Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Improve moisture resistance reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

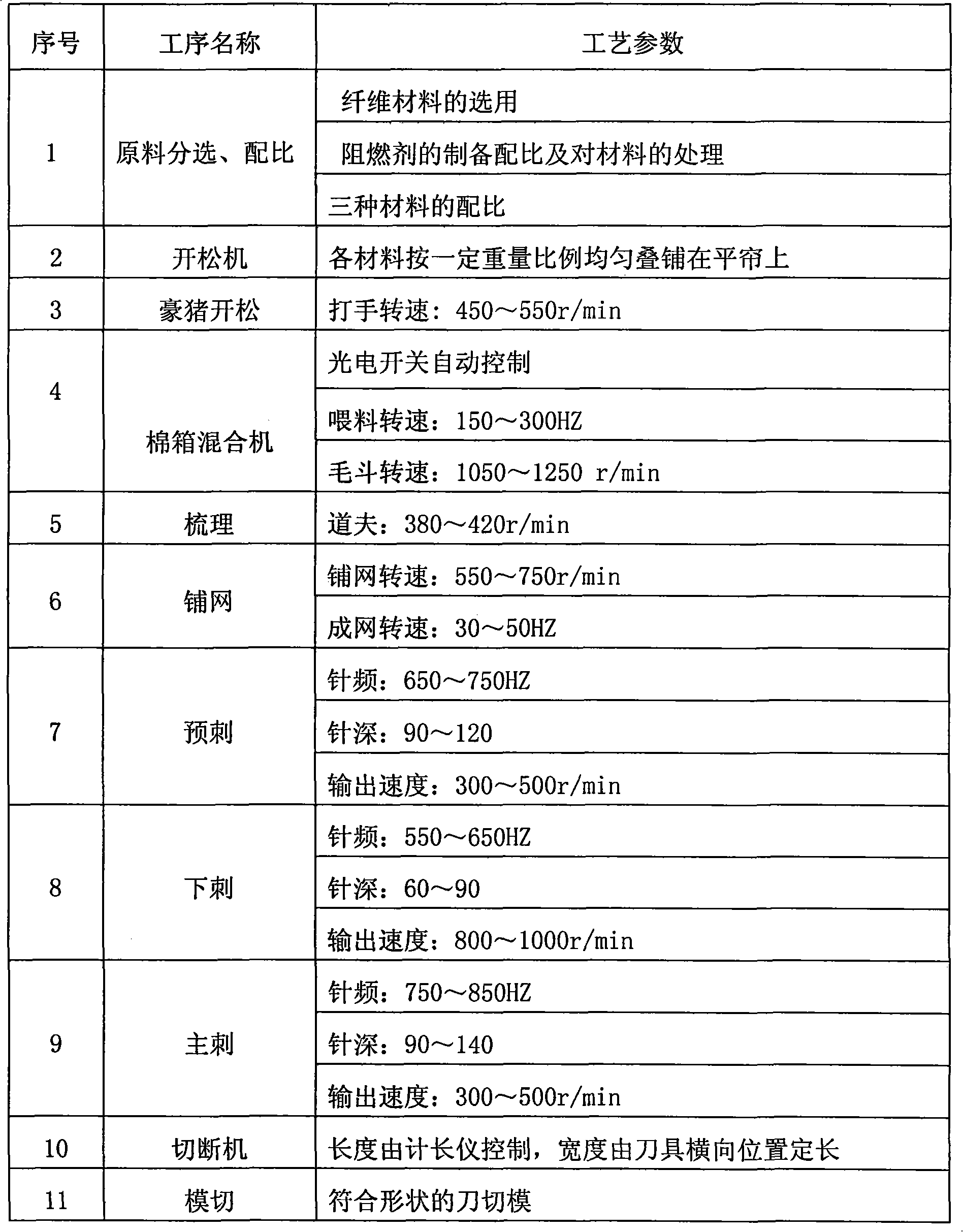

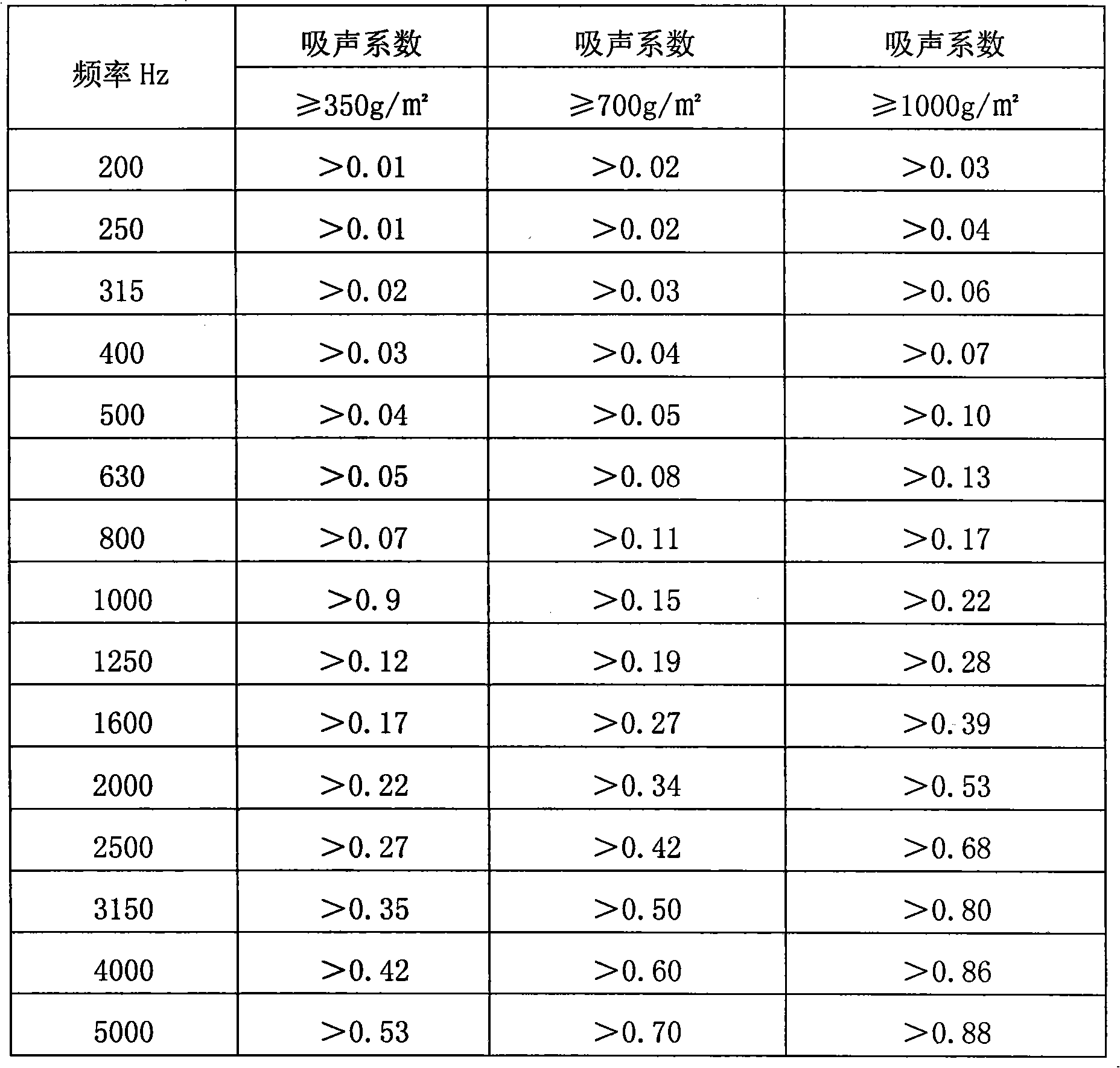

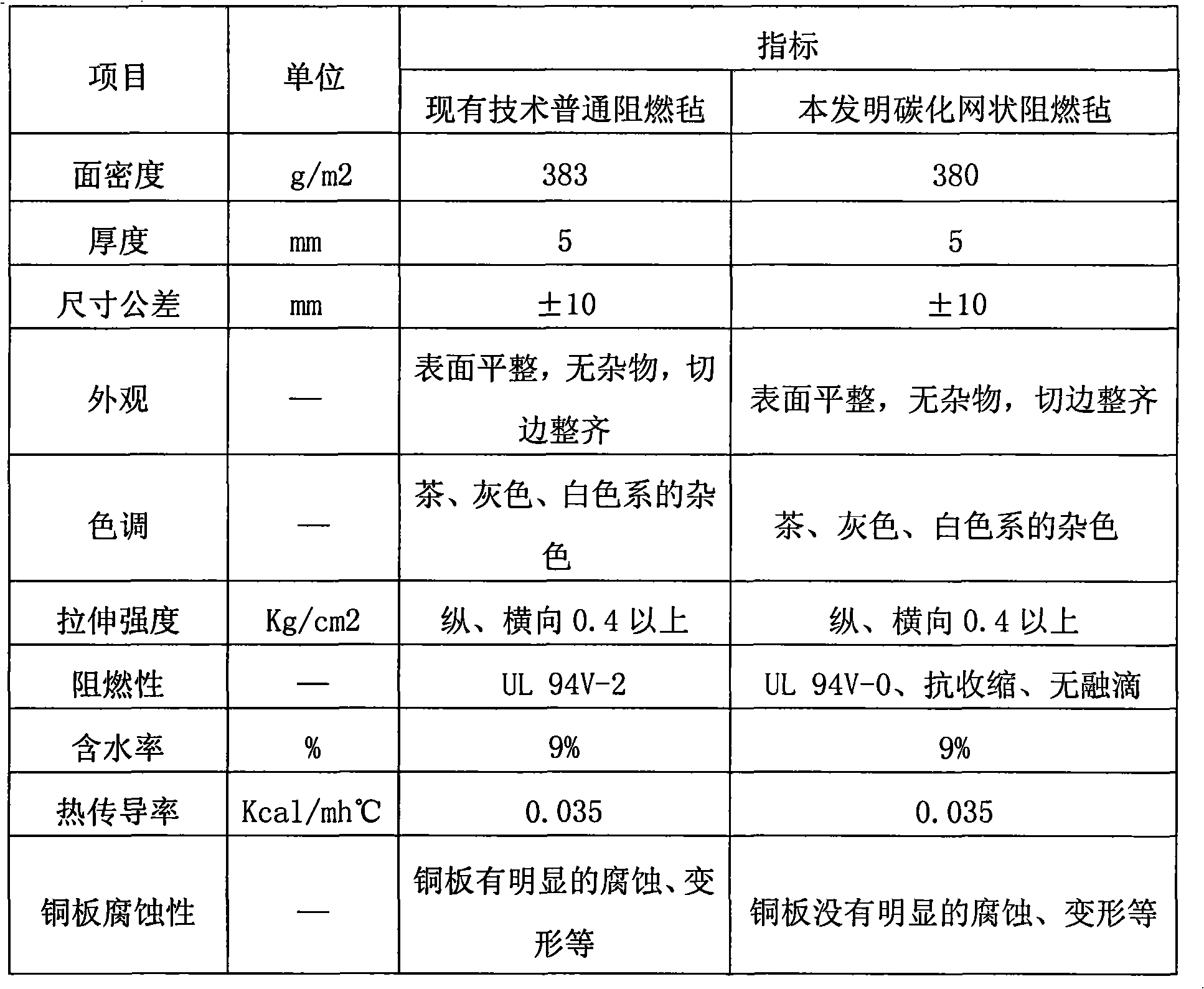

Carbonizing meshy fire retardant felt and method for preparing same

ActiveCN101285246AImprove moisture resistance reliabilityNo corrosionNon-woven fabricsVegetal fibresPolyesterCellulose

The invention discloses a carbonized netty flame retardant felt and a method for making the same. The carbonized netty flame retardant felt consists of the following compositions by weight percentage: 32 to 41 percent of high-temperature resistant fiber, 25 to 42 percent of flame retardant and shrinkproof polyester, 25 to 38 percent flame retardant treated cellulose base fibre and 3 to 5 percent of flame retardant; microencapsulation red phosphorus P, diantimony trioxide Sb2O3, zinc borate ZnBO3, magnesia MgO and aluminium hydroxide AL(OH)3 are weighed according to a proportion and added with water in a proper amount to prepare an evenly-mixed flame retardant solvent; various fibers are respectively treated by adopting spraying, solvent removing and drying and processed to the flame retardant felt with a crossed netty structure. The carbonized netty flame retardant felt uses the self-prepared red phosphorus ammonia-free flame retardant which has high and strong flame retardance as well as shrinkage resistance and drop melting resistance, has high tensile strength and no odour and is beneficial to human health.

Owner:INTERIOR DECORATION MATERIALS CO LTD ZHENJIANGTONGDA

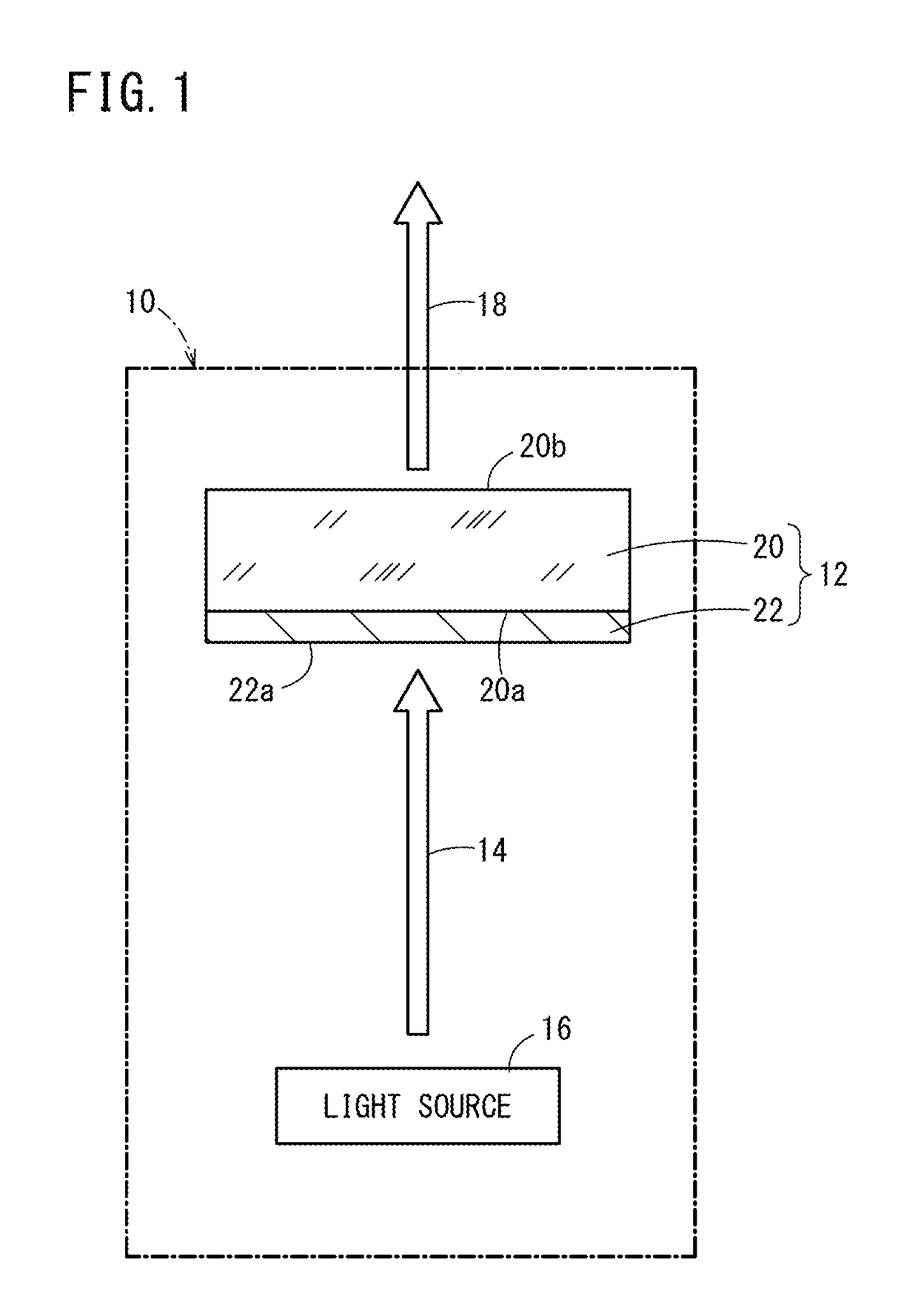

Wavelength converter, light-emitting device using same, and production method for wavelength converter

InactiveUS20170233647A1Small surface areaImprove luminous efficiencyOptical filtersGlass shaping apparatusPhosphorWavelength

A wavelength converter is provided with a light-transmitting substrate and with a thin film that is formed on a surface of the light-transmitting substrate and that contains a phosphor. A sintered body that constitutes the light-transmitting substrate has an average particle size of 5-40 μm. The light-transmitting substrate contains at least 10-500 ppm by mass of MgO. The principal component of the phosphor is an α-sialon that is indicated by the general formula (Caα,Euβ) (Si,Al)12(O,N)16 (provided that 1.5<α+β<2.2, 0<β<0.2, and O / N≦0.04).

