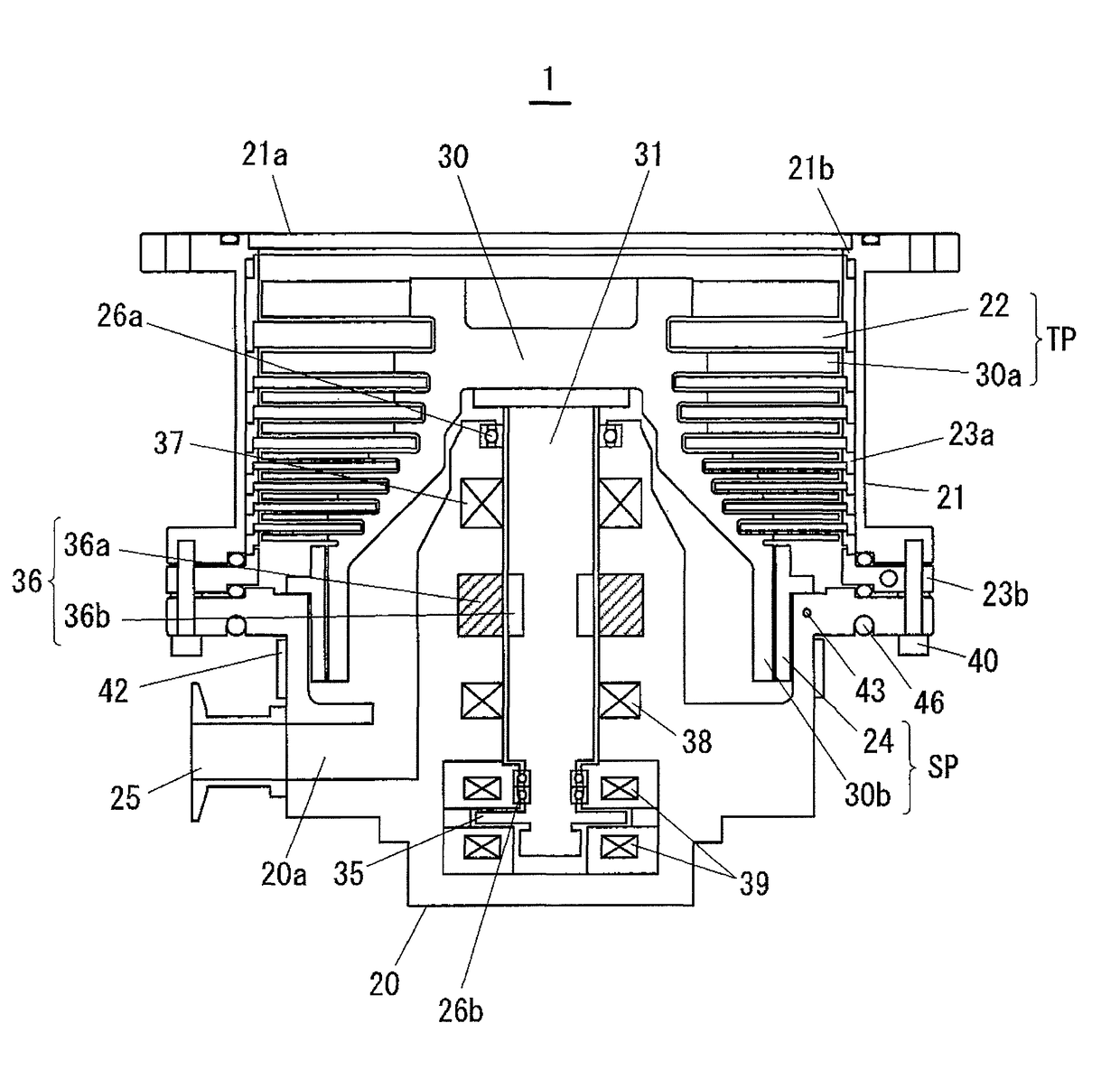

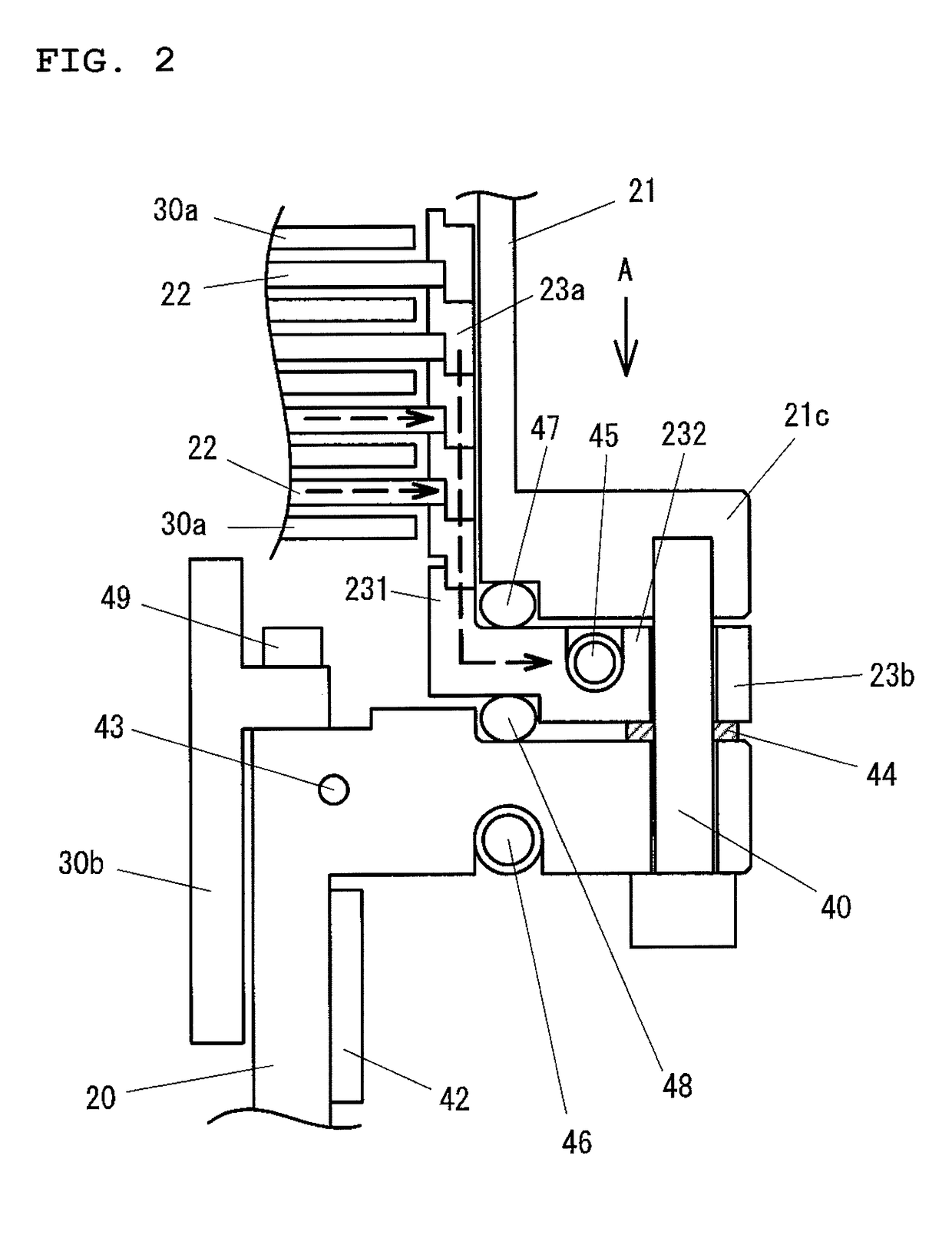

Turbo-molecular pump

ActiveUS20150226229A1Improve exhaust flow ratePrevent accumulationWind motor controlPump componentsStatorTurbomolecular pump

A turbo-molecular pump comprises: a rotor; stationary blades; a stator; a plurality of spacers; a heater disposed on the base; a temperature sensor for detecting a temperature of the stator; and a temperature regulation section for on / off controlling the heater based on a temperature detected by the temperature sensor to regulate the temperature of the stator so as to be a reaction product accumulation prevention temperature. At least one spacer arranged on a base side of the plurality of spacers is cooled by coolant, and the turbo-molecular pump further comprises a heat insulation member disposed between the base and the spacer arranged on the base.

