High-barrier all-biodegradable BOPLA film and preparation method thereof

An all-biological, high-barrier technology, applied in chemical instruments and methods, flat products, other household appliances, etc., can solve the problem of poor barrier performance of polylactic acid films, eliminate white pollution and marine plastic pollution, and reduce processes. Steps, excellent results of physical and mechanical performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

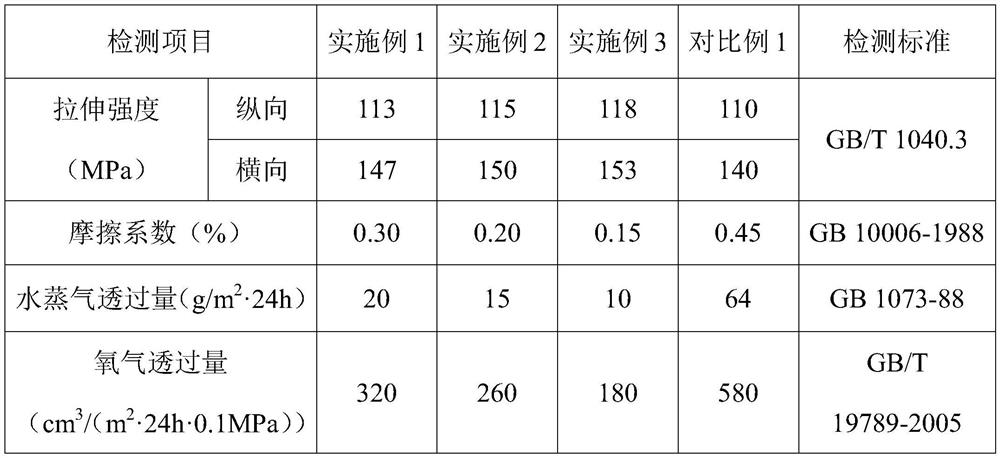

Examples

Embodiment 1

[0026] The high-barrier, fully biodegradable BOPLA film proposed by the present invention is composed of an upper surface layer, a core layer and a lower layer. The thickness of the upper surface layer and the lower layer respectively account for 10% of the total thickness of the film.

[0027] The upper surface layer is an organic polymer anti-adhesive layer, and its material is blended by weight percentages of the following components: 95% polylactic acid chips, 5.0% organic polymer anti-adhesive masterbatch; among them, the organic polymer anti-adhesive masterbatch is The polymethyl methacrylate microbeads and polylactic acid chips are mixed and co-extruded according to a weight ratio of 3:97. The active ingredient content of the polymethyl methacrylate microbeads is 2500ppm and the particle size is 2.0μm. The thermal decomposition temperature is 260°C.

[0028] The core layer is a quaternary compound polylactic acid layer, and its materials are blended by weight percentages of ...

Embodiment 2

[0040] The high-barrier, fully biodegradable BOPLA film proposed by the present invention is composed of an upper surface layer, a core layer and a lower layer, and the thickness of the upper surface layer and the lower layer respectively account for 13% of the total thickness of the film.

[0041] The upper surface layer is an organic polymer anti-adhesion layer, and its material is blended by weight percentages of the following components: 94% polylactic acid chip, 6.0% organic polymer anti-adhesion masterbatch; among them, the organic polymer anti-adhesion masterbatch is The polymethyl methacrylate microbeads and polylactic acid chips are mixed and melted and co-extruded in a weight ratio of 4:96. The effective ingredient content of the polymethyl methacrylate microbeads is 2800ppm, and the particle size is 2.2μm. The thermal decomposition temperature is 270°C.

[0042] The core layer is a quaternary compound polylactic acid layer, and its material is blended by weight percentag...

Embodiment 3

[0054] The present invention proposes a high-barrier, fully biodegradable BOPLA film, which is composed of an upper surface layer, a core layer and a lower layer. The thickness of the upper surface layer and the lower layer respectively account for 15% of the total thickness of the film.

[0055] The upper surface layer is an organic polymer anti-adhesive layer, and its material is blended by weight percentages of the following components: polylactic acid chips 92%, organic polymer anti-adhesive masterbatch 8.0%; among them, organic polymer anti-adhesive masterbatch is The polymethyl methacrylate microbeads and polylactic acid chips are mixed and melted and co-extruded in a weight ratio of 5:95. The effective ingredient content of the polymethyl methacrylate microbeads is 3000ppm, and the particle size is 2.5μm. The thermal decomposition temperature is 280°C.

[0056] The core layer is a quaternary compound polylactic acid layer, and its materials are blended by weight percentages ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com