Owner:DENKA CO LTD +1

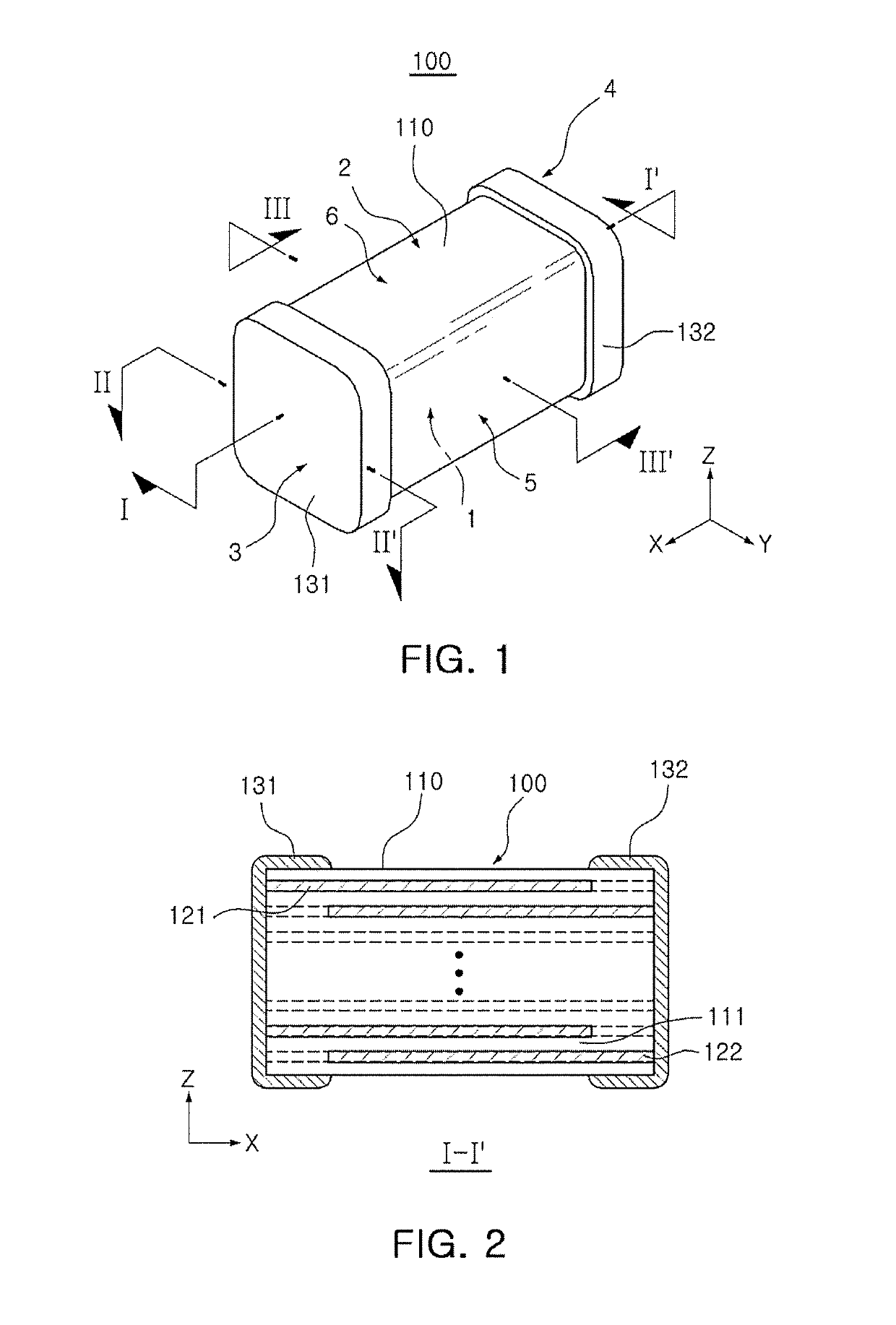

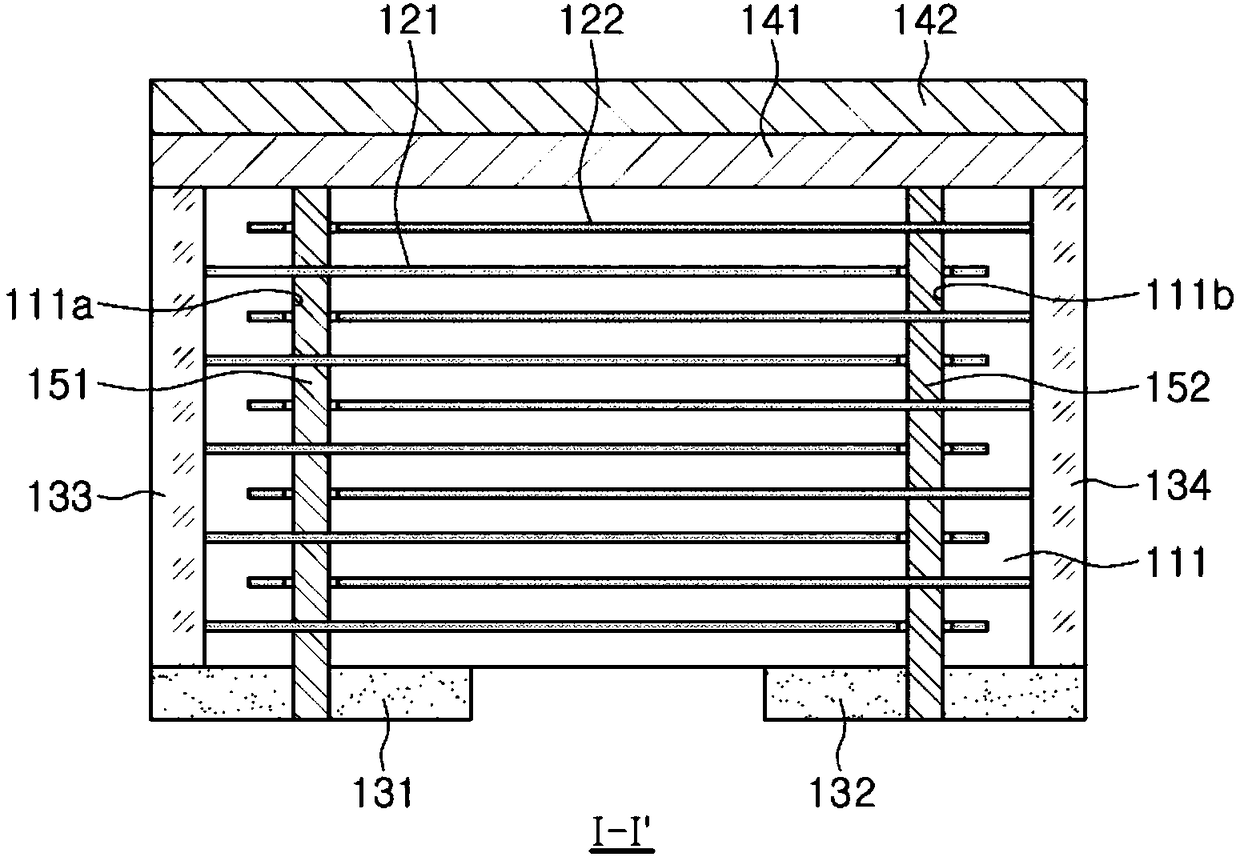

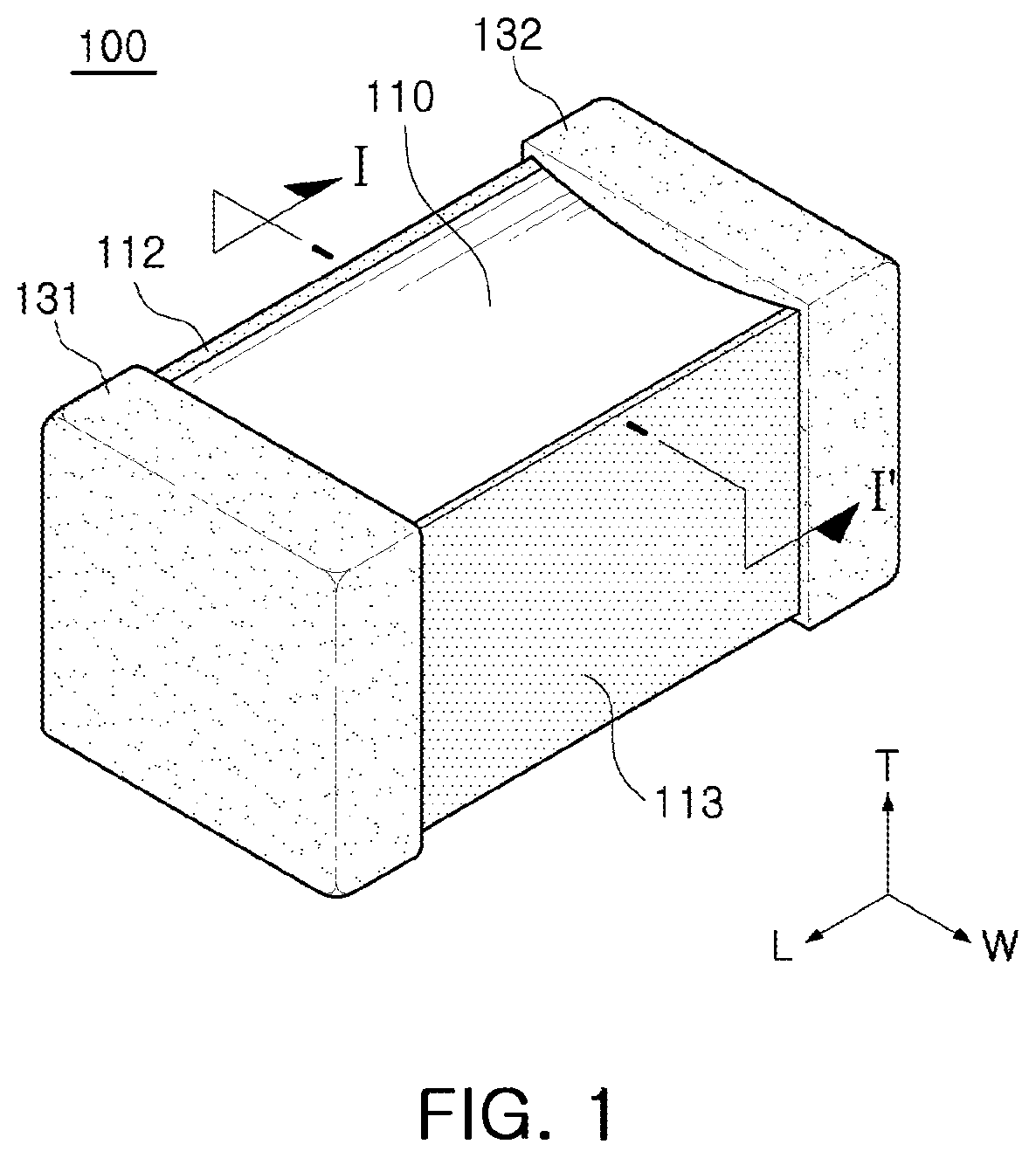

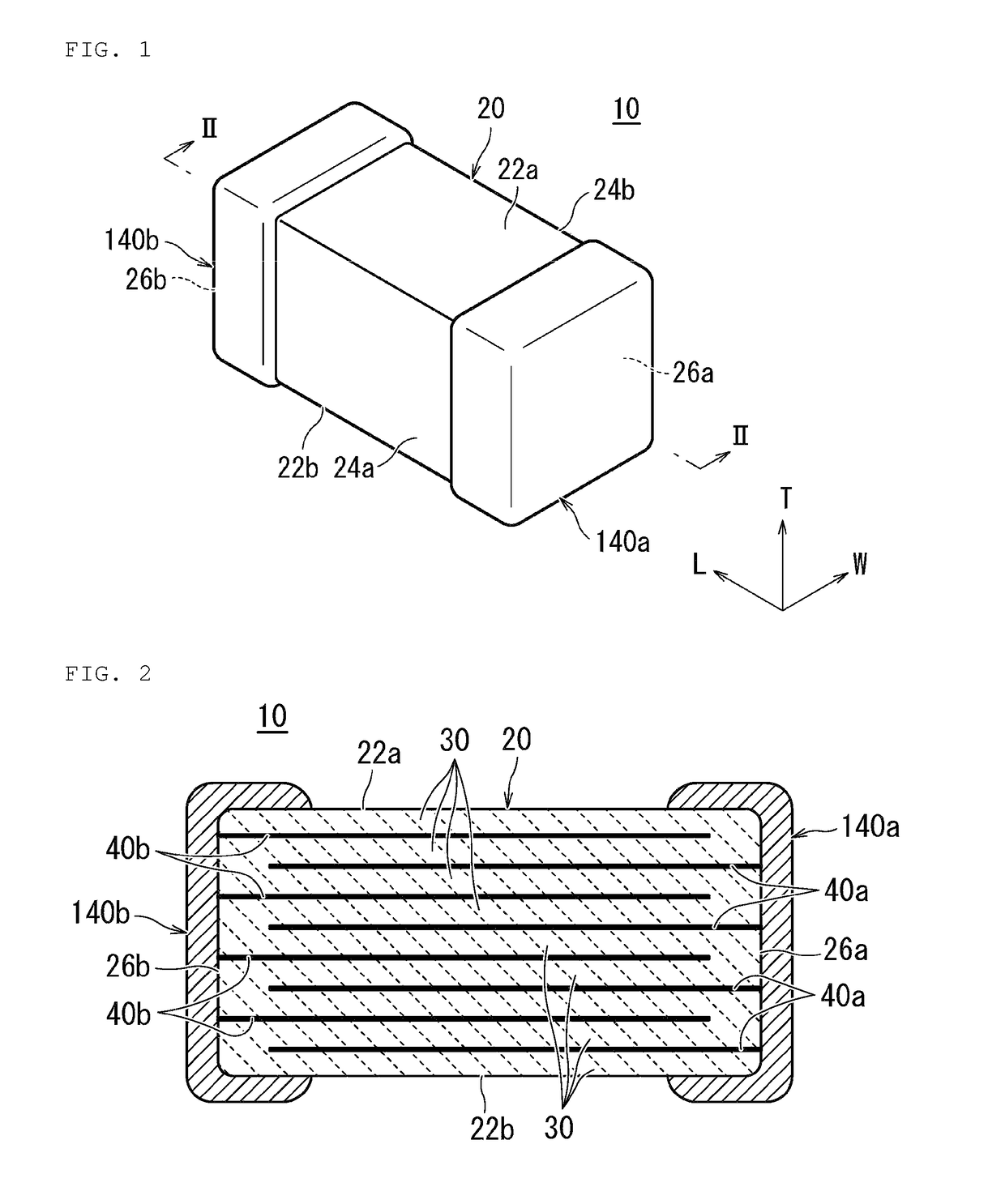

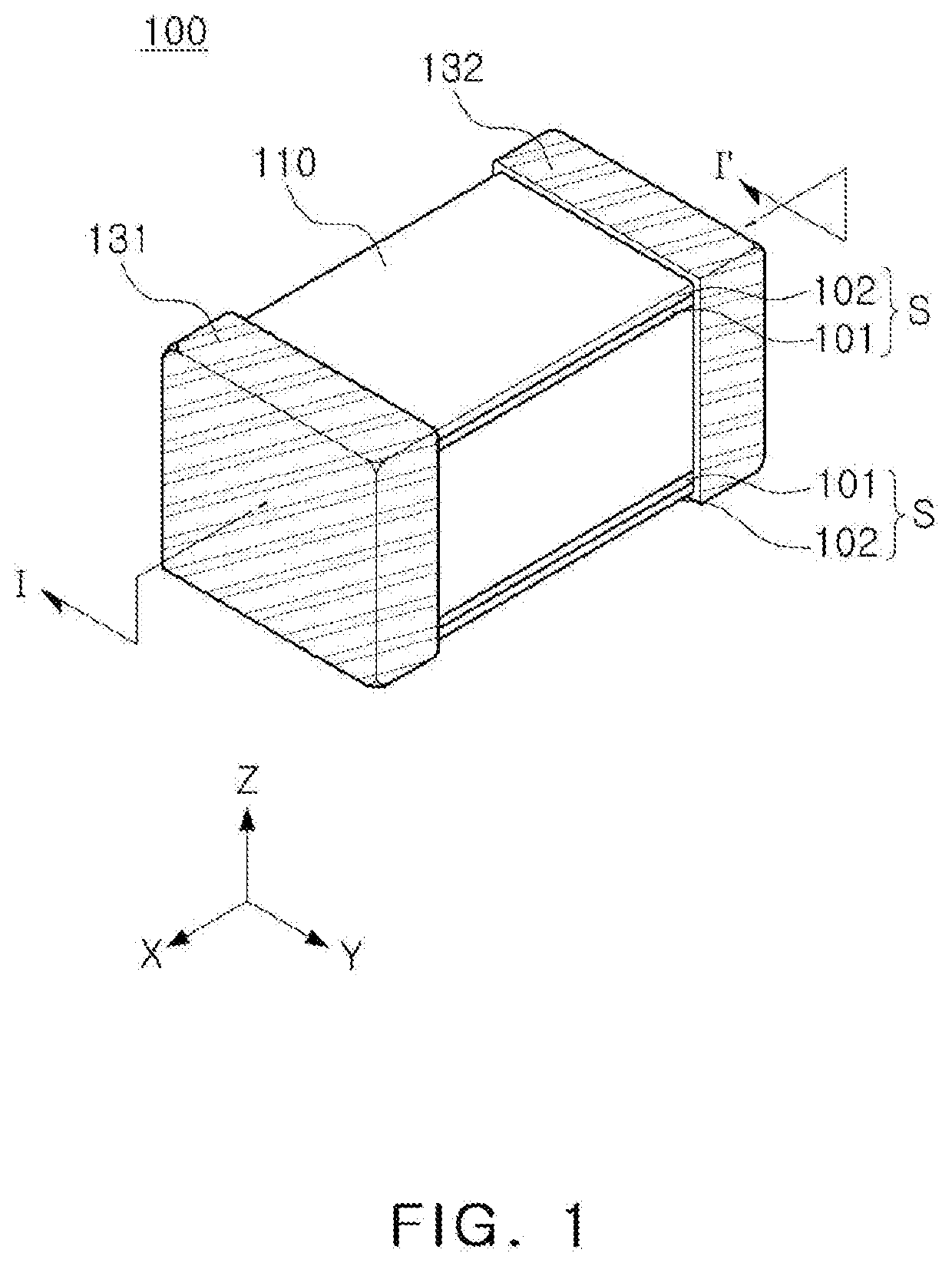

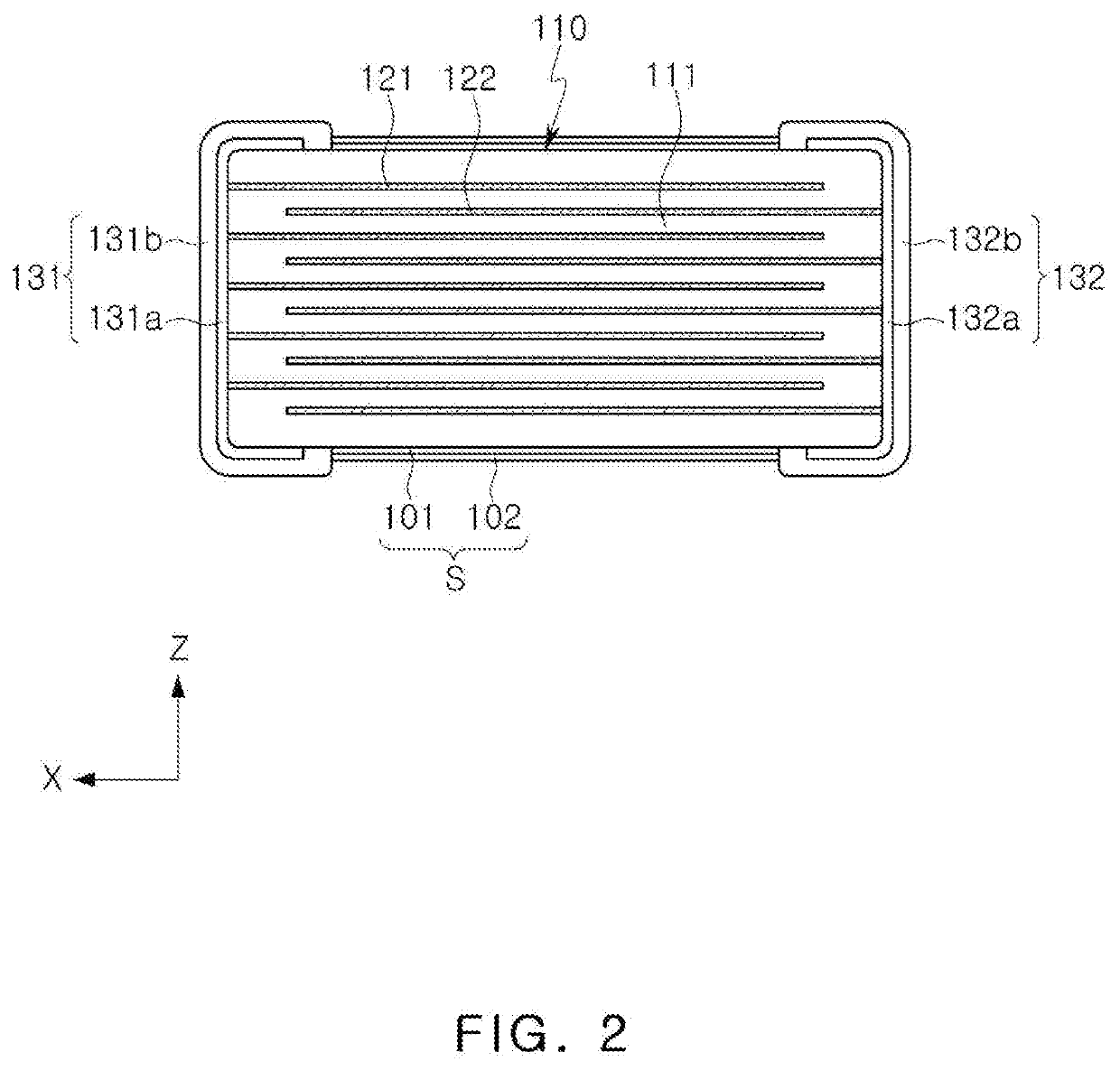

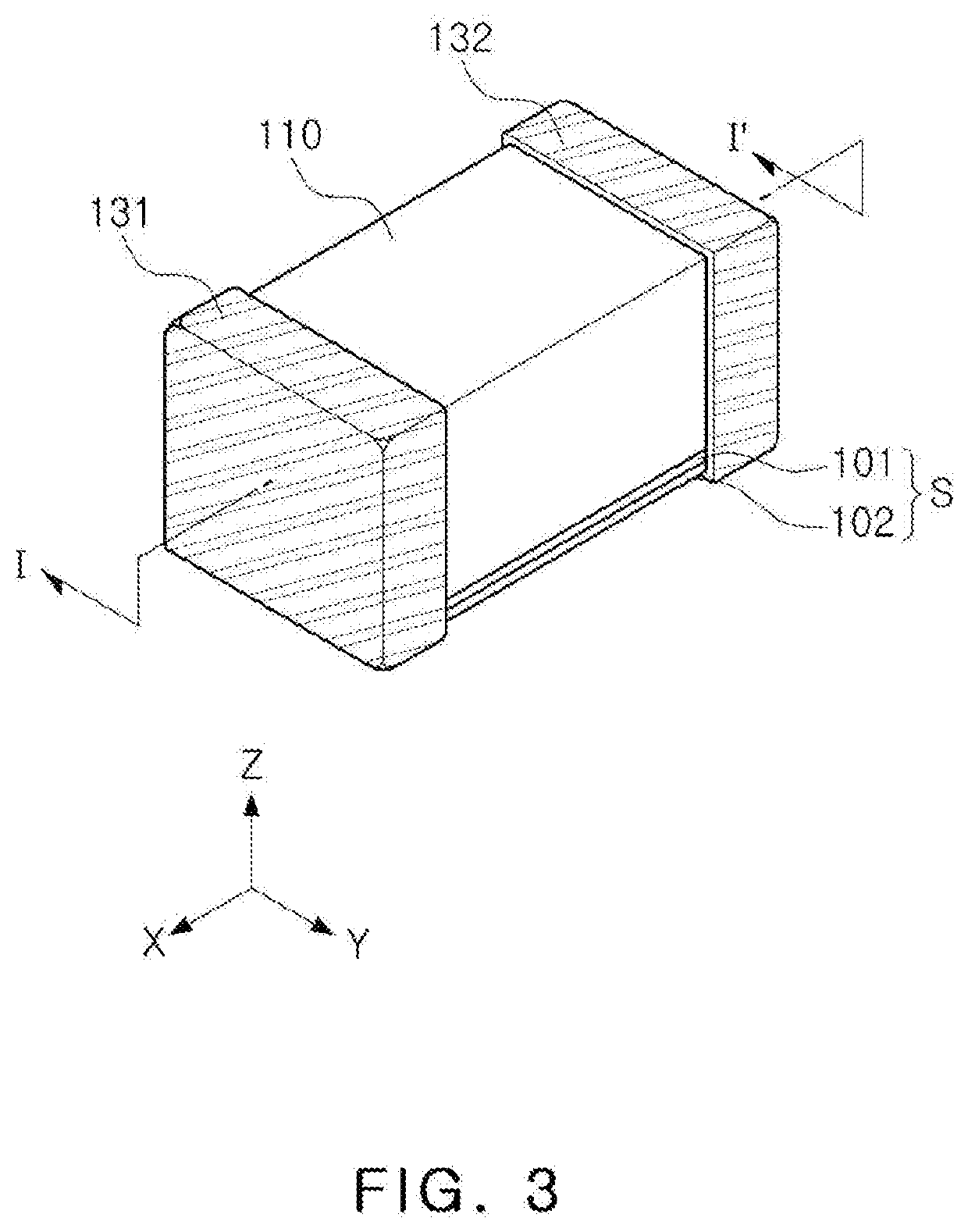

Multilayer capacitor

ActiveUS20200058443A1Improve moisture resistance reliabilityImprove reliabilityFixed capacitor electrodesStacked capacitorsBarium titanateEngineering physics

A multilayer capacitor includes a body, including a stacked structure formed of a plurality of dielectric layers and a plurality of internal electrodes, and a plurality of external electrodes. Each external electrode includes a conductive layer, disposed at the end of the body and connected to the plurality of internal electrodes, and a plating layer covering the conductive layer. Each conductive layer includes nickel (Ni) and barium titanate (BT), and an area occupied by nickel with respect to the total area of the respective conductive layer is 30% to 65%.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