Owner:SHIMADZU CORP

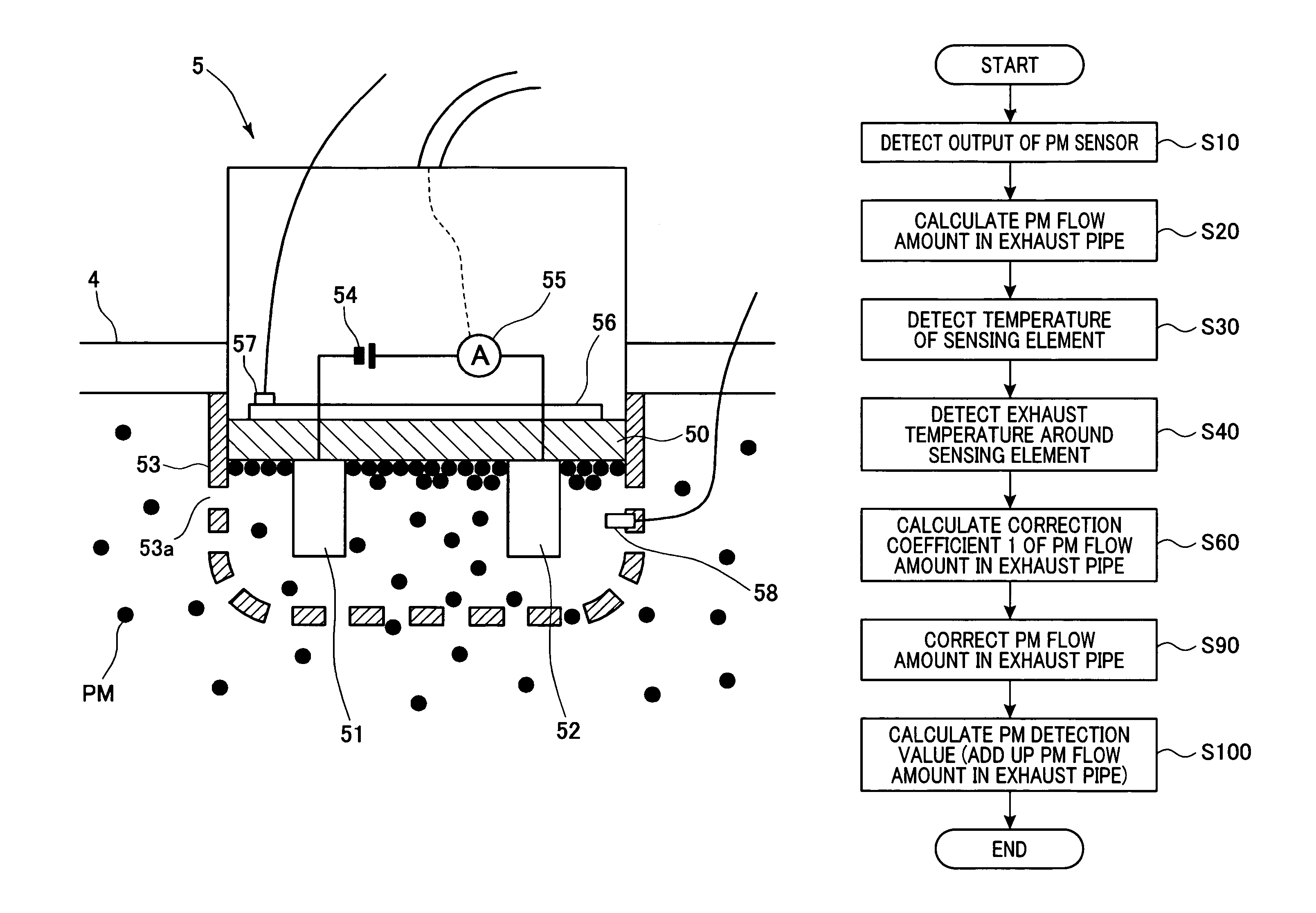

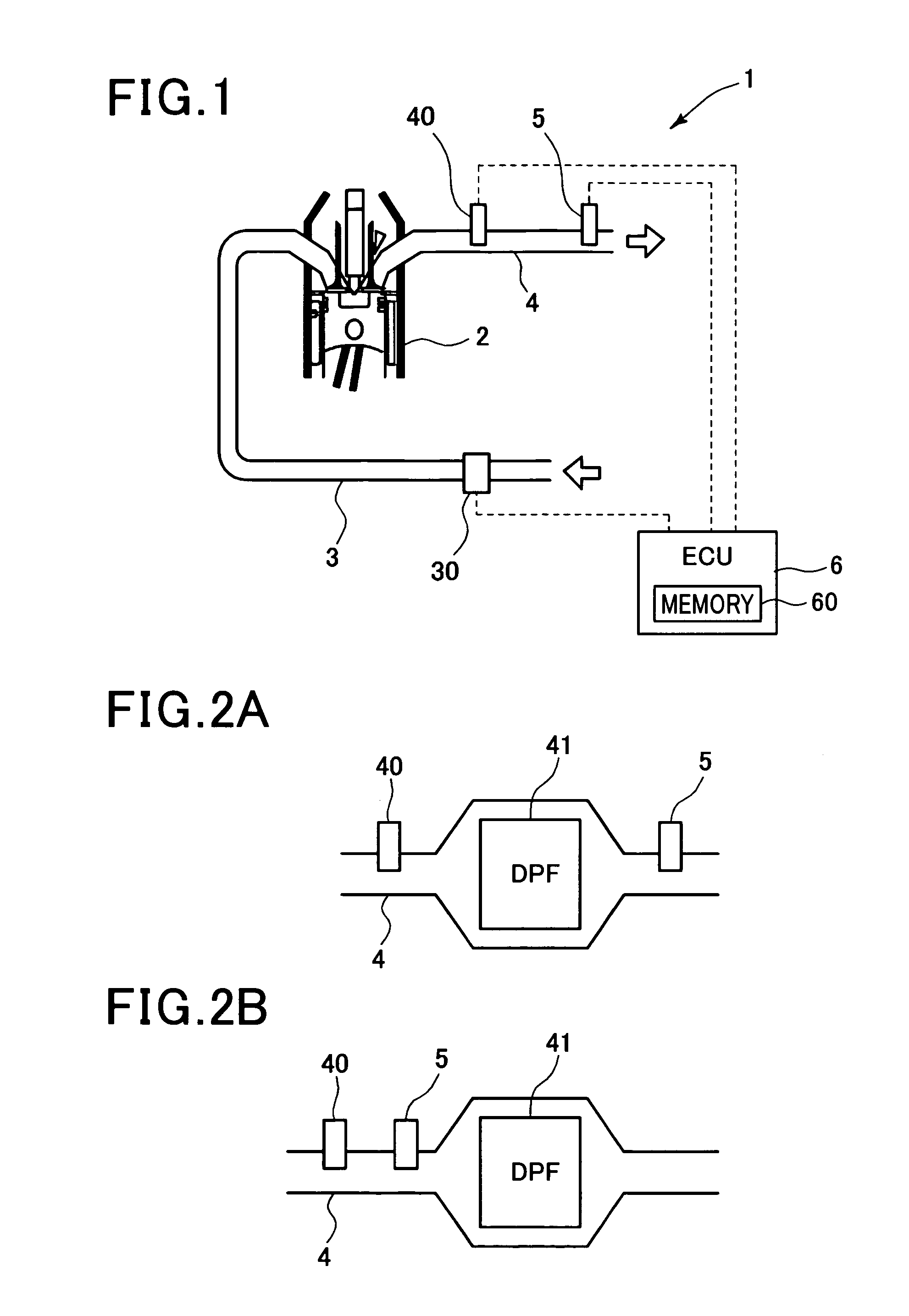

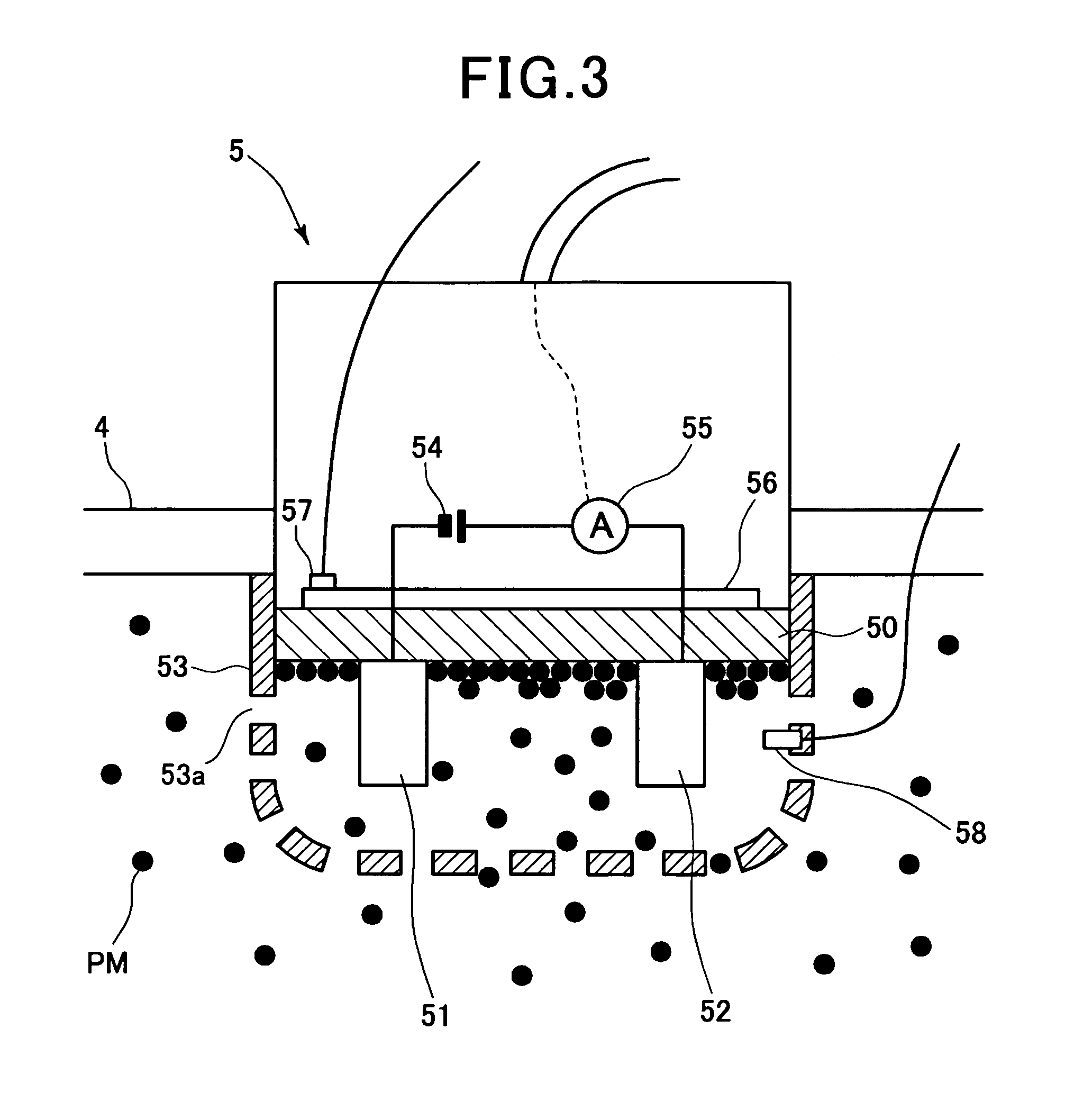

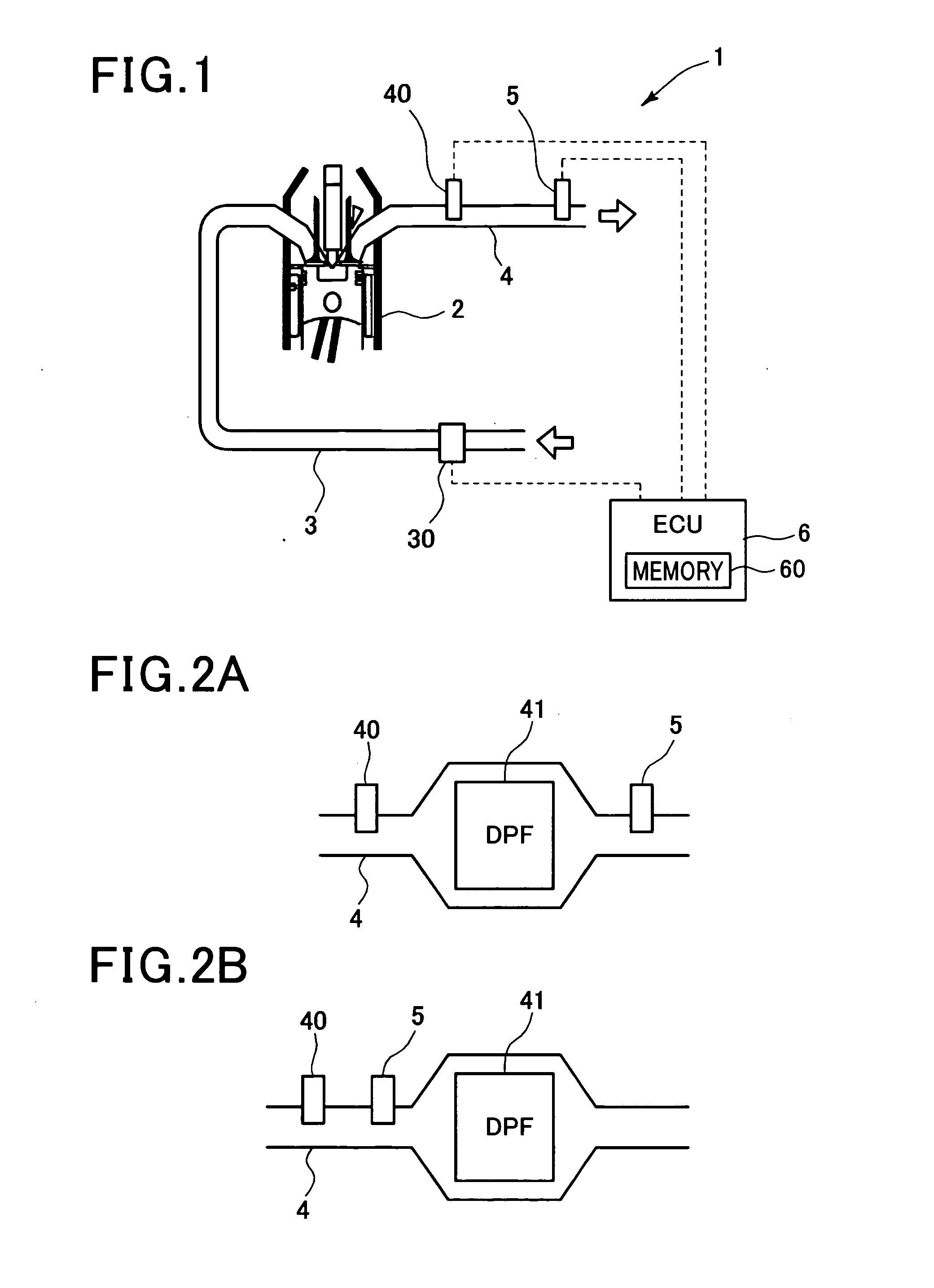

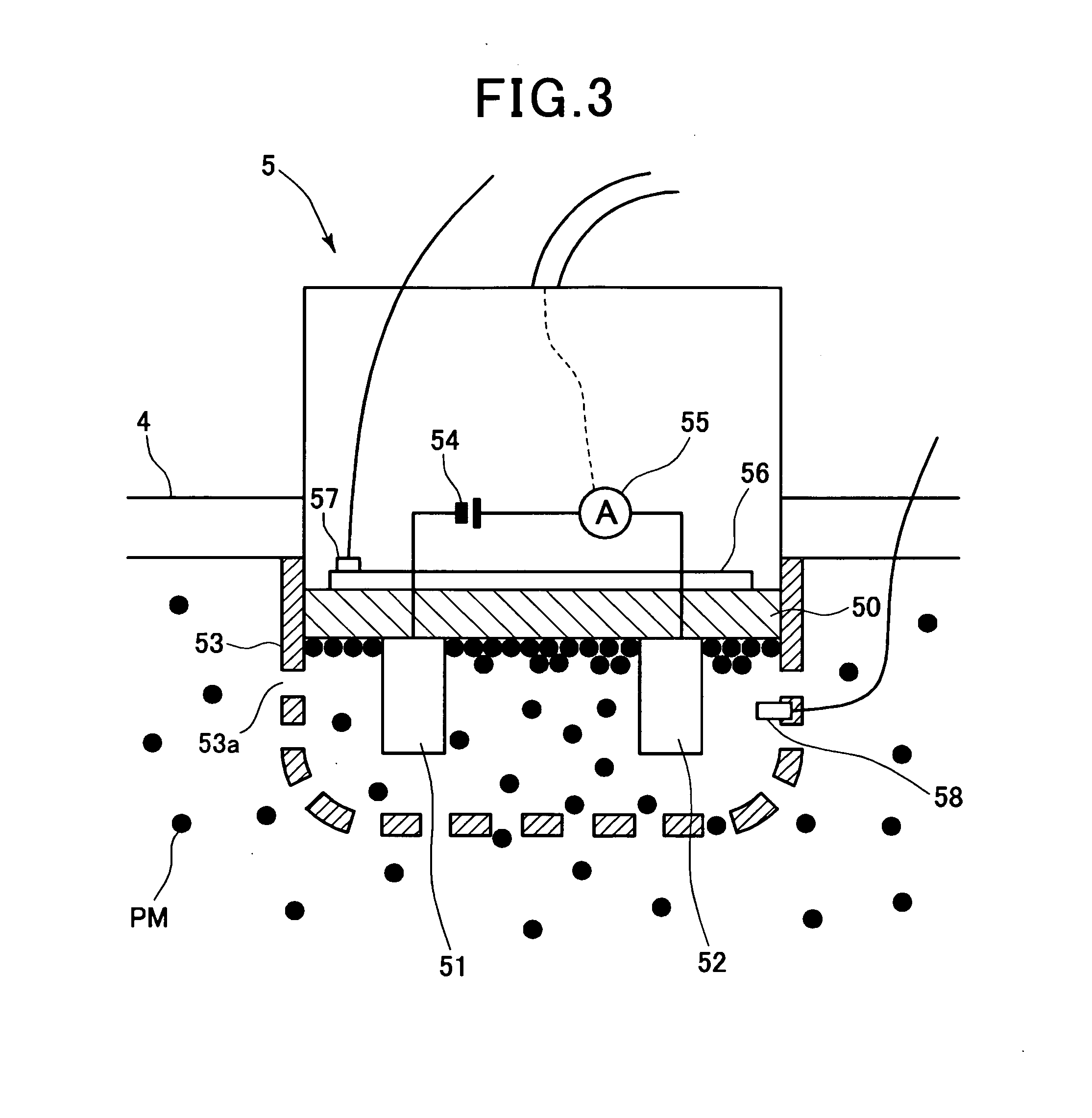

Particulate matter sensor, system, and method of using a correction unit

ActiveUS8915119B2Reduce impactImprove accuracyInternal combustion piston enginesExhaust apparatusParticulatesEngineering

A detection apparatus includes a particulate matter (PM) detection unit, a temperature detection unit, and a correction unit. The PM detection unit includes an insulator, a pair of electrodes, and a detector. The insulator is disposed in an exhaust path of an internal combustion engine through which an exhaust gas flows. The pair of electrodes are arranged in contact with at least a part of the insulator. The detector detects a PM detection value which is a value correlated to an amount of PM in the exhaust gas. The temperature detection unit detects at least one of an exhaust temperature of the exhaust gas passing through the PM detection unit and an insulator temperature of the insulator. The correction unit corrects the PM detection value detected by the PM detection unit based on at least one of the exhaust temperature and the insulator temperature.

Owner:DENSO CORP

Detection apparatus

ActiveUS20120186330A1Highly accurate exhaust flow rateImprove accuracyInternal-combustion engine testingInternal combustion piston enginesParticulatesEngineering

A detection apparatus includes a particulate matter (PM) detection unit, a temperature detection unit, and a correction unit. The PM detection unit includes an insulator, a pair of electrodes, and a detector. The insulator is disposed in an exhaust path of an internal combustion engine through which an exhaust gas flows. The pair of electrodes are arranged in contact with at least a part of the insulator. The detector detects a PM detection value which is a value correlated to an amount of PM in the exhaust gas. The temperature detection unit detects at least one of an exhaust temperature of the exhaust gas passing through the PM detection unit and an insulator temperature of the insulator. The correction unit corrects the PM detection value detected by the PM detection unit based on at least one of the exhaust temperature and the insulator temperature.

