Engine and supercharging system thereof

A supercharger system and engine technology, which is applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of reduced reliability of superchargers, unfavorable reliability of superchargers, overheating of turbines, etc. The effects of increased volume, high torque output, and increased air-fuel ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

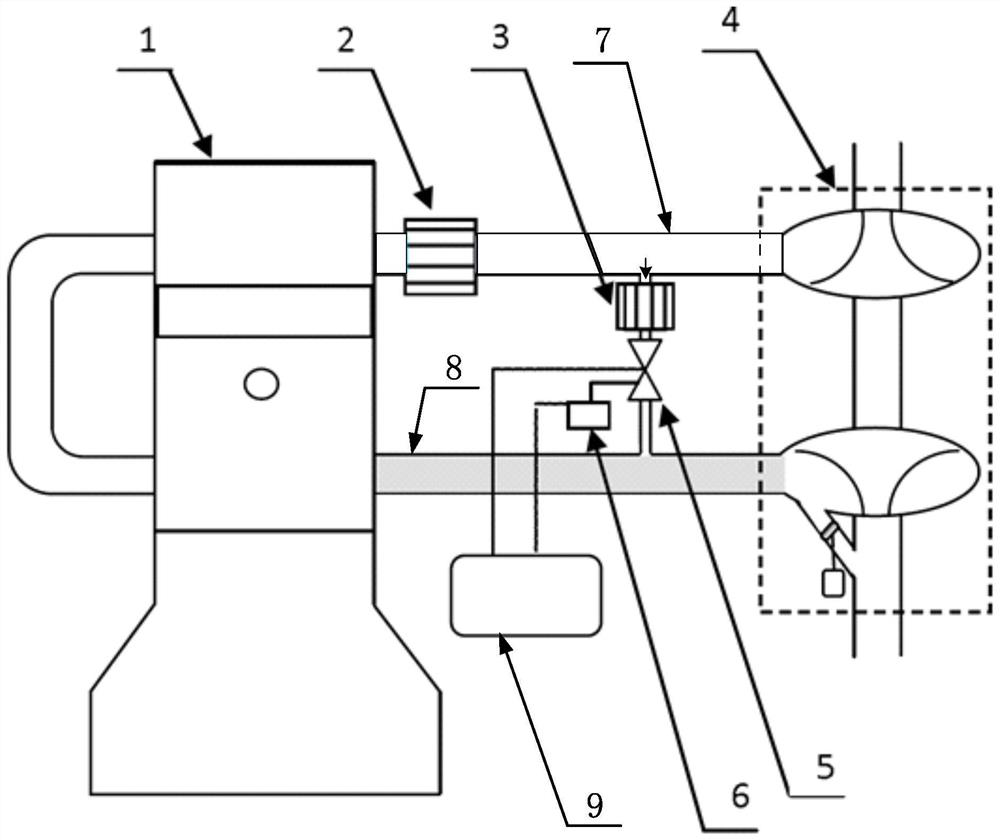

[0027] The core of the present invention is to provide an engine supercharging system to improve the reliability of the supercharger. Another core of the present invention is to provide an engine including the above-mentioned supercharging system.

[0028] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

[0029] Please refer to figure 1 and figure 2 .

[0030] In a specific embodiment, the supercharging system of the engine provided by the specific embodiment of the present invention includes an intake pipe 7 , an exhaust pipe 8 , a bypass pipe and a bypass valve 5 . Among them, the supercharging system can be used in diesel engines. The intake duct 7 connects the compressor 4-1 and the engine body 1, and the exhaust duct 8 connects the engine body and the turbine 4-2. The inlet end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com