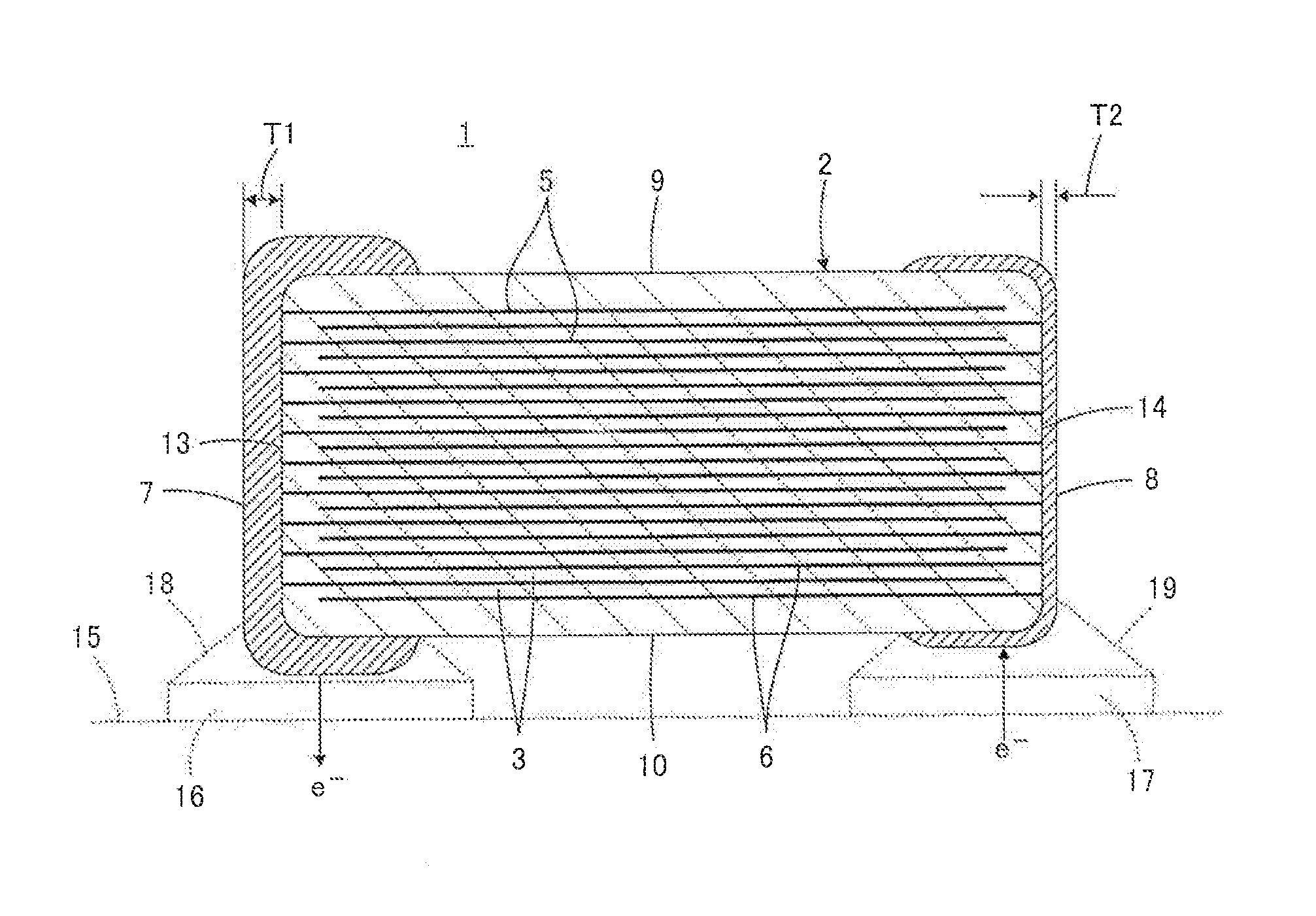

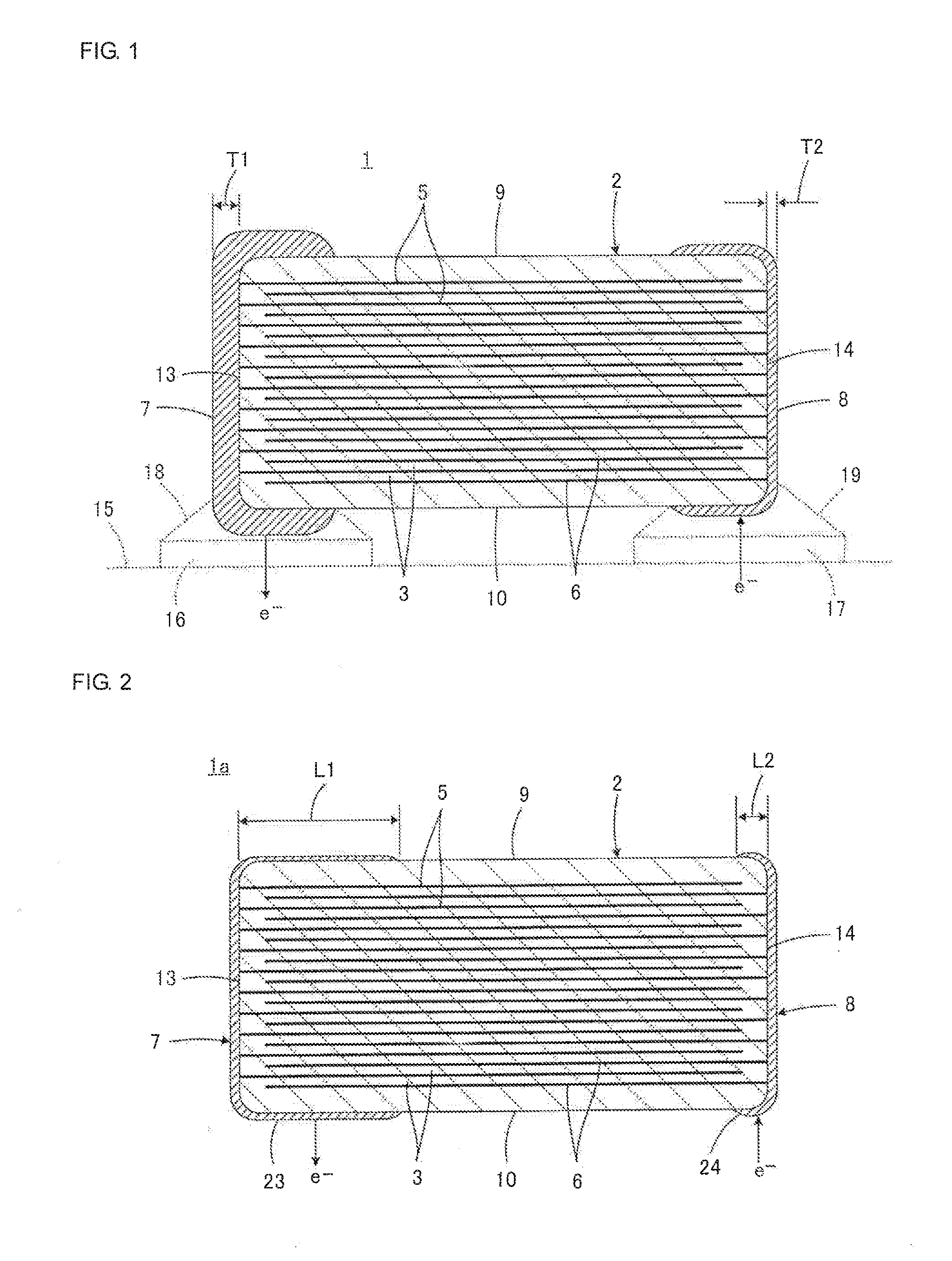

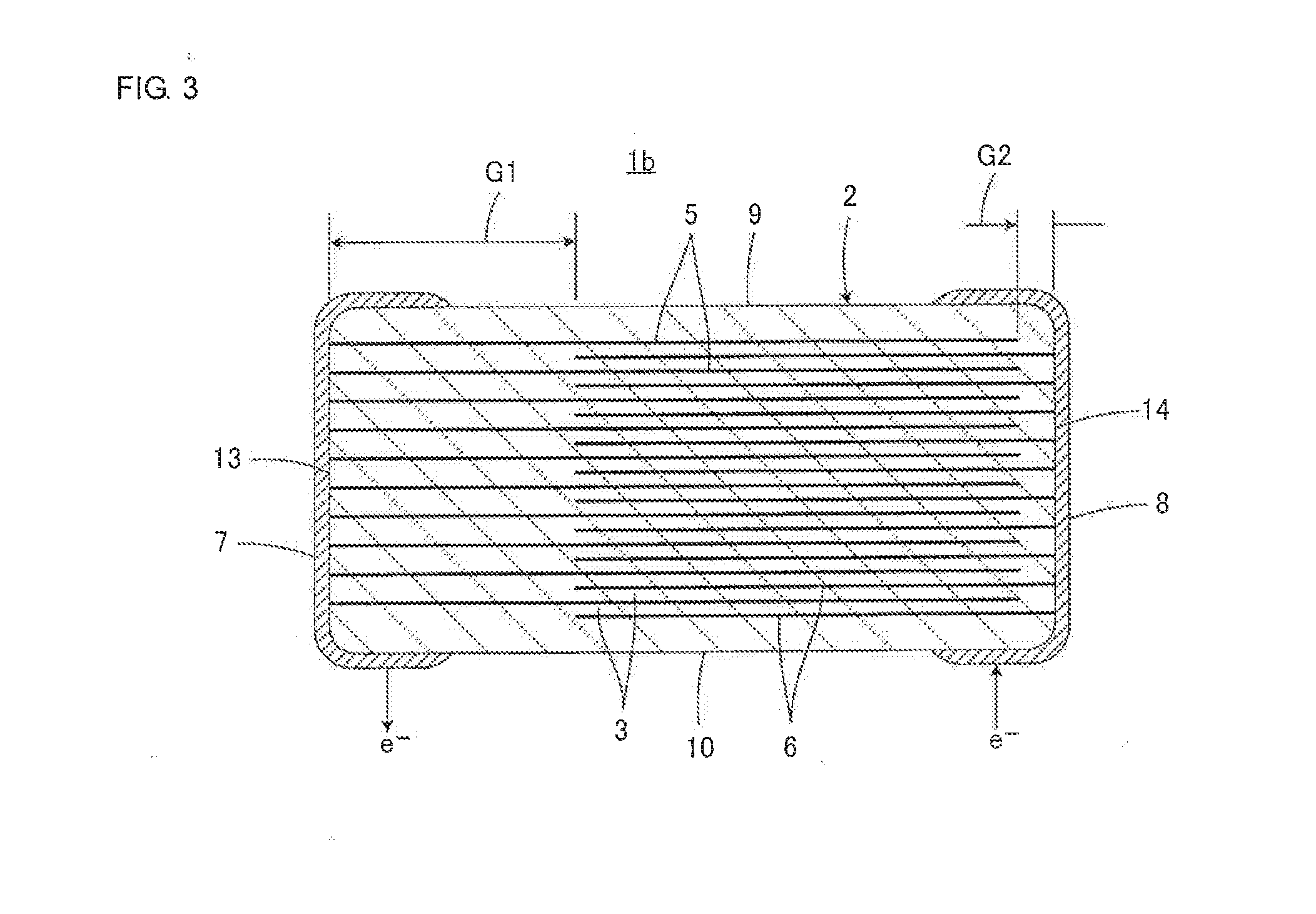

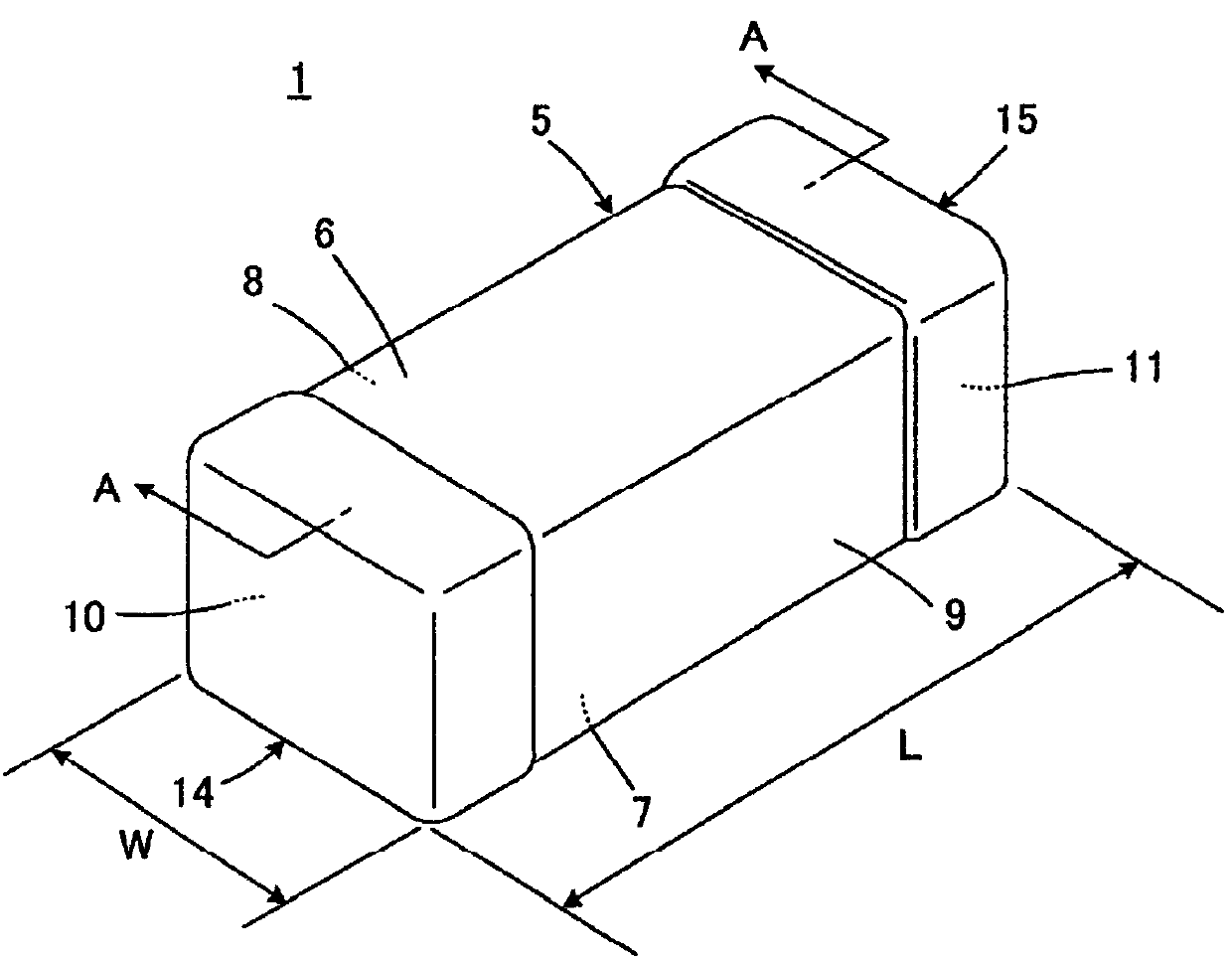

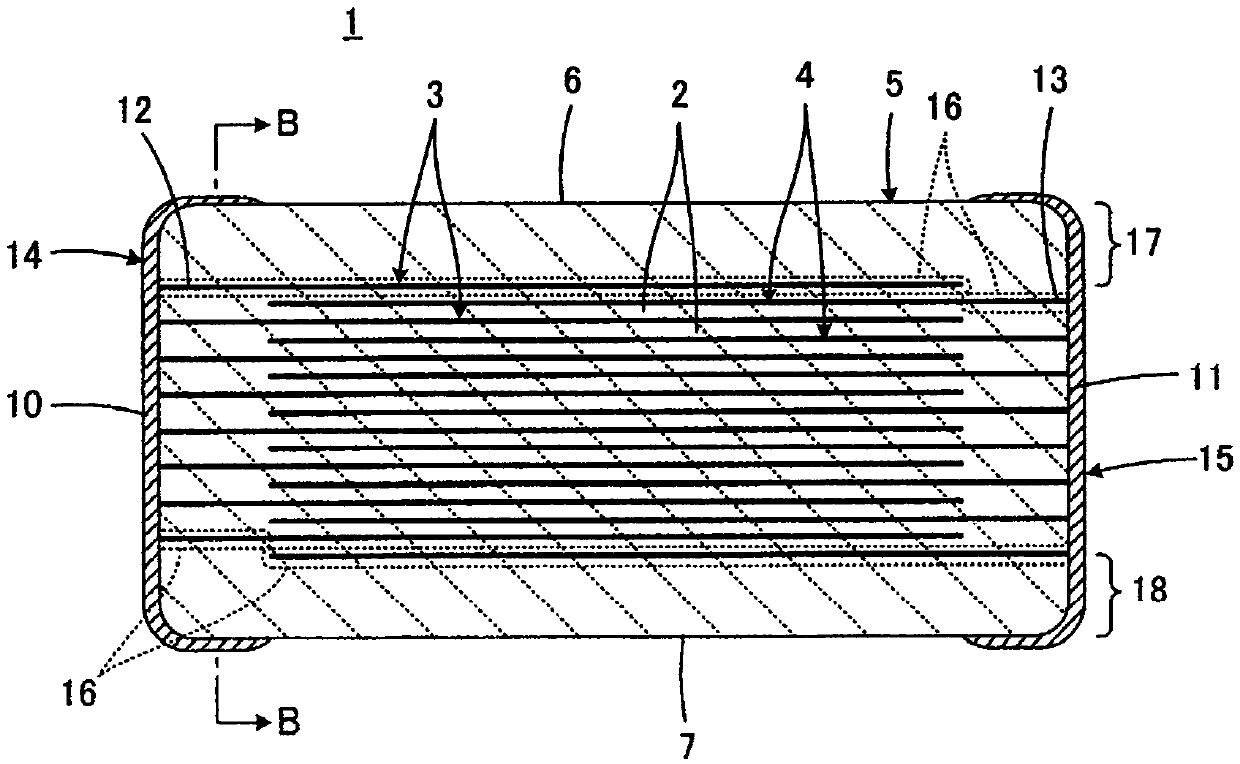

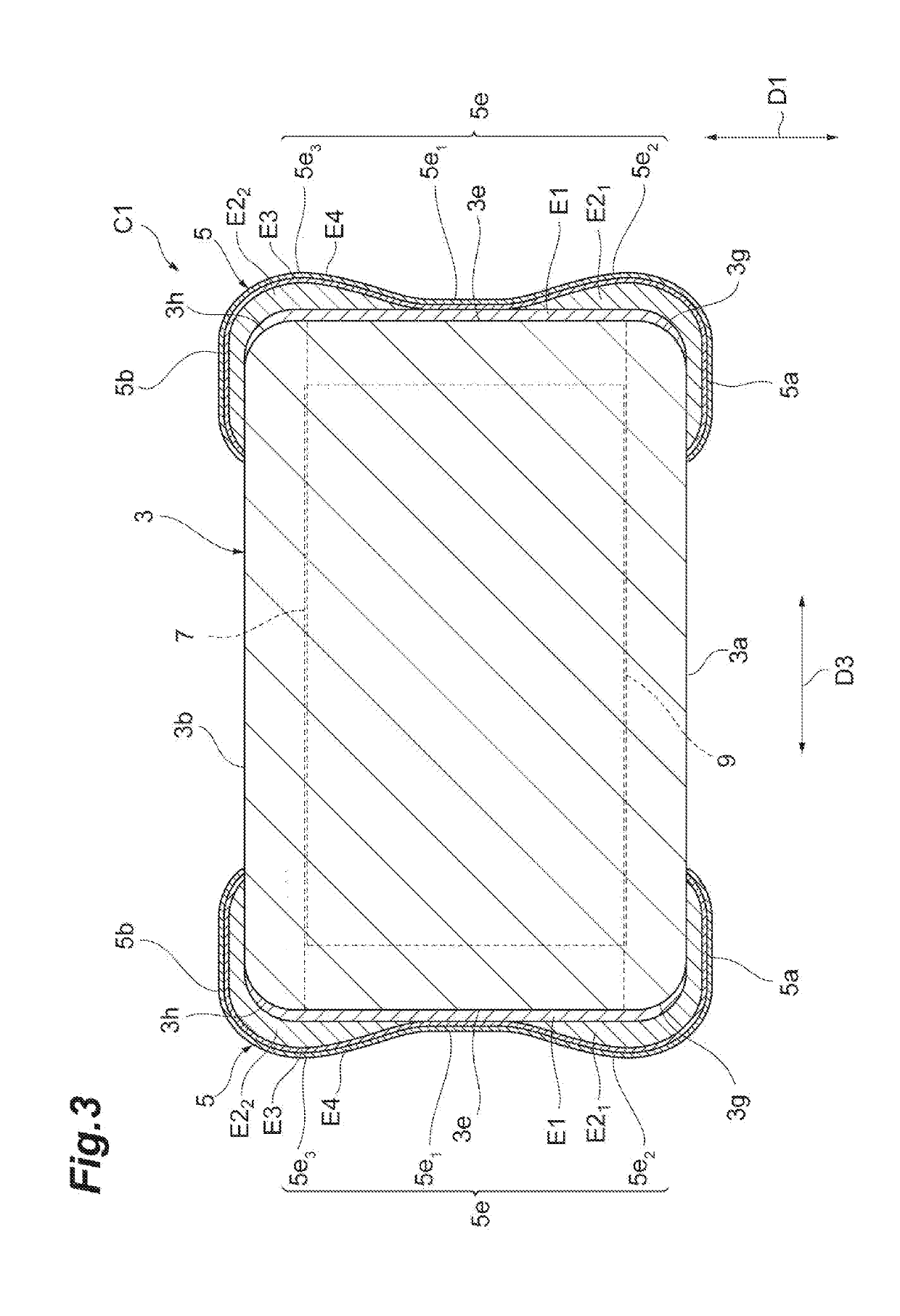

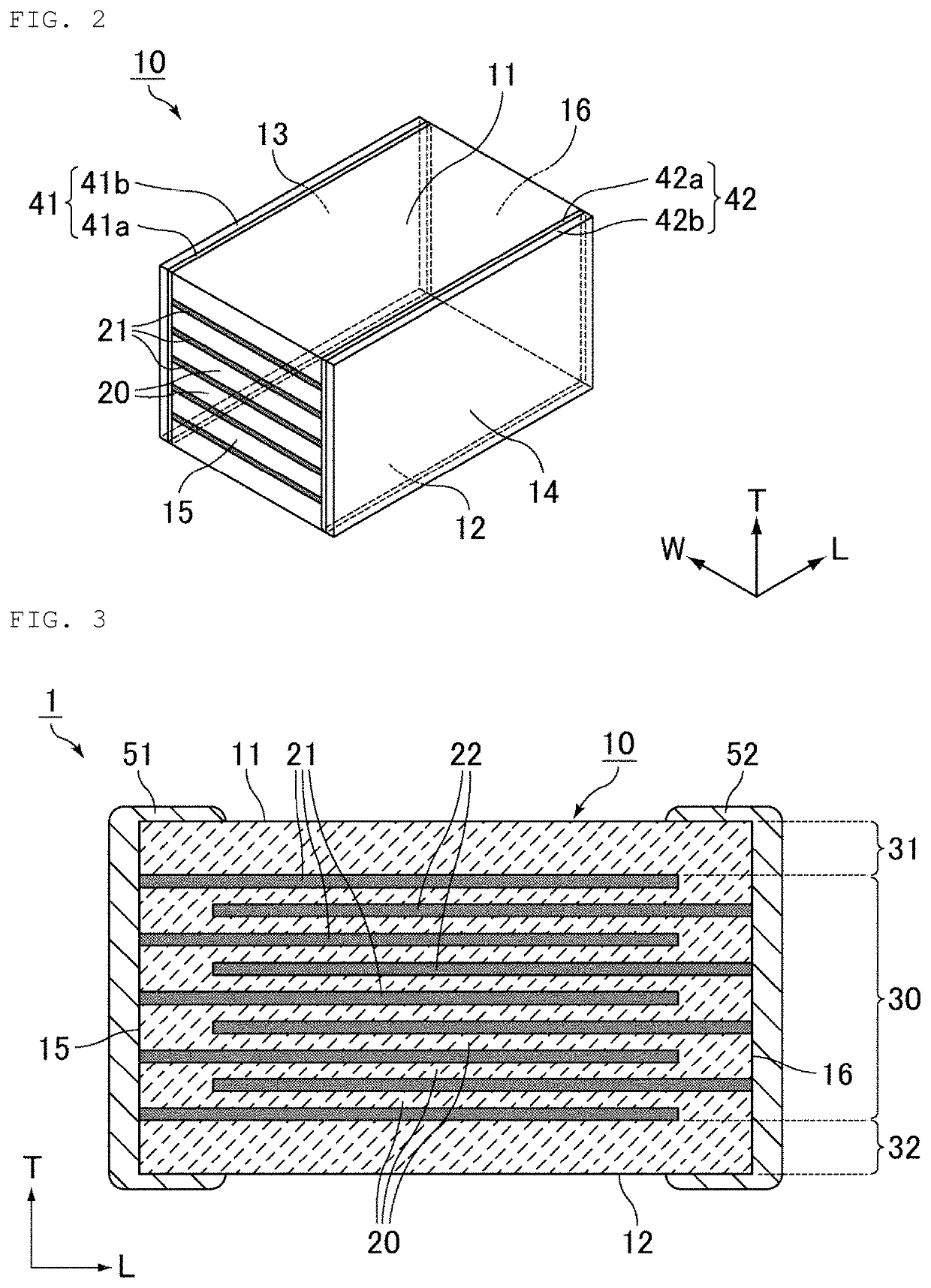

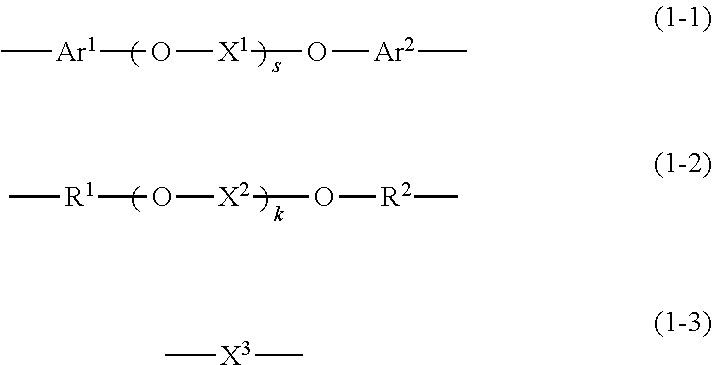

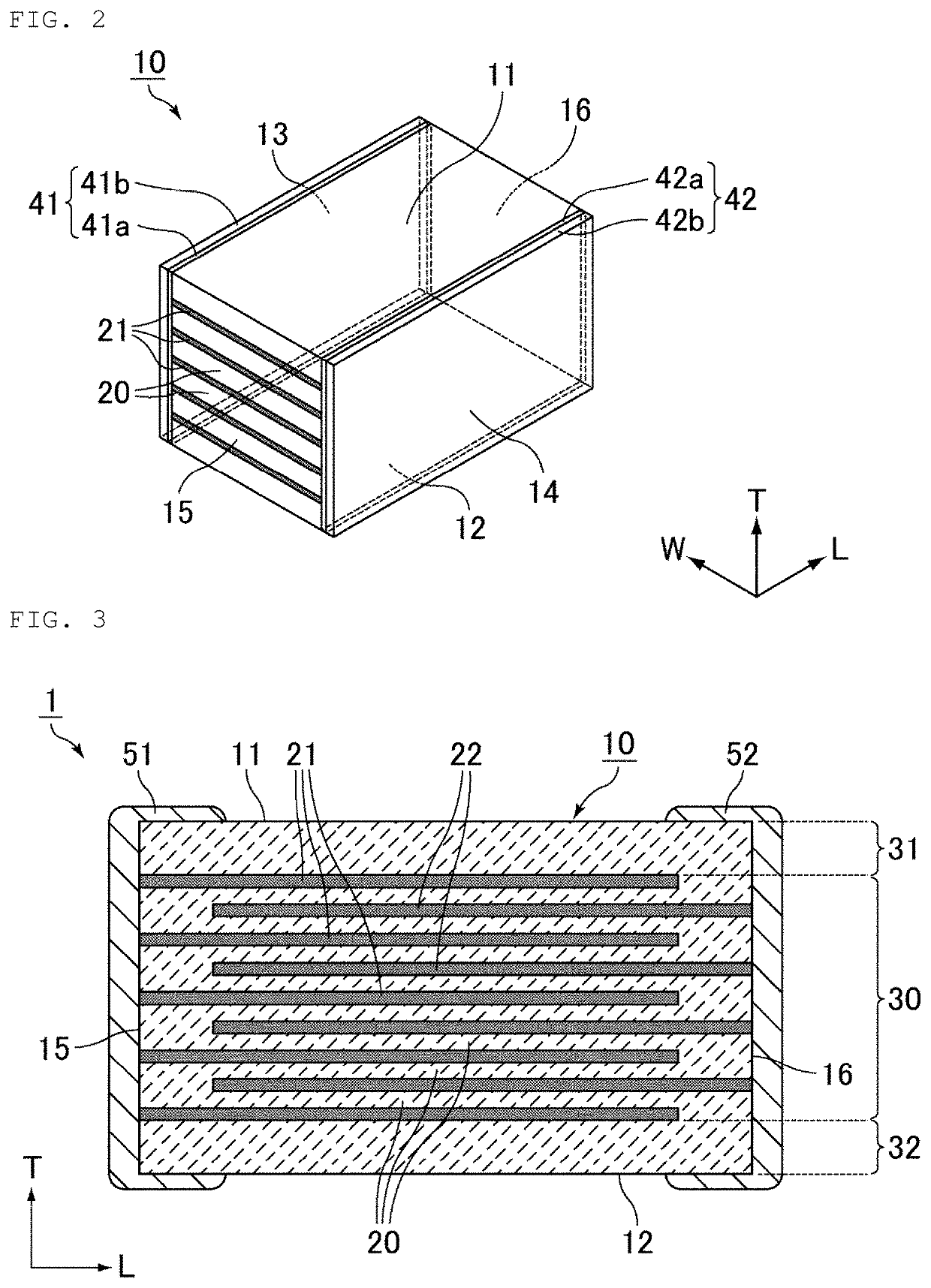

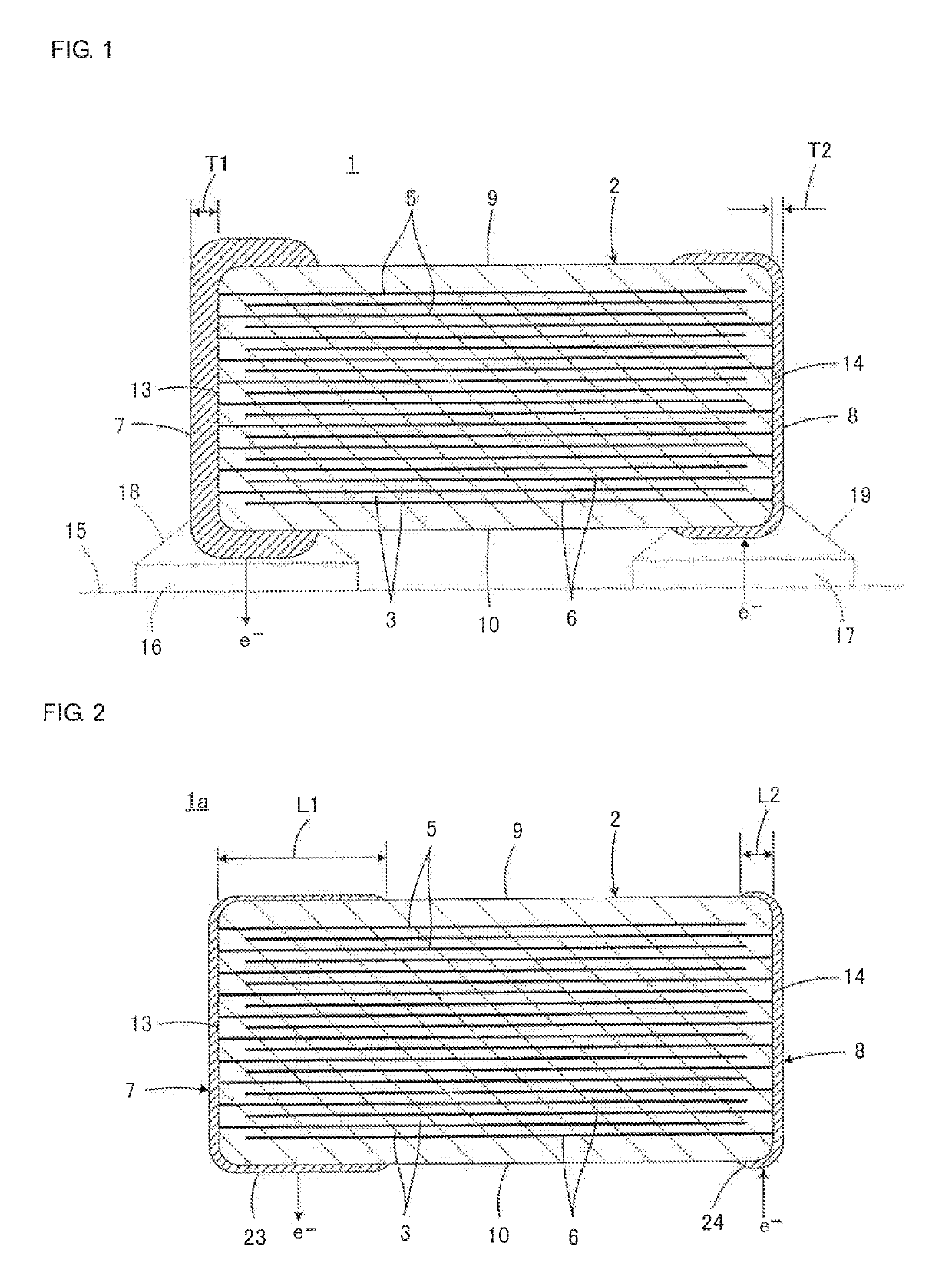

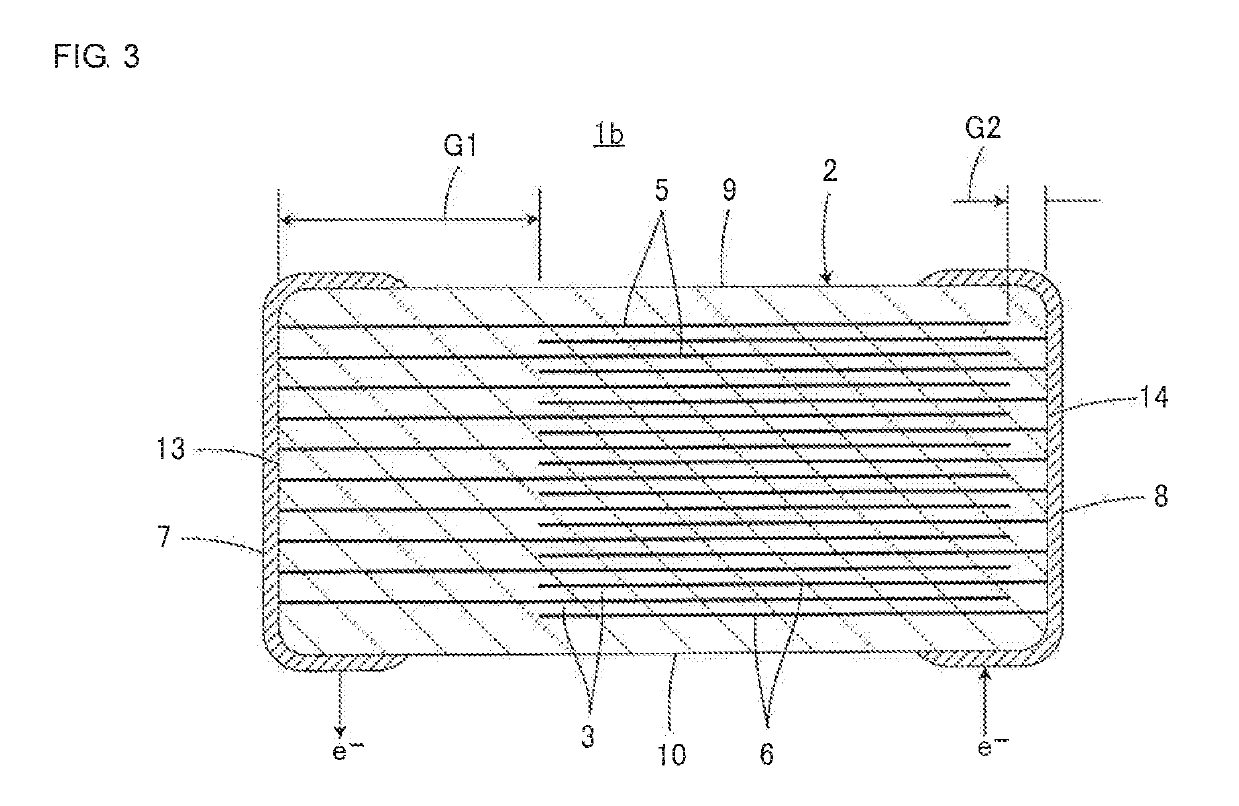

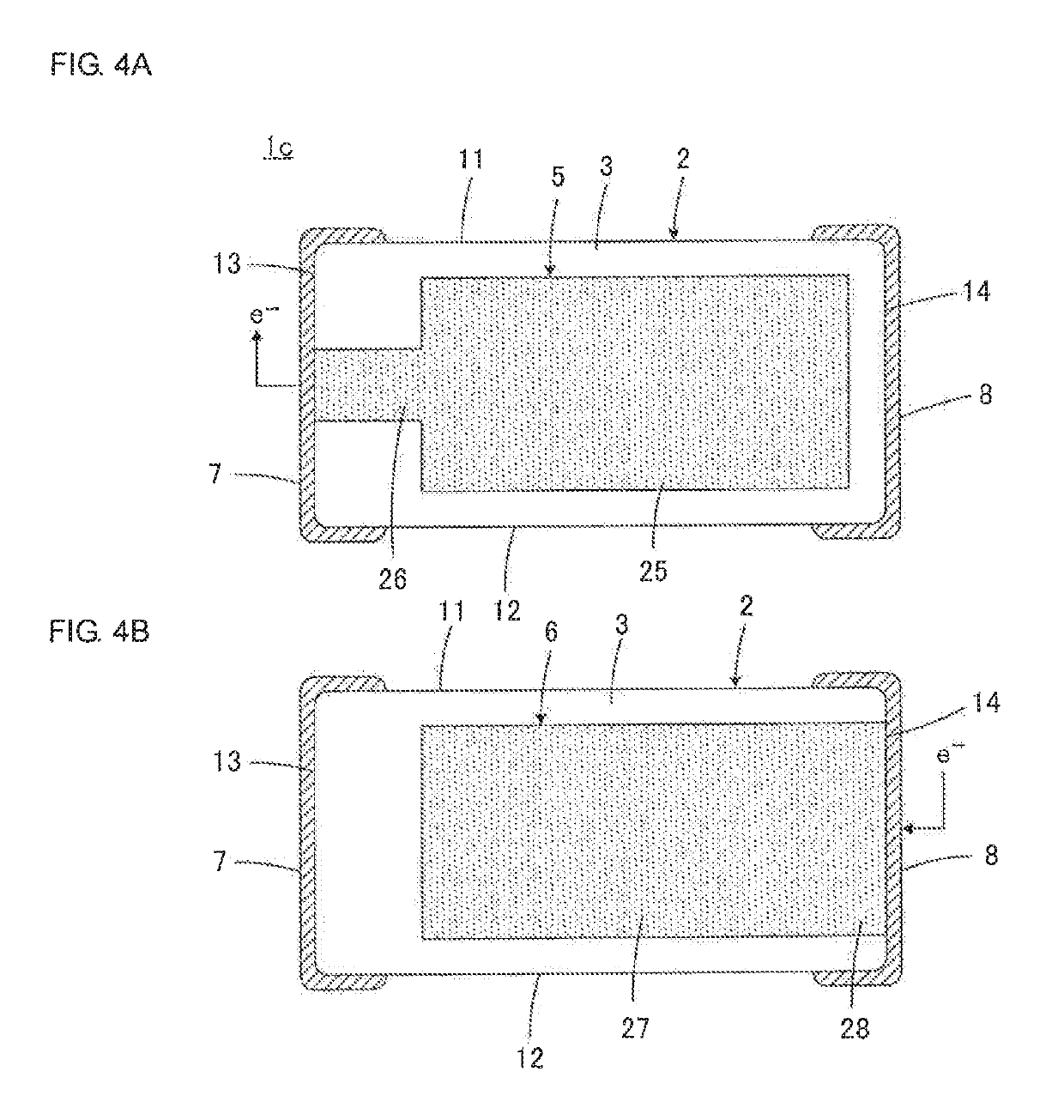

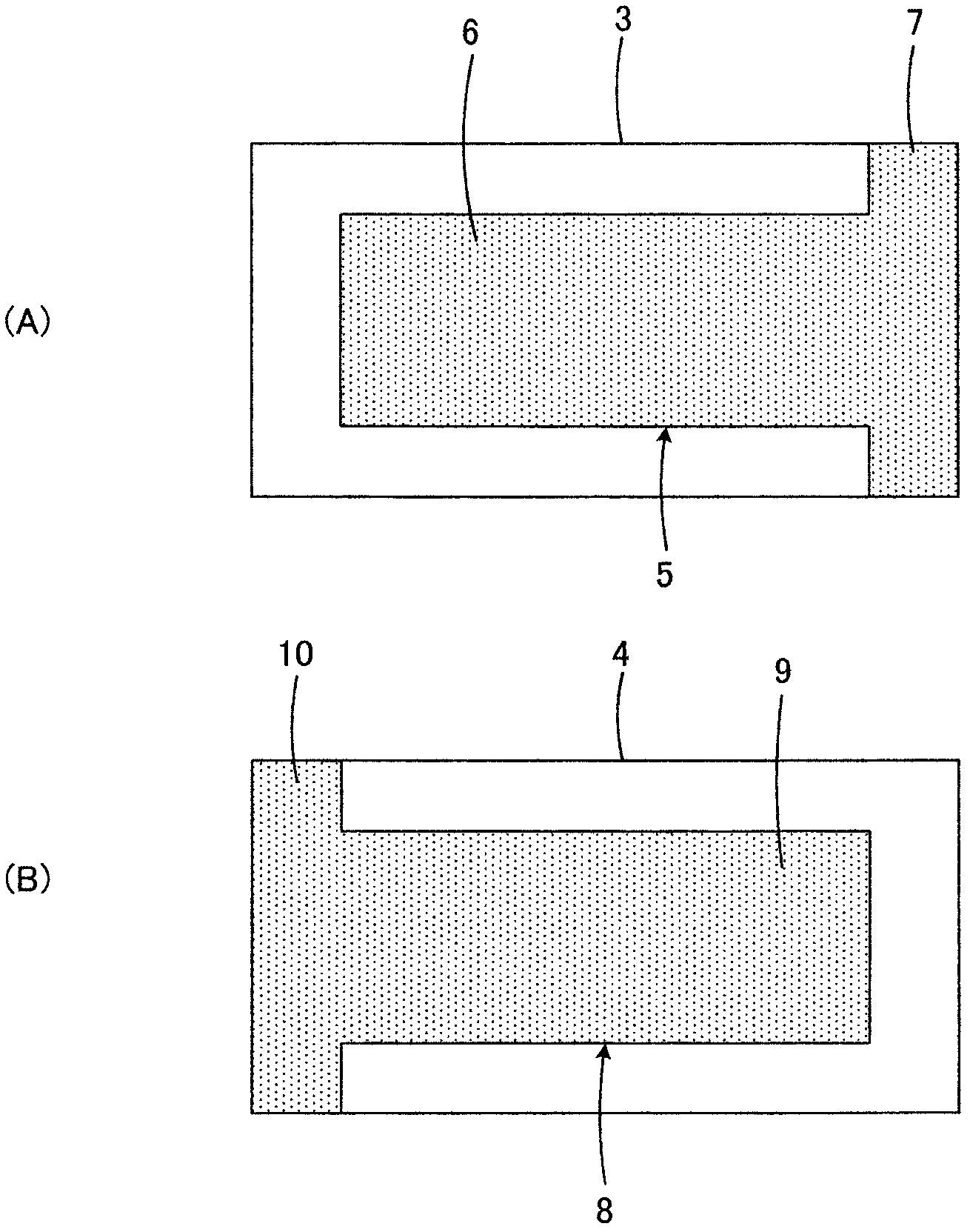

Monolithic ceramic capacitor and structure for mounting the same

ActiveUS20150279568A1Cost reductionHigh moisture-resistance reliabilityFixed capacitor electrodesFixed capacitor dielectricAnode potentialMaterials science

A first outer electrode and first inner electrodes are supplied with an anode potential and a second outer electrode and second inner electrodes are supplied with a cathode potential when a monolithic ceramic capacitor is mounted and in use. The first outer electrode supplied with the anode potential has a thickness that is greater than a thickness of the second outer electrode supplied with the cathode potential.

Owner:MURATA MFG CO LTD

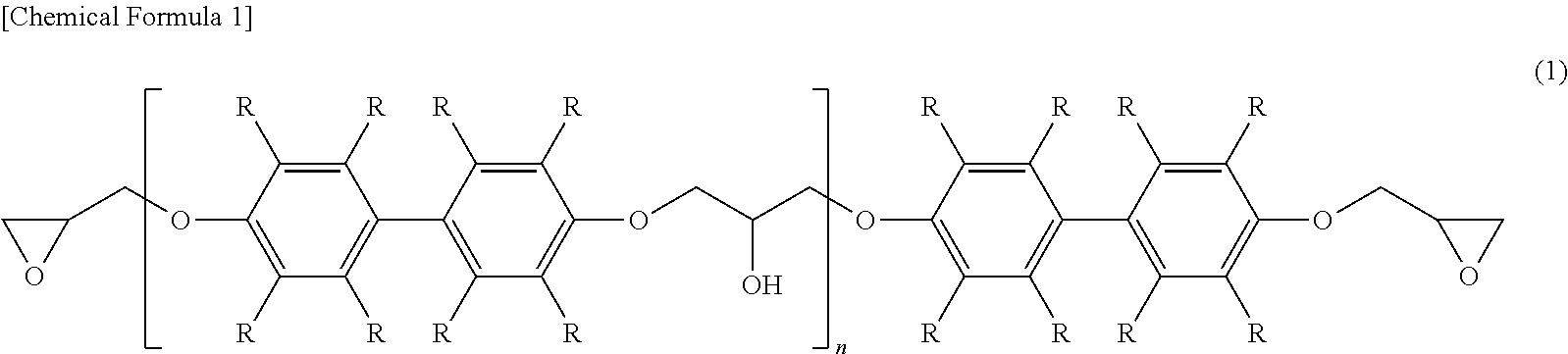

Epoxy resin composition for semiconductor encapsulation and semiconductor device

InactiveUS20130256863A1Improve moisture resistance reliabilityImprove reliabilityCosmetic preparationsMake-upElectrical junctionEpoxy

A highly reliable semiconductor device with the improved humidity resistance reliability is disclosed. A disclosed epoxy resin composition for semiconductor encapsulation encapsulates, in the manufacture of the semiconductor device, a semiconductor element that is mounted on a lead frame having a die pad unit or a circuit substrate and a wire that connects an electrical junction disposed on the lead frame or circuit substrate and an electrode pad disposed on the semiconductor element. The epoxy resin composition includes an epoxy resin (A), a curing agent (B), and an inorganic filler (C). The epoxy resin (A) has a main peak area of 90% or more with respect to the total area of all peaks as measured by the gel permeation chromatography area method.

Owner:SUMITOMO BAKELITE CO LTD

Monolithic Ceramic Electronic Component

ActiveCN103971932AImprove joint forceImprove moisture resistance reliabilityFixed capacitor electrodesFixed capacitor dielectricMetallurgyElectronic component

A monolithic ceramic electronic component includes a component body and outer electrodes. The component body includes a plurality of stacked ceramic layers and a plurality of inner electrodes which extend between the ceramic layers, which contain Ni, and which include exposed ends exposed on predetermined surfaces of the component body. The outer electrodes are electrically connected to the exposed ends of the inner electrodes and are formed on the predetermined surfaces of the component body by plating. The inner electrodes include Mg—Ni coexistence regions where Mg and Ni coexist.