Owner:DENSO CORP

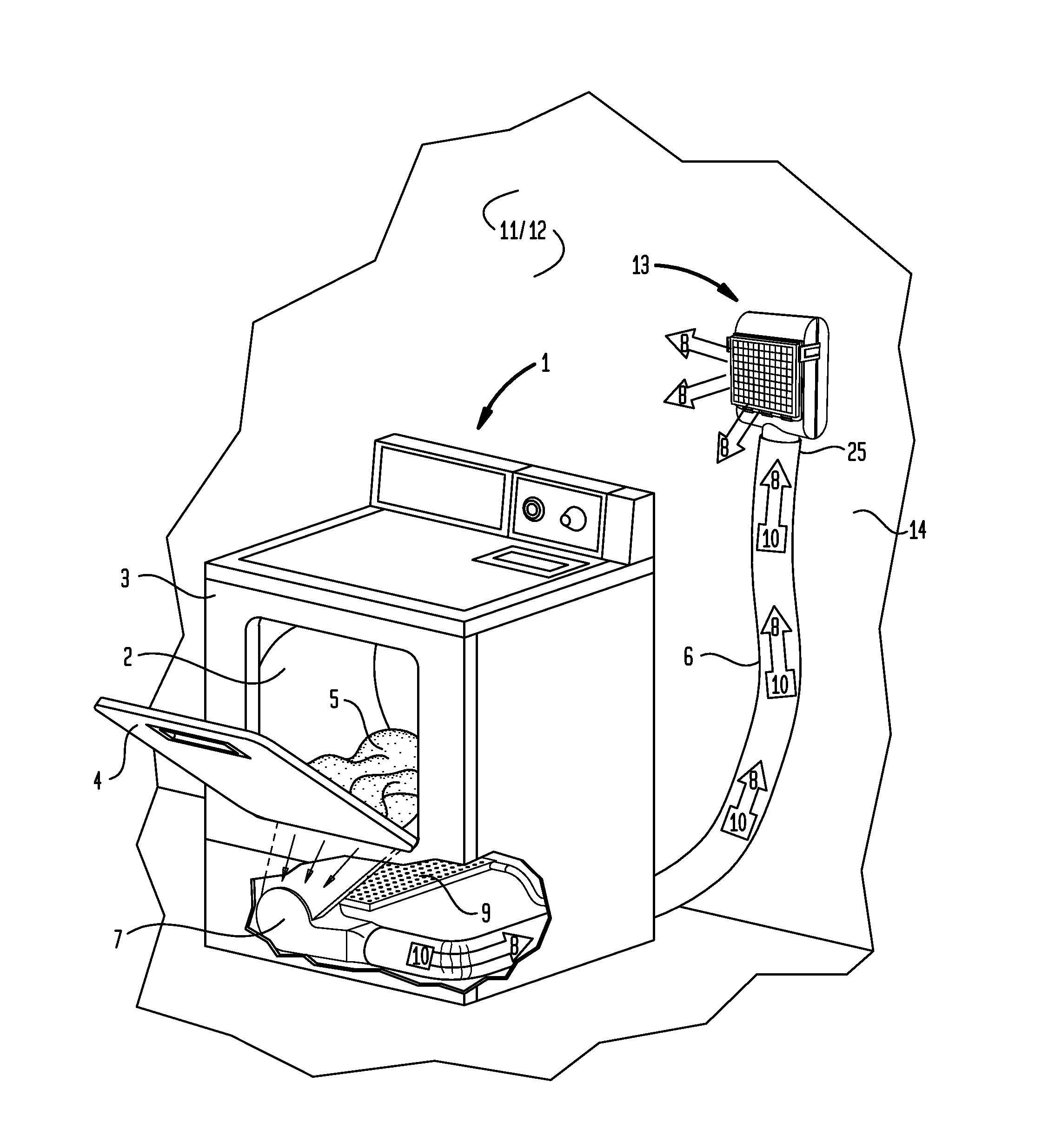

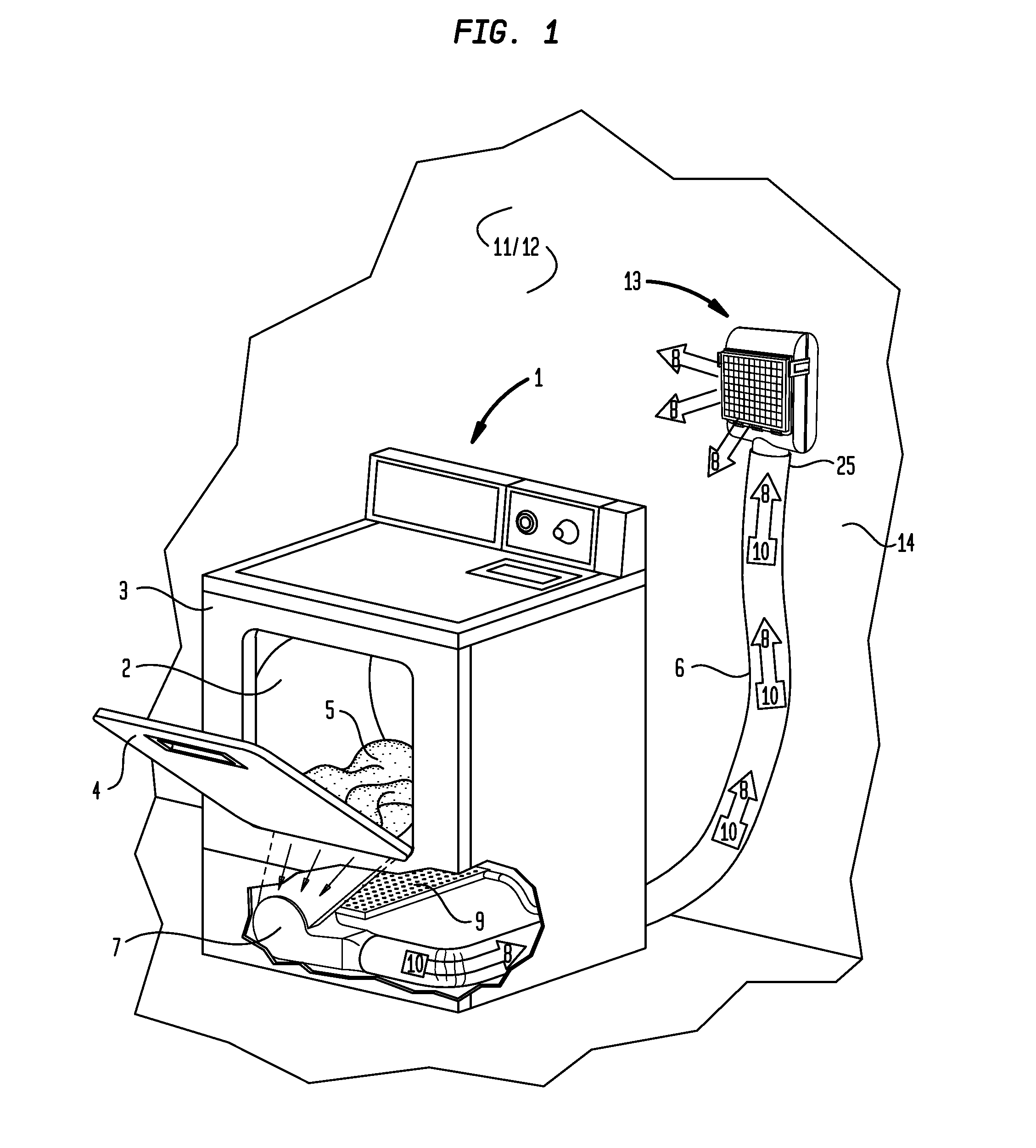

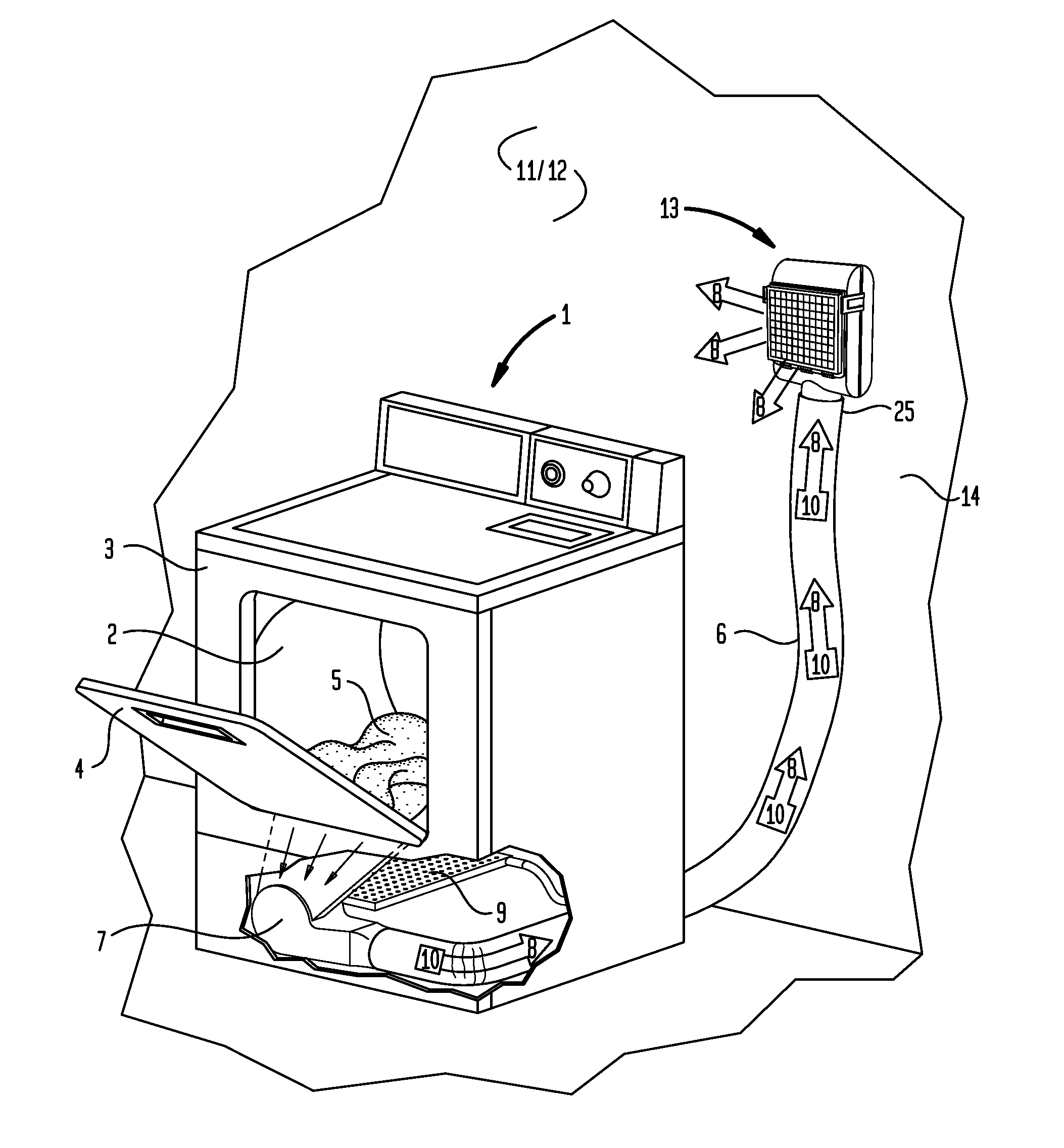

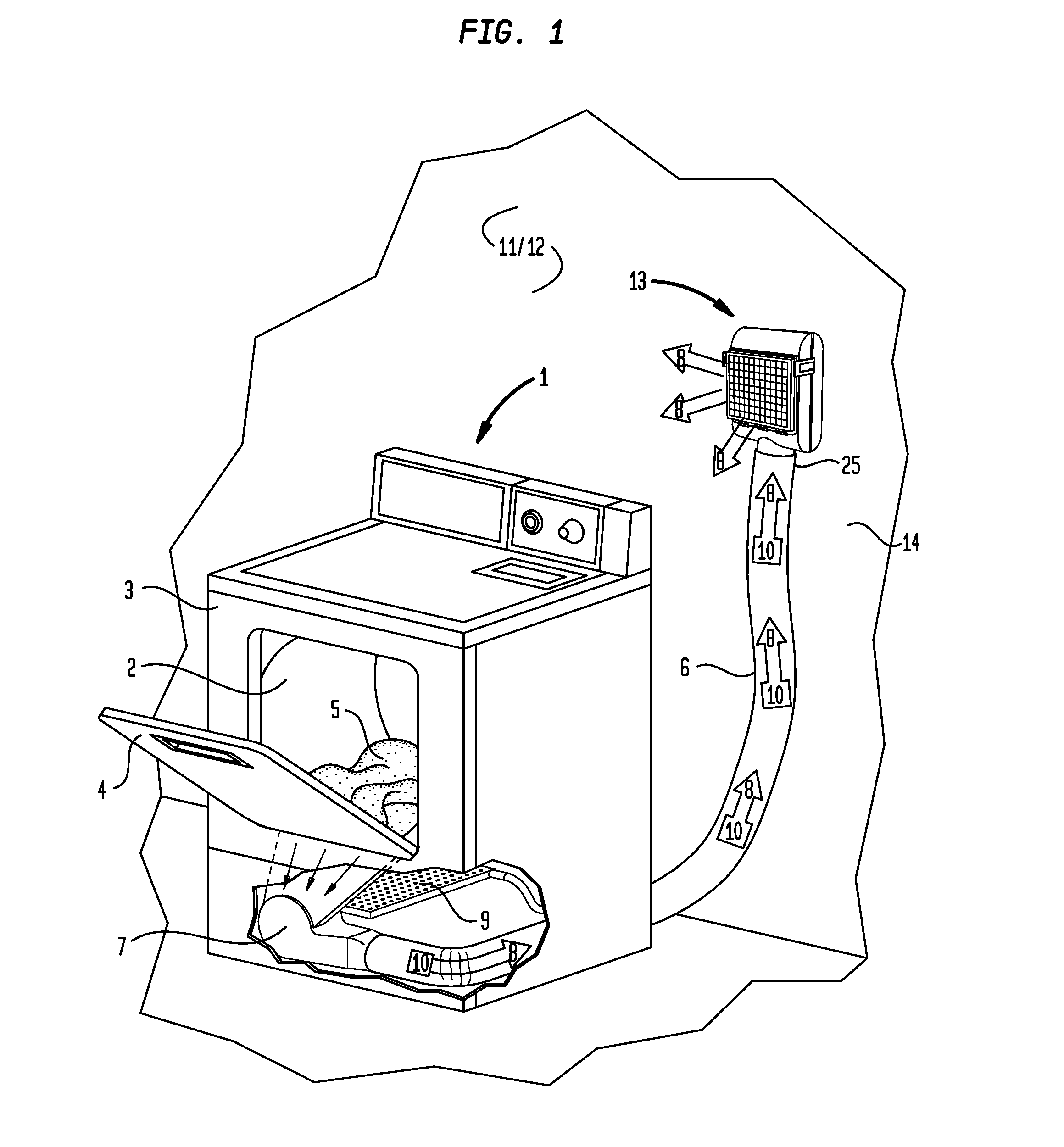

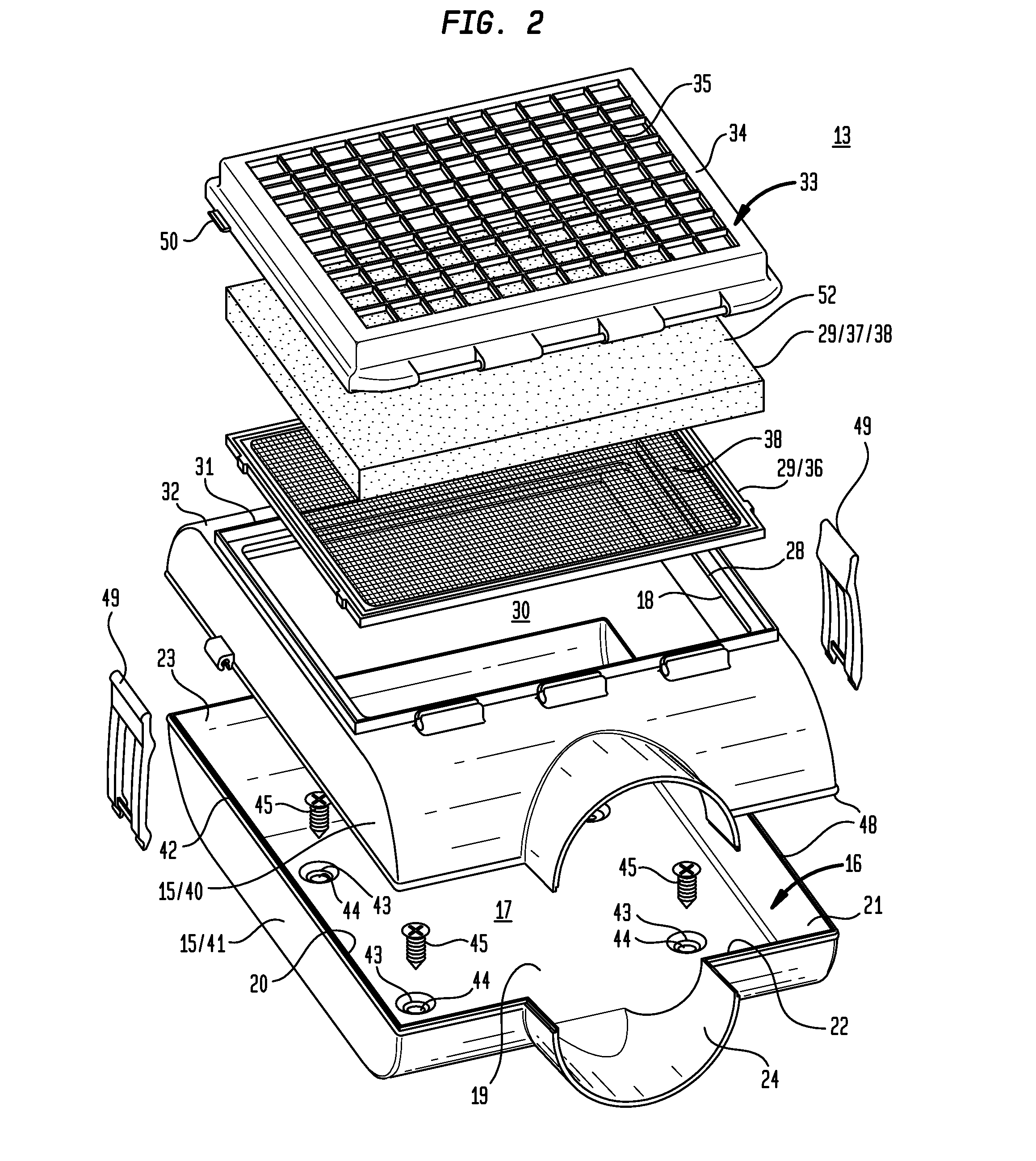

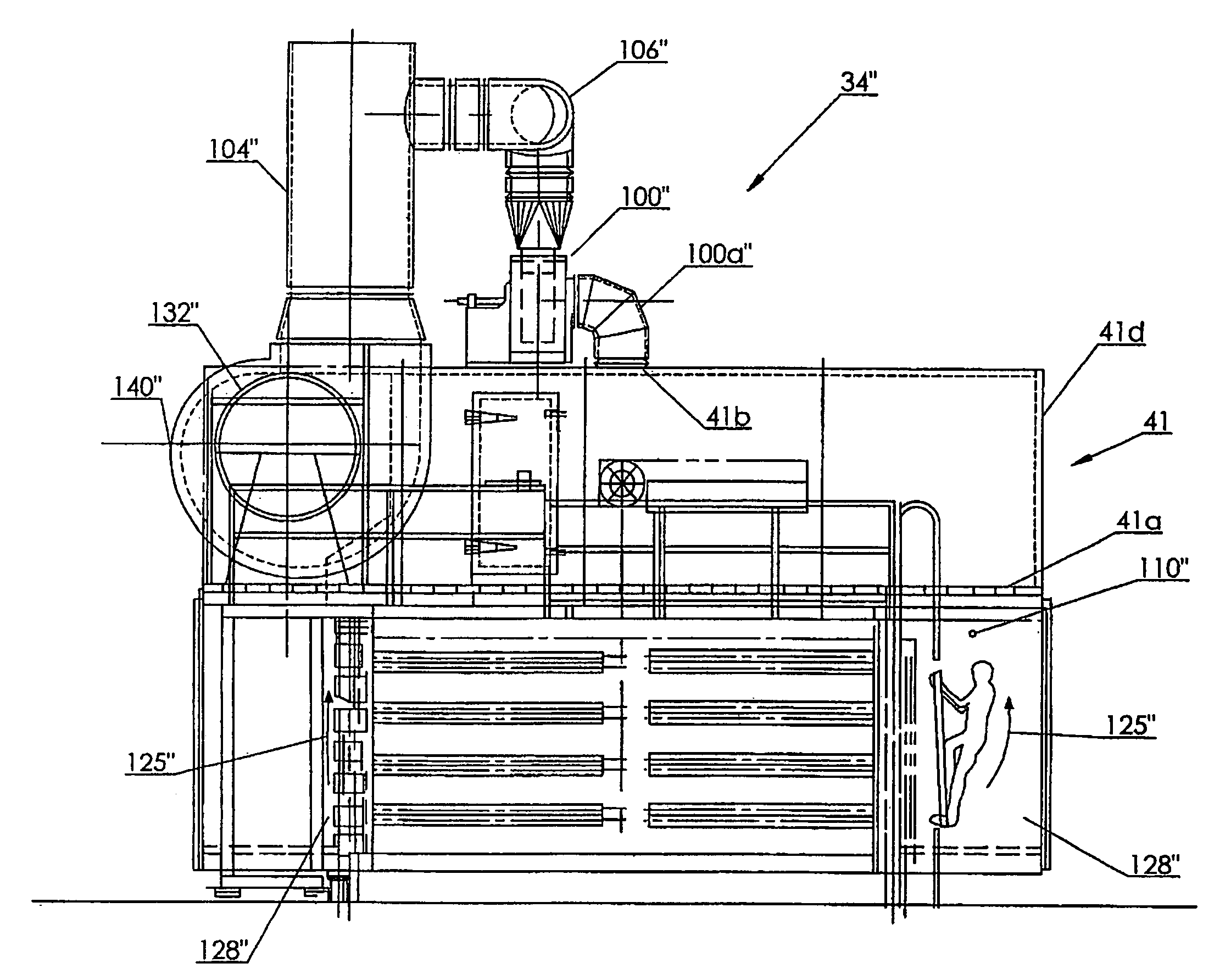

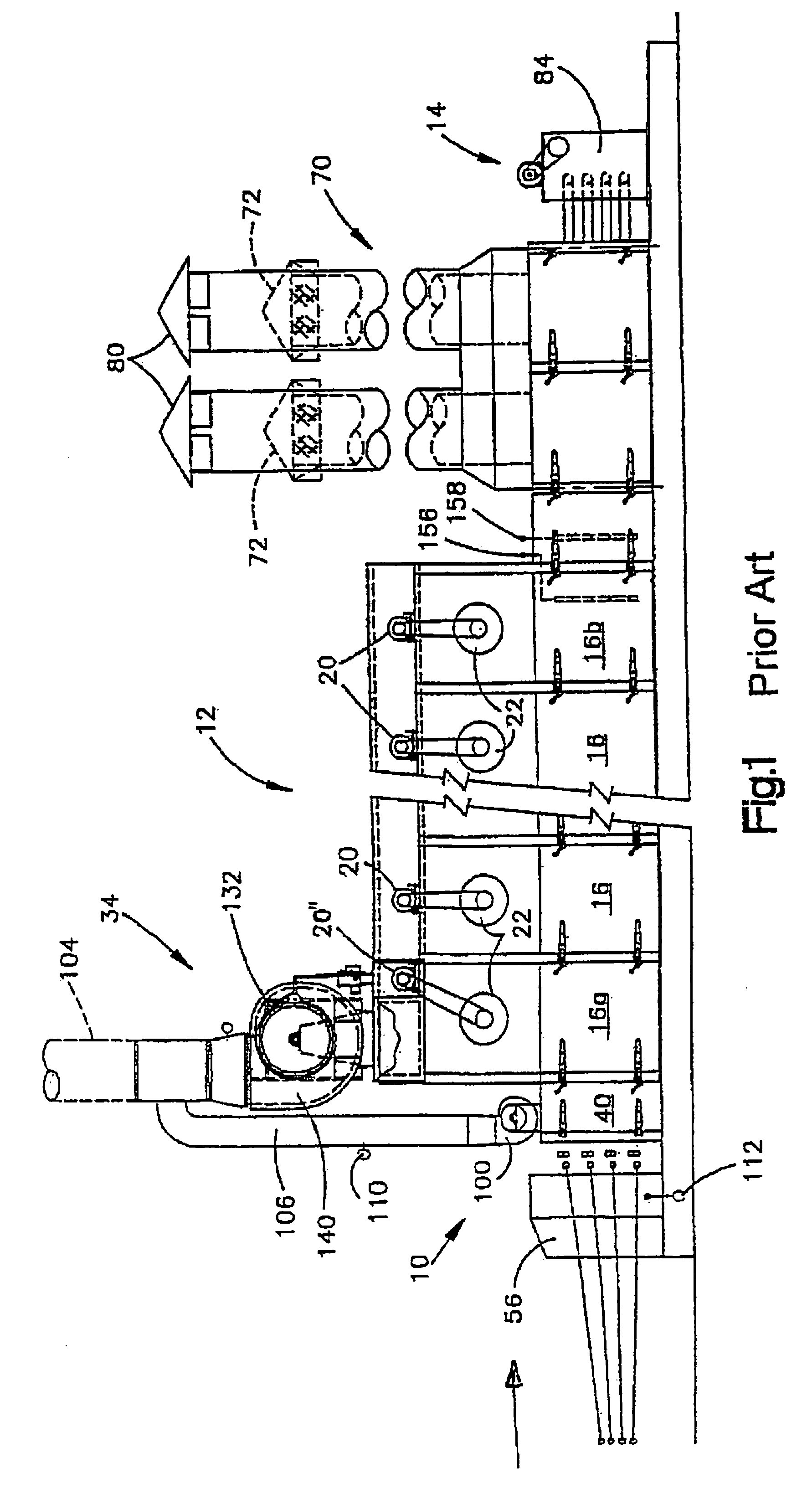

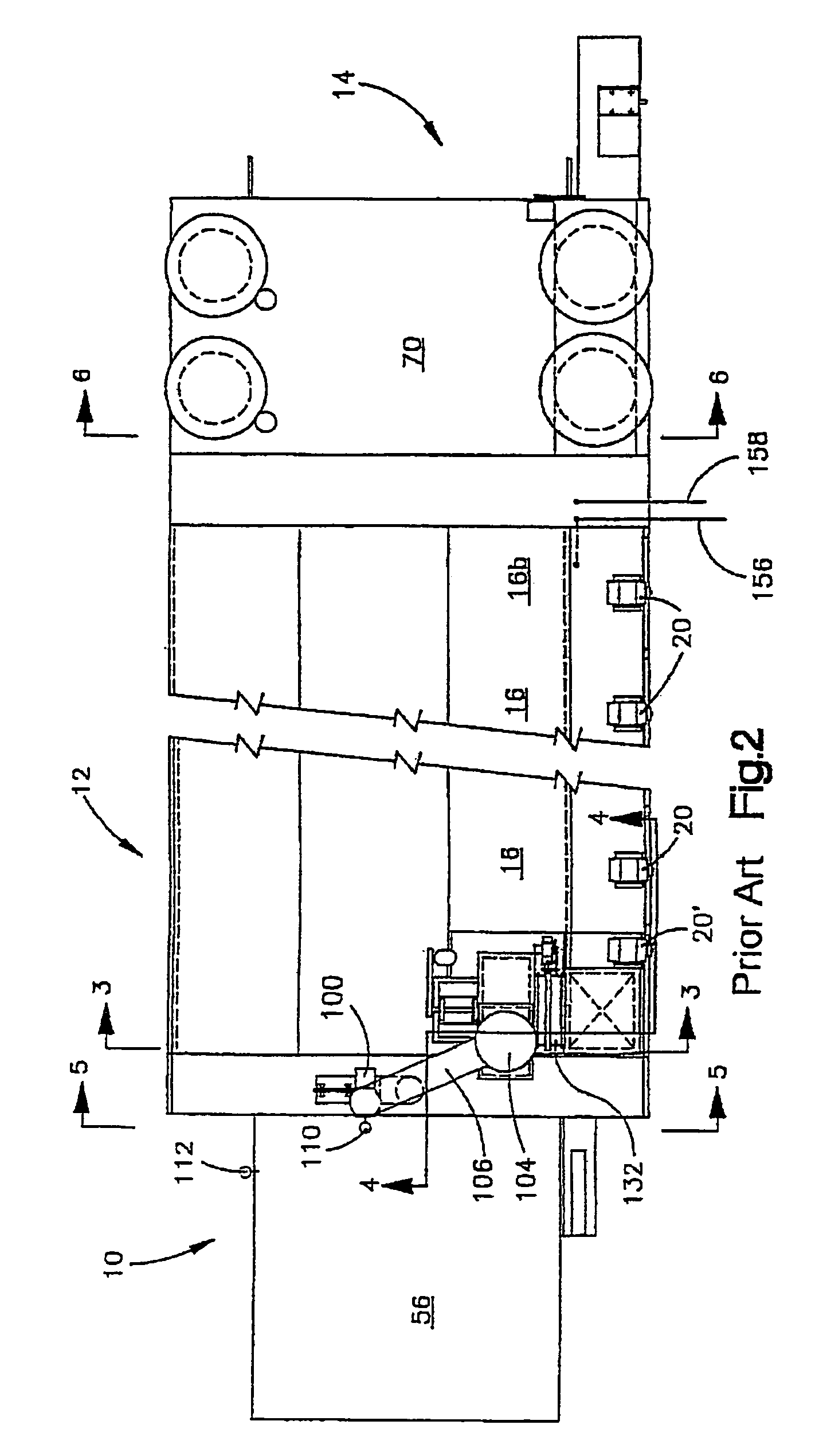

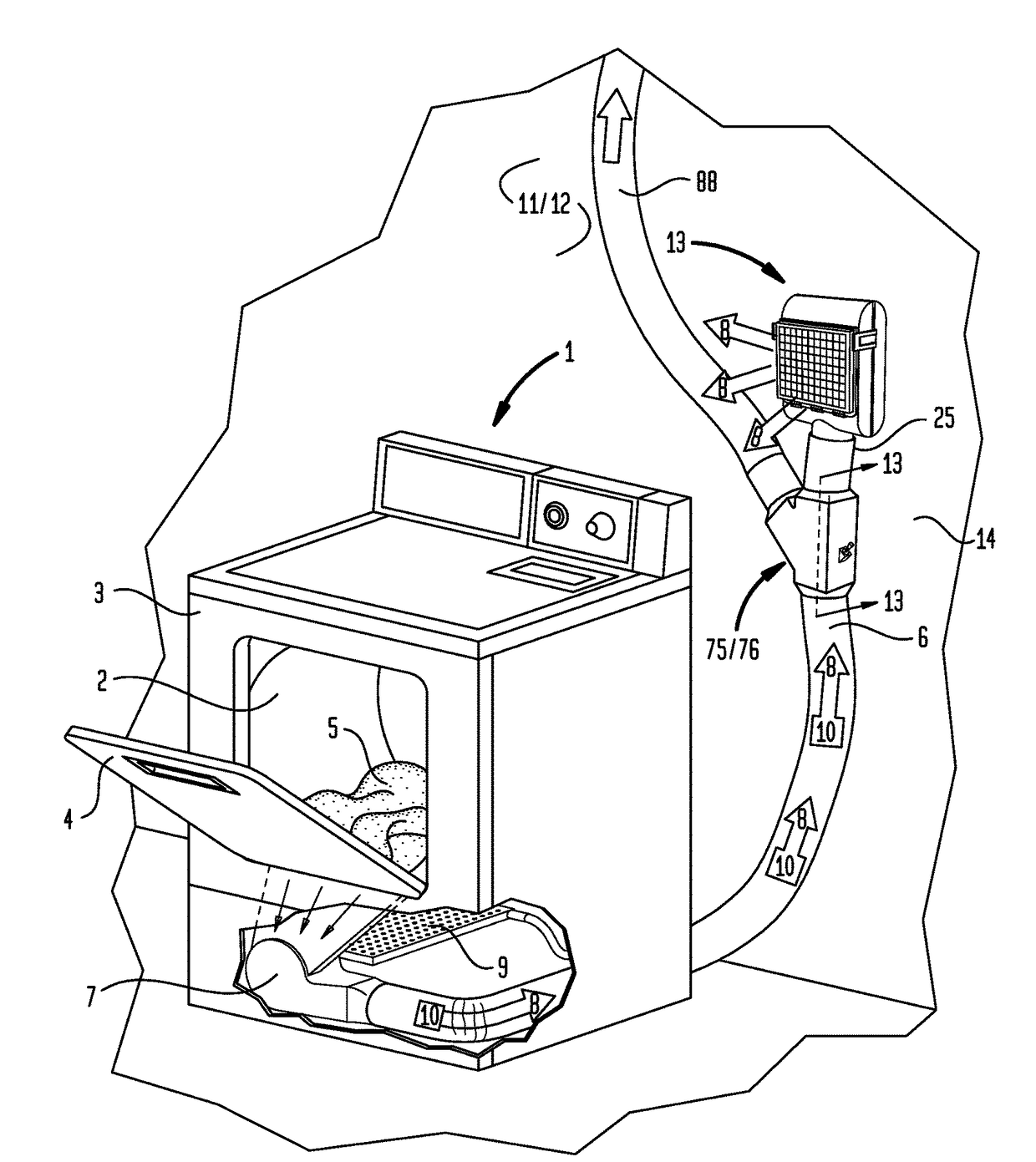

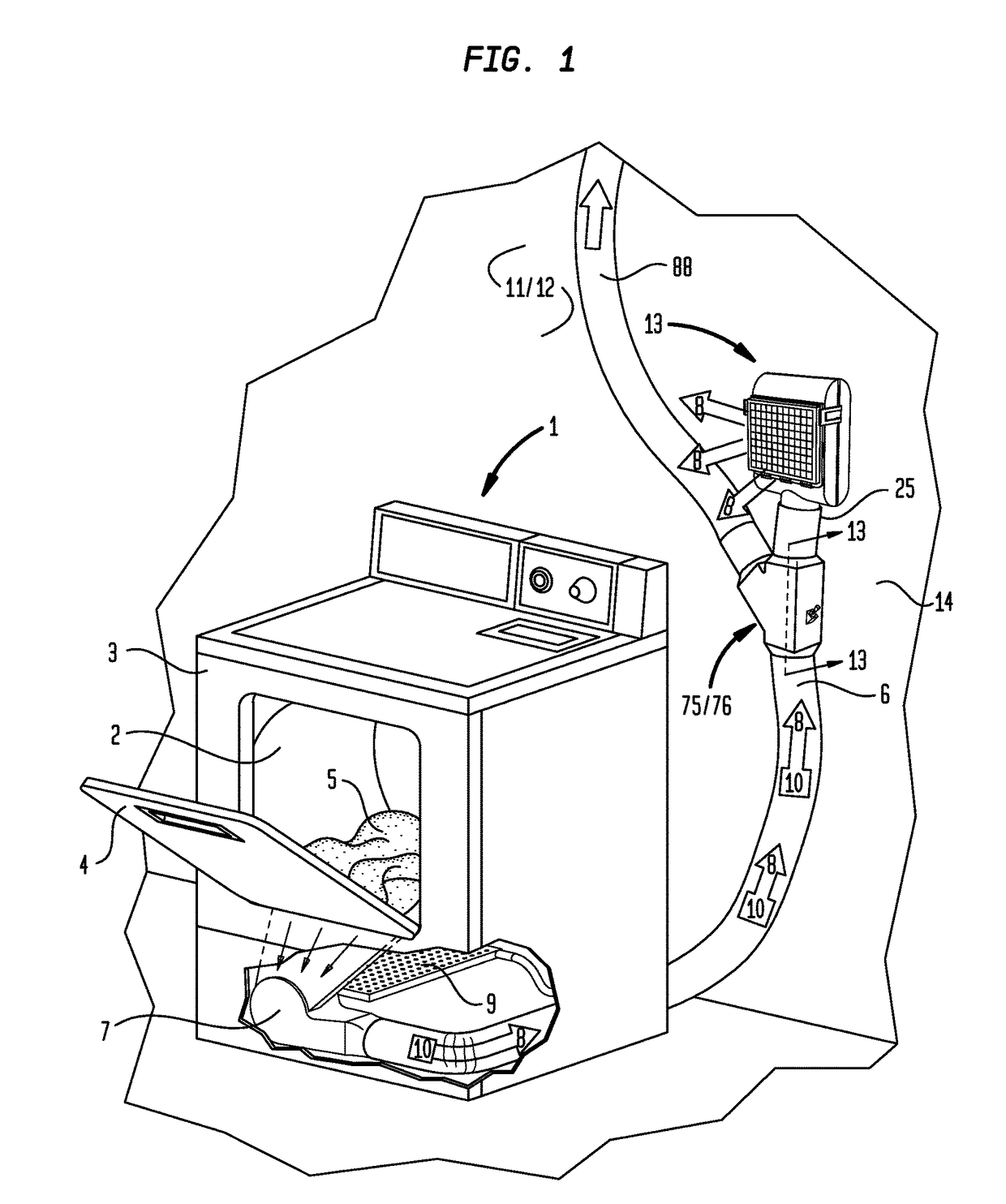

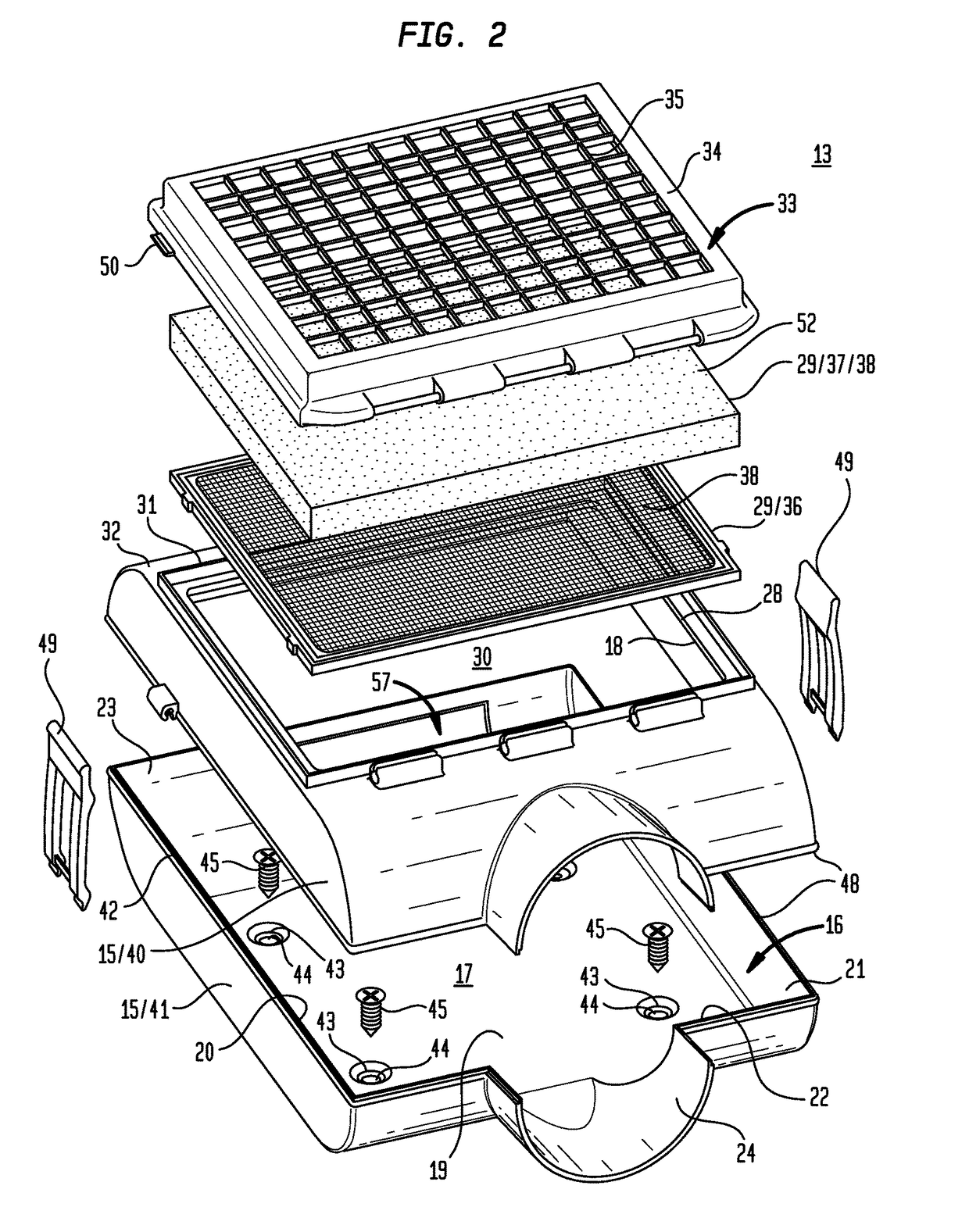

Lint catching system

ActiveUS8893399B2Increase depositionIncrease exhaust flowDrying using combination processesDrying solid materials with heatWaste management

Owner:ADR PROD

Using compressed intake air to clean engine exhaust gas recirculation cooler

InactiveUS8250865B2Improve emission effectReduce heat transferCoolant flow controlInternal combustion piston enginesTurbochargerExternal combustion engine

Systems and methods for using compressed intake air that is free of soot particles to clean the EGR cooler of an internal combustion engine having a turbocharger are provided herein. One example system includes an EGR valve for selectively diverting a portion of exhaust gas through an EGR conduit to an intake side of the internal combustion engine. The EGR cooler is disposed in the EGR conduit. The compressed intake air delivery system is configured to selectively divert a portion of compressed intake air compressed by the turbocharger through the EGR cooler to remove soot particles deposited in the EGR cooler.

Owner:FORD GLOBAL TECH LLC

Engine systems and methods

InactiveUS20050235957A1Minimal inertial lossEfficient expansionInternal combustion piston enginesEfficient propulsion technologiesCombustionHydrogen

The present invention relates generally or preferably to pulsed hypersonic compression waves and more particularly to shaped charge devices using pulsed hypersonic compression waves to create thrust, two-cycle internal and external combustion engines, rotary machines and more specifically to internal and external rotary combustion engines, fluid compressors, vacuum pumps, and drive turbines for expandable gases or pressurized fluid and water, as well as hydrogen.