Owner:MURATA MFG CO LTD

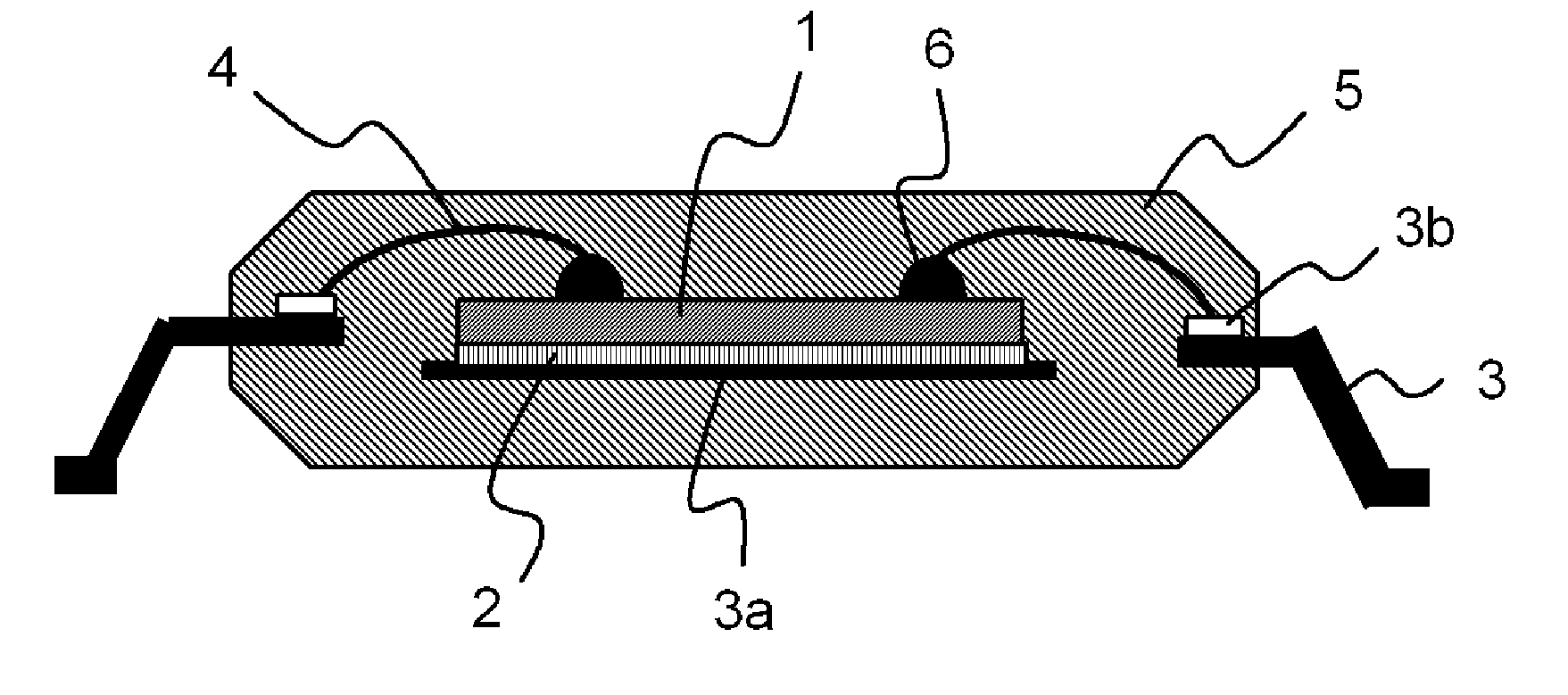

Organic electroluminescent device and method for producing same

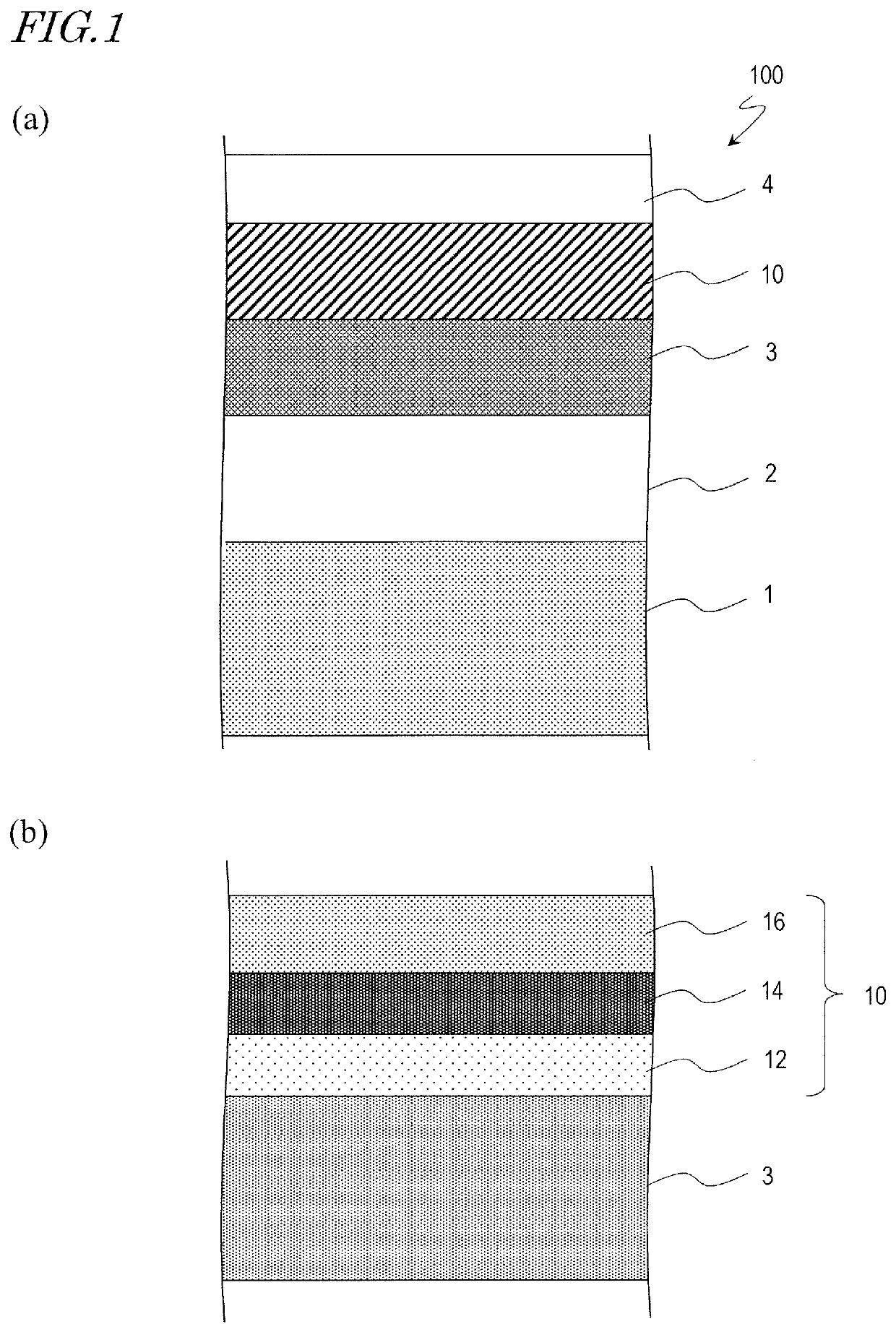

InactiveUS10276830B2Improve moisture resistance reliabilityLiquid surface applicatorsSolid-state devicesOrganic electroluminescenceMolecular physics

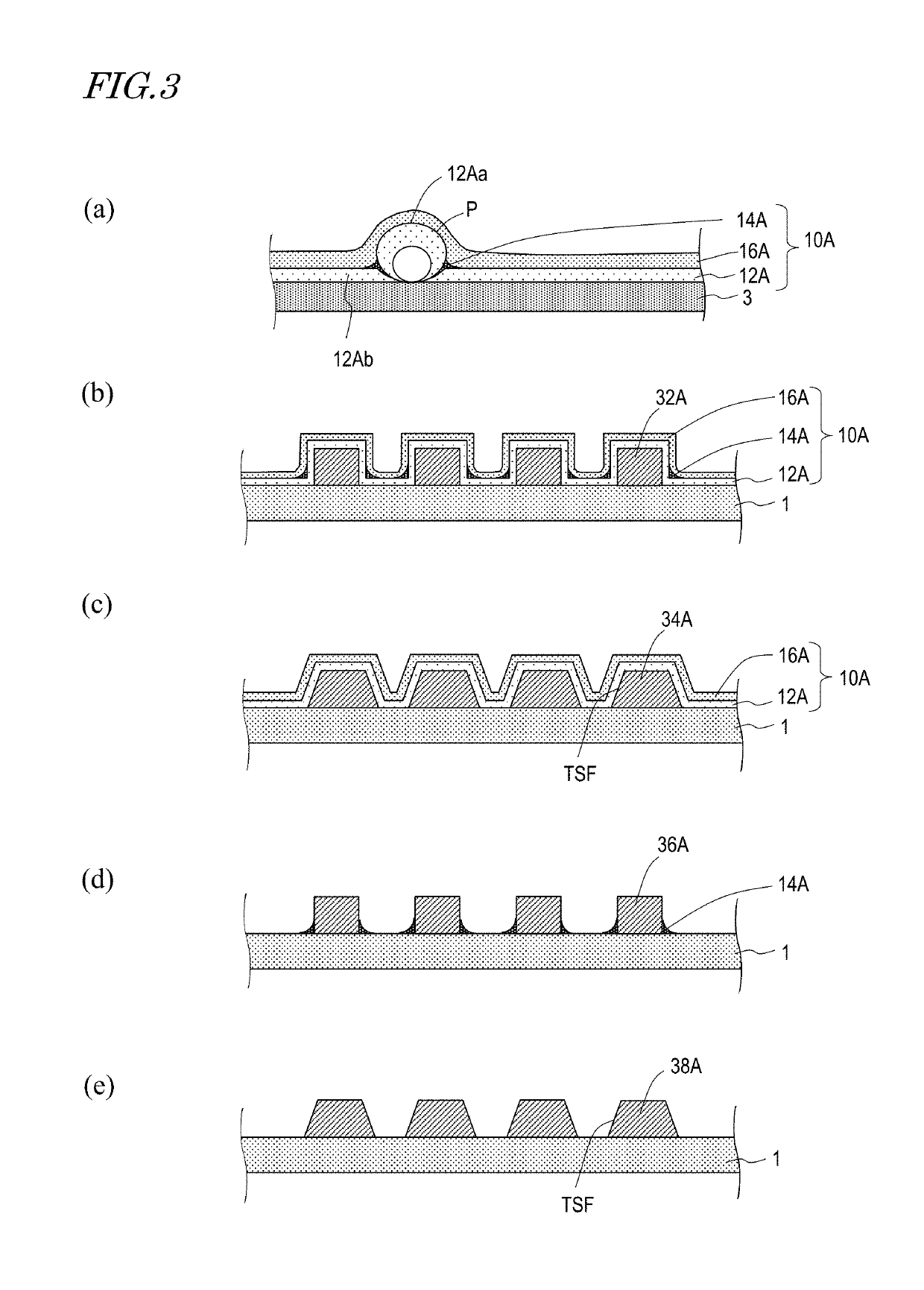

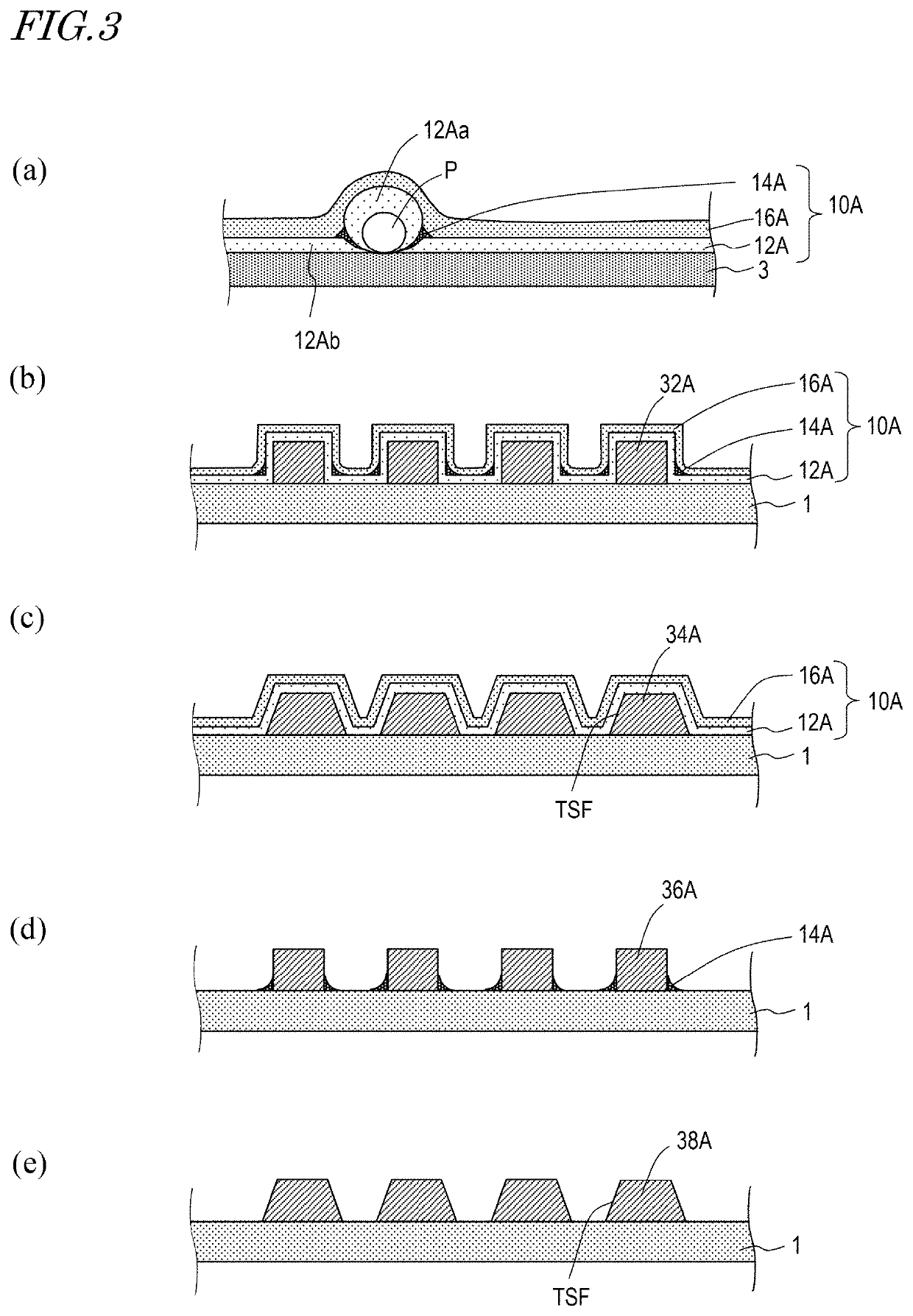

Am organic electroluminescent device (100A) in an embodiment includes an element substrate including a plurality of organic electroluminescent elements (3) supported by a substrate; and a thin film encapsulation structure (10E) formed on the plurality of organic electroluminescent elements. The thin film encapsulation structure (10E) includes at least one complex stack body (10S) including a first inorganic barrier layer (12E), an organic barrier layer (14E) in contact with a top surface of the first inorganic barrier layer (12E) and including a plurality of solid portions discretely distributed, and a second inorganic barrier layer (16E) in contact with the top surface of the first inorganic barrier layer and a top surface of each of the plurality of solid portions of the organic barrier layer. The plurality of solid portions include a plurality of solid portions discretely provided and each having a recessed surface.

Owner:SAKAI DISPLAY PROD

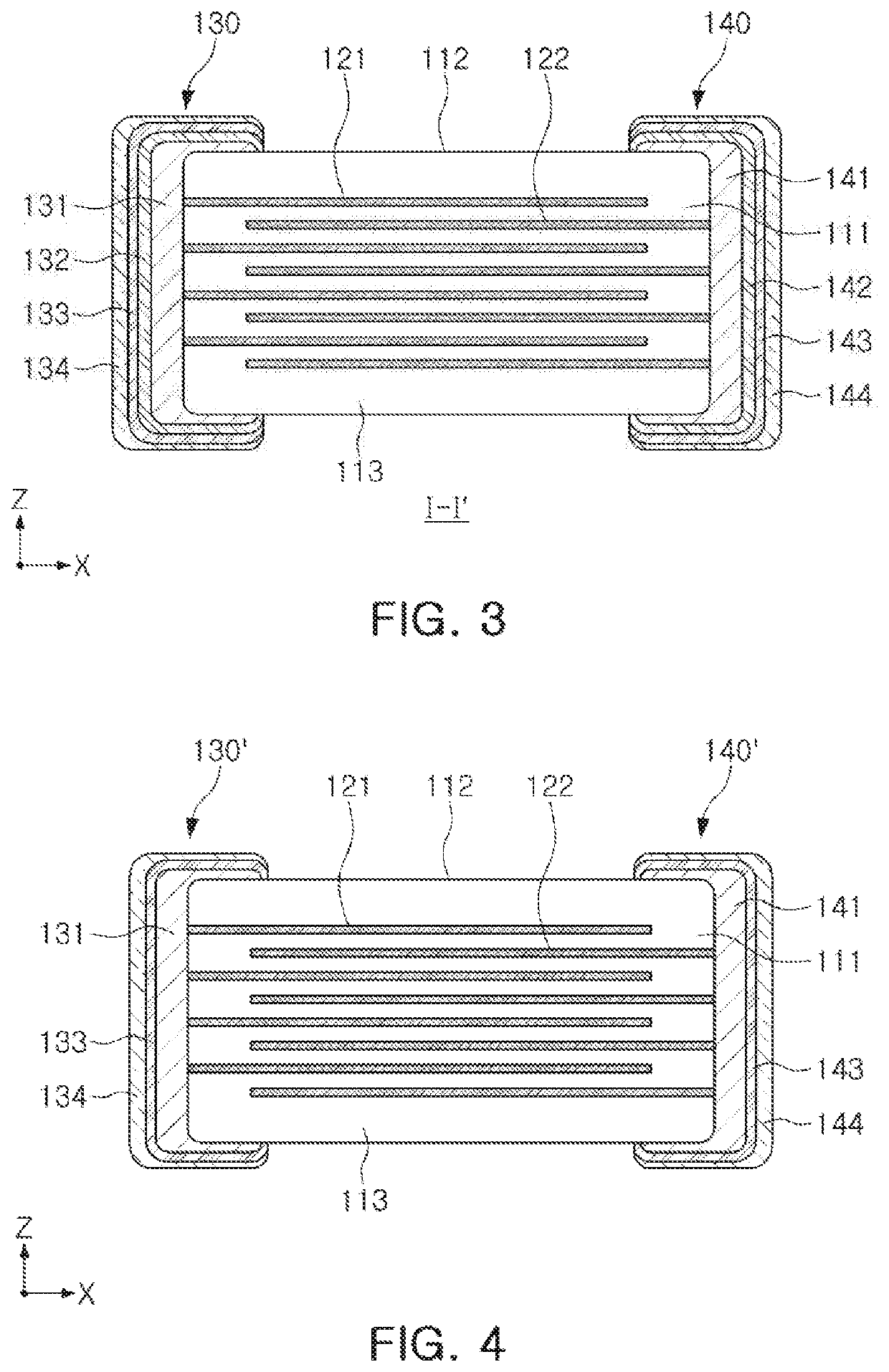

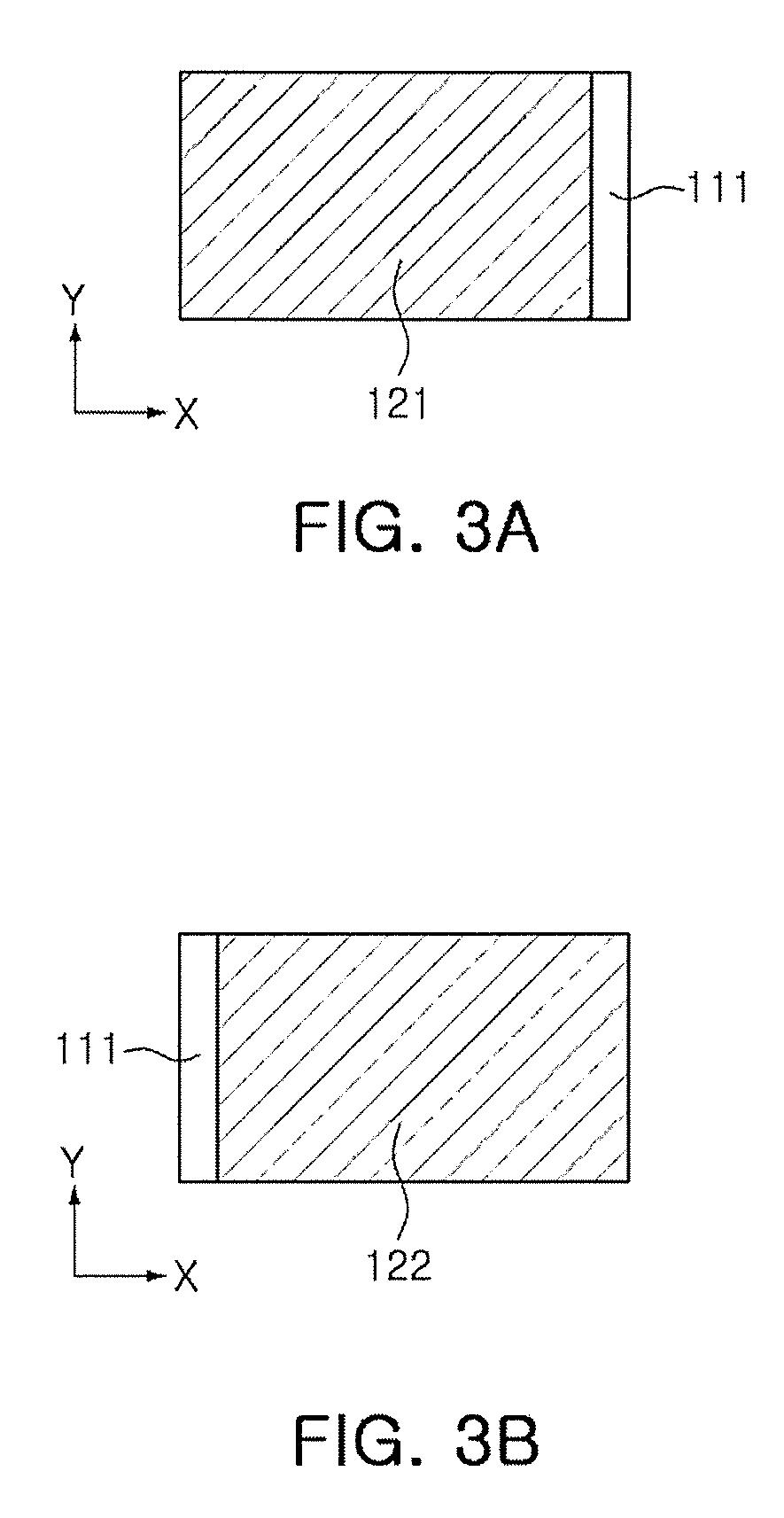

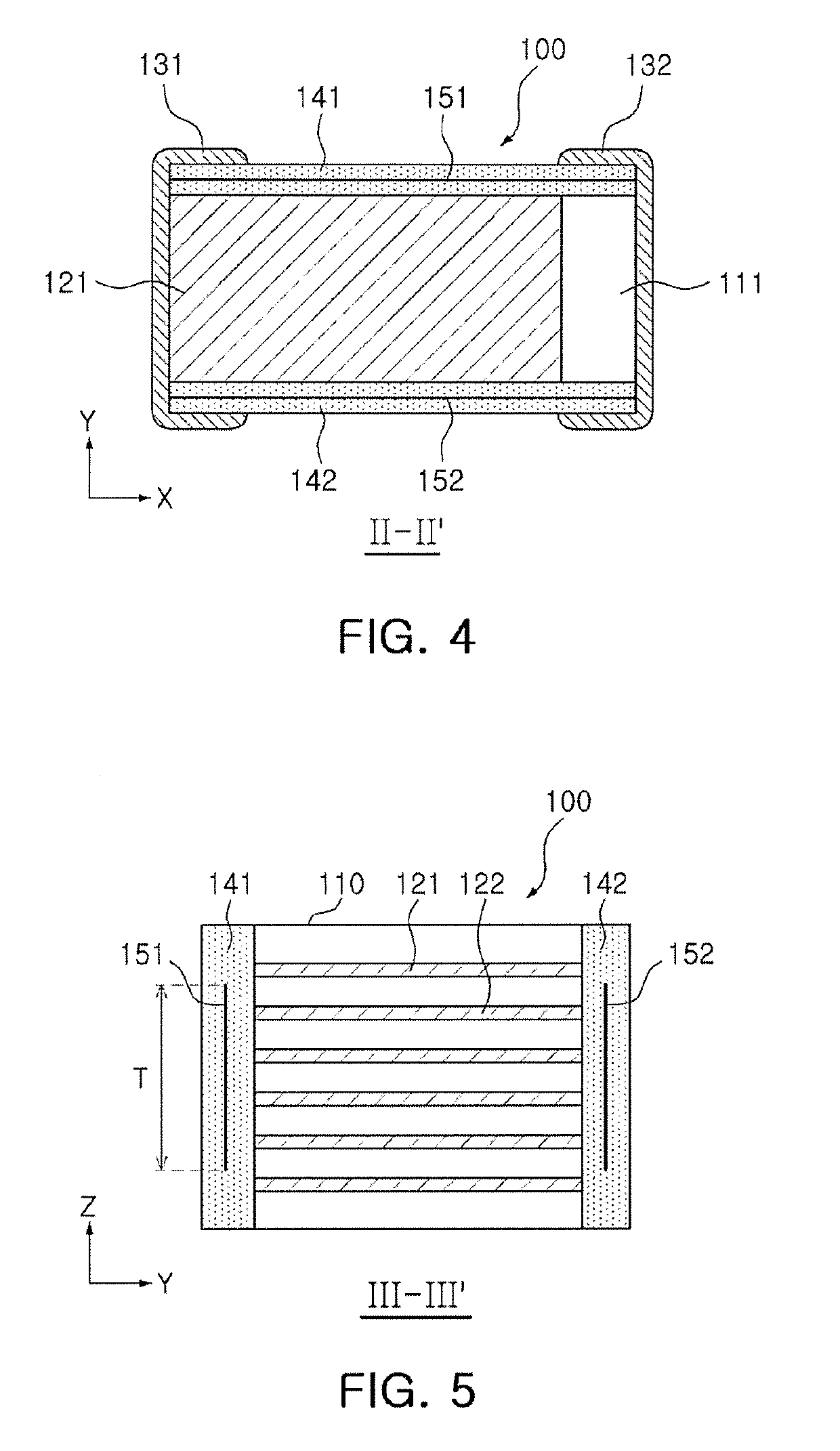

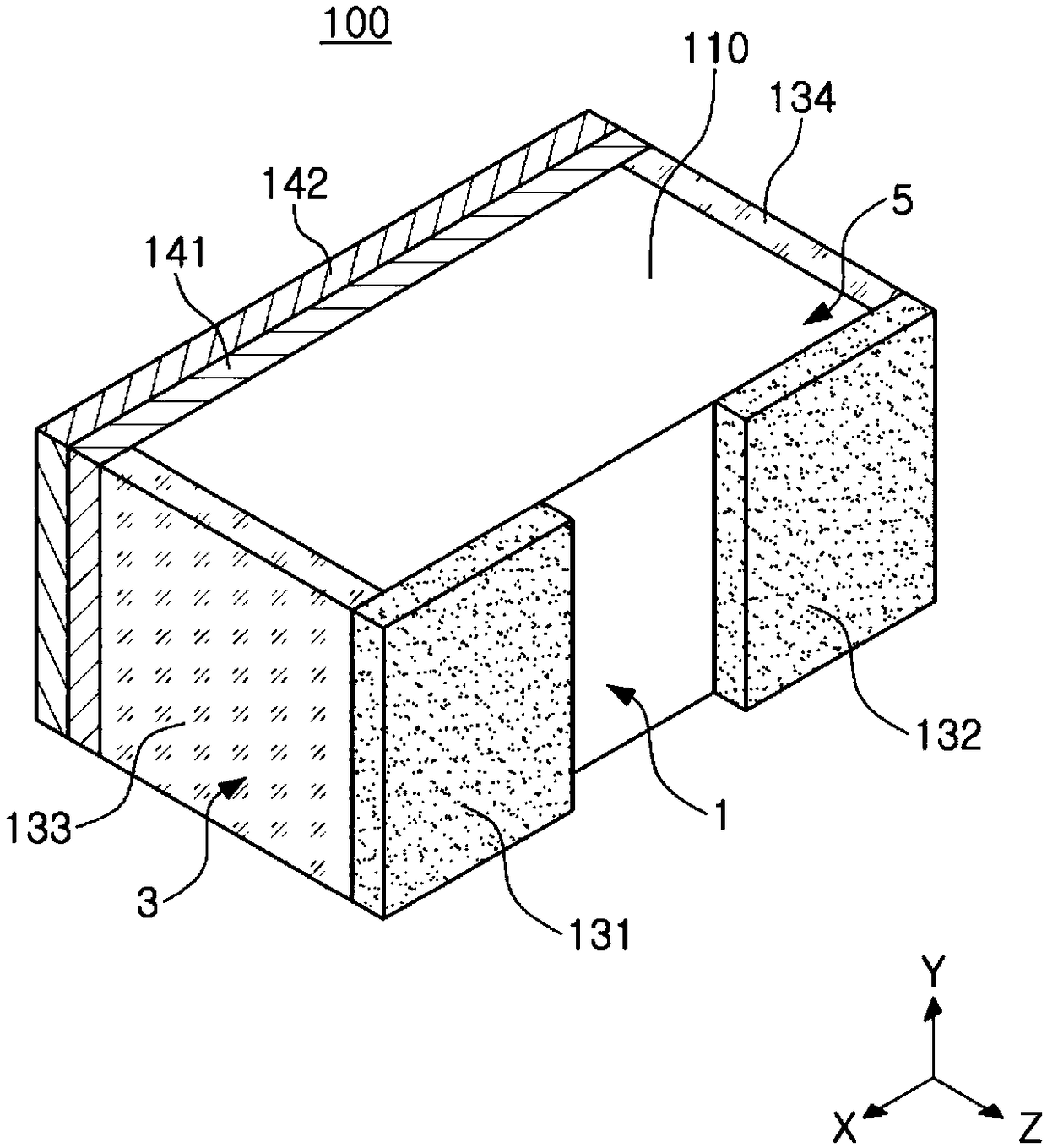

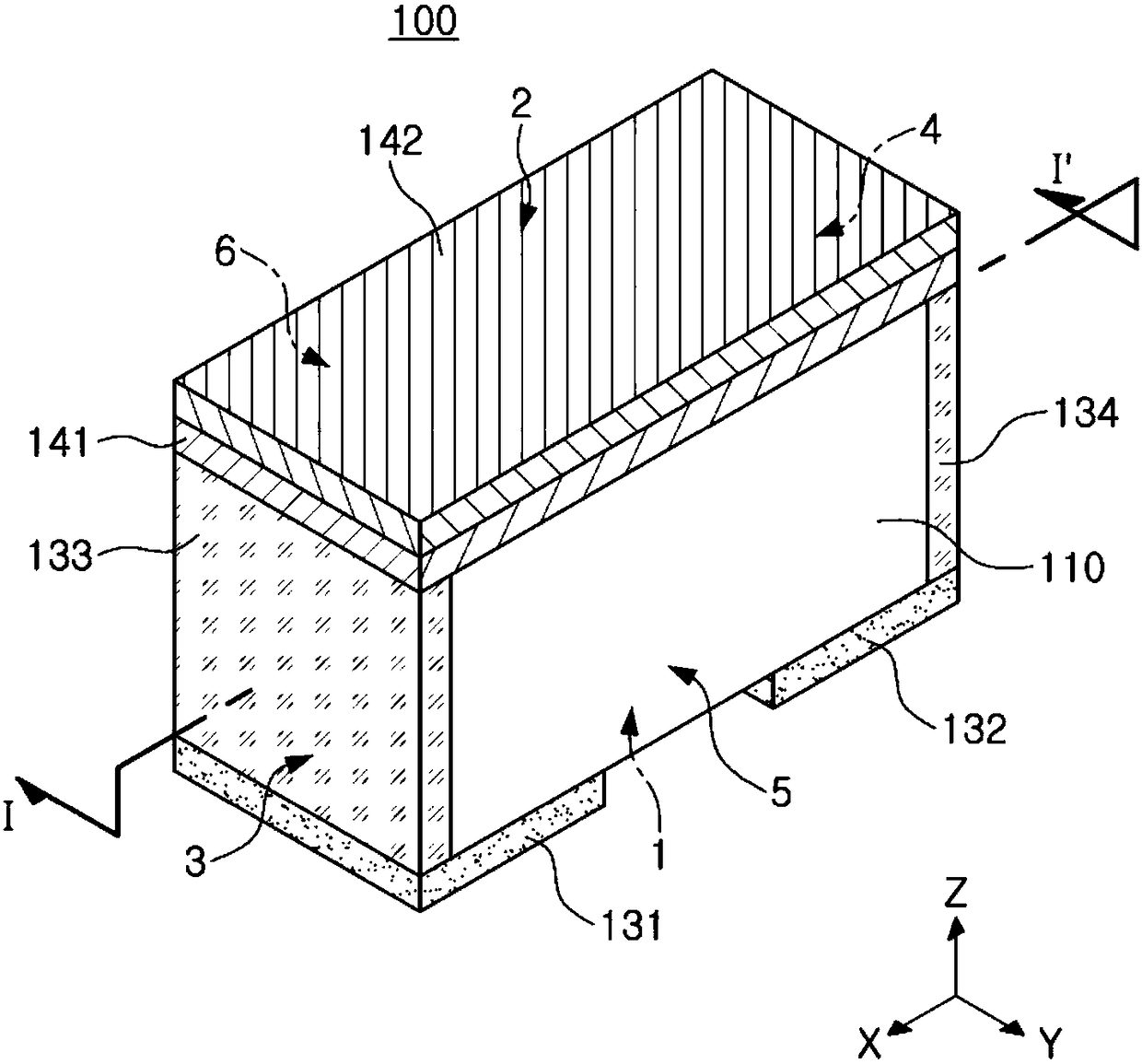

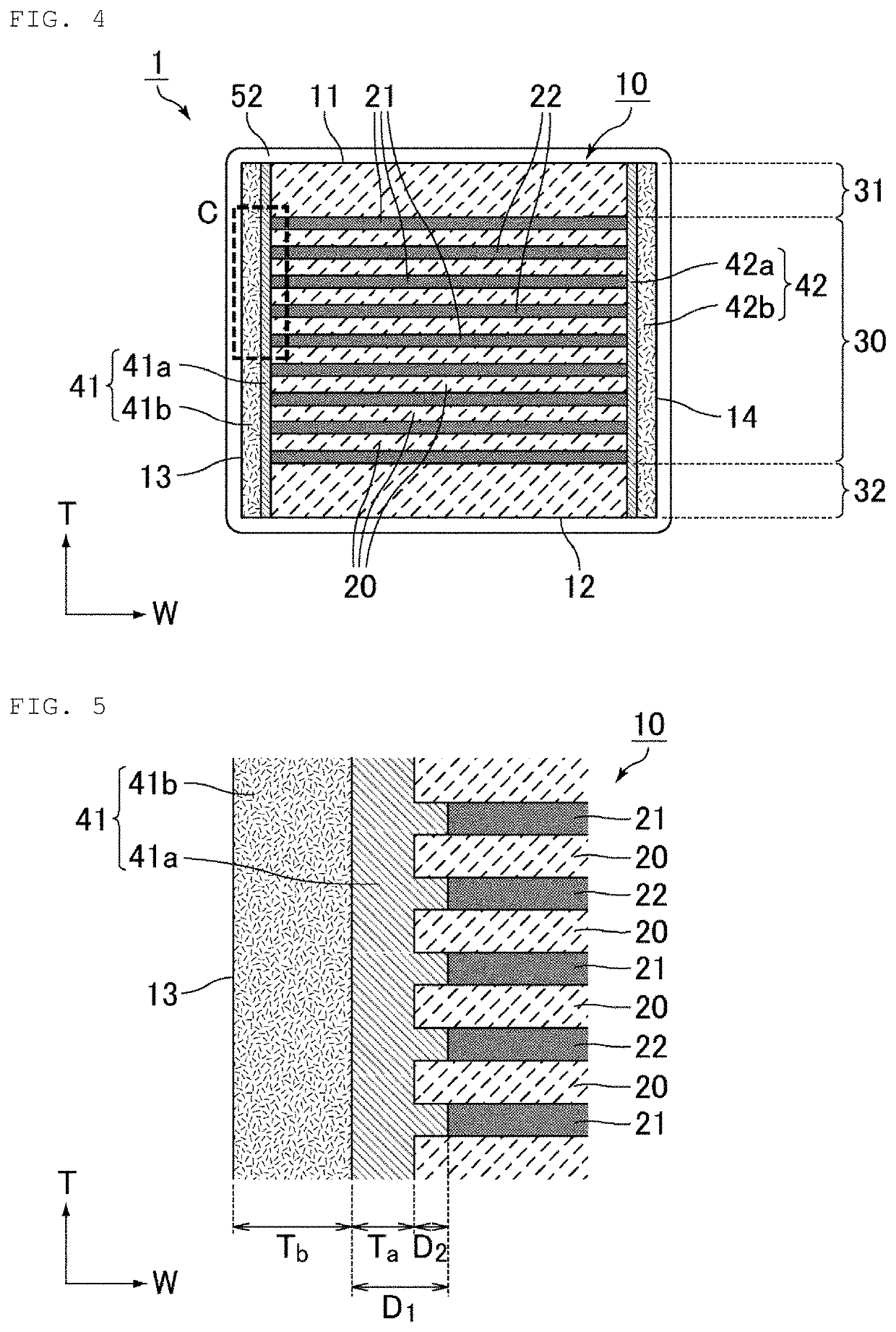

Multilayer capacitor

ActiveUS20190172643A1Improve moisture resistance reliabilityImprove reliabilityFixed capacitor electrodesStacked capacitorsEngineeringDielectric layer

A multilayer capacitor includes a body including a plurality of first and second internal electrodes alternately disposed with respective to dielectric layers interposed therebetween and having first to sixth surfaces, the first internal electrode being exposed to the third, fifth, and sixth surfaces of the body, and the second internal electrode being exposed to the fourth, fifth, and sixth surfaces of the body; first and second side portions disposed on the fifth and sixth surfaces of the body, respectively, and including first and second metal layers disposed therein; and first and second external electrodes disposed on the third and fourth surfaces of the body, respectively, and connected to the first and second internal electrodes, respectively.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Multilayered capacitor and board having the same mounted thereon

ActiveCN108695069AImprove moisture resistance reliabilityReduce warpageFixed capacitor electrodesFinal product manufactureEngineeringElectrical and Electronics engineering

The invention provides a multilayered capacitor and a board having the same mounted thereon. The multilayer capacitor includes a capacitor body including a dielectric layer and a first internal electrode and a second internal electrode; a first via electrode exposed through first and second surfaces of the capacitor body, connected to the first internal electrode and spaced apart from the second internal electrode, a second via electrode exposed through the first and second surfaces of the capacitor body, and connected to the second internal electrode and spaced apart from the first internal electrode, a first and second external electrodes disposed on the first surface of the capacitor body to be spaced apart from each other, and connected to the first and the second via electrodes, respectively, and first and second covers disposed in sequence from a bottom in the second surface of the capacitor body, wherein the first and second cover are formed of different materials.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Electronic component and electronic component device

ActiveUS20190080845A1Improve moisture resistance reliabilityImprove reliabilityFixed capacitor electrodesFinal product manufactureEngineeringElectronic component

An element body of a rectangular parallelepiped shape includes a first principal surface arranged to constitute a mounting surface, a second principal surface opposing the first principal surface in a first direction, a pair of side surfaces opposing each other in a second direction, and a pair of end surfaces opposing each other in a third direction. An external electrode is disposed at an end portion of the element body in the third direction. The external electrode includes a conductive resin layer. The conductive resin layer covers a region near the first principal surface of the end surface. A height of the conductive resin layer in the first direction is larger at an end portion in the second direction than at a center in the second direction, when viewed from the third direction.

Owner:TDK CORPARATION

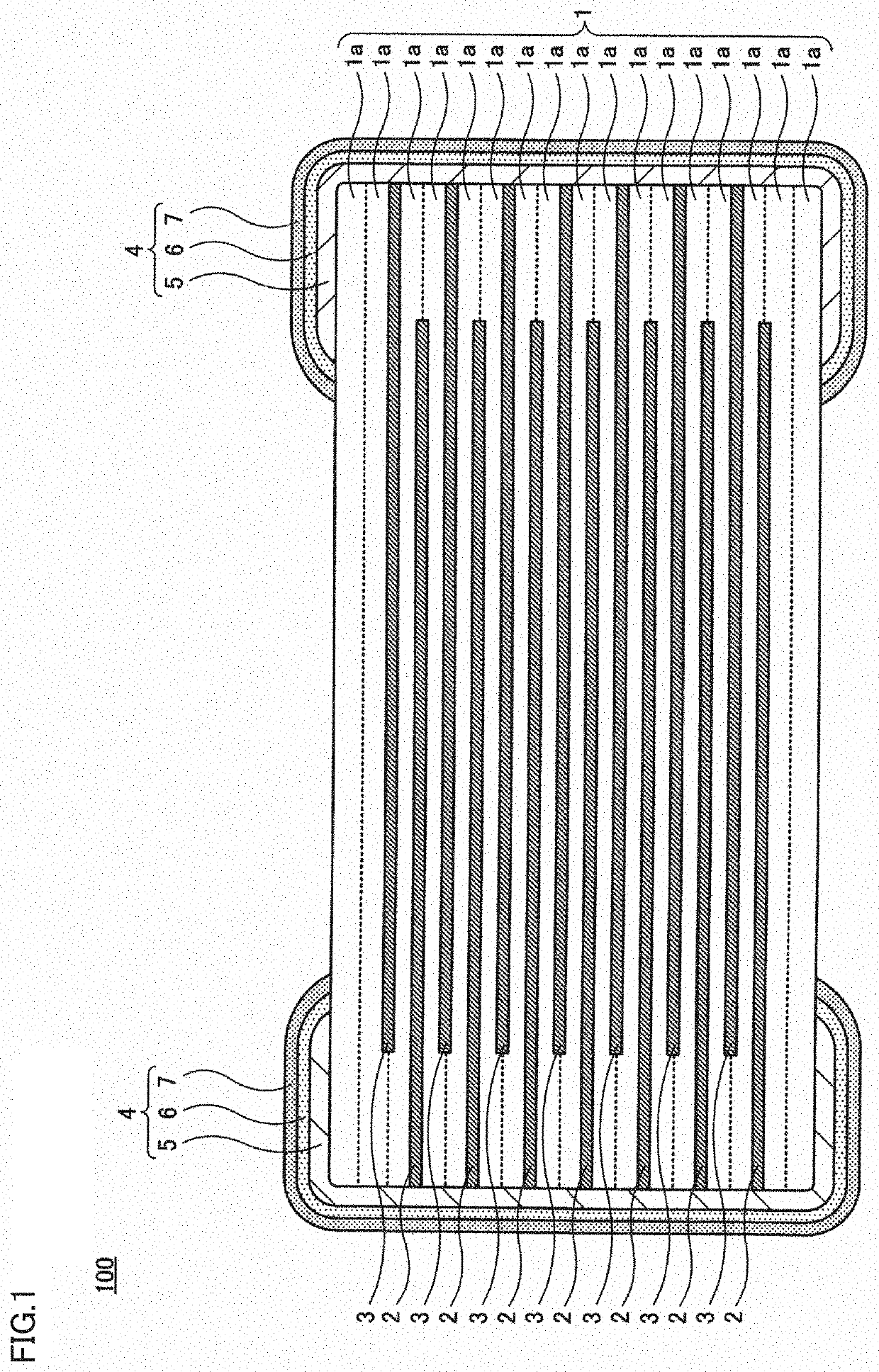

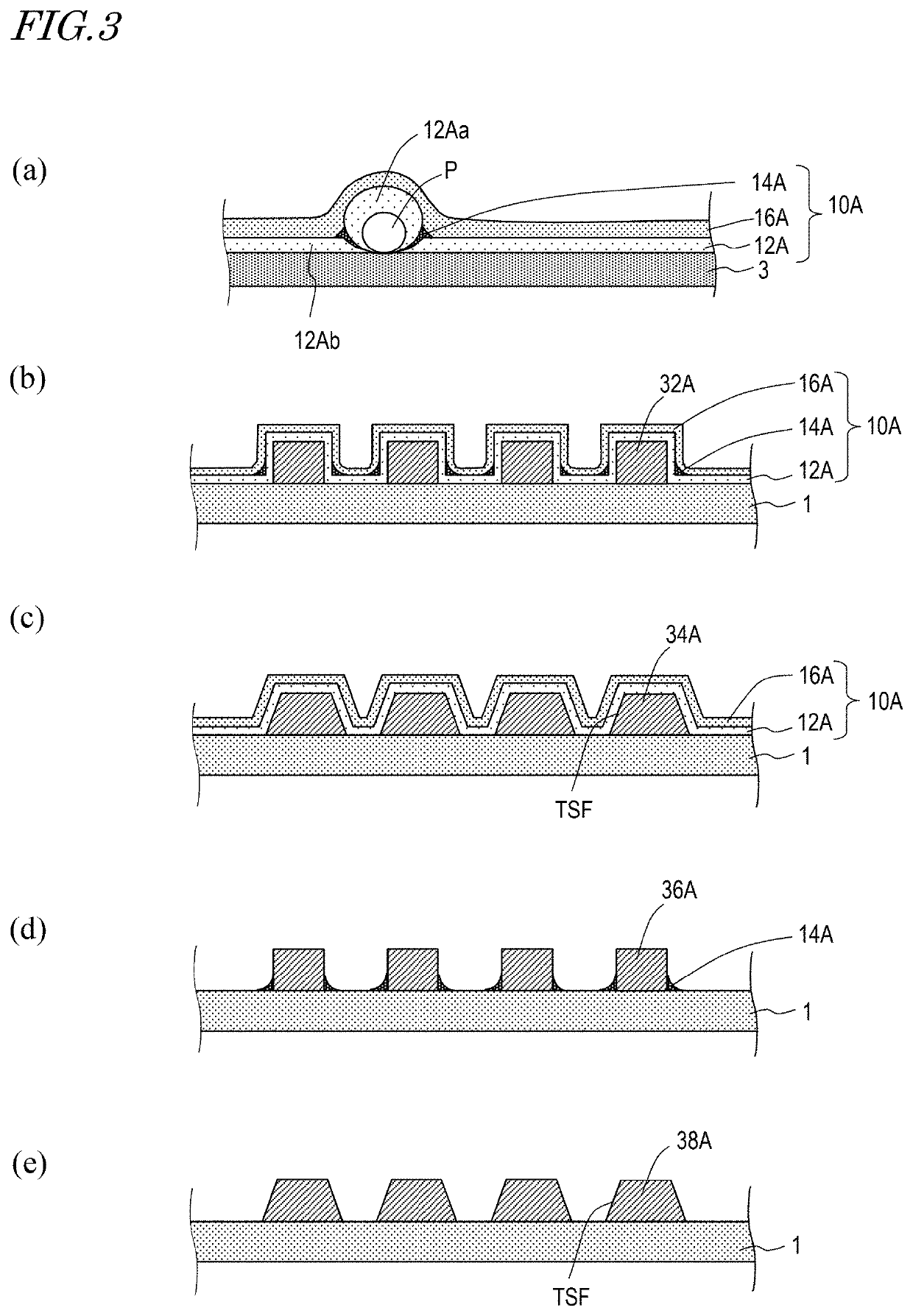

Method for manufacturing organic el device, film-forming method, and film-forming apparatus

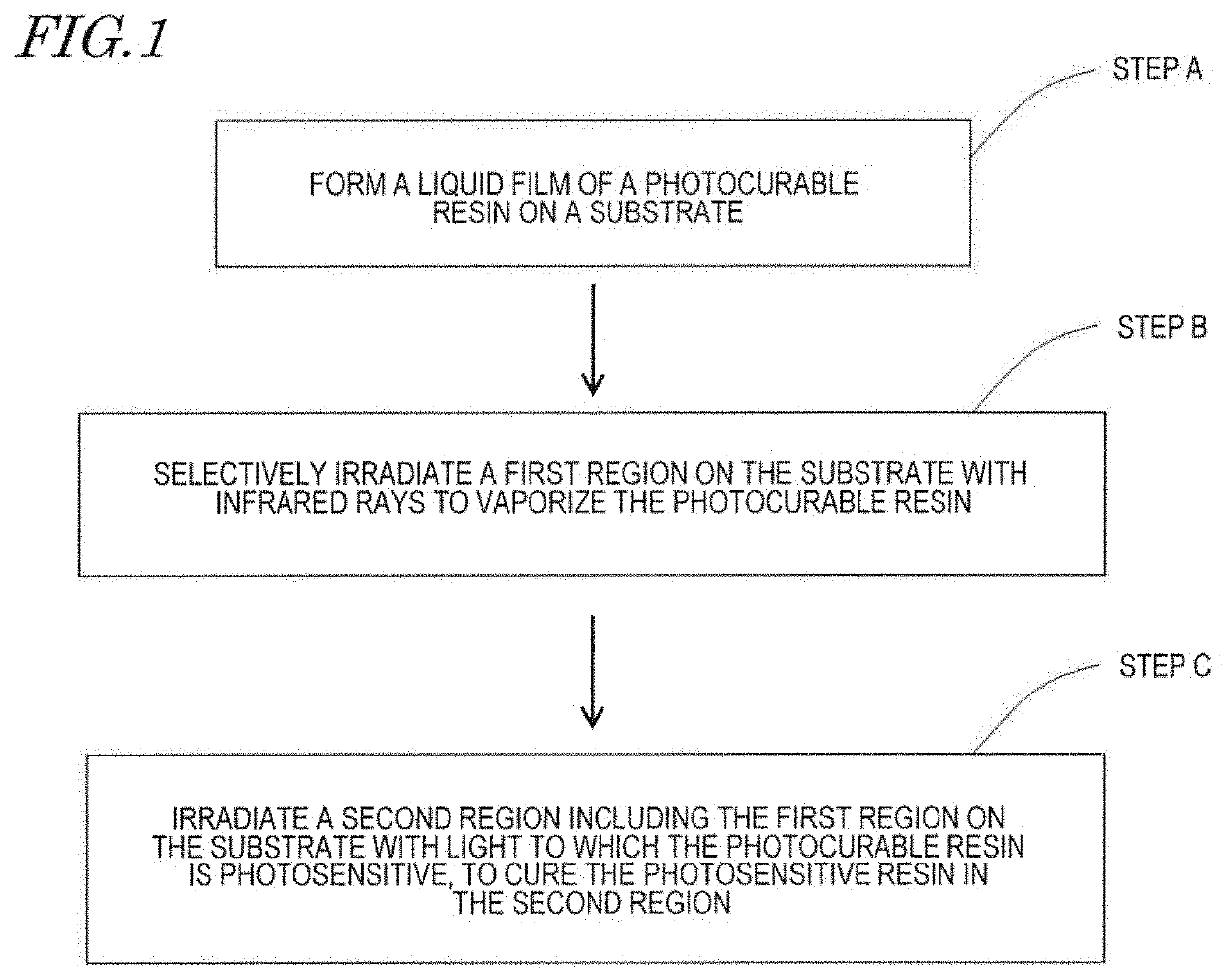

ActiveUS20200020892A1Improved in mass-productivityImproved in moisture-resistance reliabilityFinal product manufactureElectroluminescent light sourcesInfraredOrganic chemistry

The film-forming method according to an embodiment of the present invention includes: a step A for forming a photocurable resin liquid film on a substrate; a step B for vaporizing the photocurable resin in a first region on the substrate by selectively irradiating the first region with infrared rays or visible light having a wavelength that is longer than 550 nm; and a step C for obtaining a photocured resin film by curing the photocurable resin in the second region on the substrate, said second region including the first region, by irradiating, simultaneously with the step 3 or after performing the step 3, the second region with light, to which the photocurable resin is sensitive.

Owner:SAKAI DISPLAY PROD

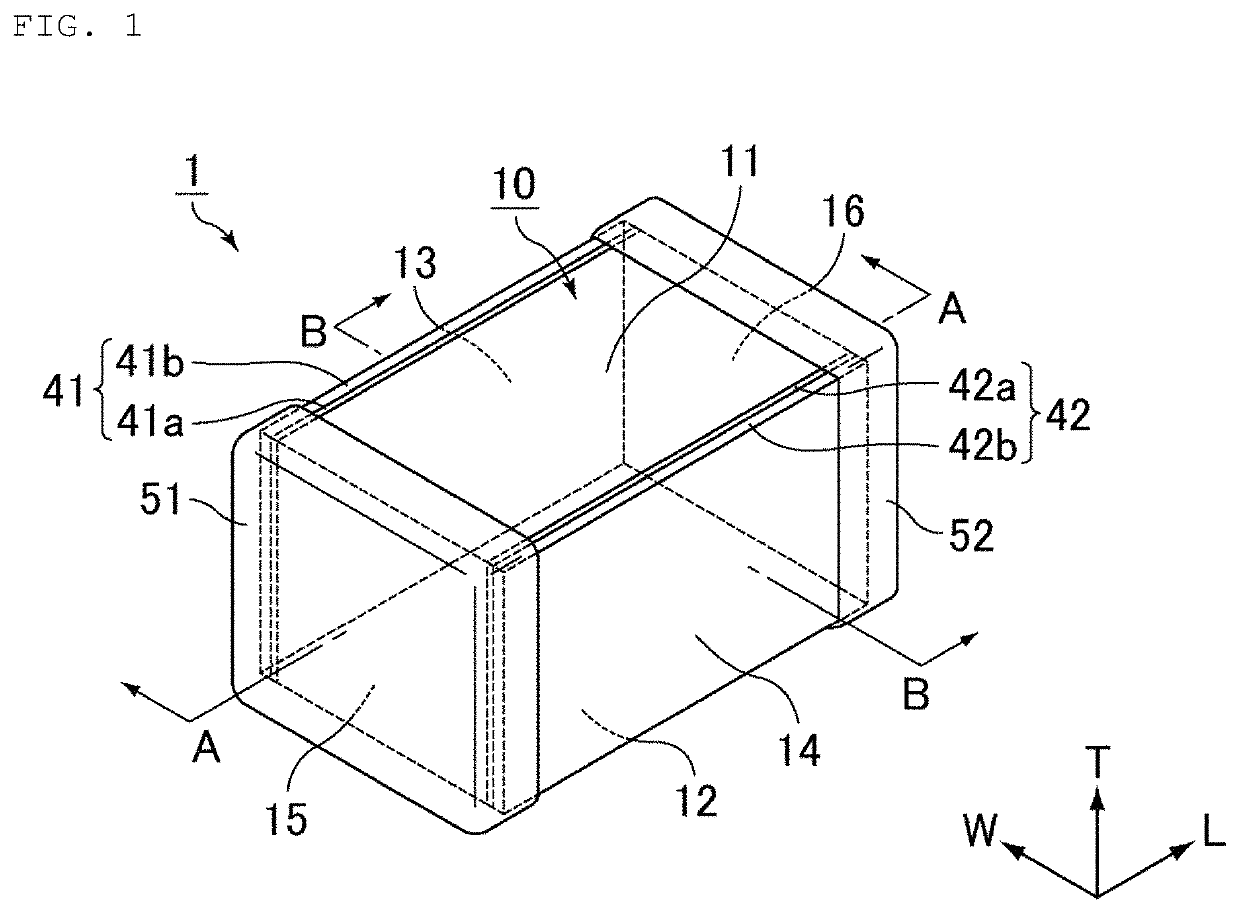

Electronic component and electronic component device

ActiveUS20190131073A1Inhibit the generation of cracksImprove moisture resistance reliabilityFixed capacitor electrodesStacked capacitorsEngineeringElectronic component

An element body of a rectangular parallelepiped shape includes first and second principal surfaces opposing each other in a first direction, a pair of side surfaces opposing each other in a second direction, and a pair of end surfaces opposing each other in a third direction. An external electrode disposed at an end portion of the element body in the third direction. The external electrode includes a first conductive resin layer and a second conductive resin layer. The first conductive resin layer continuously covers one part of the first principal surface, one part of the end surface, and one part of each of the pair of side surfaces. The second conductive resin layer is separated from the first conductive resin layer, and continuously covers one part of the second principal surface, one part of the end surface, and one part of each of the pair of side surfaces.

Owner:TDK CORPARATION

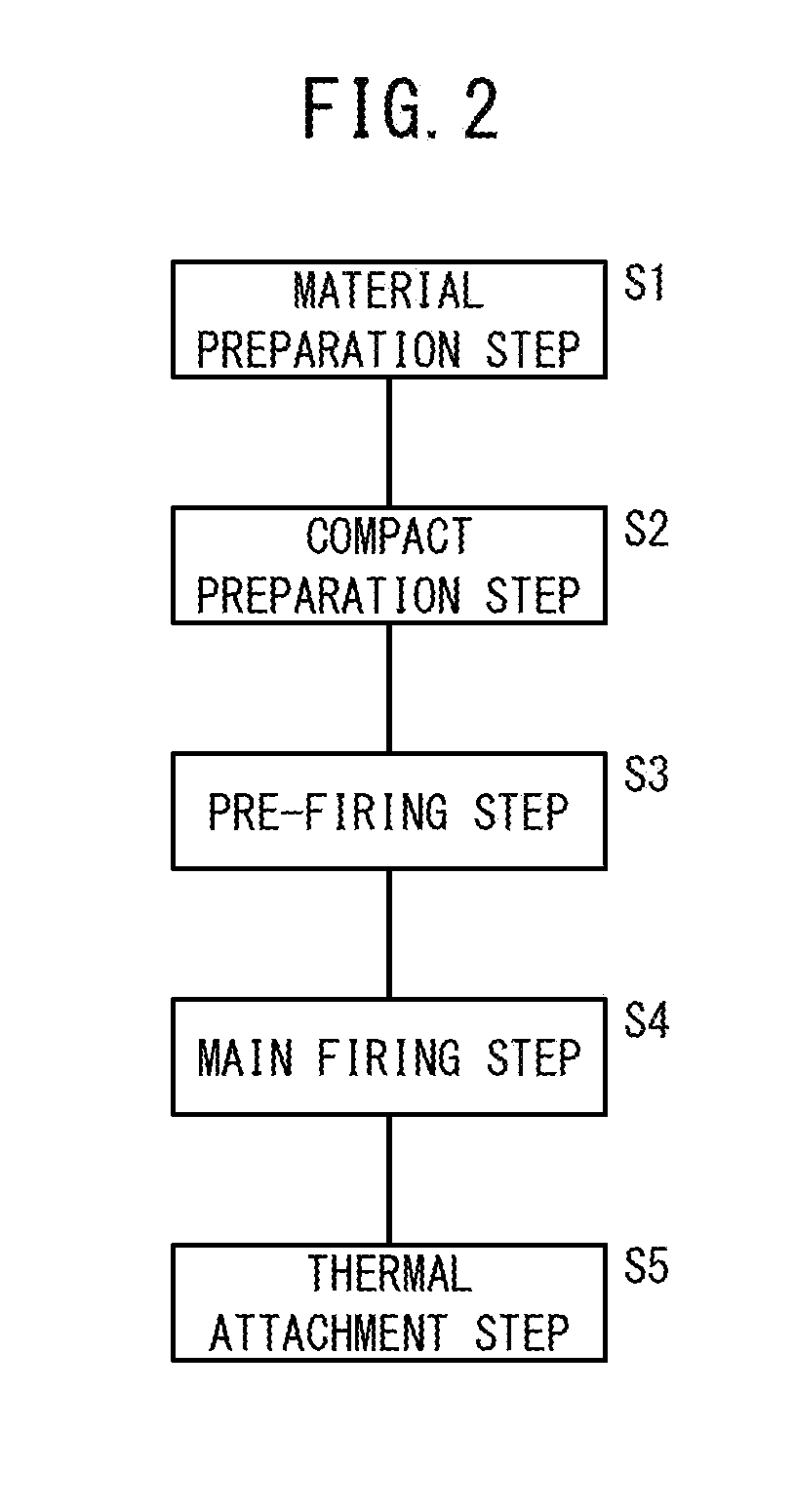

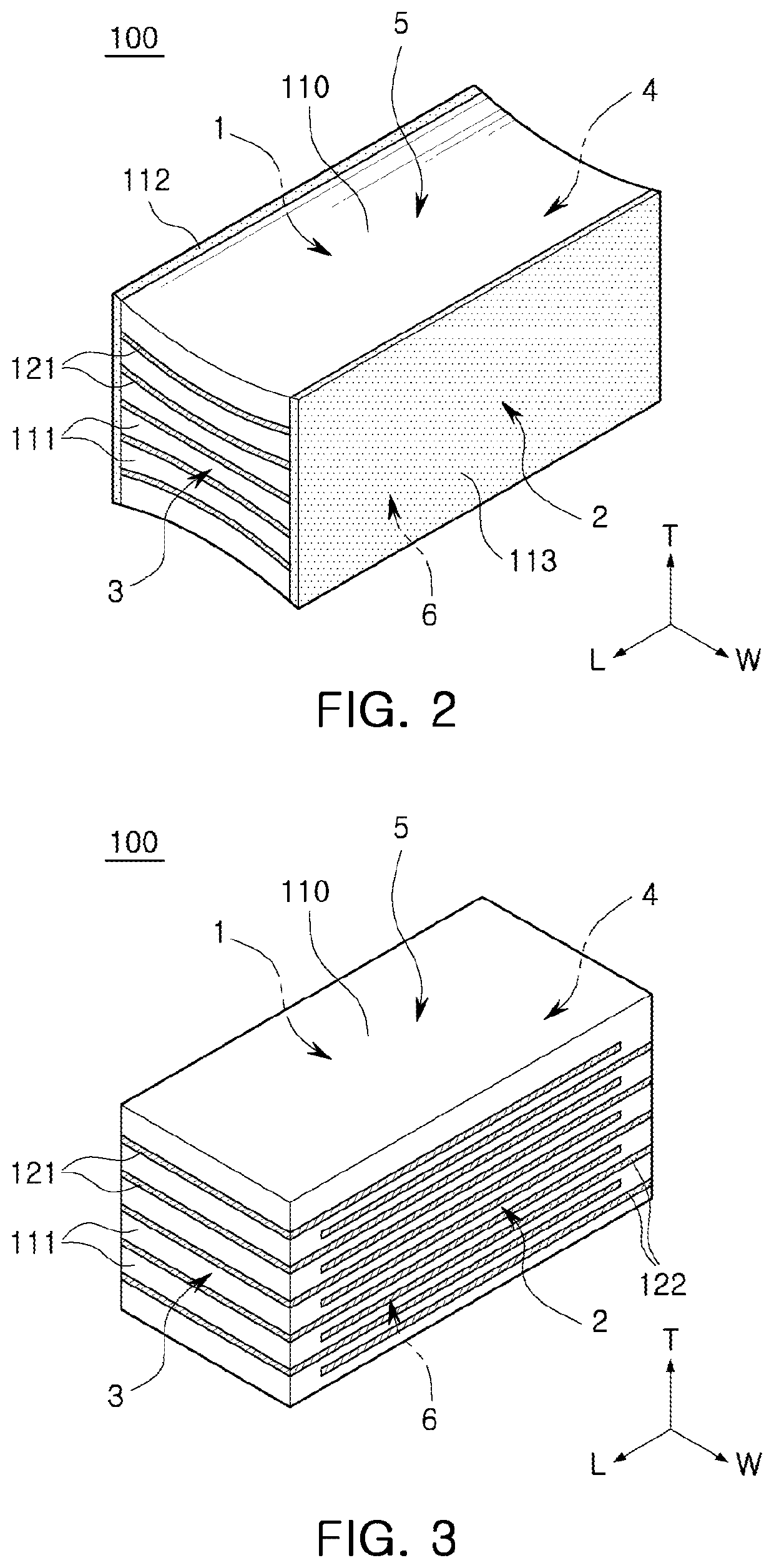

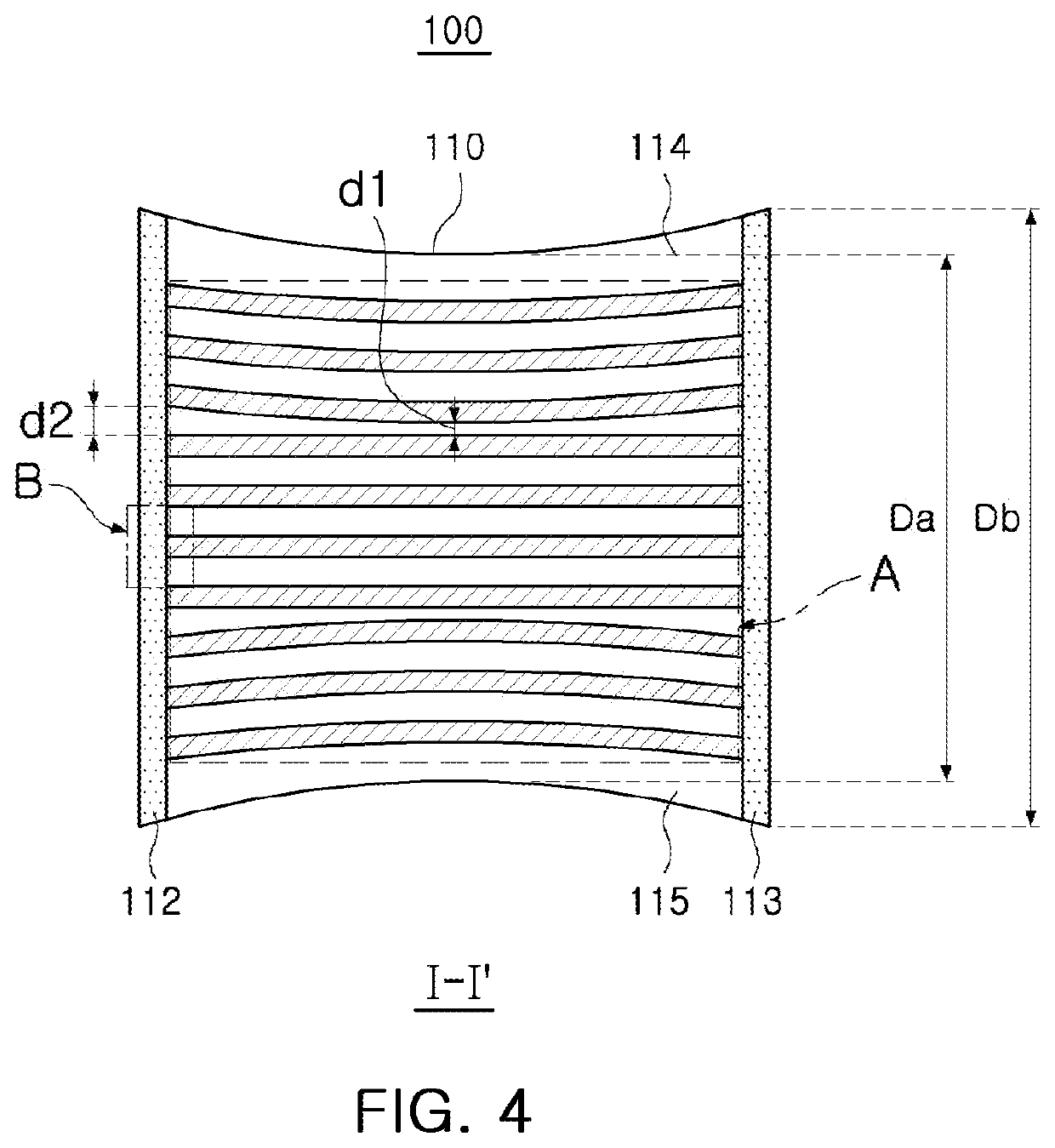

Multilayer ceramic capacitor and method of manufacturing the same

ActiveUS20210166881A1Improve moisture resistance reliabilityImprove pressure resistanceFixed capacitor electrodesFixed capacitor dielectricCeramic capacitorDielectric layer

A multilayer ceramic capacitor includes a ceramic body including a dielectric layer, a plurality of first and second internal electrodes disposed inside the ceramic body, exposed to the first and second surfaces, and having ends exposed to the third or fourth surface, and a first side margin portion and a second side margin portion disposed on side portions of the plurality of first and second internal electrodes exposed to the first and second surfaces. A ratio Db / Da satisfies 1.00 to 1.07, inclusive, where ‘Db’ is a distance, in a stacking direction of the dielectric layer, between both end points of respective edge regions of the first side margin portion and the second side margin portion, and ‘Da’ is a distance in a central region of the ceramic body in the stacking direction.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Electronic component

ActiveUS20190237250A1Inhibit the generation of cracksImprove moisture resistance reliabilityFixed capacitor electrodesFixed capacitor dielectricElectronic componentElectrode

An element body of a rectangular parallelepiped shape includes a first principal surface arranged to constitute a mounting surface, a second principal surface opposing the first principal surface in a first direction, a pair of side surfaces opposing each other in a second direction, and a pair of end surfaces opposing each other in a third direction. An external electrode is disposed on the element body. The external electrode includes a conductive resin layer. The conductive resin layer continuously covers one part of the first principal surface, one part of the end surface, and one part of each of the pair of side surfaces. A length of the conductive resin layer in the third direction is smaller than a length of the conductive resin layer in the first direction.