Owner:DUNCAN RONNIE J

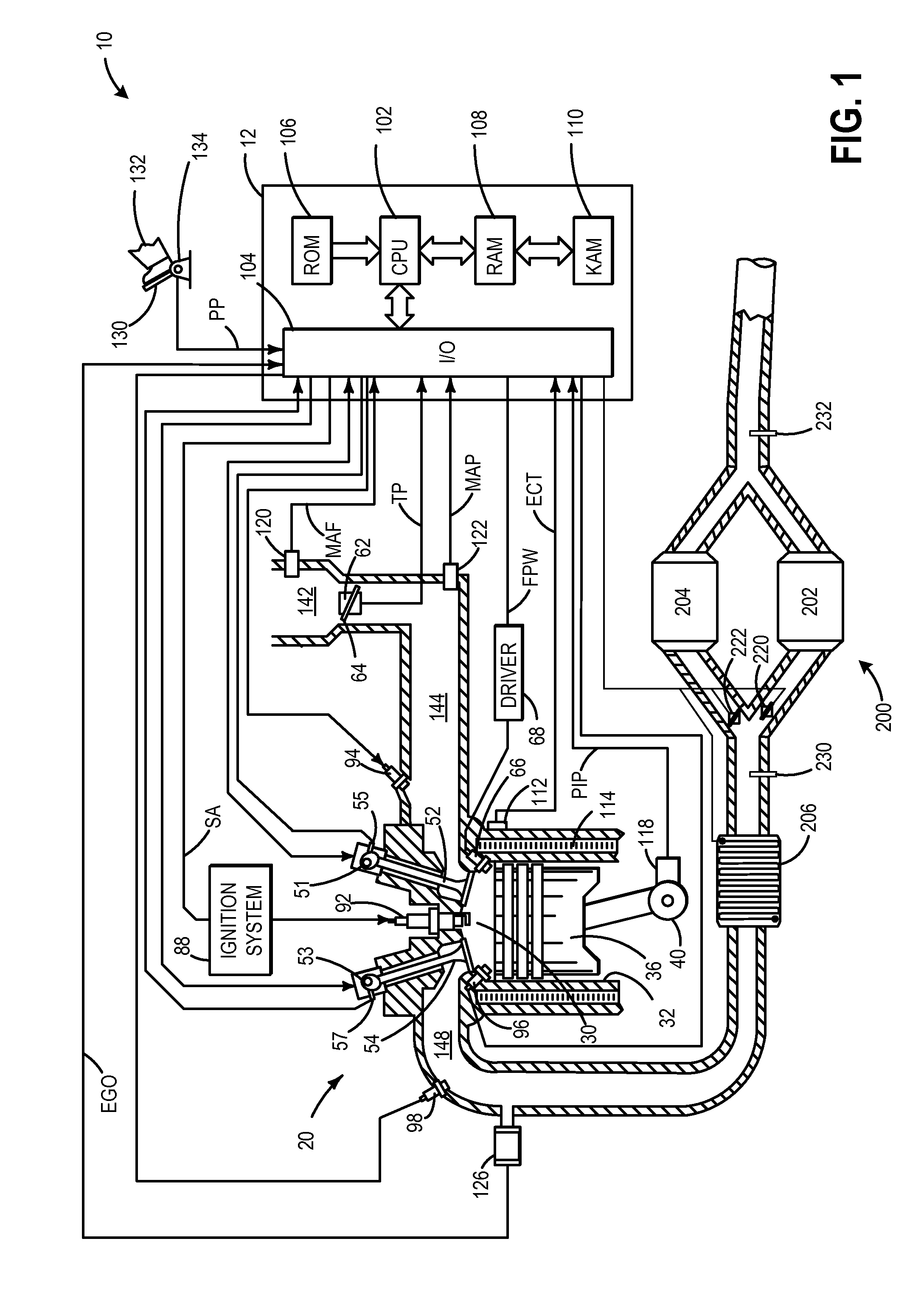

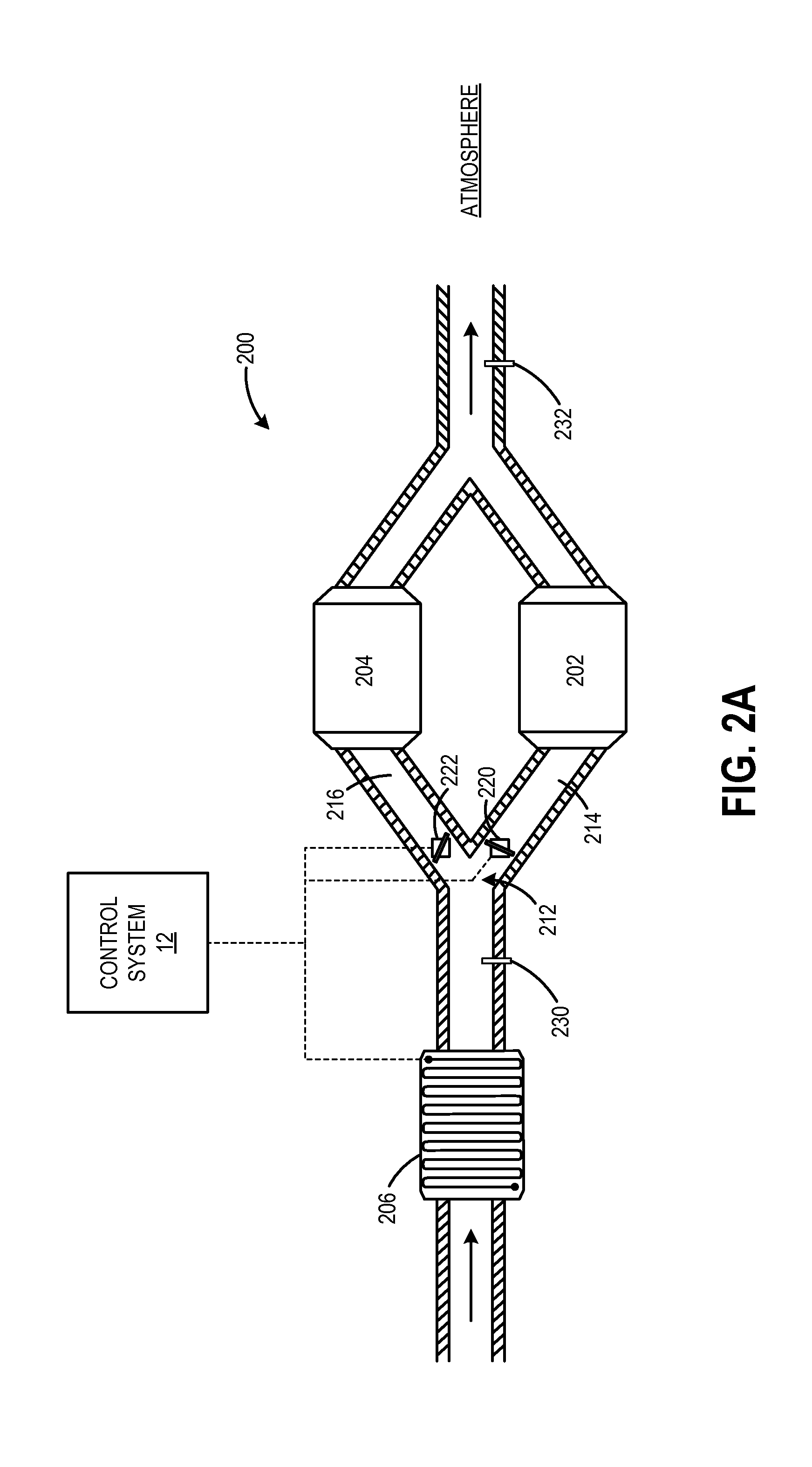

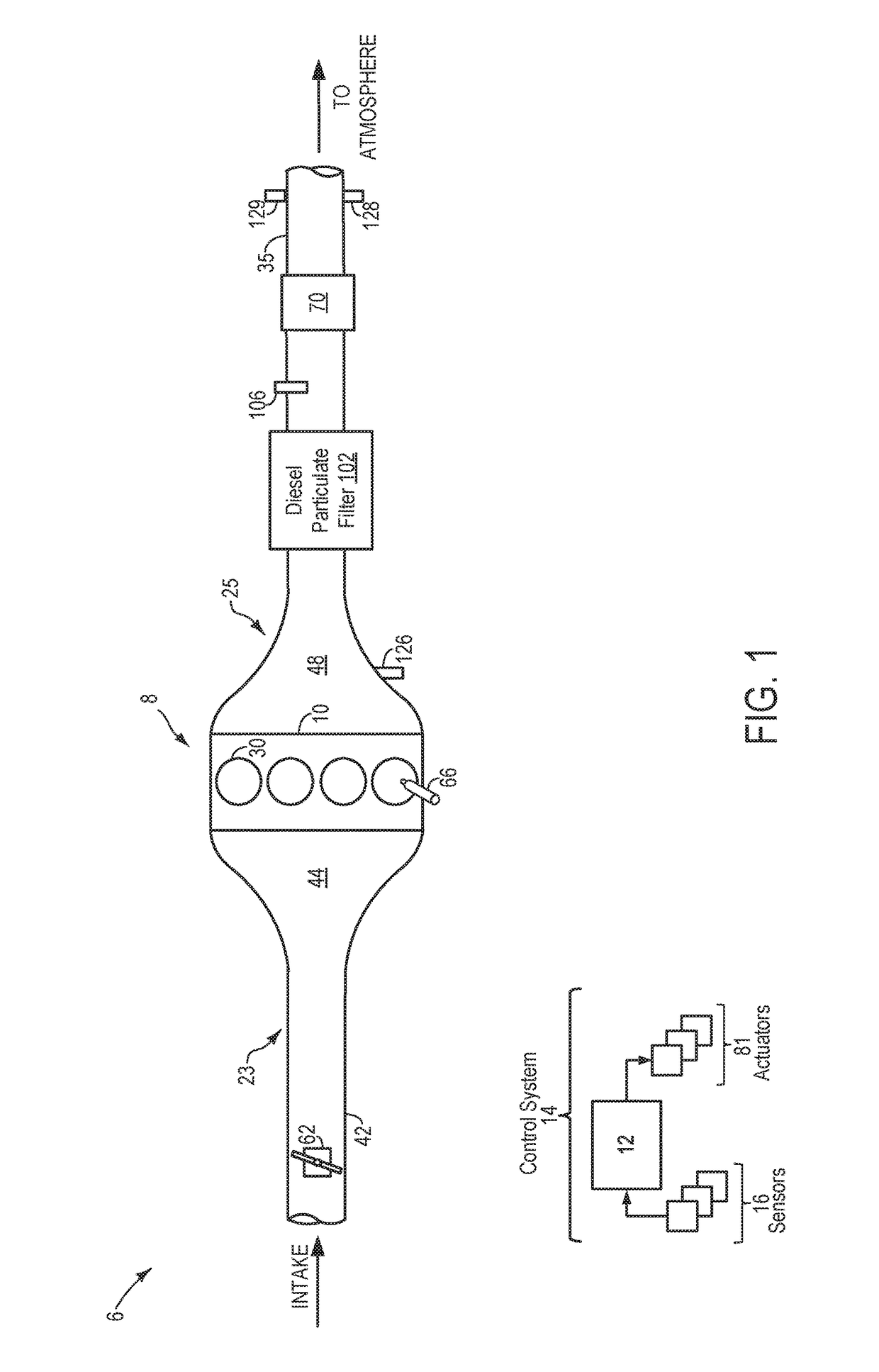

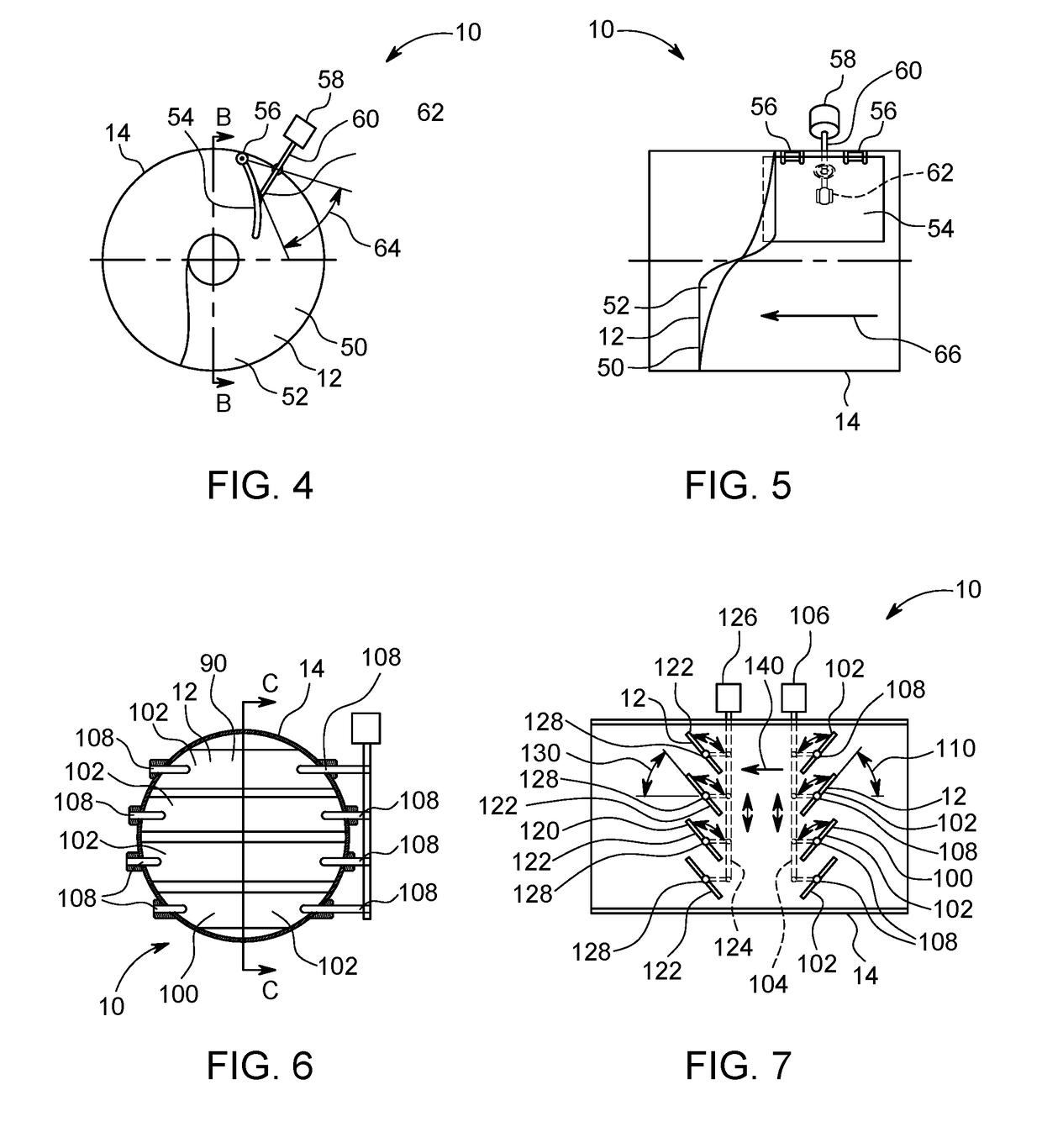

Systems and methods for differential heating of exhaust catalysts

ActiveUS20160251989A1Improve device performanceIncreasing heater thermal outputInternal combustion piston enginesExhaust apparatusOperating temperatureExhaust gas

Exhaust aftertreatment systems and methods are described for reducing emissions output therefrom. In one example, an exhaust gas aftertreatment system comprises a first catalyst downstream of a branchpoint in a first exhaust pathway, a second catalyst downstream of the branchpoint in a second exhaust pathway, an electrical heater positioned upstream of the branchpoint for heating the exhaust flow, a control unit for adjusting an exhaust heating current of the electrical heater, and a valve for adjusting a distribution of exhaust flow to the first and second catalyst, the control unit including instructions to adjust the valve responsive to a substrate temperature within one or more of the first and second catalysts. In this way, an exhaust system with increased efficiency across a range of operating temperatures is realized that reduces emissions and energy expended during usage.

Owner:FORD GLOBAL TECH LLC

Lint Catching System

ActiveUS20130125410A1Increase depositionIncrease exhaust flowDrying gas arrangementsOther manufacturing equipments/toolsWaste management