Owner:TDK CORPARATION

Multilayer ceramic capacitor

ActiveUS10186378B2High mechanical strengthImprove moisture resistance reliabilityFixed capacitor electrodesFixed capacitor dielectricCeramic capacitorAlloy

A multilayer ceramic capacitor includes a laminate of ceramic layers and internal electrodes, and a pair of external electrodes located on both end surfaces of the laminate and electrically connected to the internal electrodes. Each of the pair of external electrodes includes an underlying electrode layer on the surface of the laminate and including Cu, a bonding portion partially provided on a surface of the underlying electrode layer and including a Cu3Sn alloy, and a conductive resin layer provided on surfaces of the underlying electrode layer and the bonding portion, and a total area of the bonding portion is not less than about 2.7% and not more than about 40.6% of a total area of the underlying electrode layer.

Owner:MURATA MFG CO LTD

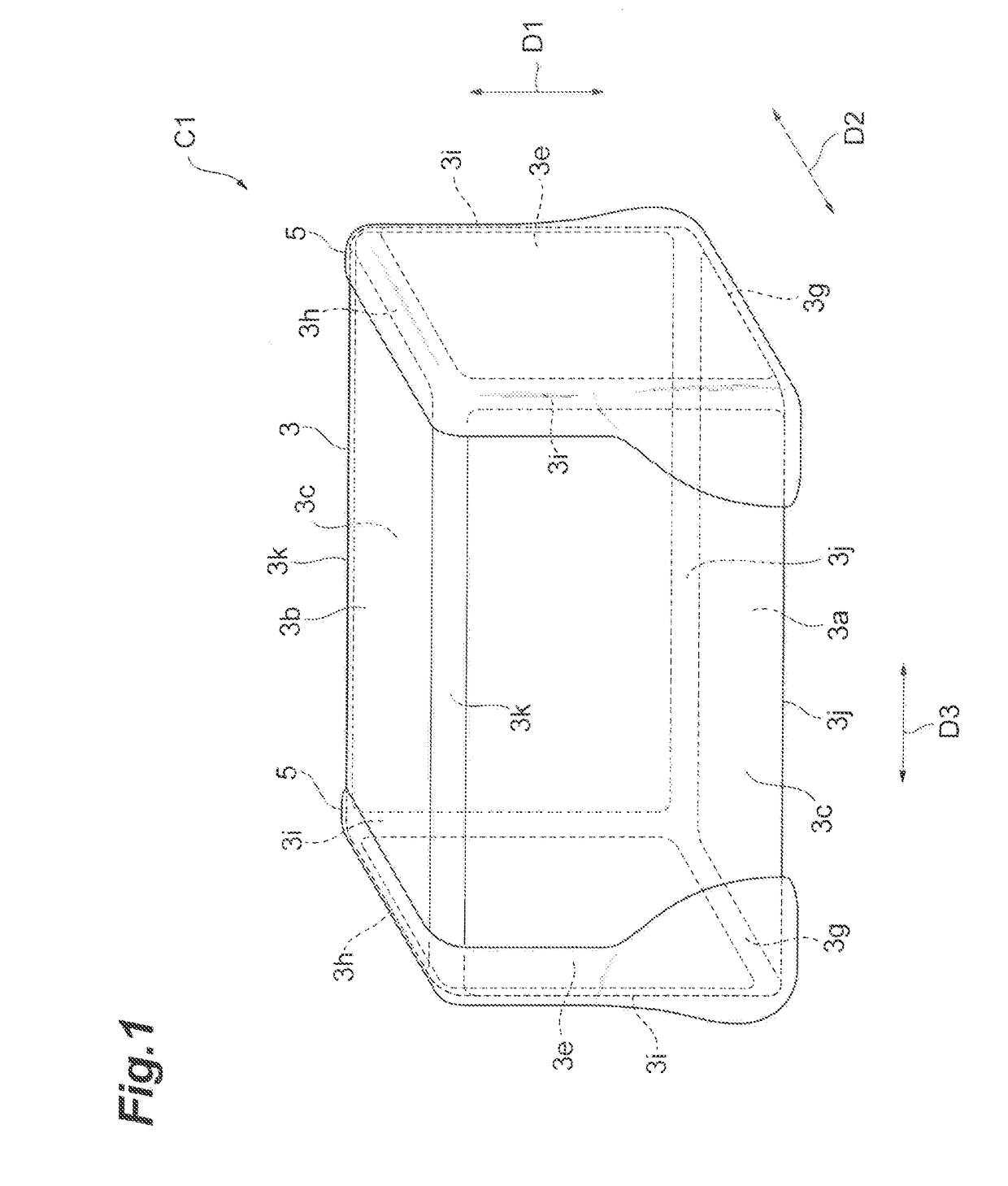

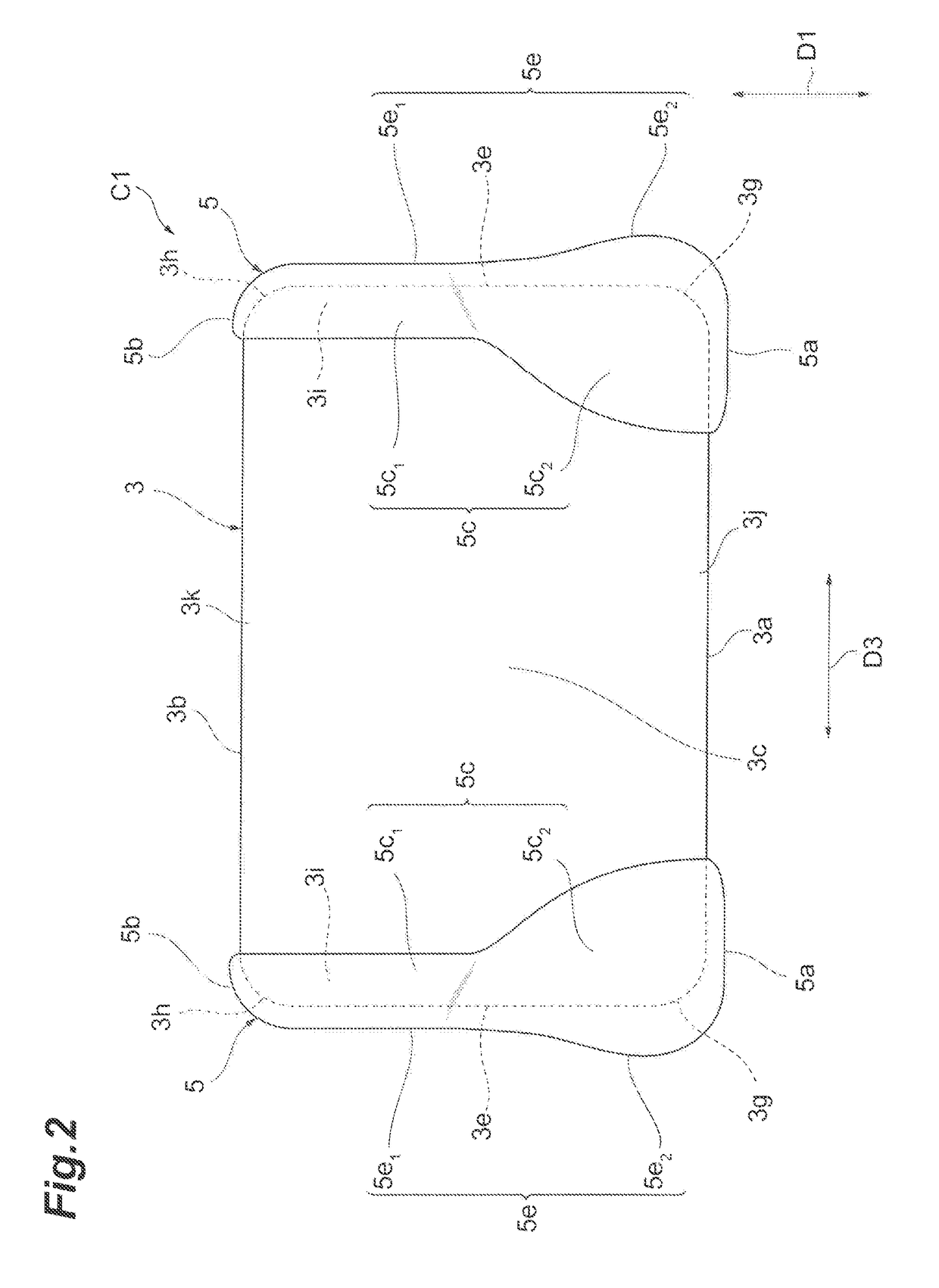

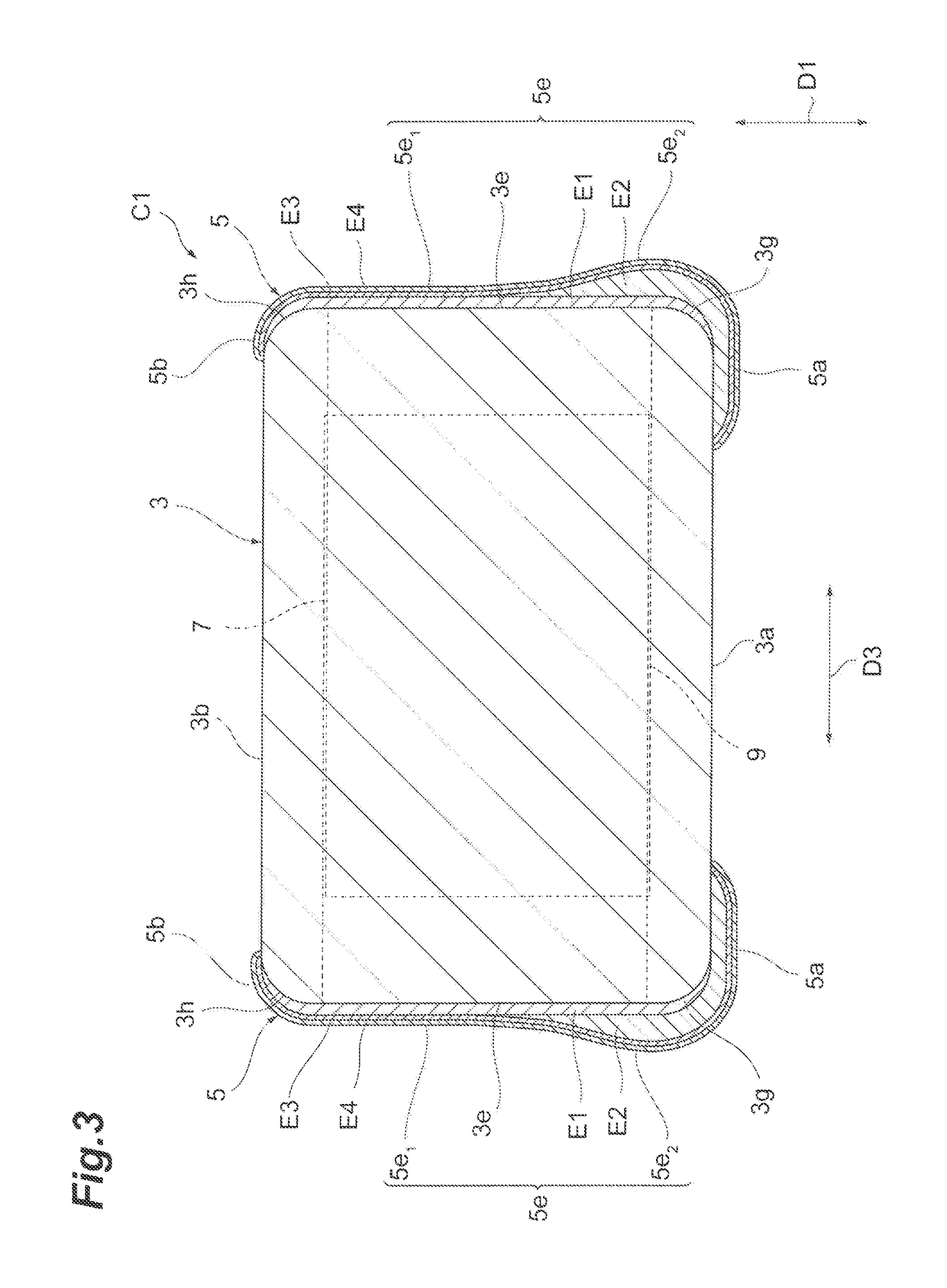

Organic electroluminescent device and method for producing same

PendingUS20210091345A1Improve moisture resistance reliabilityElectroluminescent light sourcesSolid-state devicesHemt circuitsOrganic electroluminescence

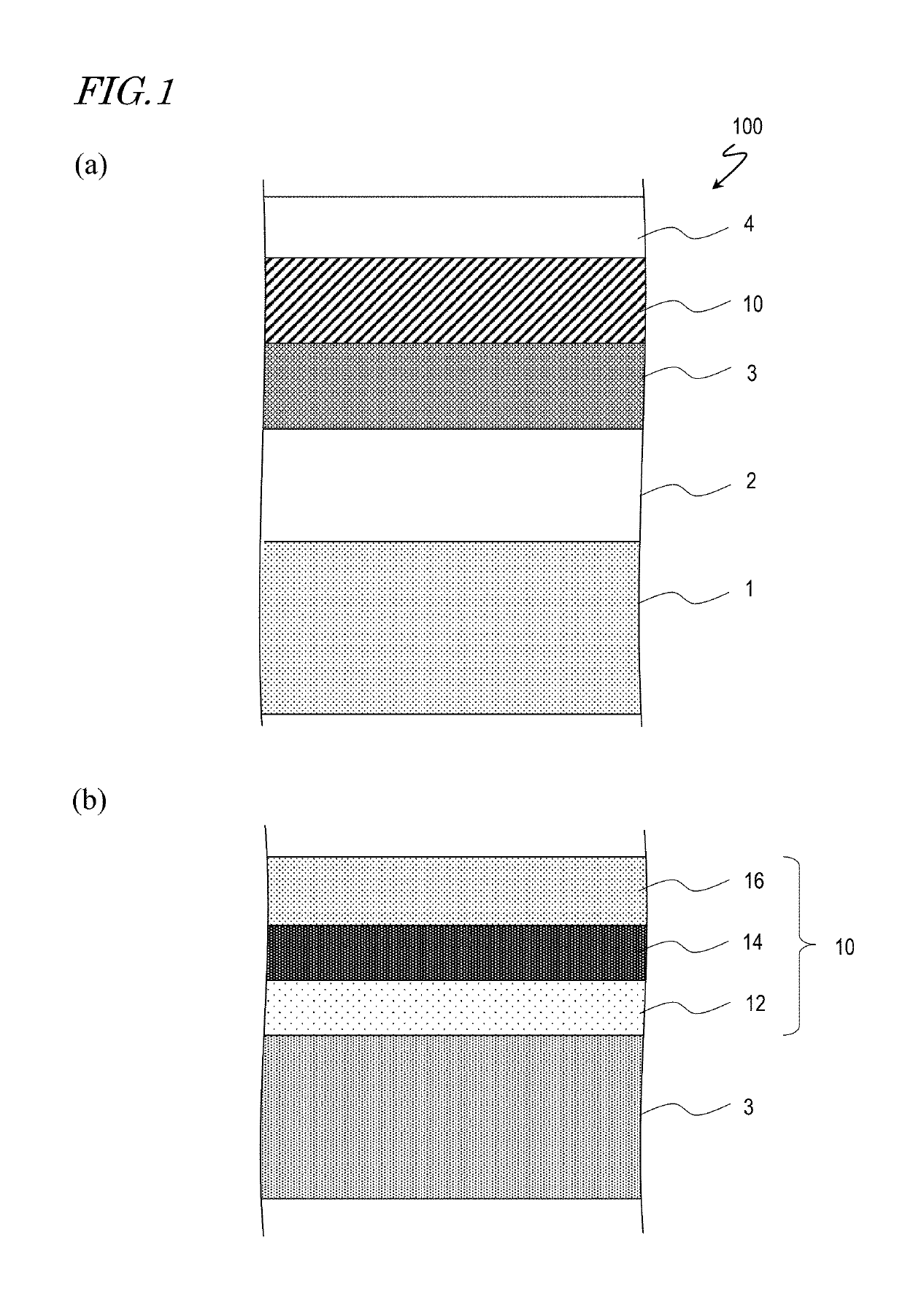

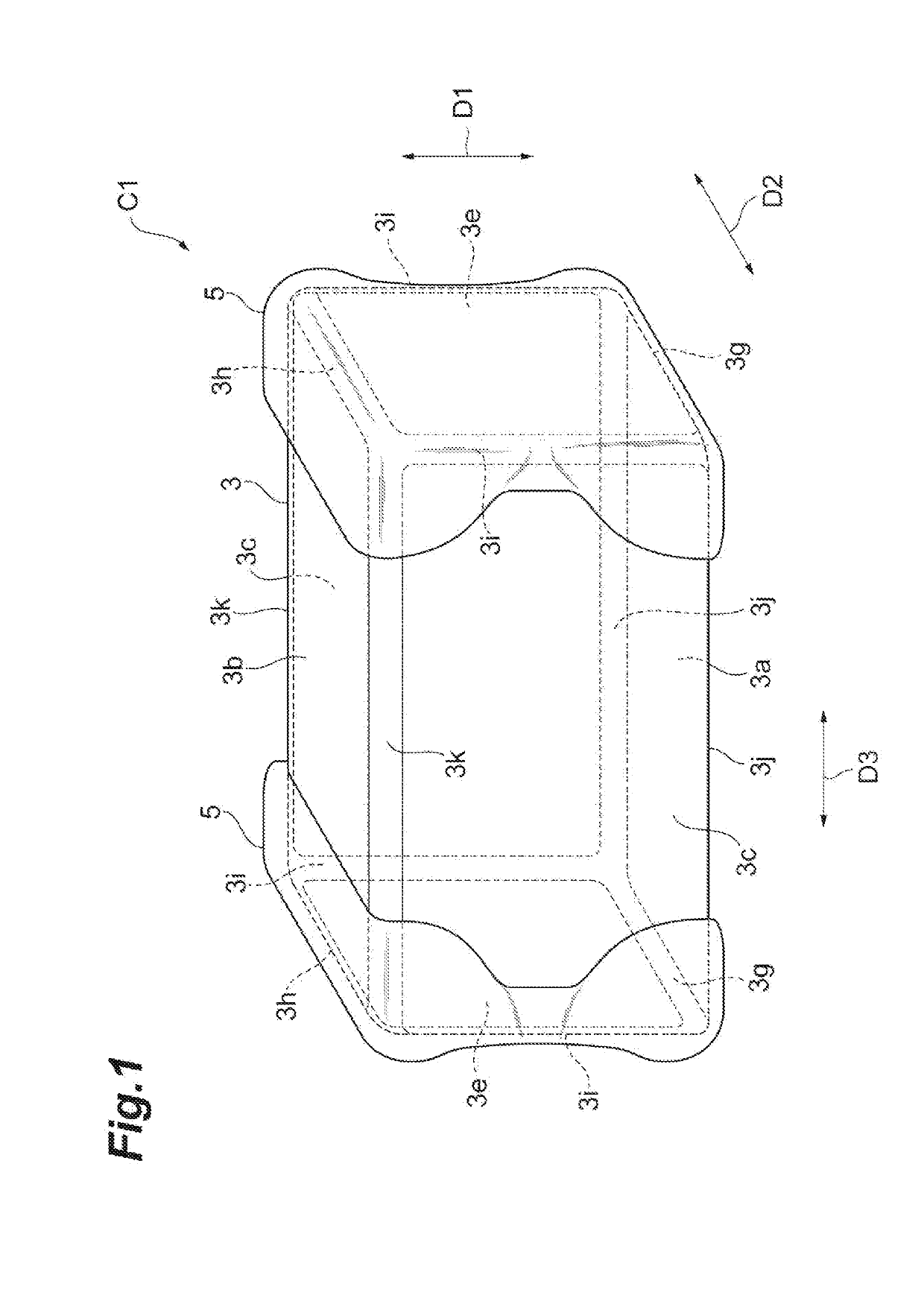

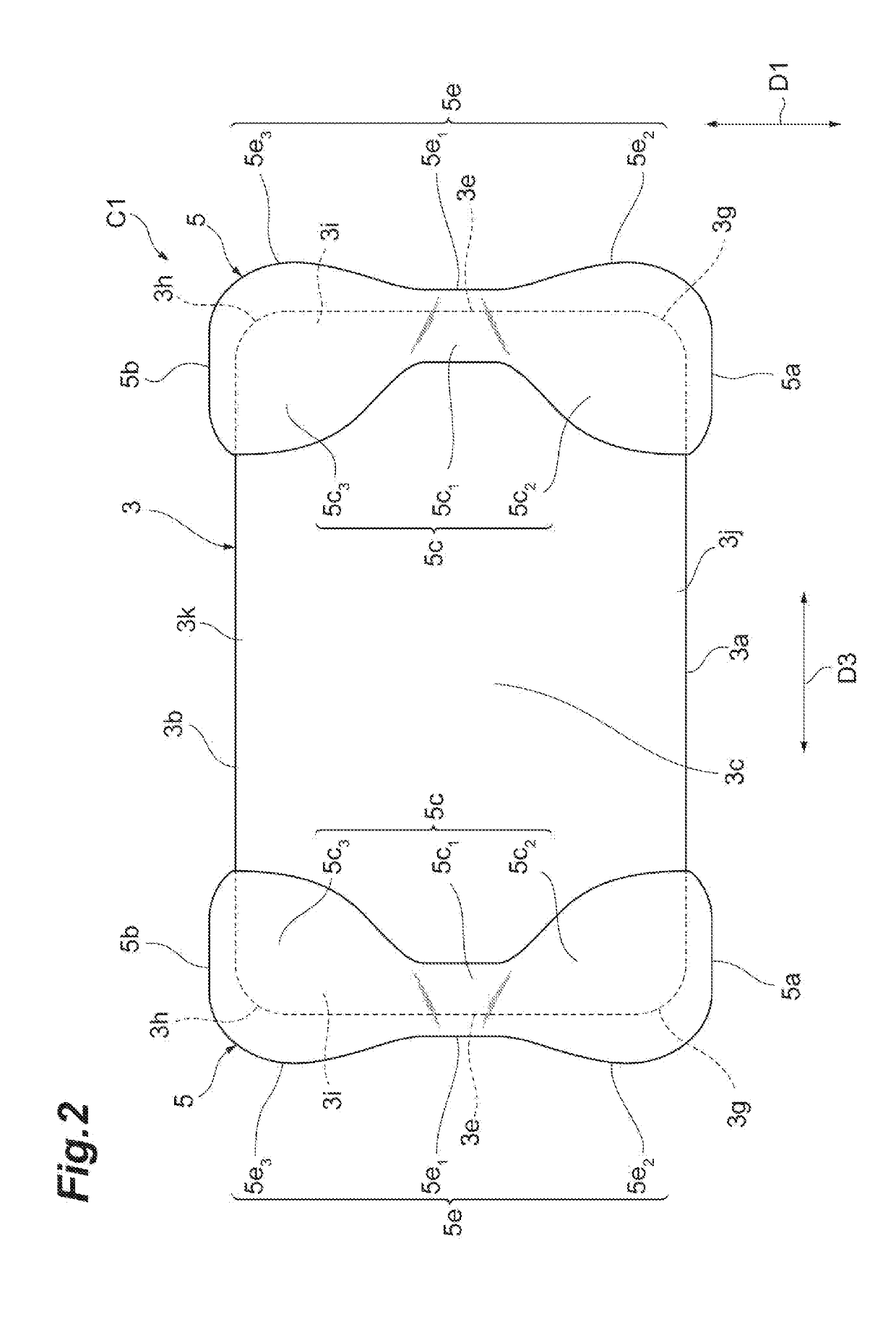

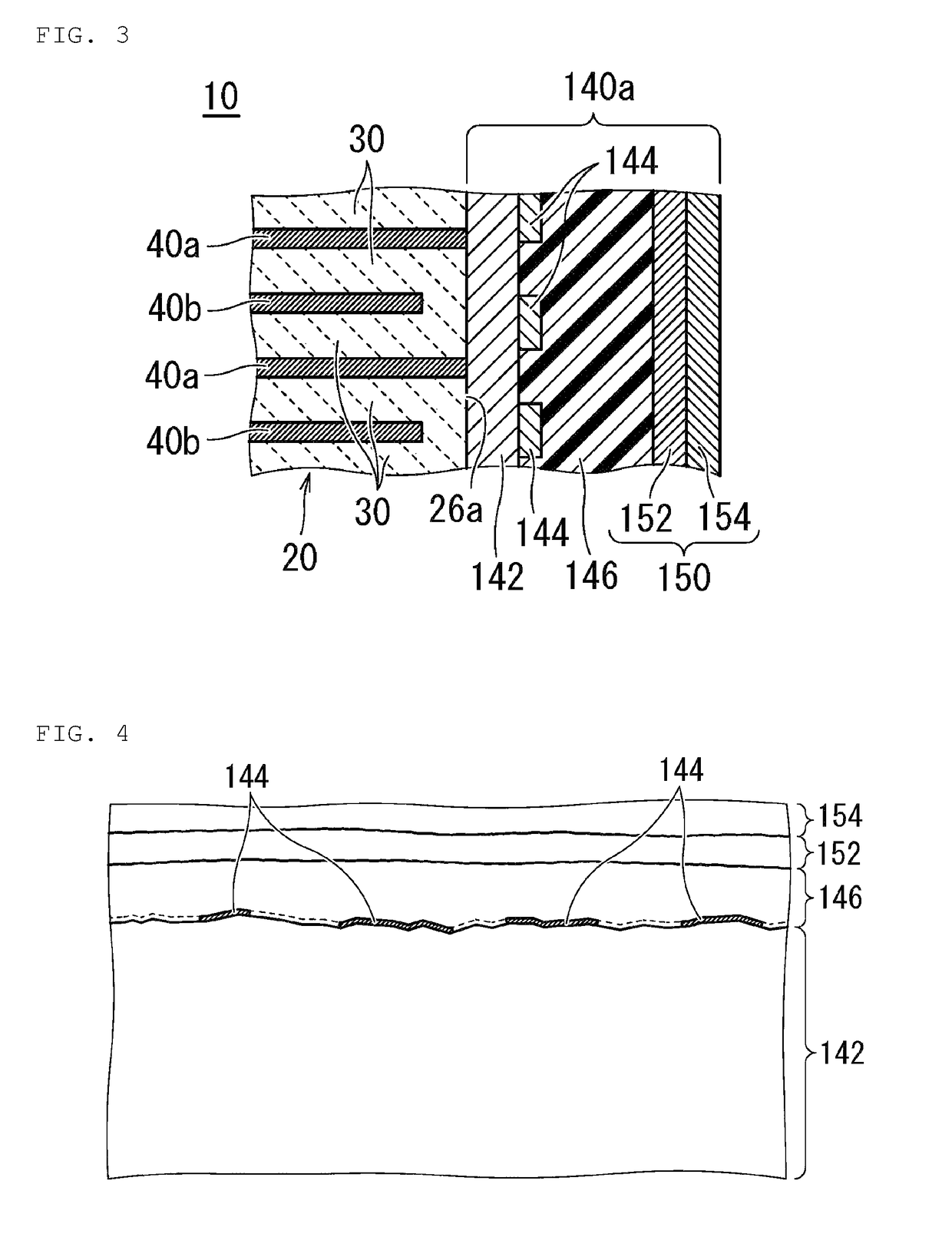

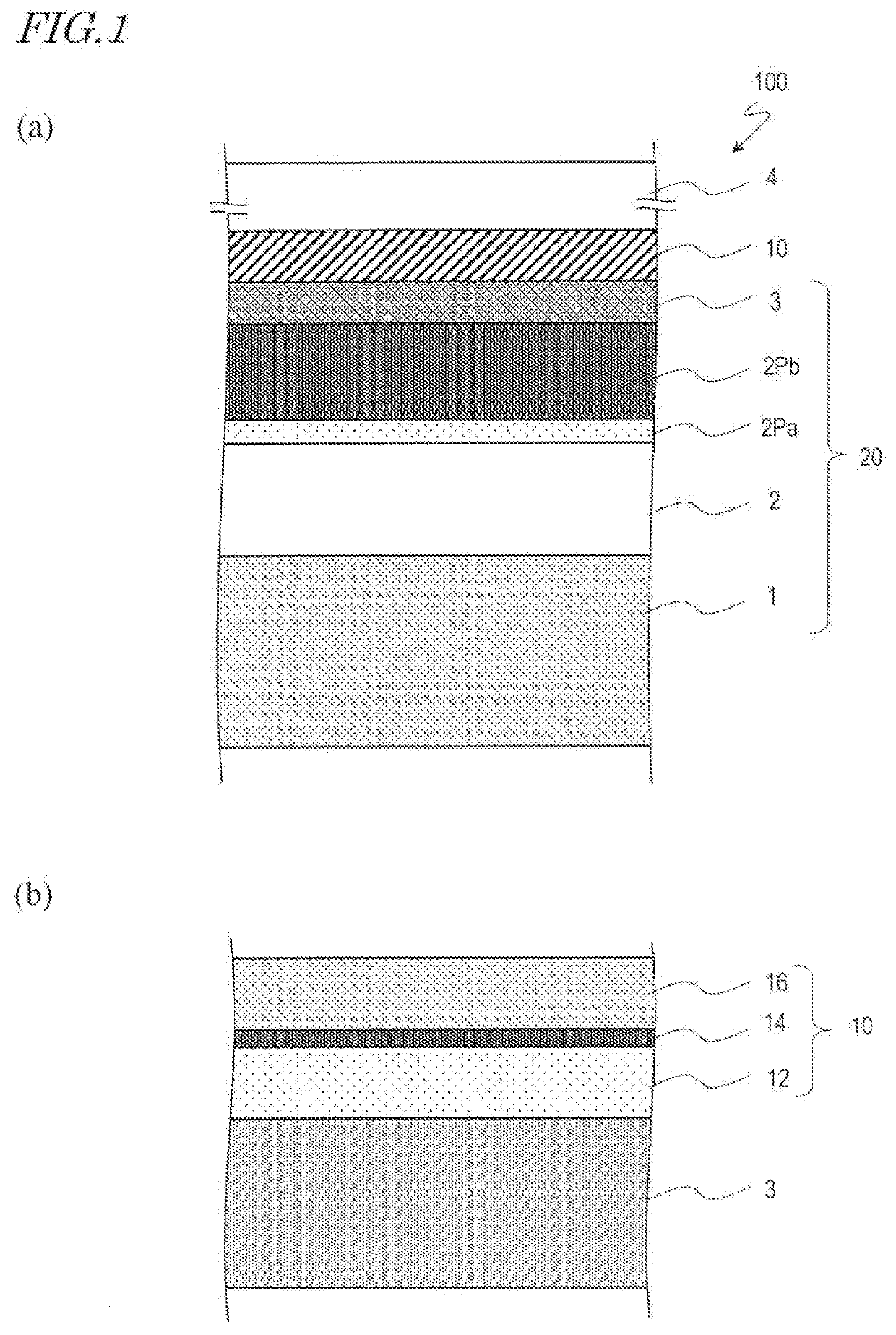

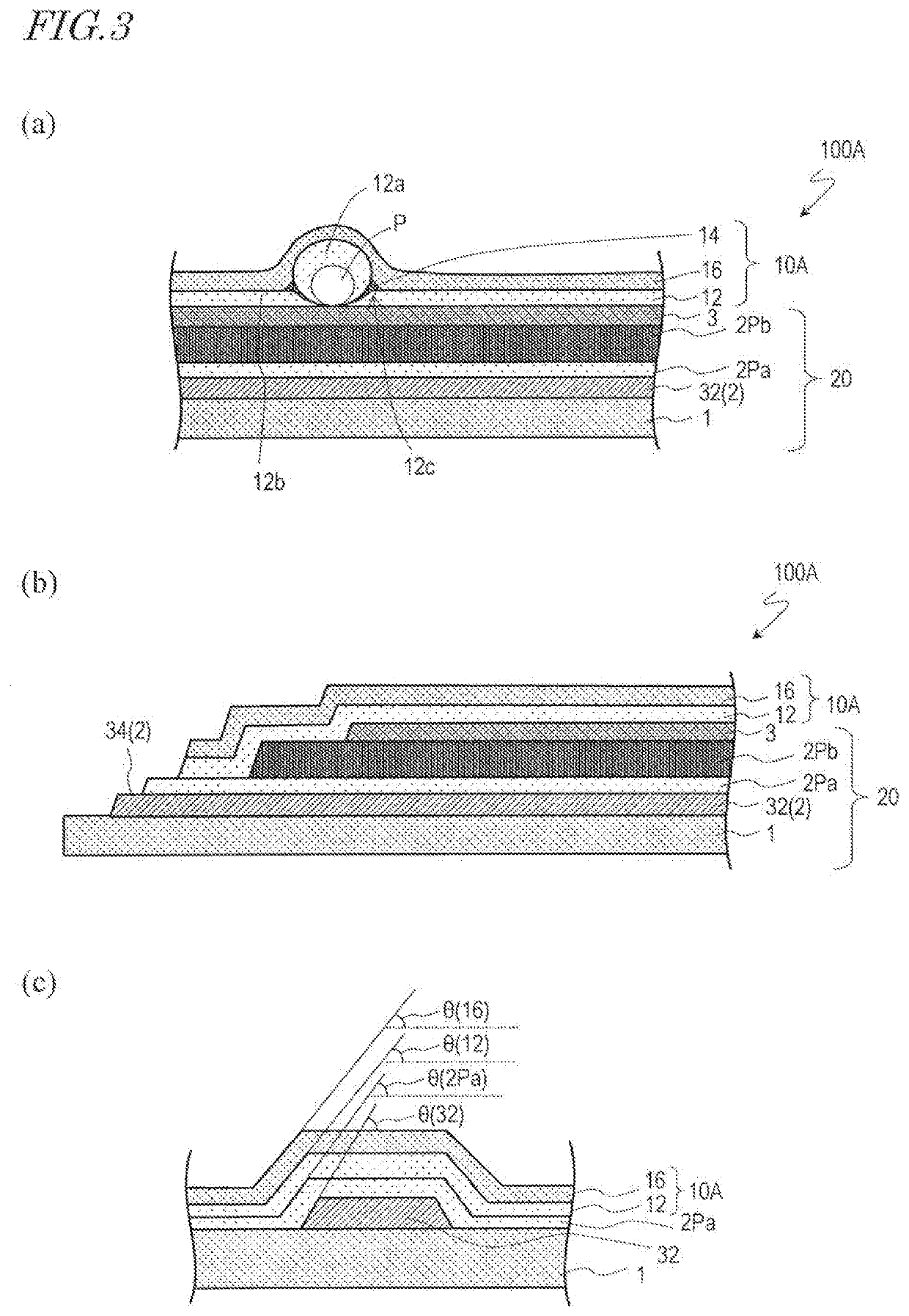

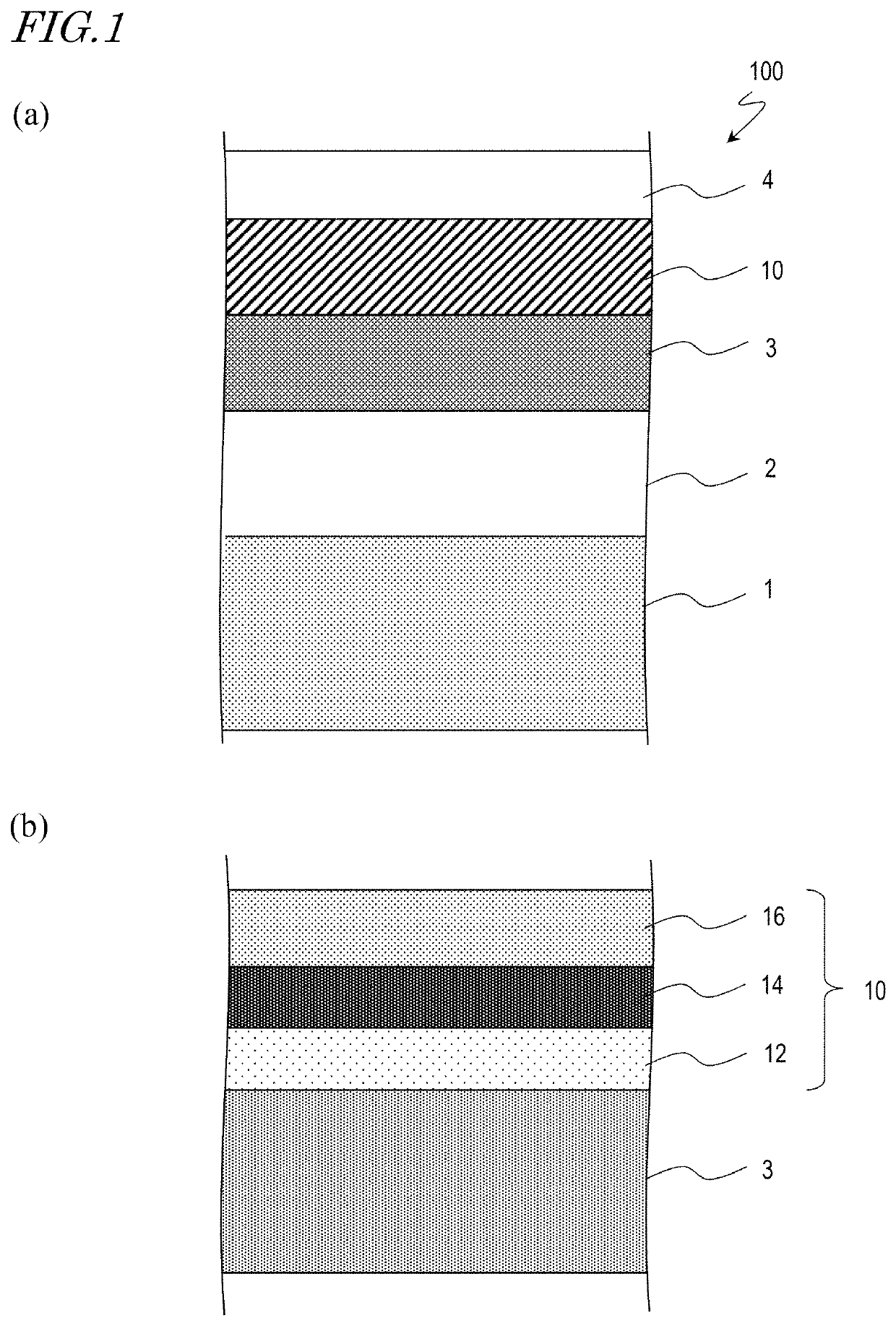

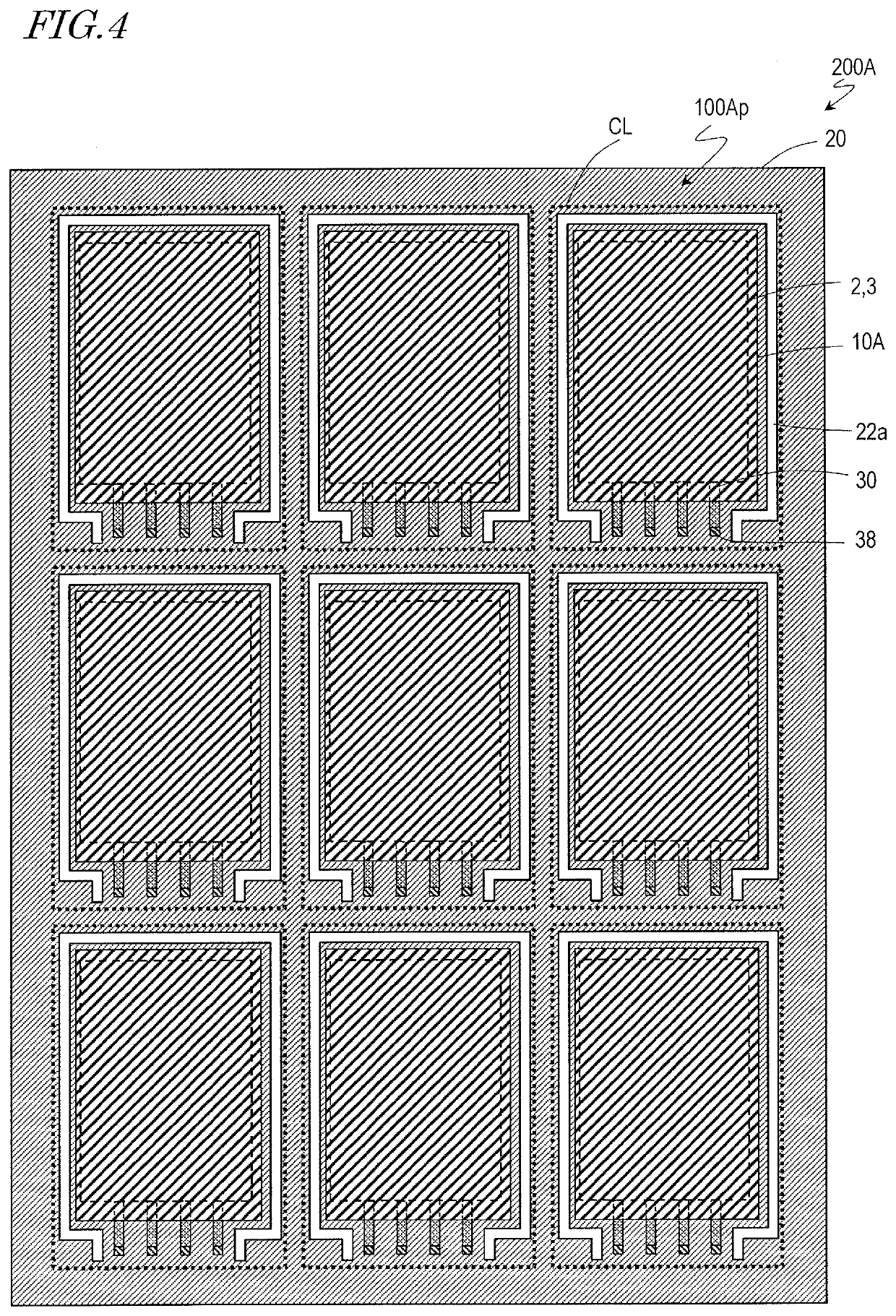

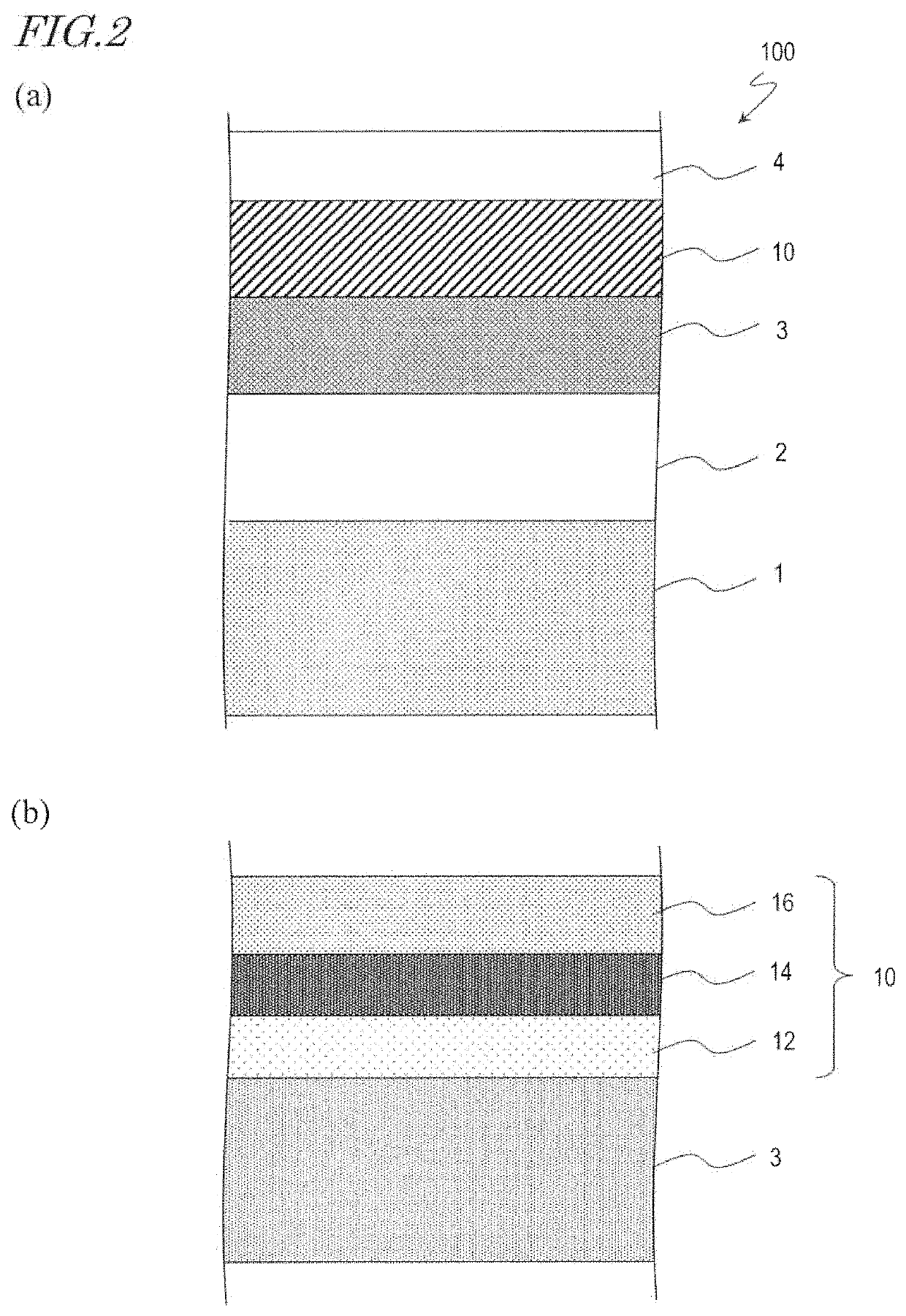

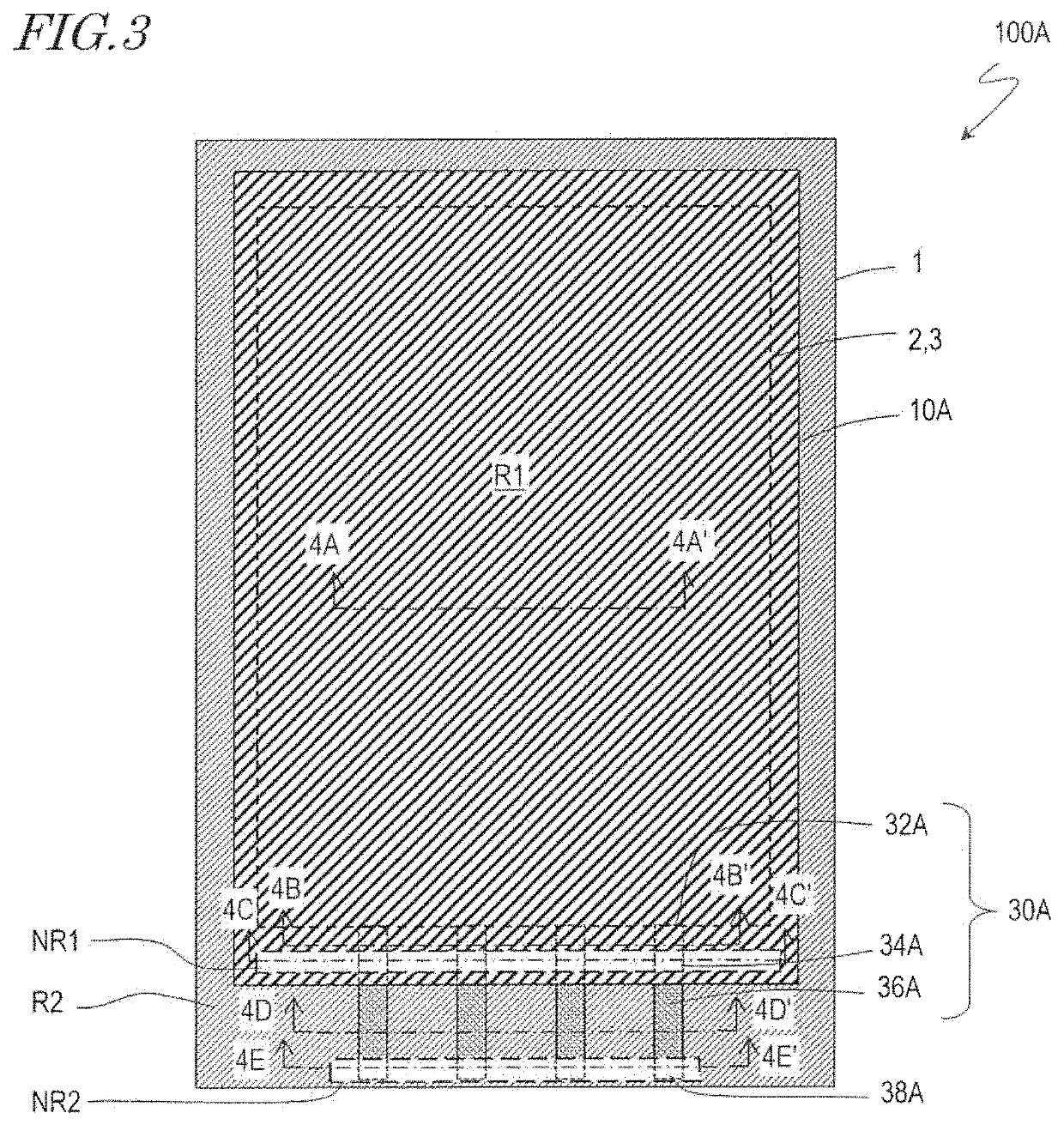

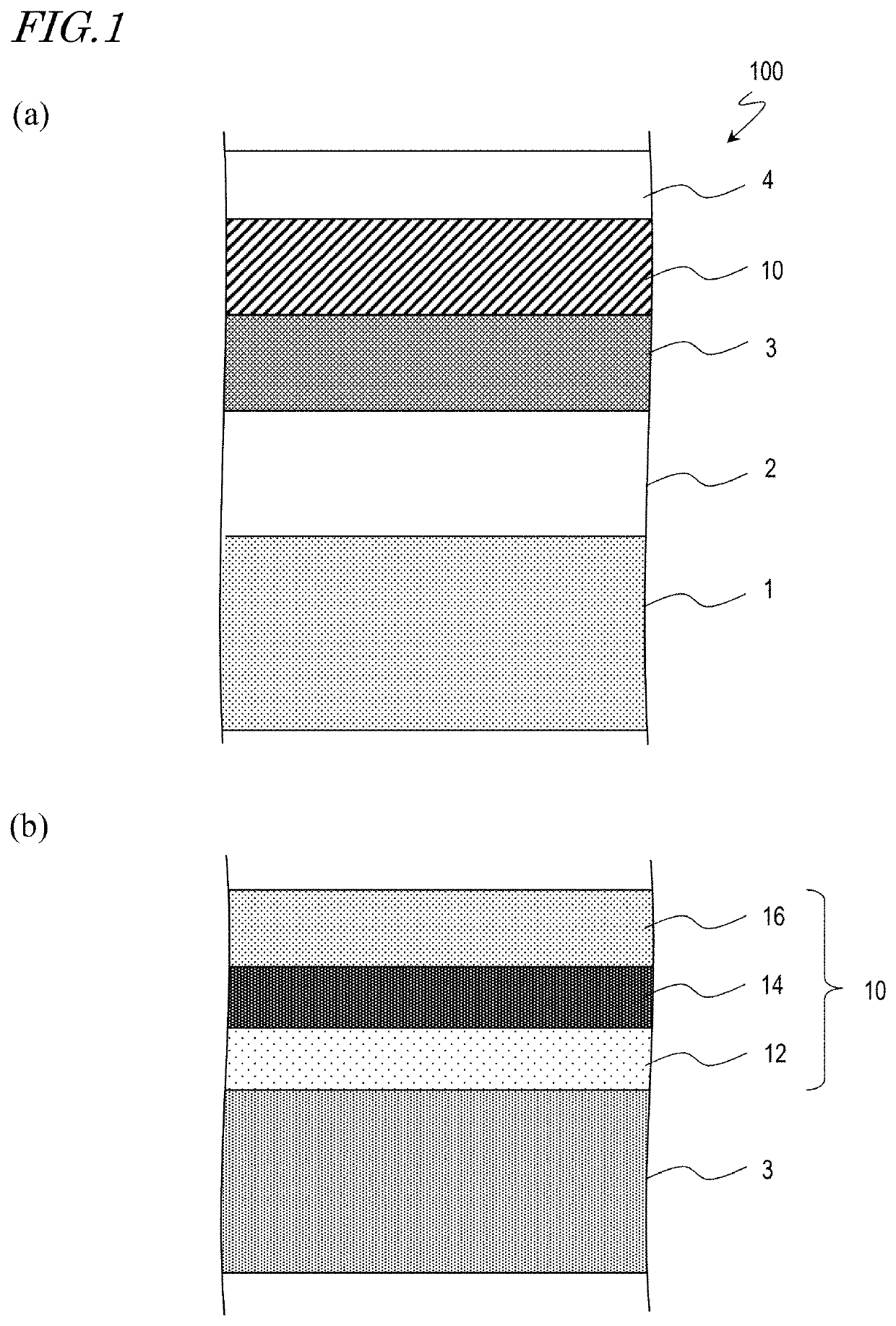

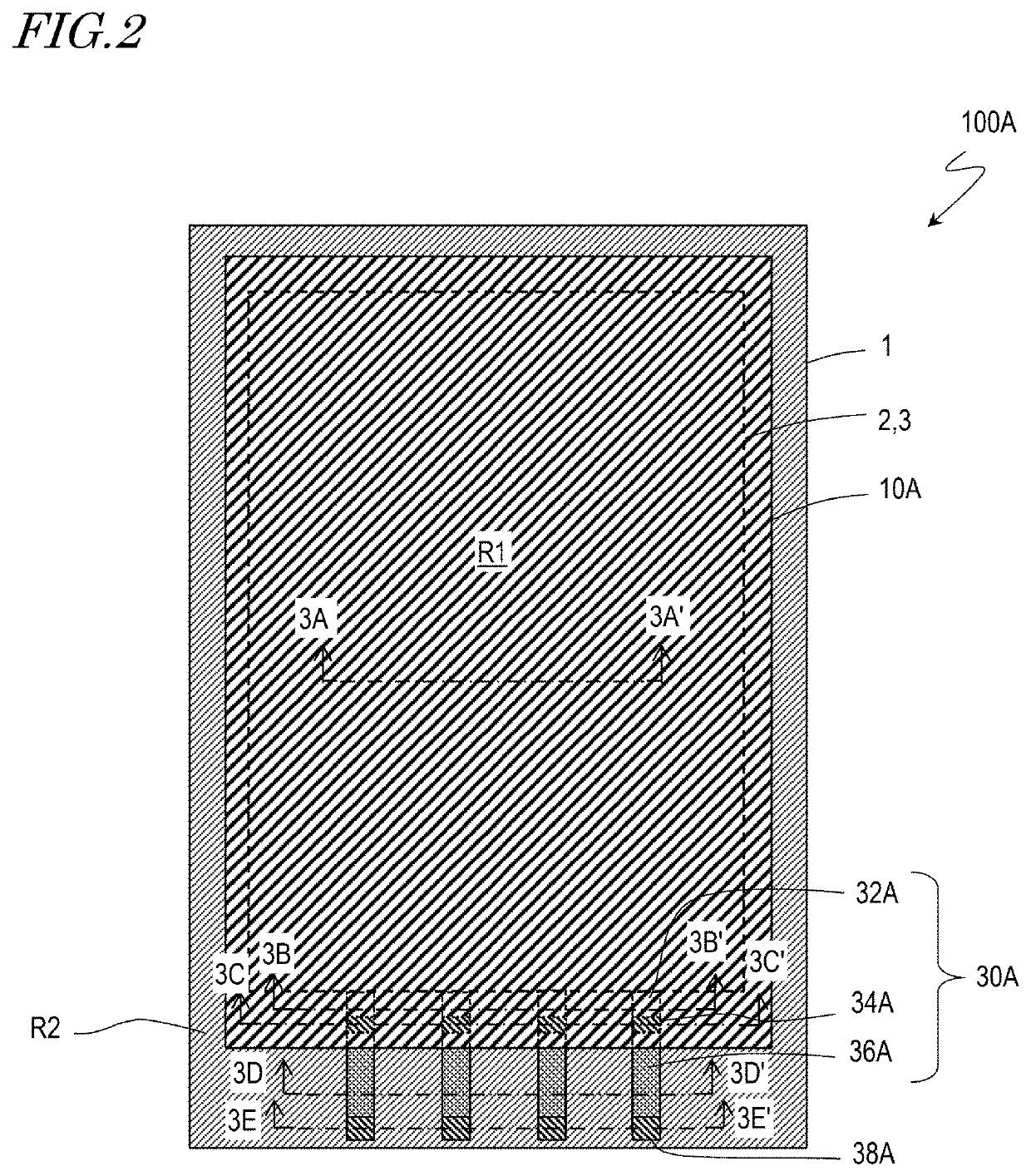

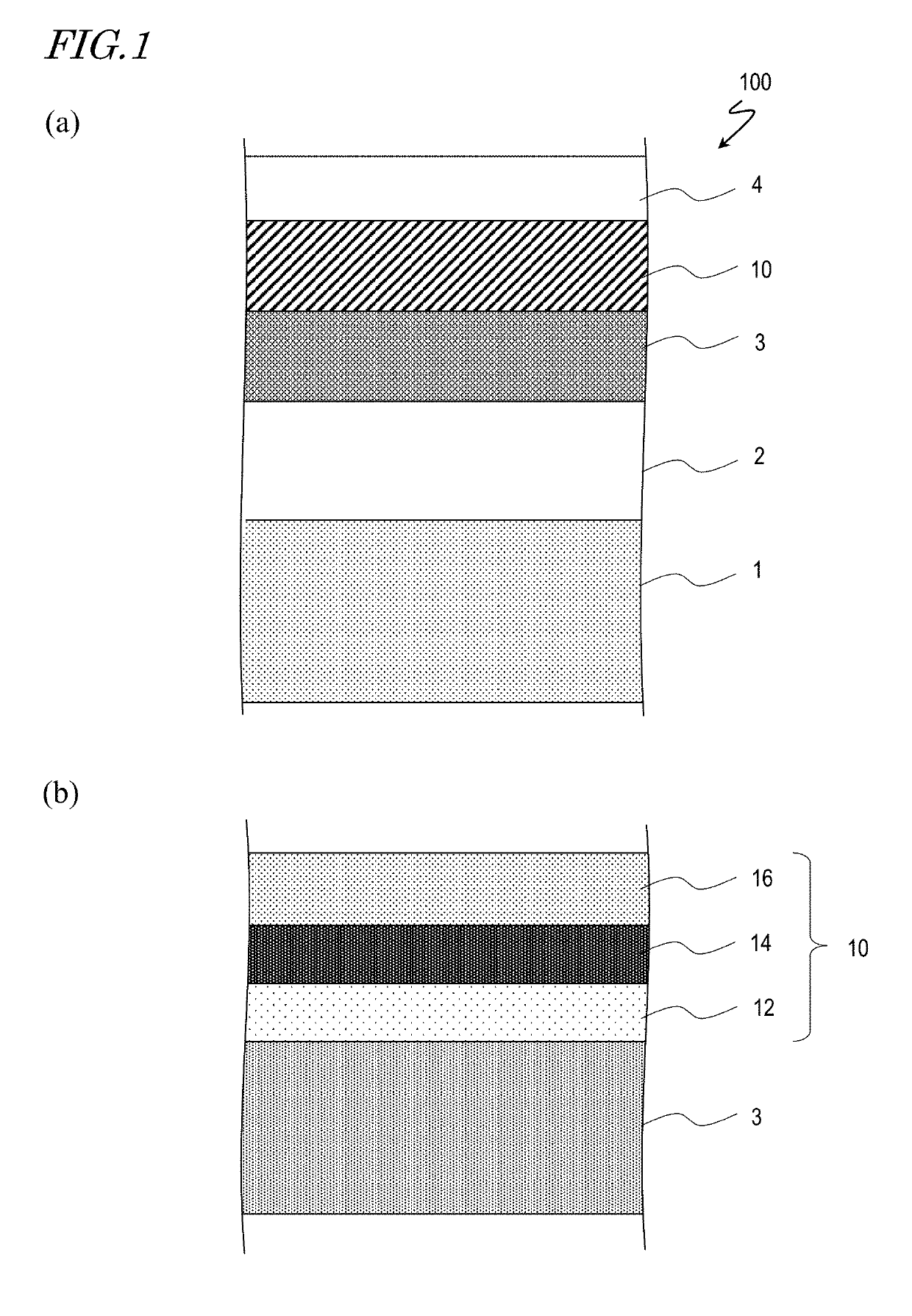

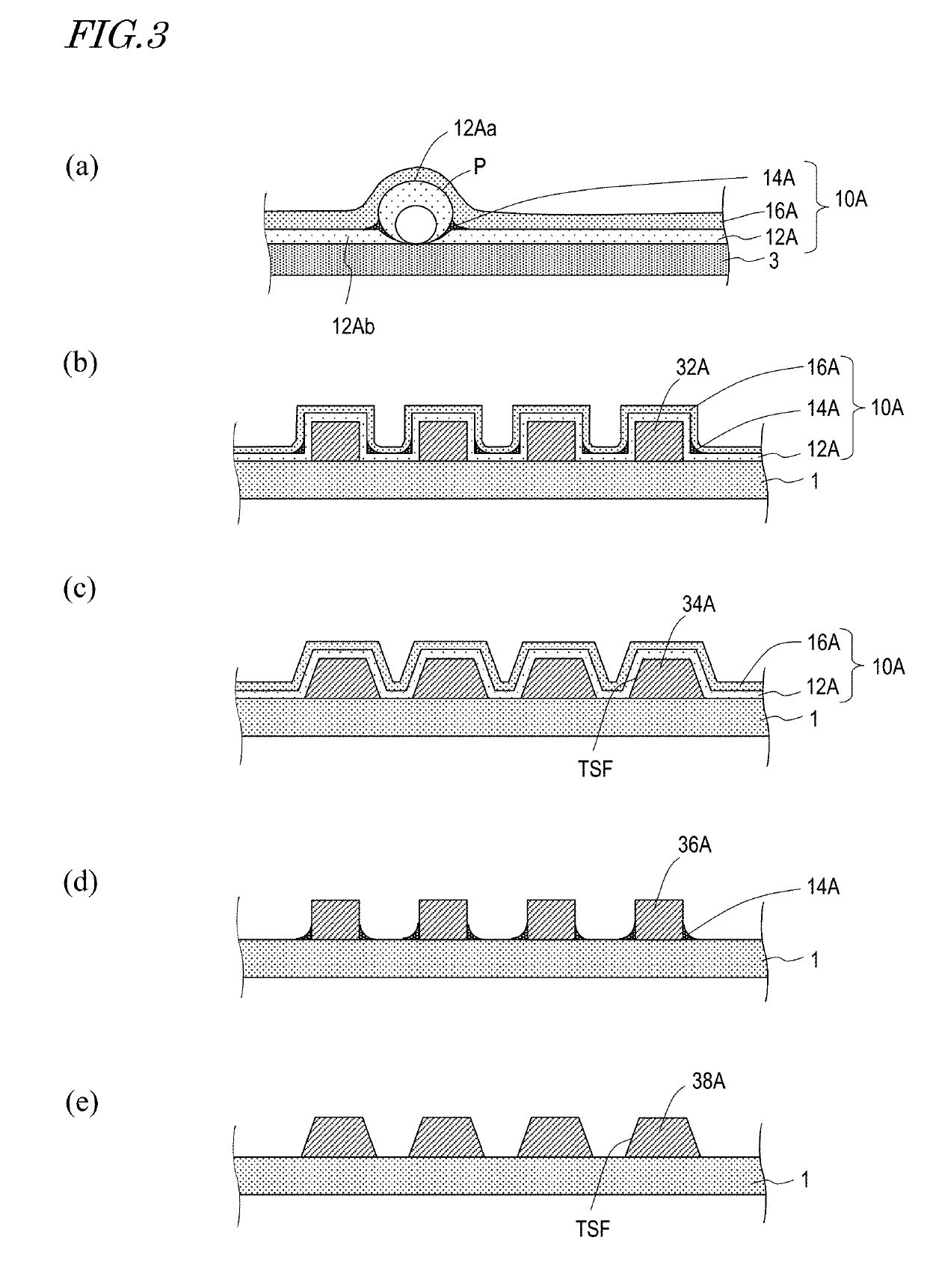

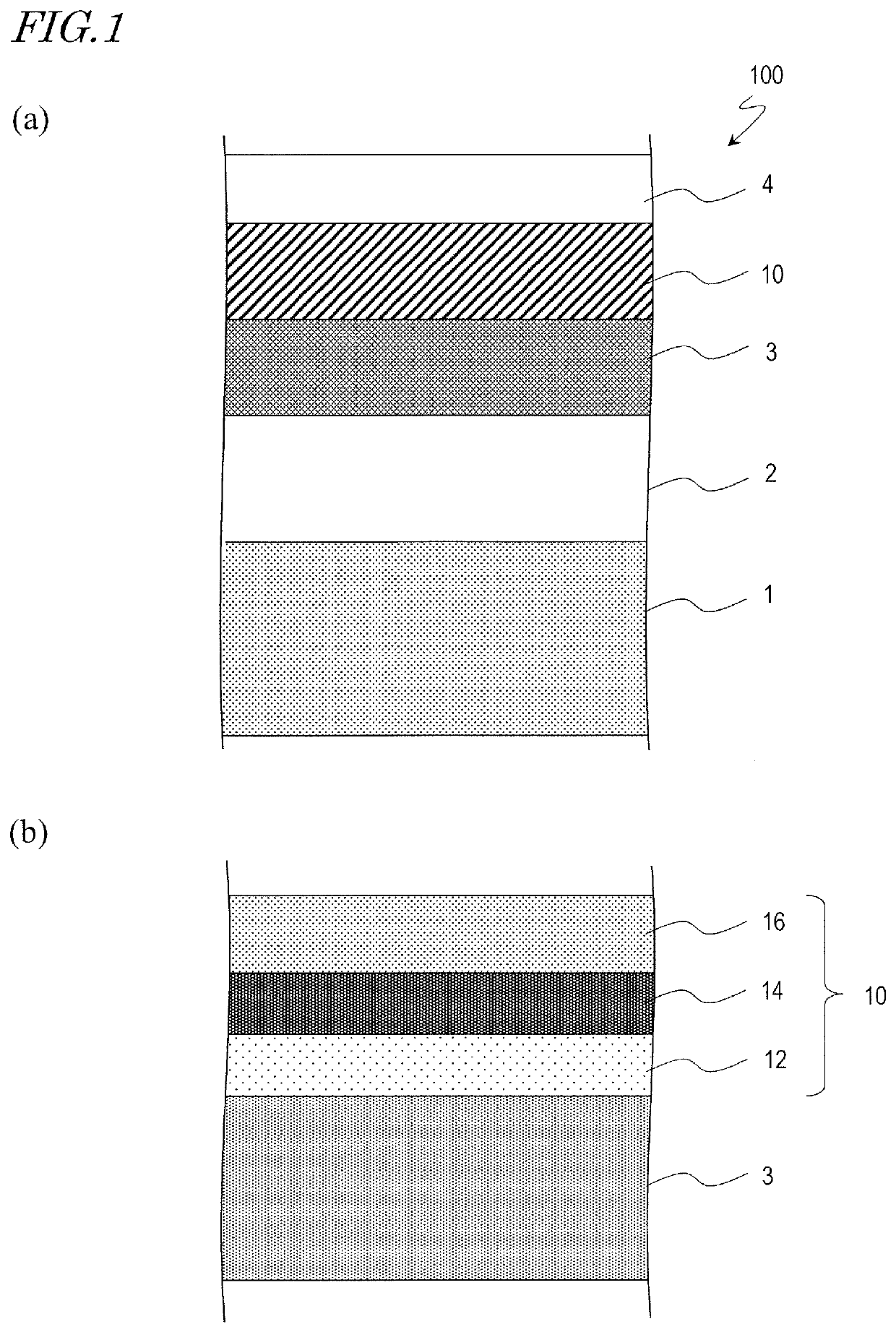

This organic EL device (100) has a substrate (1), a drive circuit layer (2), a first inorganic protective layer (2Pa), an organic planarizing layer (2Pb), an organic EL element layer (3), and a TFE structure (10). The TFE structure has a first inorganic barrier layer (12), an organic barrier layer (14), and a second inorganic barrier layer (16). When viewed from a normal line of the substrate, the organic planarizing layer is formed within a region where the first inorganic protective layer is formed, while an organic EL element is disposed within a region where the organic planarizing layer is formed. The TFE structure has an exterior edge which intersects with a lead-out line (32) and which is situated between an exterior edge of the organic planarizing layer and an exterior edge of the first inorganic protective layer. In a portion where the first inorganic protective layer and the first inorganic barrier layer are in direct contact with each other on the lead-out line, the first inorganic barrier layer has, in a cross-section parallel to the line width direction of the lead-out line, a lateral face that is configured to have a taper angle θ (12) of less than 90°. The organic planarizing layer has a surface that is not more than 50 nm in arithmetic average roughness Ra.

Owner:SAKAI DISPLAY PROD

Organic electroluminescent display device and method for producing same

ActiveUS10720603B2Improve moisture resistance reliabilityFinal product manufactureElectroluminescent light sourcesThin membraneEngineering