Owner:ADR PROD

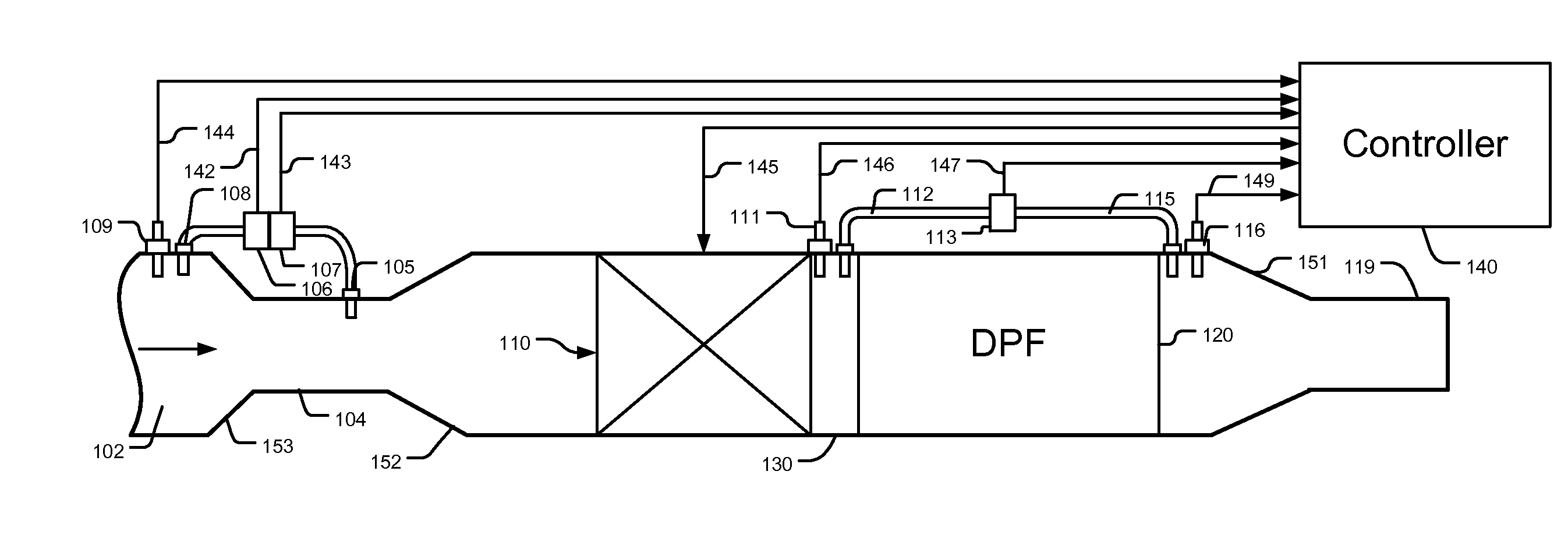

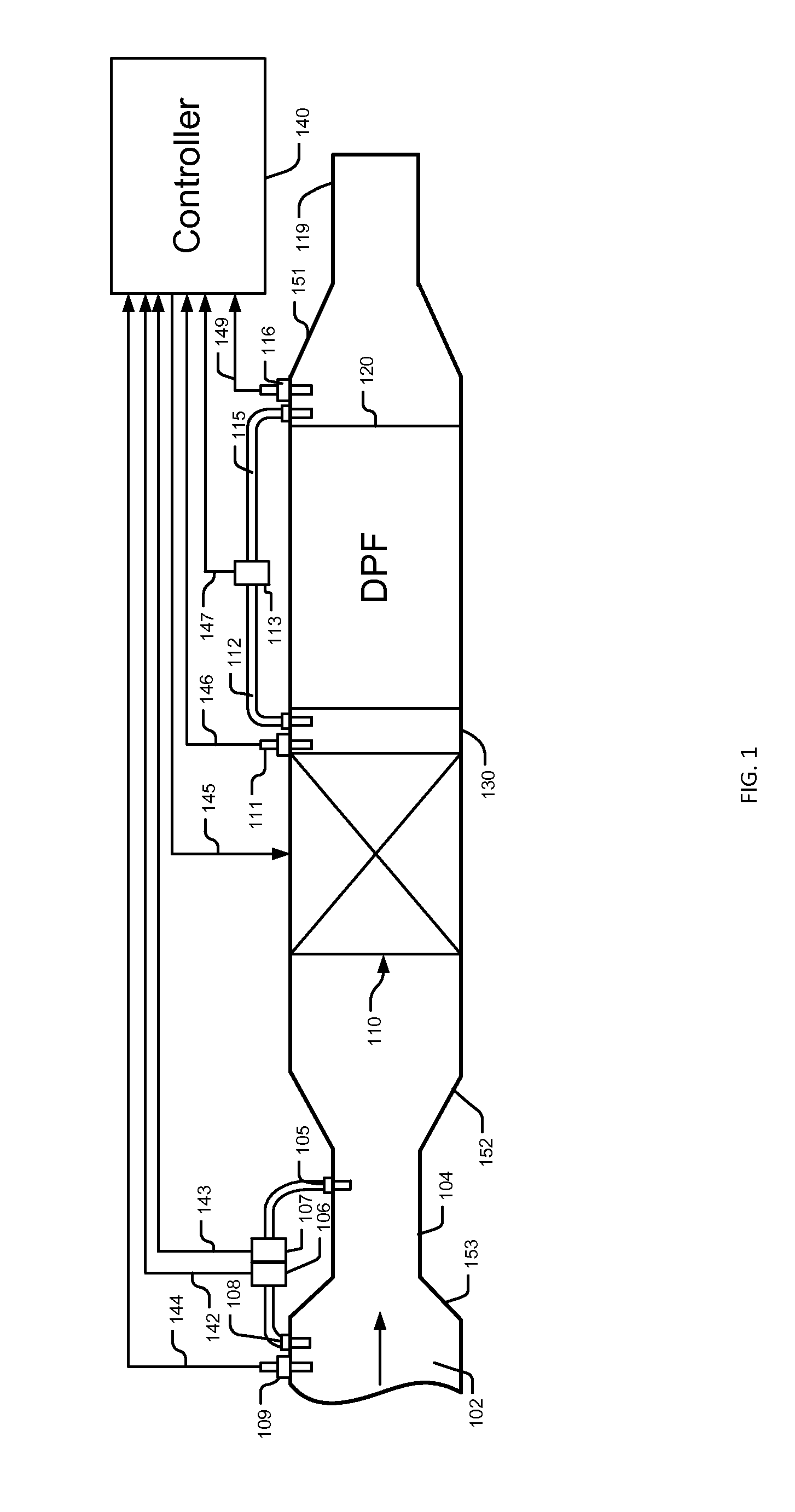

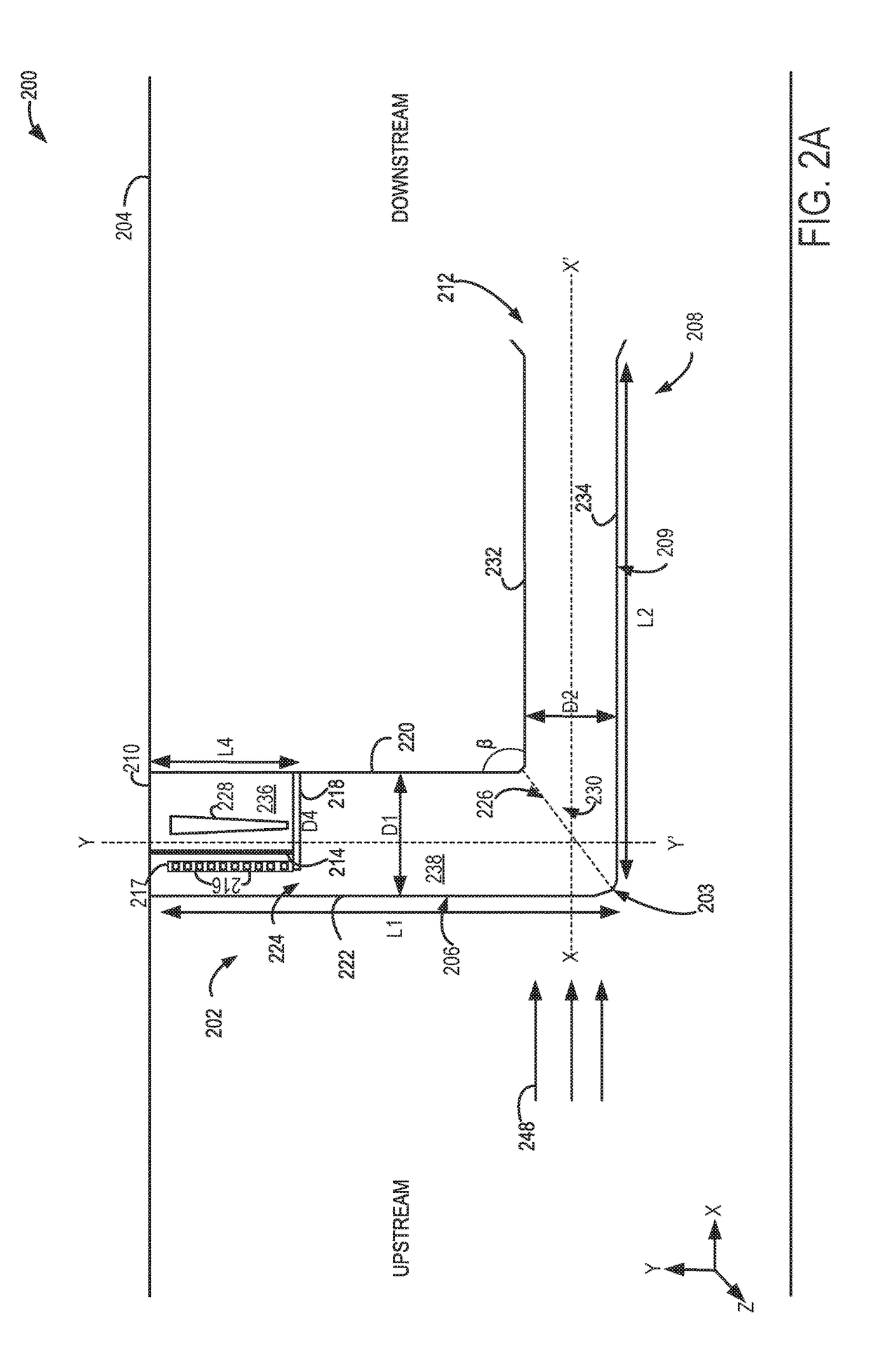

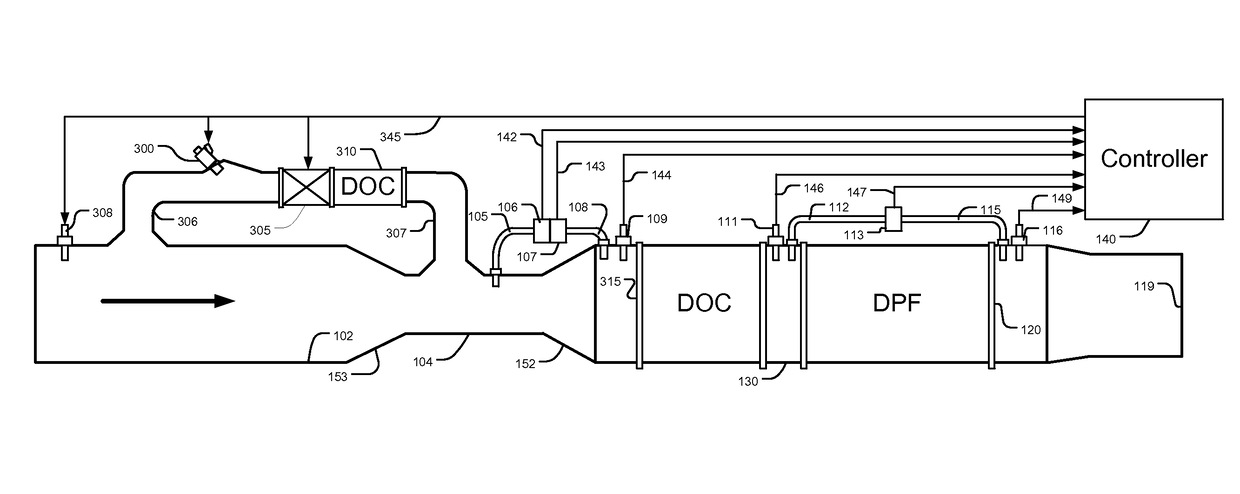

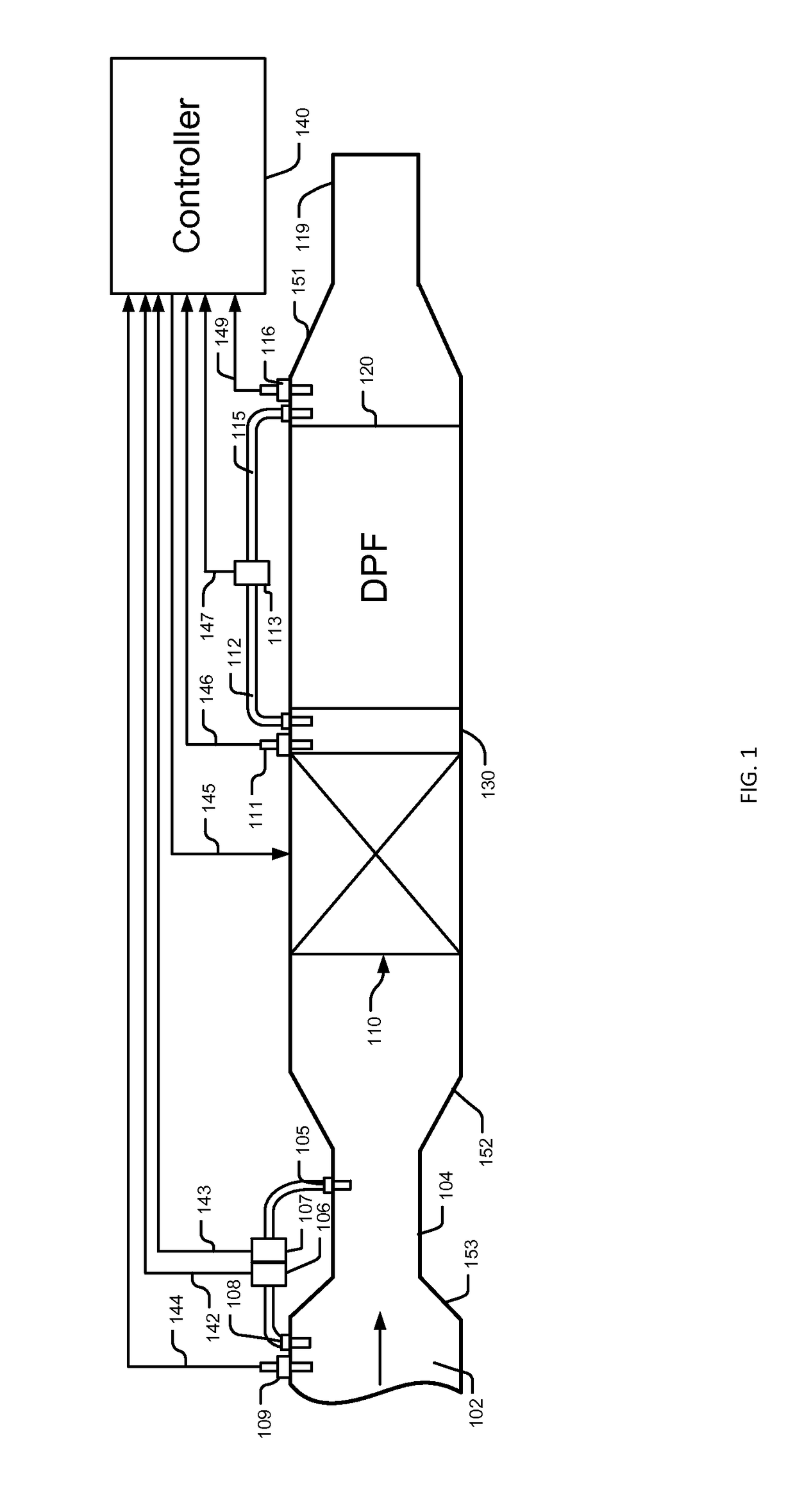

Dpf system with venturi exhaust passage devices

ActiveUS20150361860A1High temperatureHigh efficiencyInternal combustion piston enginesExhaust apparatusThermal runawayExhaust gas

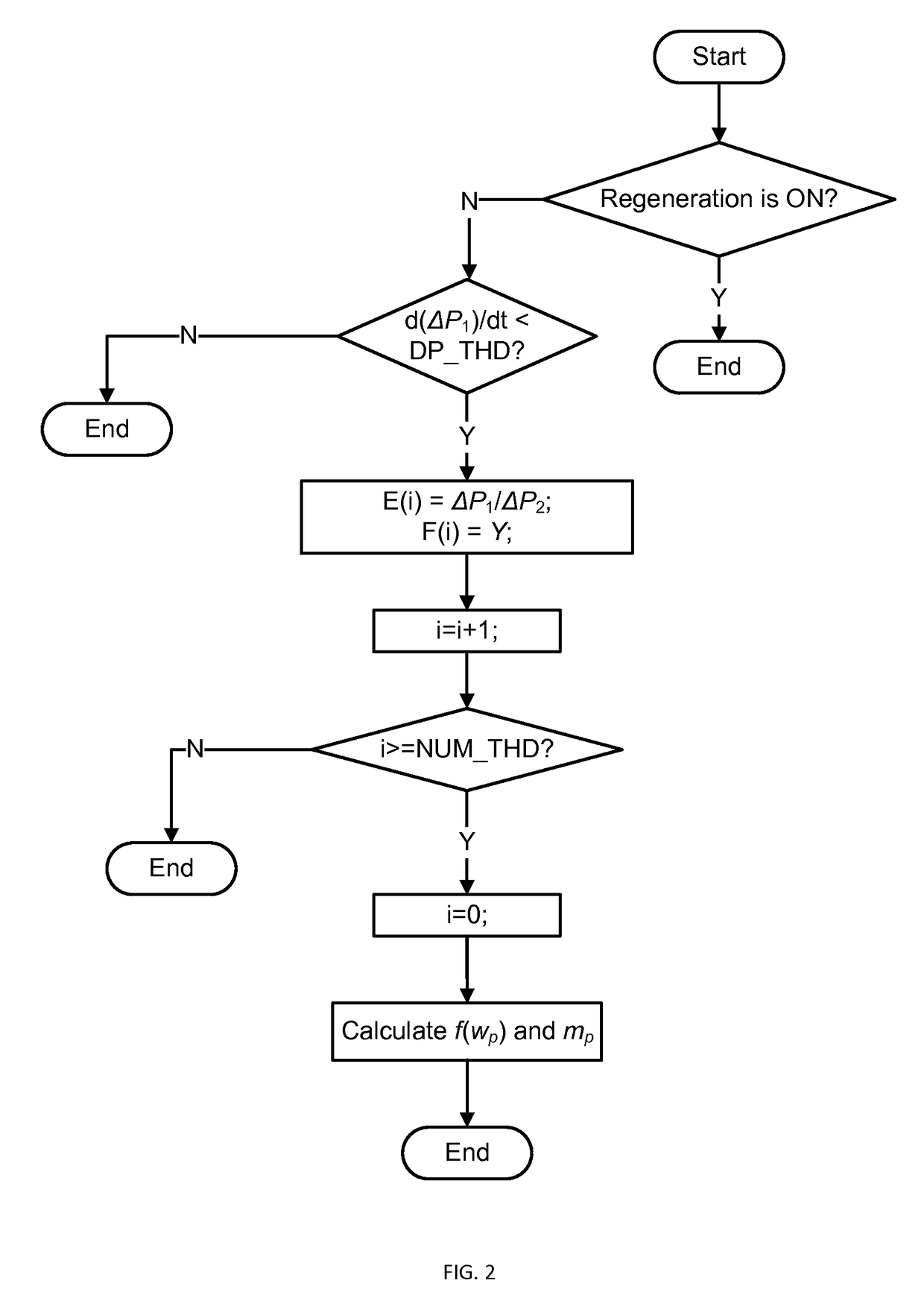

A DPF system including a Venturi exhaust passage device, in which a temperature and a pressure in a high pressure passage are measured, together with a difference of pressures in the high pressure passage and a low pressure passage, while a pressure drop across a DPF is monitored. A PM amount and an exhaust flow rate, which are key parameters in DPF control, can be calculated with the measured values. With the Venturi exhaust passage device, a two-stage bootstrapping heating device with two DOCs and an electrical heater can be used to heat exhaust gas at a temperature lower than a light-off temperature, while a flow-back passage fluidly connected to an outlet of the DPF can be used for increasing exhaust flow-rate and making PM distribution in the DPF more uniform. These technologies decrease risks of thermal runaways, and enable a DPF system controlled without using engine operating parameters.

Owner:QI BAOHUA

Method and apparatus for inhibiting pitch formation in the wet seal exhaust duct of a veneer dryer

ActiveUS8046932B2Reduce moisture contentReduce and increase rateDrying solid materials with heatDrying gas arrangementsCondensation temperatureEngineering

A method and apparatus for operating a dryer used to reduce the moisture content of sheet material. A drying chamber is provided and includes a plurality of drying sections and a single point exhaust system. A seal section located at the input end of the dryer includes an exhaust passage through which a gas sample is drawn by a sampling fan. Gases within the seal section are a combination of ambient air drawn through restricted passages at the entry to the seal section and exhaust gas that bleeds into the seal section from the drying chamber. A controller monitors the temperature of the sampled gases and ambient air and adjusts the rate of exhaust flow from the main exhaust system as a function of the temperature differential. A heating system is also provided for heating the seal exhaust gases above the pitch condensation temperature for the flow.

Owner:USNRKOCKUMS CANCAR +1

Lint catching system and exhaust assembly

ActiveUS9593441B2Increase depositionIncrease exhaust flowDrying solid materialsTextiles and paperWaste management

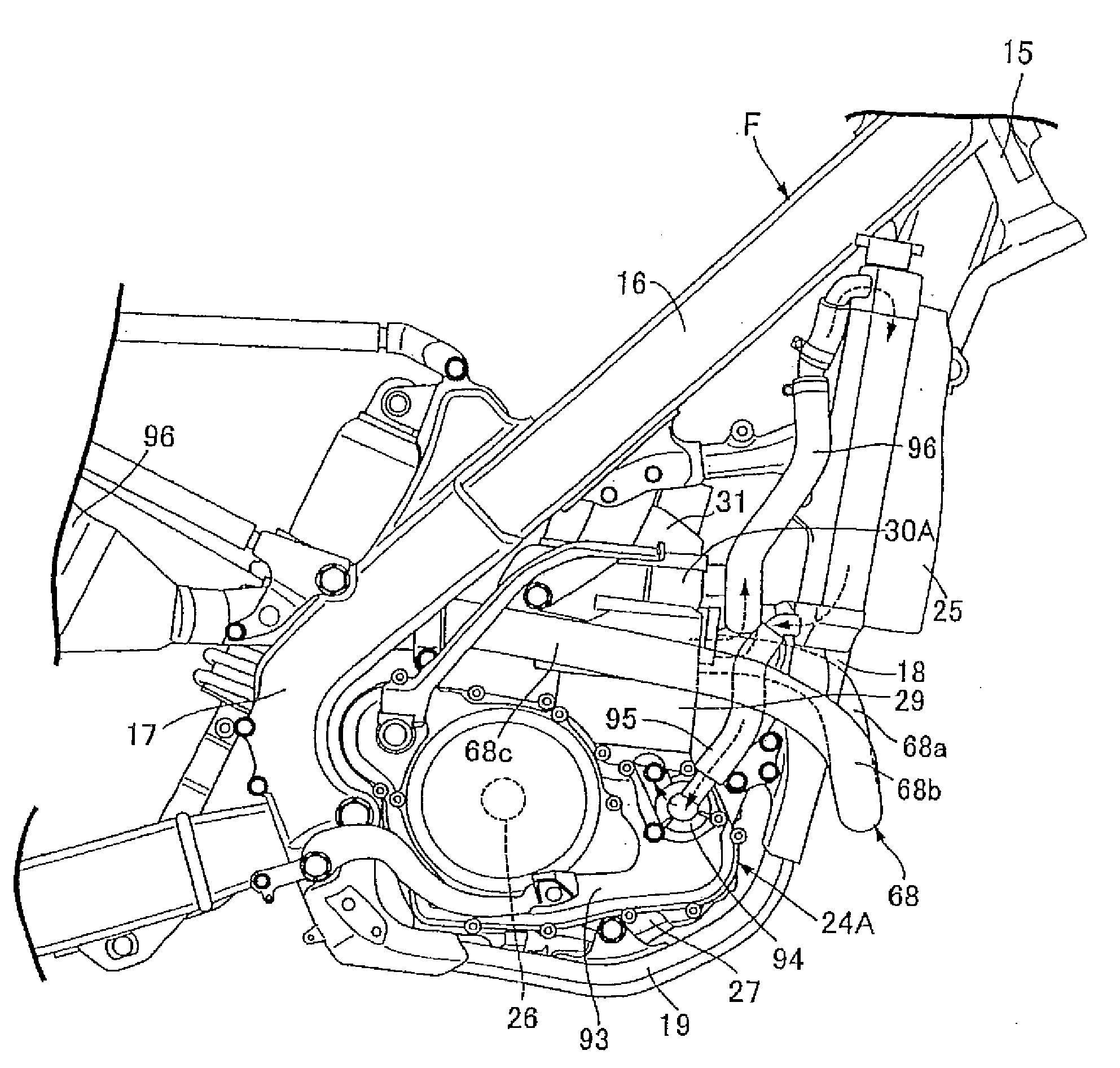

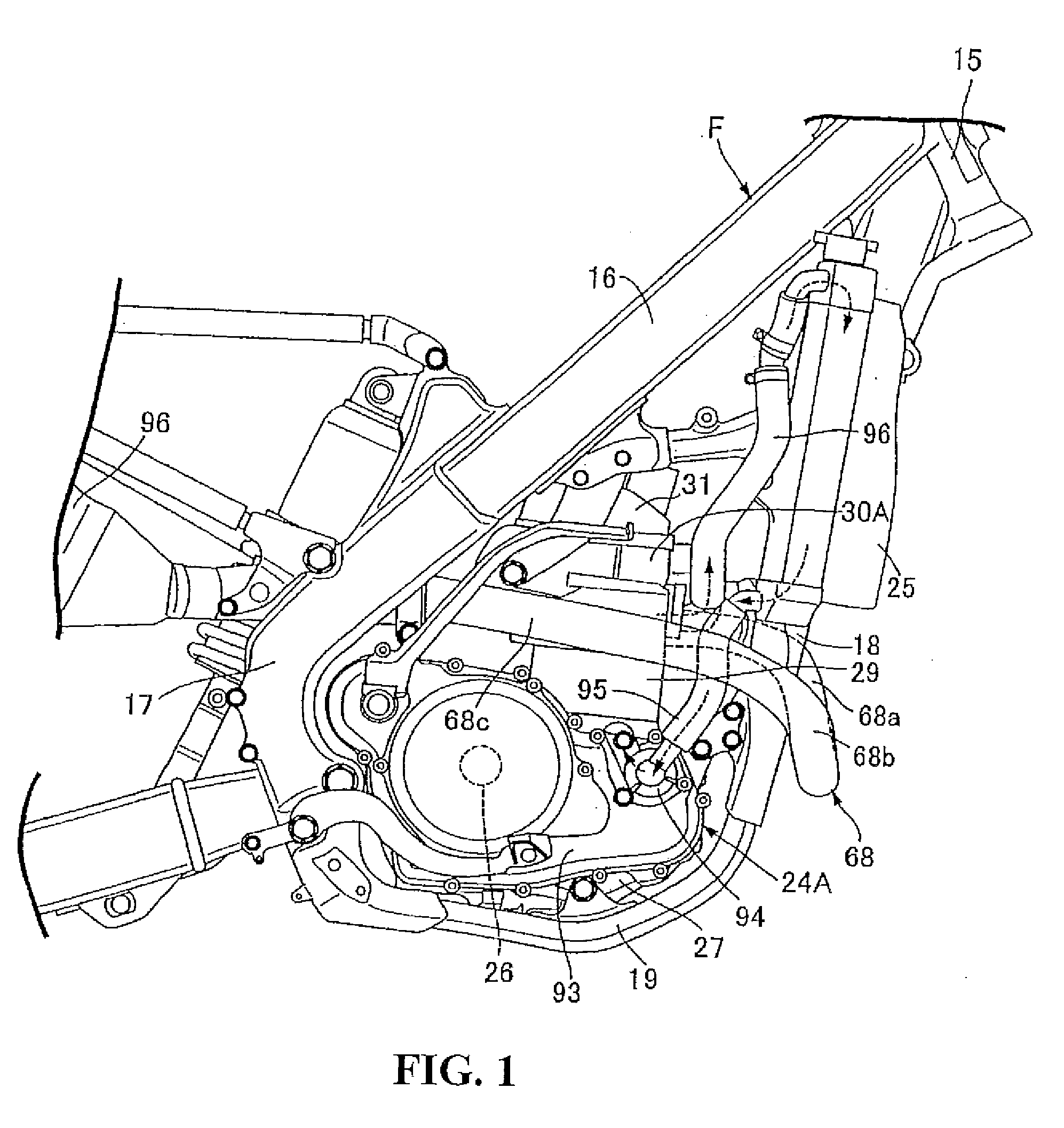

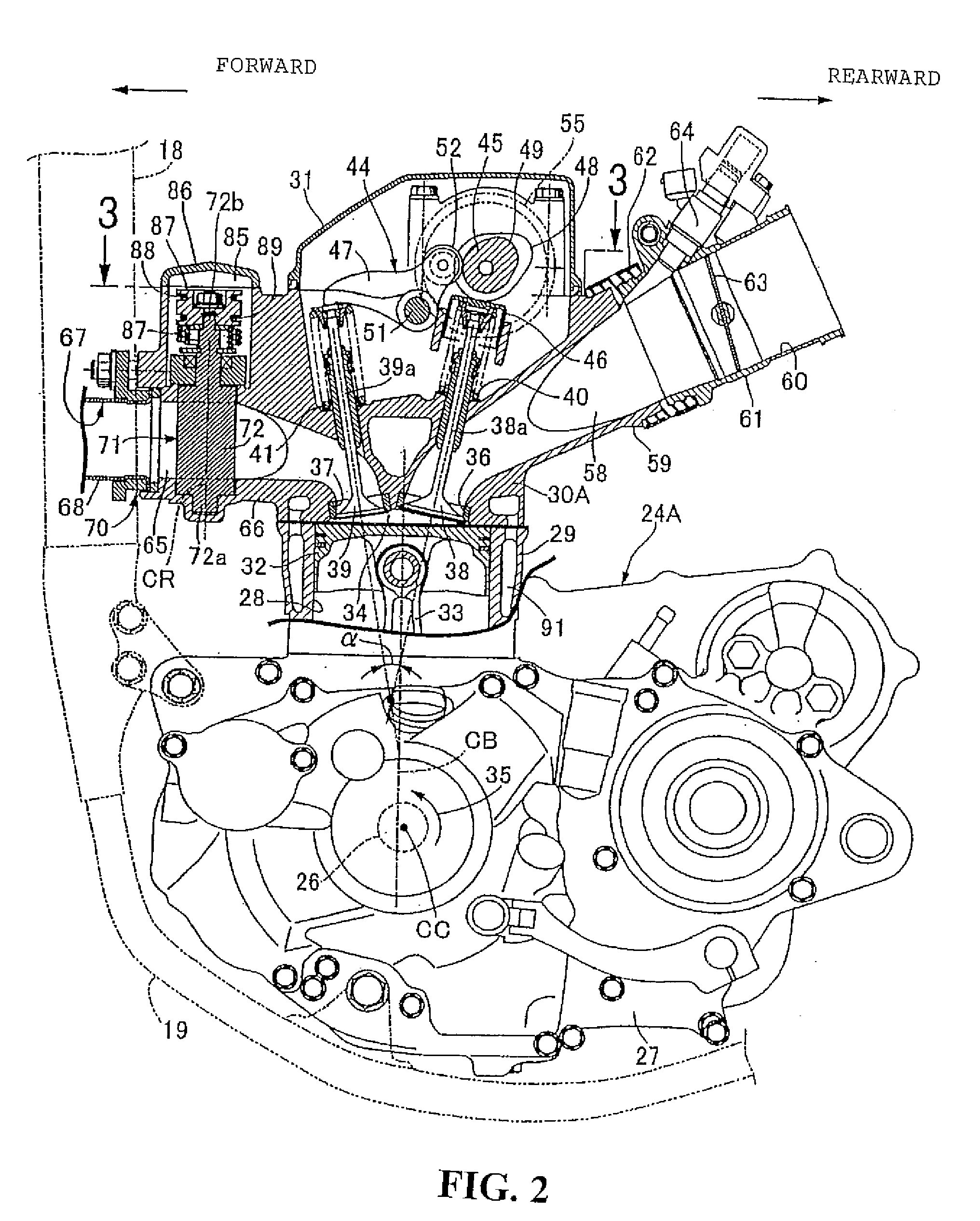

Exhaust control device for vehicle engine

InactiveUS20090084098A1Reduce amount of exhaustHigh exhaust flow rateElectrical controlNon-fuel substance addition to fuelEngineeringExhaust valve

An exhaust control device for a vehicle engine includes an exhaust control valve capable of changing the opening area of an exhaust passage. The exhaust control valve is disposed in exhaust passage forming means so as to be able to change a bent-internal side partial passage sectional area of the passage sectional area of an exhaust passage. Specifically the exhaust control valve is disposed at a bent portion of the exhaust passage that is closest to an exhaust valve port. With this configuration, the exhaust flow rate can be controlled satisfactorily.

Owner:HONDA MOTOR CO LTD

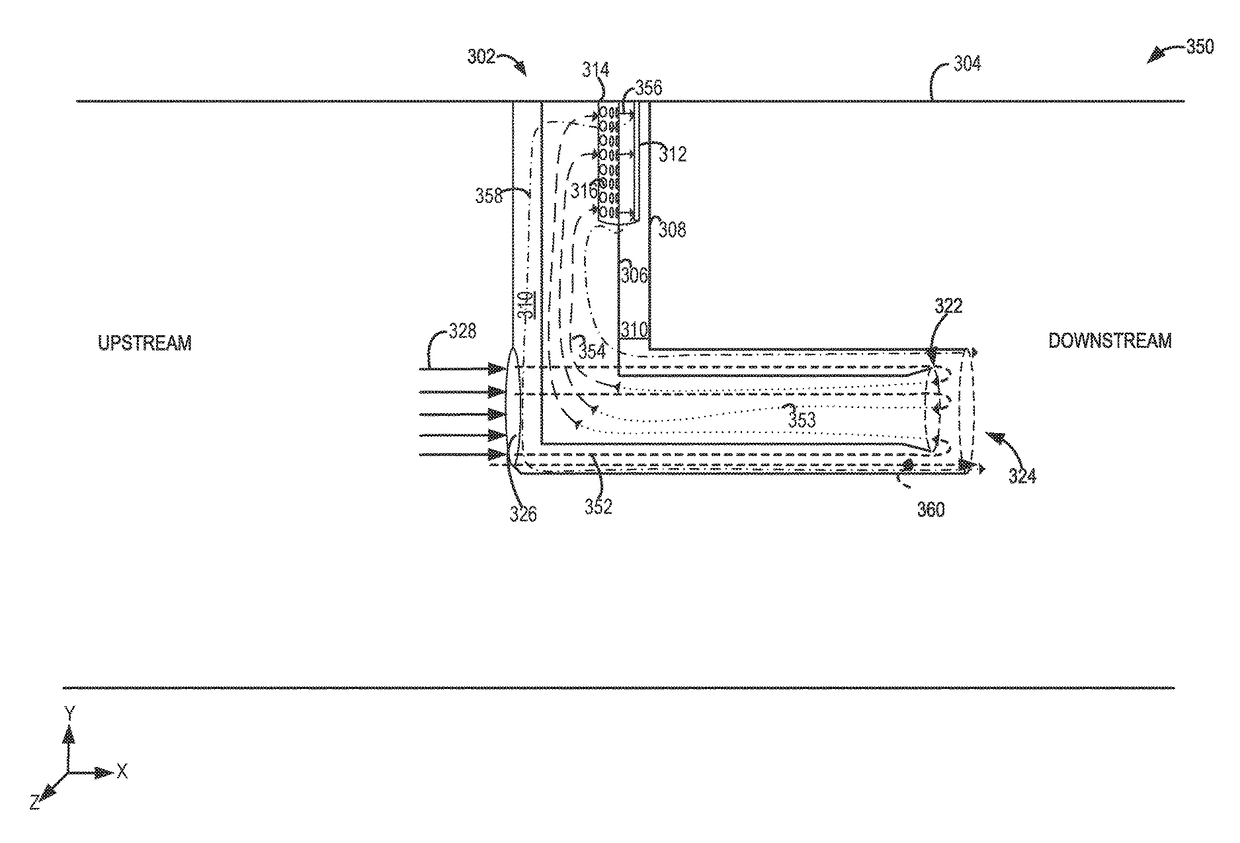

Method and system for exhaust particulate matter sensing

InactiveUS20180023448A1Reduce flow rateReduce sensitivityInternal combustion piston enginesExhaust apparatusEngineeringDiesel particulate filter

Methods and systems are provided for a particulate matter (PM) sensor assembly positioned downstream of a diesel particulate filter in an exhaust system. In one example, a PM sensor assembly may include a bent tube having a first, upstream end coupled to an exhaust passage, and a second outwardly flared end at a downstream end of the assembly. In this way, the second end of the bent tube may form a venturi that serves to block larger particulates from entering the assembly, and additionally serves to increase exhaust flow into the sensor assembly.

Owner:FORD GLOBAL TECH LLC

Marine muffler with angularly disposed internal baffle

ActiveUS20080035422A1Solve the quick installationPerformance in of easeExhaust apparatusValve members for absorbing fluid energyEngineeringMuffler

A marine muffler comprises an elongate cylindrical housing having an inlet and an outlet and defining an internal volume partitioned, by an angularly disposed internal baffle, into a lower chamber in communication with the inlet and an upper chamber in communication with the outlet. A vertically disposed duct is insertably secured to the baffle to allow exhaust gas and exhaust cooling water to flow from the lower inlet chamber to upper outlet chamber. The exhaust duct may preferably be further adapted with internal structure forming a plurality of individual flow conduits or passages. The duct is preferably positioned such that a plurality of flow passage inlets are positioned in proximity to the lower cylindrical housing wall, with flow passage outlets positioned in proximity to the upper housing wall. The lower duct wall may further be adapted with sidewall apertures for improving exhaust flow dynamics therethrough.

Owner:WOODS WOODROW

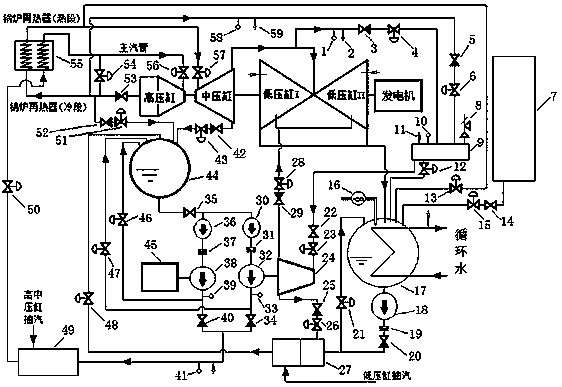

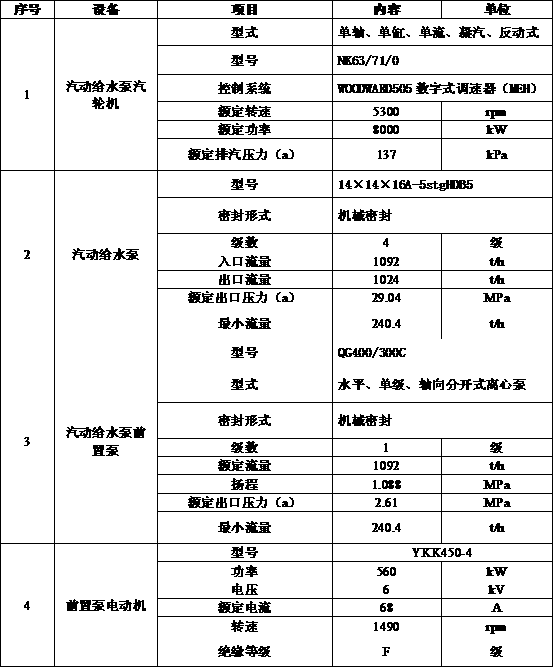

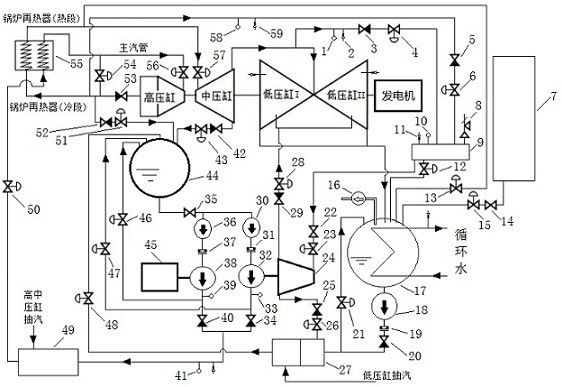

System and method for controlling high back pressure steam feed pump of large generator set

ActiveCN110454769AIncrease exhaust flowReduce heat loadLiquid degasificationWater circulationWorking capacityTemperature measurement

The invention belongs to the technical field of power generation engineering and control thereof, and particularly relates to a system and method for controlling a high back pressure steam feed pump of a large generator set. The system comprises a high back pressure steam feed pump set, an electric feed pump set, a condenser, a low-pressure heater, a steam header, a deaerator, a condensate pump, avacuum pump, a monitoring system, a pressure measuring device, a temperature measuring device, a flow measuring device, a pipeline and a valve. According to the system and method for controlling thehigh back pressure steam feed pump of the the large generator set, the number of the equipment is reduced, the operation efficiency of the equipment is improved, and the working capacity of the exhaust steam of a steam turbine driving the steam feed pump and the condensation of the exhaust steam are fully utilized to release the latent heat of vaporization, so that the energy utilization efficiency and the flexibility of the equipment control are improved.

Owner:GUANGXI POWER GRID ELECTRIC POWER RES INST

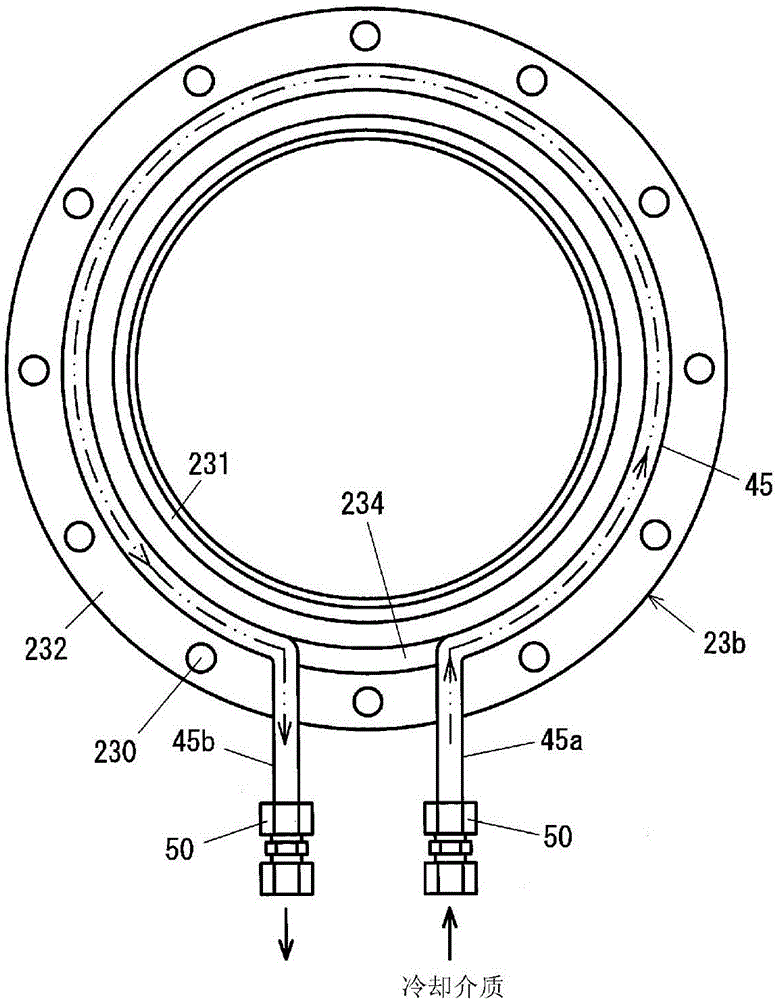

Turbo molecular pump

ActiveCN105952665AAvoid accumulationIncrease exhaust flowPump componentsAxial flow pumpsEngineeringRotary wing

The invention discloses a turbo molecular pump. The turbo molecular pump comprises a rotor, a plurality of sections of fixed wings, a stator and a plurality of separating slices, wherein the rotor is provided with a plurality of sections of rotary wings and a cylinder part; the multiple sections of fixed wings are arranged alternately relative to the multiple sections of rotary wings; the stator is arranged relative to the cylinder part in a spaced mode; the multiple separating slices are laminated on a base where the stator is fixed and used for positioning the multiple sections of fixed wings; and at least one separating slice, arranged on the side of the base, of the multiple separating slices is a cooling separating slice which is cooled by a cooling medium. The cooling separating slice comprises a separating slice part and a cooling part, the separating slice part is laminated with other separating slices, and an annular groove is formed in the cooling part so that a cooling pipe for allowing the cooling medium to flow can be stored. The cooling pipe is formed to be annular and stored in the groove and moreover comprises a cooling medium feed part and a cooling medium discharge part which are arranged on the atmospheric side of the side edge of the cooling separating slice.

Owner:SHIMADZU SEISAKUSHO CO LTD

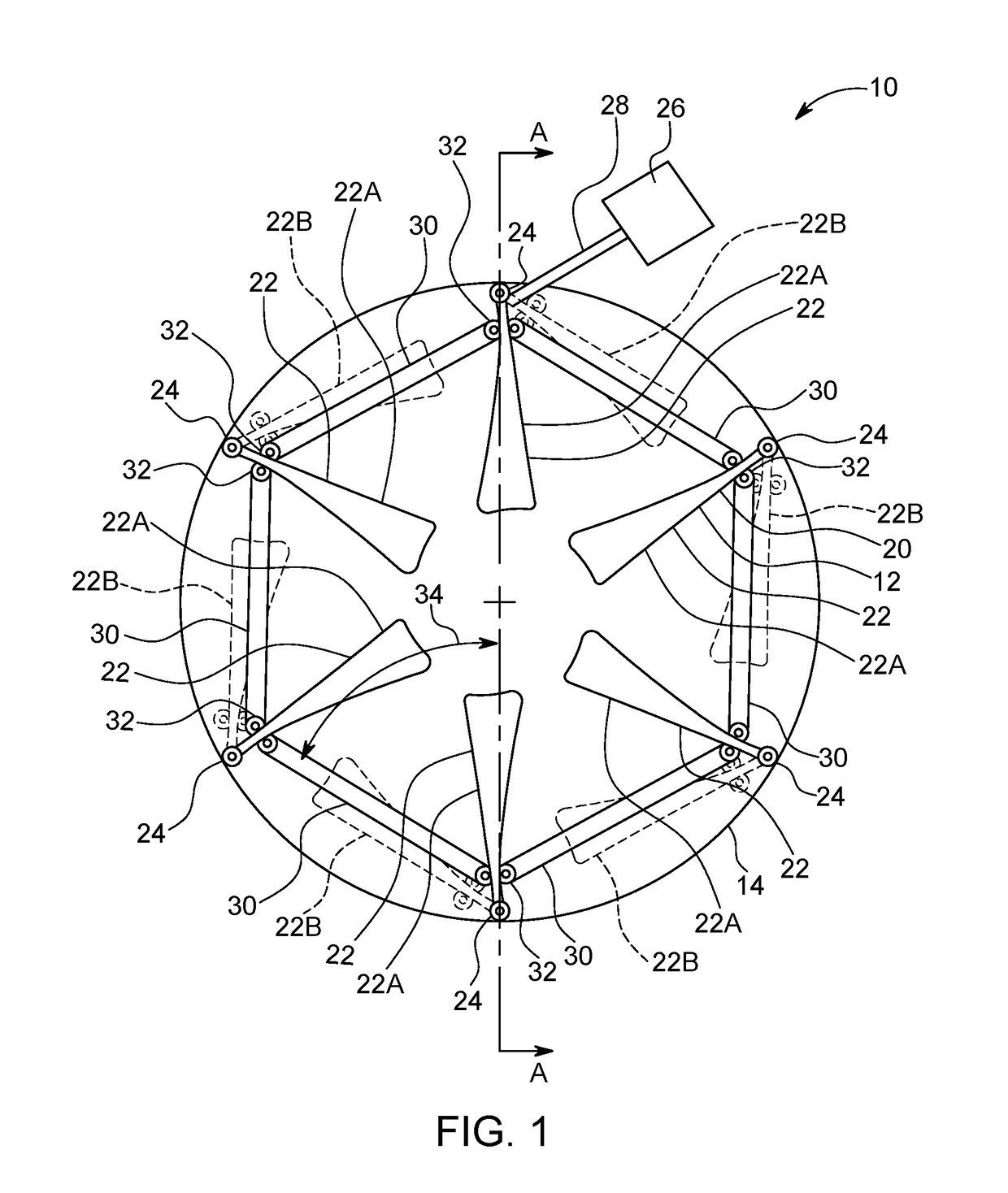

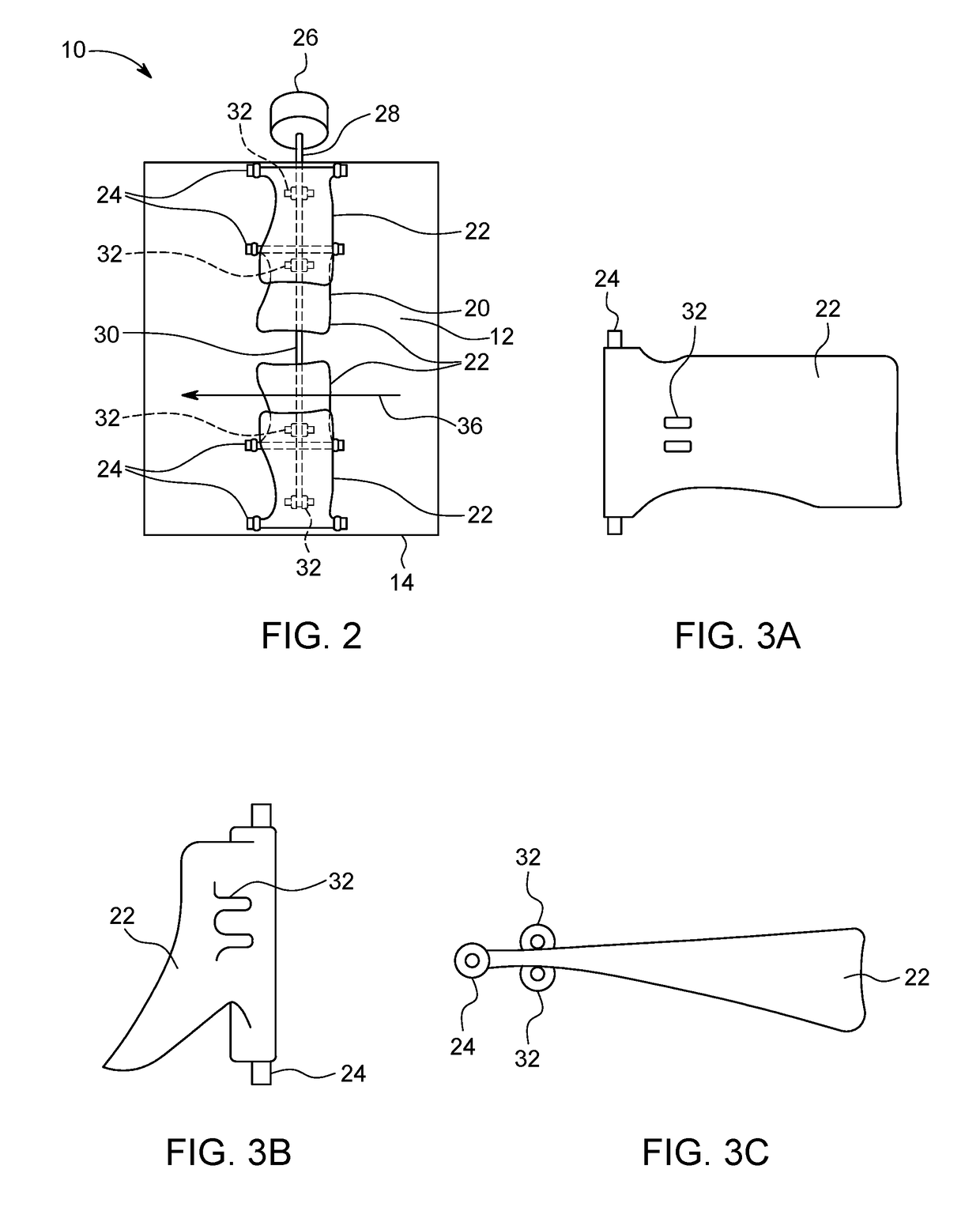

Variable geometry def mixer design

InactiveUS20190040780A1Decreased swirl and rotationSmooth rotationFlow mixersRegistering/indicating working of vehiclesParticulatesVariable geometry

A variable geometry mixer for mixing reductant with engine exhaust includes at least one movable mixer blade or set of movable vanes. The variable geometry mixer is operable to extend the mixer blade(s) into the flow of exhaust under low exhaust flow conditions and to retract the mixer blade(s) out of the flow of exhaust under high exhaust flow conditions, or to increase the angle of the movable vanes under low exhaust flow conditions and to decrease the angle of the movable vanes under high exhaust flow conditions. The movable mixer blade(s) may adjoin at least one fixed geometry defining component. Control of the angle or position of the mixer blade(s) or movable vanes may be based on exhaust flow conditions, exhaust temperature, reductant dosing quantity, a particulate filter regeneration event, vehicle information, vehicle engine information, vehicle location, topographical information, and / or environmental information.

Owner:INT ENGINE INTPROP CO LLC

Marine muffler with angularly disposed internal baffle

ActiveUS20100116585A1Improving exhaust flow dynamicImprove performanceExhaust apparatusValve members for absorbing fluid energyClosed chamberEngineering

A marine muffler comprises an elongate cylindrical housing having an inlet and an outlet and defining an internal volume partitioned, by an angularly disposed internal baffle, into a lower chamber in communication with the inlet and an upper chamber in communication with the outlet. A vertically disposed duct is insertably secured to the baffle to allow exhaust gas and exhaust cooling water to flow from the lower inlet chamber to upper outlet chamber. The exhaust duct may preferably be further adapted with internal structure forming a plurality of individual flow conduits or passages. The duct is preferably positioned such that a plurality of flow passage inlets are positioned in proximity to the lower cylindrical housing wall, with flow passage outlets positioned in proximity to the upper housing wall. The lower duct wall may further be adapted with sidewall apertures for improving exhaust flow dynamics therethrough.

Owner:WOODS WOODROW

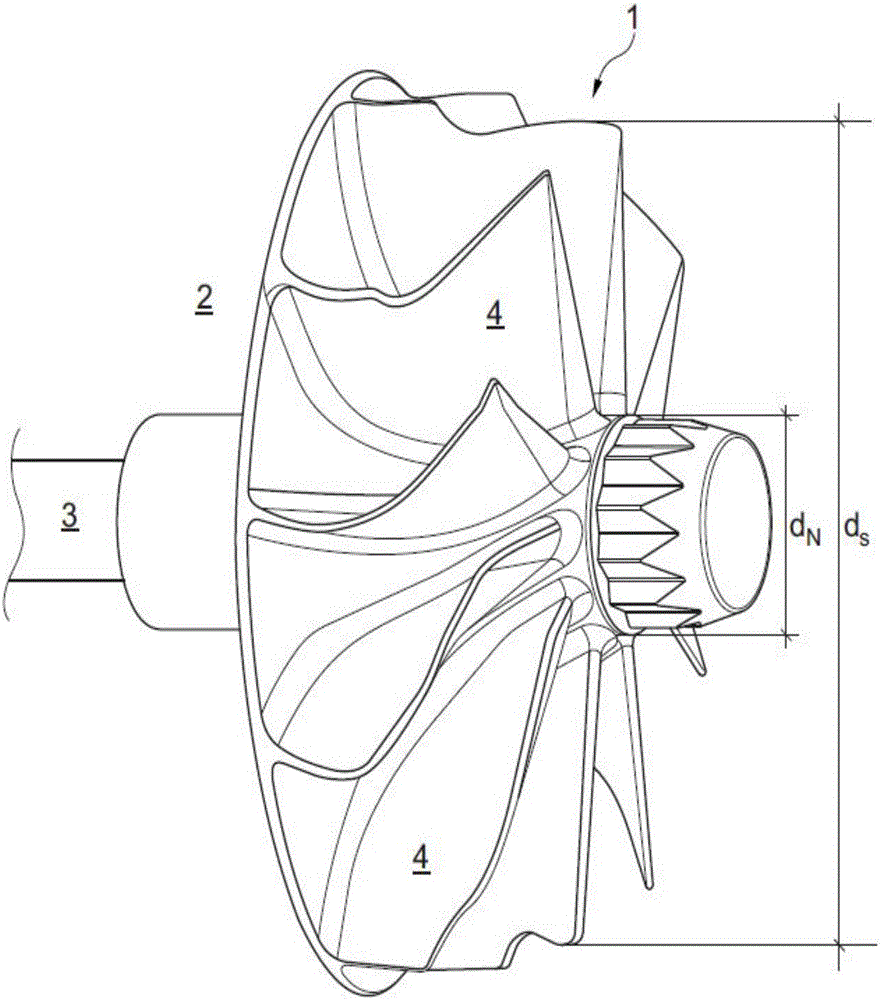

Turbine wheel of an exhaust gas turbocharger and associated production method

InactiveCN105298547AImproved Center of GravityReduce weightTurbinesAdditive manufacturing apparatusExhaust gasEngineering

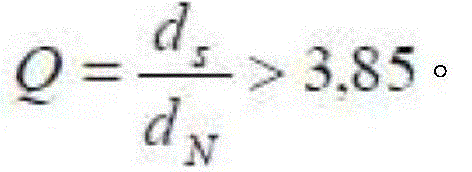

The invention relates to a turbine wheel of an exhaust gas turbocharger which may include a body composed of a TiAl alloy via at a metal injection moulding (MIM), selective laser melting (SIM) or electron beam melting (EBM). The body may have a quotient Q of a diameter dS defined by each of the outlet blade tips to a diameter dN defined by each of the outlet blade roots corresponding to the following relationship: Q=dS / dN>3.85 in this condition.

Owner:BOSCH MAHLE TURBO SYST GMBH & CO KG

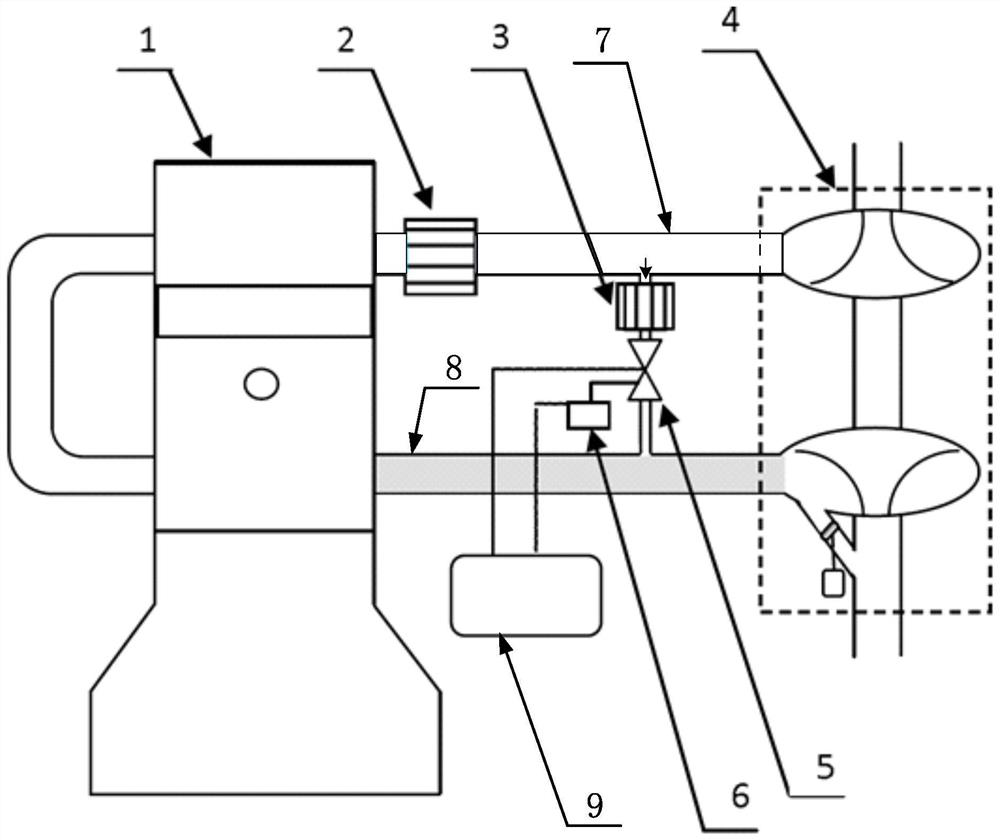

Engine and supercharging system thereof

InactiveCN112539107AIncrease the air-fuel ratioIncrease output powerInternal combustion piston enginesAir compressorHigh torque

The invention discloses an engine and a supercharging system thereof. The supercharging system of the engine comprises an air inlet pipeline, an exhaust pipeline, a bypass pipeline and a bypass valve,wherein the air inlet pipeline is connected with an air compressor and an engine body; the exhaust pipeline is connected with the engine body and a turbine; an air inlet end of the bypass pipeline isconnected with the air inlet pipeline, and an air outlet end is connected with the exhaust pipeline; and the bypass valve is arranged on the bypass pipeline and controls the ventilation capacity of the bypass pipeline. According to the engine and the supercharging system thereof, the bypass valve is properly opened at a certain opening according to requirements under the appropriate working condition, supercharged intake air is bypassed to an exhaust side under the action of differential pressure, and the flow and energy of exhausted air are increased after being bypassed, so that the outputpower of the turbine is increased; and due to increase of surge margin of the engine and increase of the air-fuel ratio, the fuel injection quantity can be increased by the engine to obtain higher torque output, the surge problem of a supercharger cannot be caused, and the reliability of the supercharger is improved.

Owner:WEICHAI POWER CO LTD

Marine muffler with angularly disposed internal baffle

ActiveUS20100000821A1Solve the quick installationPerformance in of easeExhaust apparatusFlushing devicesClosed chamberMuffler

A marine muffler comprises an elongate cylindrical housing having an inlet and an outlet and defining an internal volume partitioned, by an angularly disposed internal baffle, into a lower chamber in communication with the inlet and an upper chamber in communication with the outlet. A vertically disposed duct is insertably secured to the baffle to allow exhaust gas and exhaust cooling water to flow from the lower inlet chamber to upper outlet chamber. The exhaust duct may preferably be further adapted with internal structure forming a plurality of individual flow conduits or passages. The duct is preferably positioned such that a plurality of flow passage inlets are positioned in proximity to the lower cylindrical housing wall, with flow passage outlets positioned in proximity to the upper housing wall. The lower duct wall may further be adapted with sidewall apertures for improving exhaust flow dynamics therethrough.

Owner:WOODS WOODROW

Systems and methods for differential heating of exhaust catalysts

ActiveUS9657621B2Improve device performanceImproved heat outputInternal combustion piston enginesExhaust apparatusElectricityPower flow

Exhaust aftertreatment systems and methods are described for reducing emissions output therefrom. In one example, an exhaust gas aftertreatment system comprises a first catalyst downstream of a branchpoint in a first exhaust pathway, a second catalyst downstream of the branchpoint in a second exhaust pathway, an electrical heater positioned upstream of the branchpoint for heating the exhaust flow, a control unit for adjusting an exhaust heating current of the electrical heater, and a valve for adjusting a distribution of exhaust flow to the first and second catalyst, the control unit including instructions to adjust the valve responsive to a substrate temperature within one or more of the first and second catalysts. In this way, an exhaust system with increased efficiency across a range of operating temperatures is realized that reduces emissions and energy expended during usage.

Owner:FORD GLOBAL TECH LLC

Exhaust-gas aftertreatment system with venturi exhaust passage devices

ActiveUS9689297B2Increase temperatureEfficient conversionInternal combustion piston enginesExhaust apparatusExhaust fumesHigh pressure

A Diesel Particulate Filter (DPF) system including a Venturi exhaust passage device, in which a temperature and a pressure in a high pressure passage are measured, together with a difference of pressures in the high pressure passage and a low pressure passage, while a pressure drop across a DPF is monitored. A PM amount and an exhaust flow rate, which are key parameters in DPF control, can be calculated with the measured values. With the Venturi exhaust passage device, a two-stage bootstrapping heating device with two DOCs and an electrical heater can be further used to heat exhaust gas at a temperature lower than a light-off temperature, while a flow-back passage fluidly connected to an outlet of the DPF can be used for increasing exhaust flow-rate and making PM distribution in the DPF more uniform.

Owner:QI BAOHUA

A control system and control method for a high-back pressure steam-driven feed pump for a large-scale generator set

ActiveCN110454769BIncrease exhaust flowReduce heat loadLiquid degasificationWater circulationSystem pressureDeaerator

The invention belongs to the technical field of power generation engineering and control thereof, and particularly relates to a system and method for controlling a high back pressure steam feed pump of a large generator set. The system comprises a high back pressure steam feed pump set, an electric feed pump set, a condenser, a low-pressure heater, a steam header, a deaerator, a condensate pump, avacuum pump, a monitoring system, a pressure measuring device, a temperature measuring device, a flow measuring device, a pipeline and a valve. According to the system and method for controlling thehigh back pressure steam feed pump of the the large generator set, the number of the equipment is reduced, the operation efficiency of the equipment is improved, and the working capacity of the exhaust steam of a steam turbine driving the steam feed pump and the condensation of the exhaust steam are fully utilized to release the latent heat of vaporization, so that the energy utilization efficiency and the flexibility of the equipment control are improved.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

Turbo-molecular pump

ActiveUS9745989B2Avoid accumulationIncrease exhaust flowPump componentsEngine fuctionsEngineeringCoolant

A turbo-molecular pump comprises: a rotor; stationary blades; a stator; a plurality of spacers; a heater disposed on the base; a temperature sensor for detecting a temperature of the stator; and a temperature regulation section for on / off controlling the heater based on a temperature detected by the temperature sensor to regulate the temperature of the stator so as to be a reaction product accumulation prevention temperature. At least one spacer arranged on a base side of the plurality of spacers is cooled by coolant, and the turbo-molecular pump further comprises a heat insulation member disposed between the base and the spacer arranged on the base.

Owner:SHIMADZU CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com