A thin film encapsulation structure included in an organic EL display apparatus includes a first inorganic barrier layer, an organic barrier layer in contact with the inorganic barrier layer, and a second inorganic barrier layer in contact with the organic barrier layer. The thin film encapsulation structure is formed on an active region and the active region side portion of a plurality of lead wires extending from the active region to a terminal. Each of the lead wires at least partially includes, at at least the lowermost portions of two side surfaces thereof in contact with the first inorganic barrier layer, a forward tapering side surface portion having a tapering angle smaller than 90 degrees in a cross-section parallel to a line width direction thereof. The thin film encapsulation structure includes an inorganic barrier layer joint portion in which the organic barrier layer is not present, and the first inorganic barrier layer and the second inorganic barrier layer are in direct contact with each other. On the respective portions, of the lead-out wires, having the forward tapered side surface portions, the inorganic barrier layer joint portion is formed and the active region is completely enclosed by the inorganic barrier layer joint portion.

Owner:SAKAI DISPLAY PROD

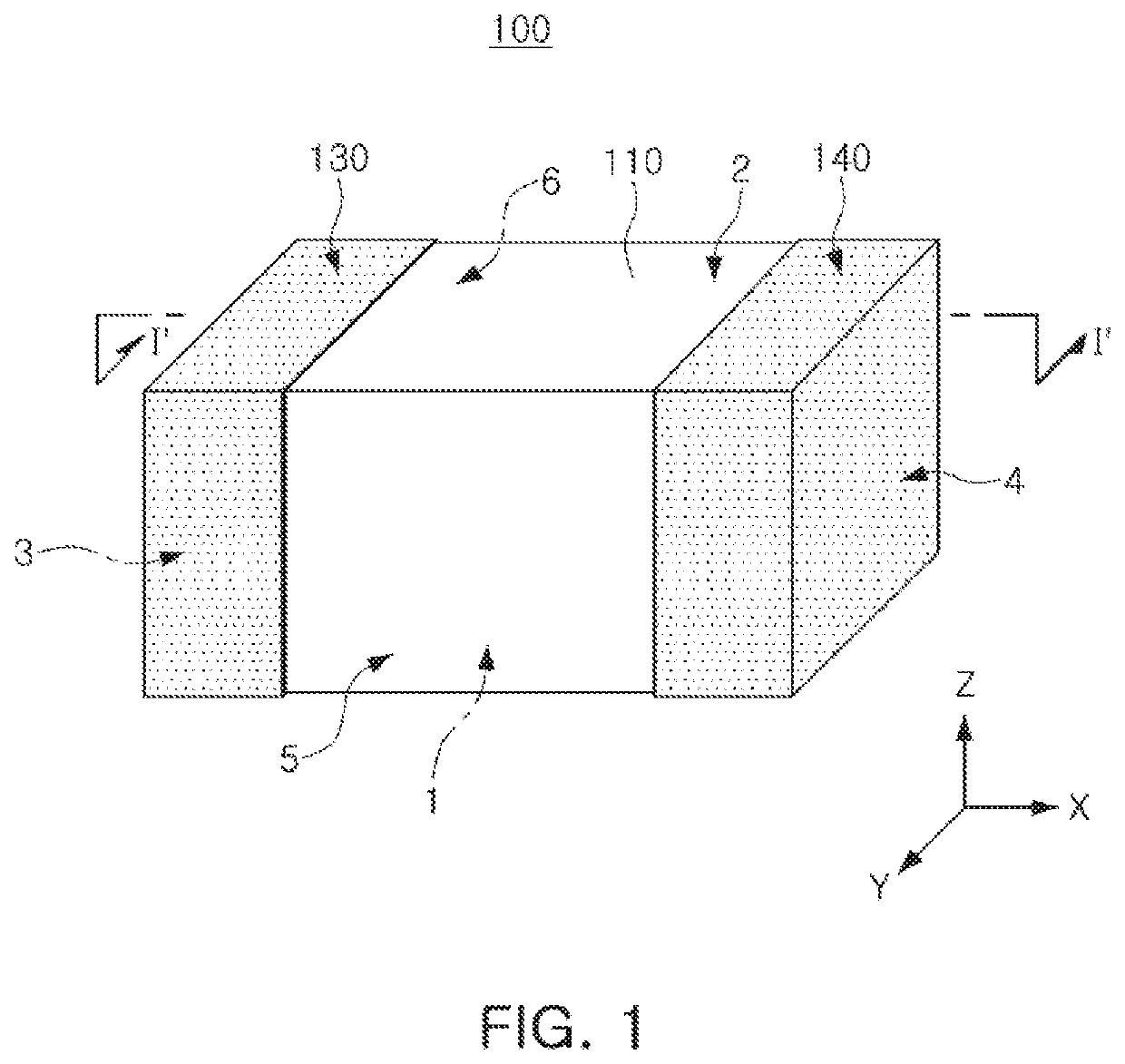

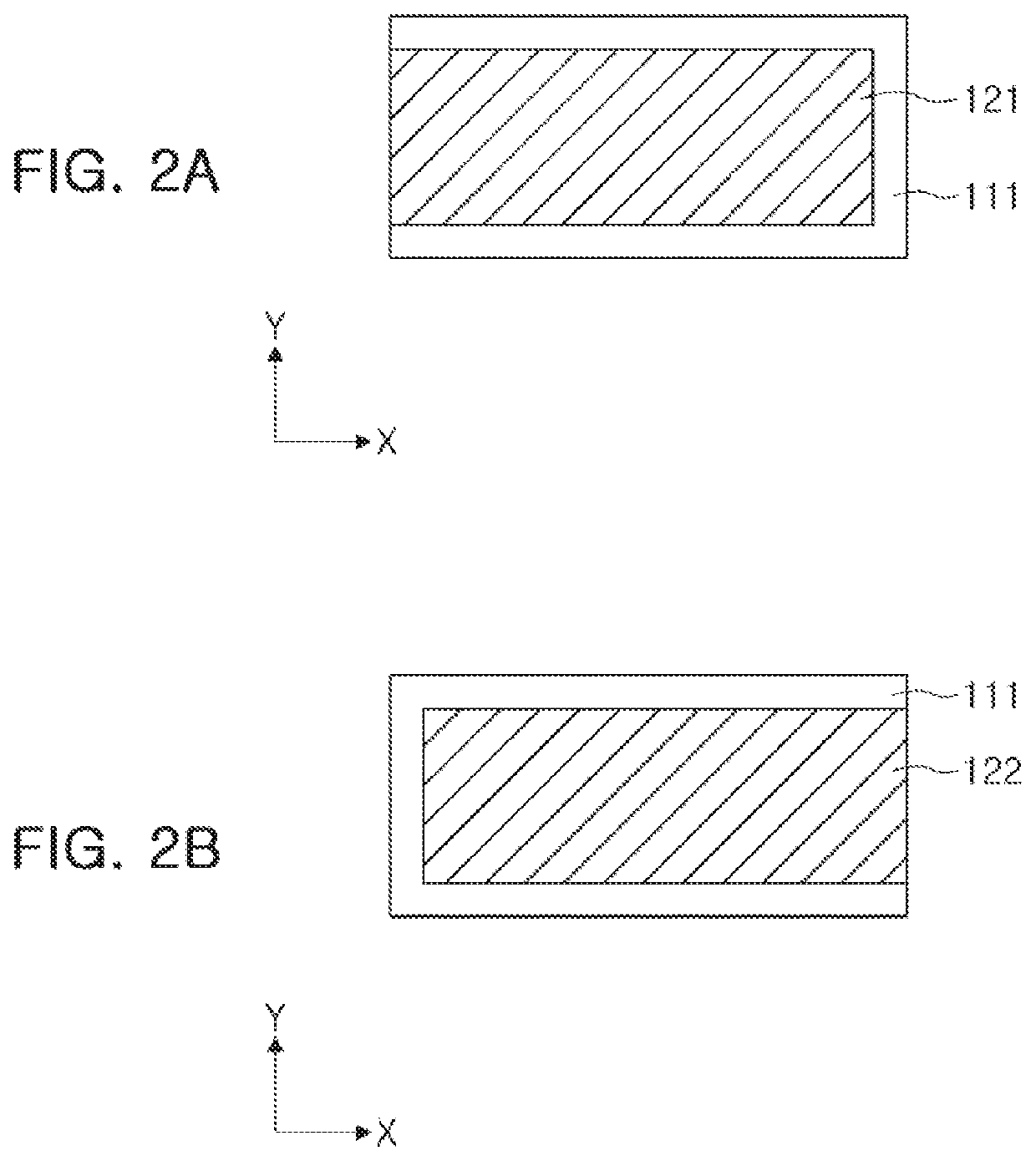

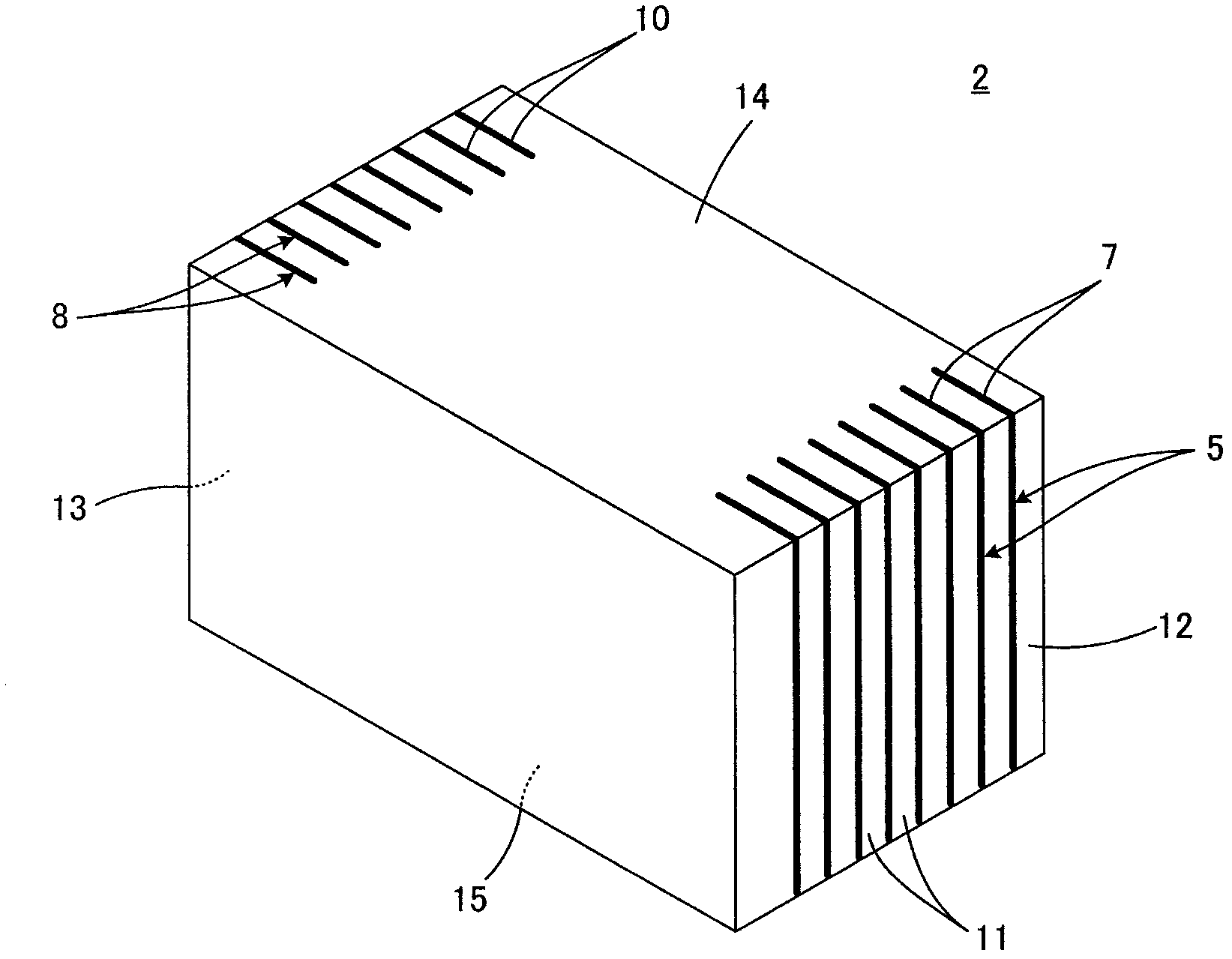

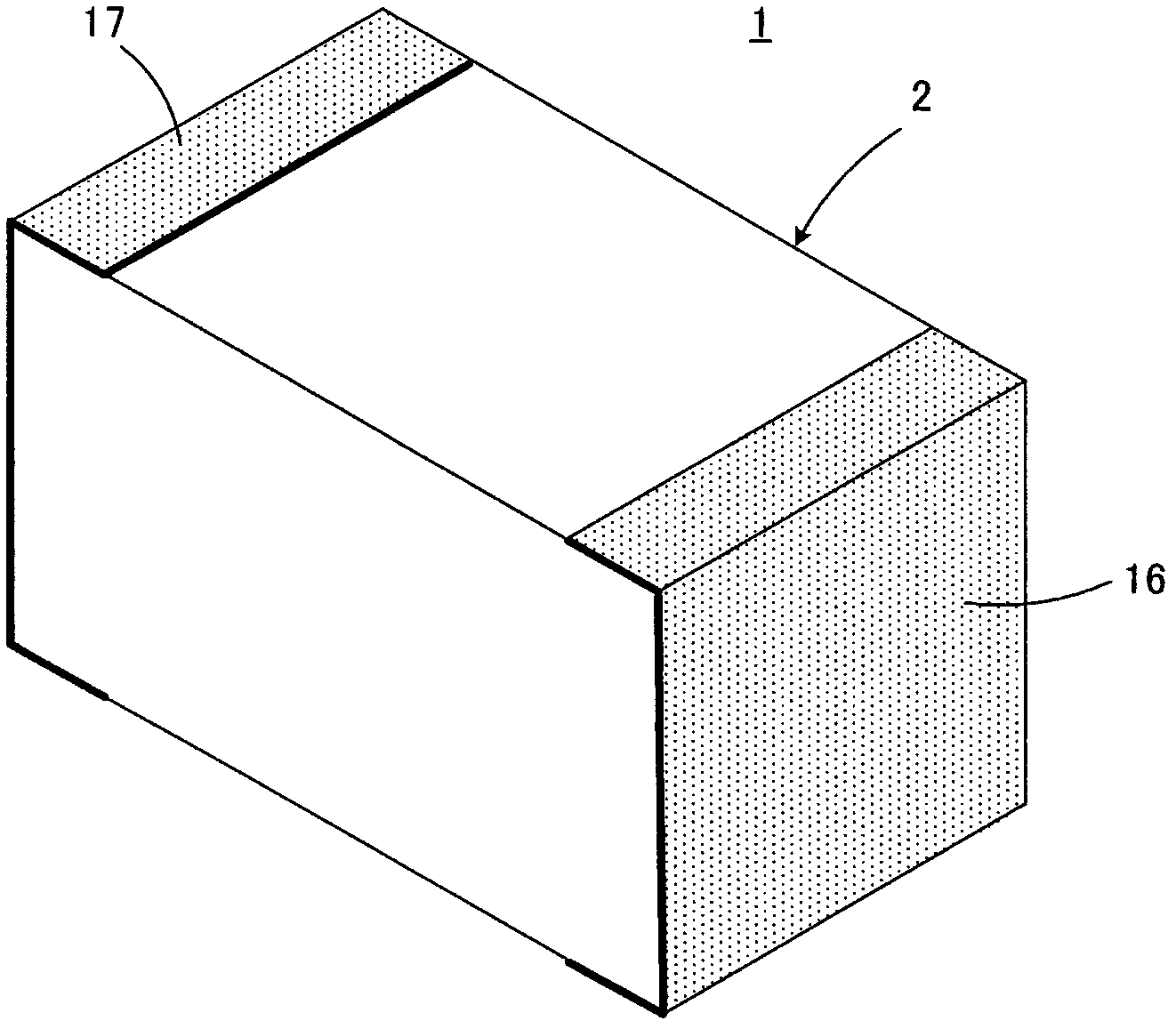

Multilayer ceramic electronic component

ActiveUS11011308B2Improve moisture resistance reliabilityFixed capacitor electrodesFixed capacitor dielectricDielectric ceramicsElectronic component

A multilayer ceramic electronic component includes a laminated body, and first and second external electrodes respectively provided on first and second end surfaces of the laminated body. The laminated body includes an inner layer portion in which the first and second internal electrode layers oppose each other with the dielectric ceramic layers interposed therebetween, and outer layer portions sandwiching the inner layer portion in the lamination direction and a side margin portion sandwiching the inner layer portion and the outer layer portions in the width direction. The side margin portion is defined by ceramic layers laminated in the width direction, and includes, as the ceramic layers, an inner layer on an innermost side of the laminated body and an outer layer on an outermost side of the laminated body.

Owner:MURATA MFG CO LTD

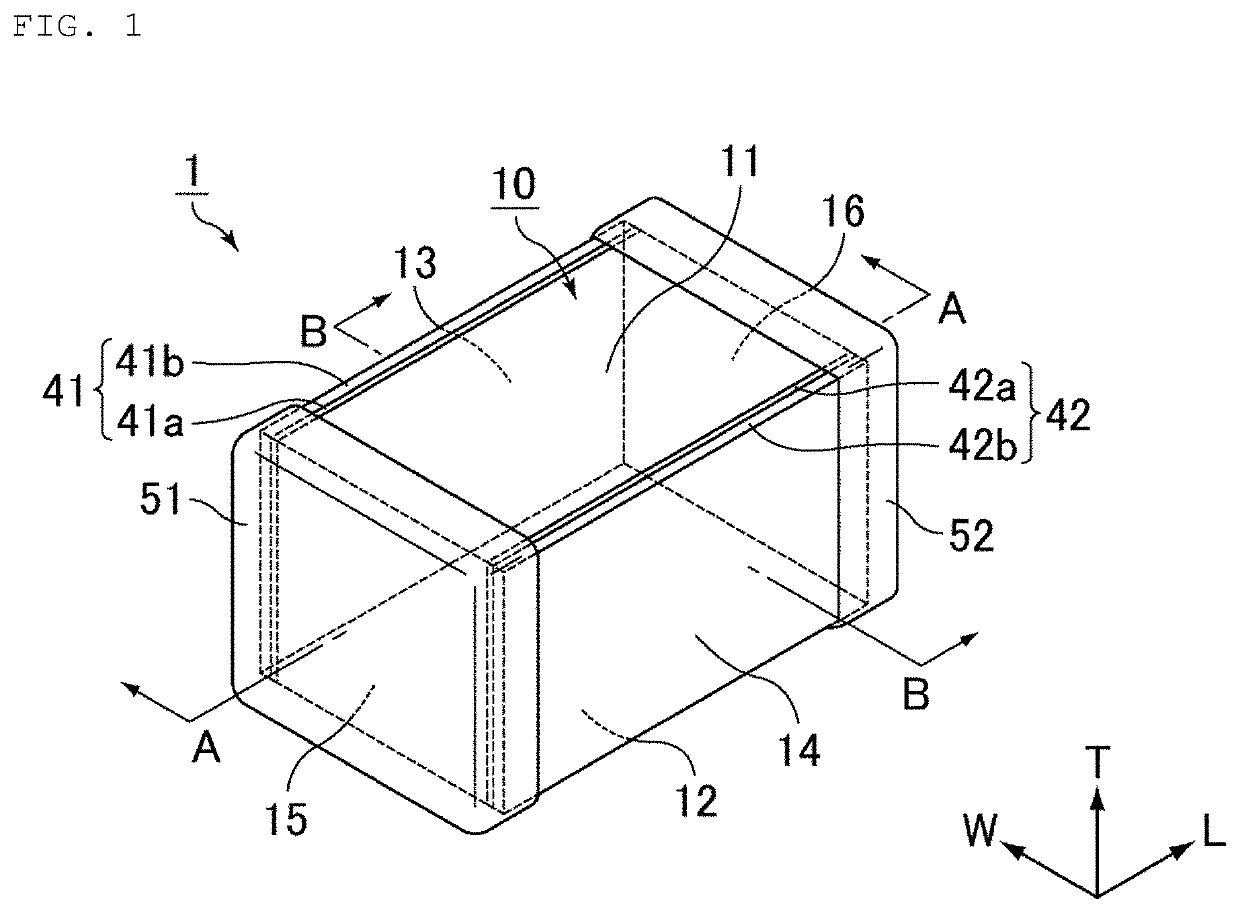

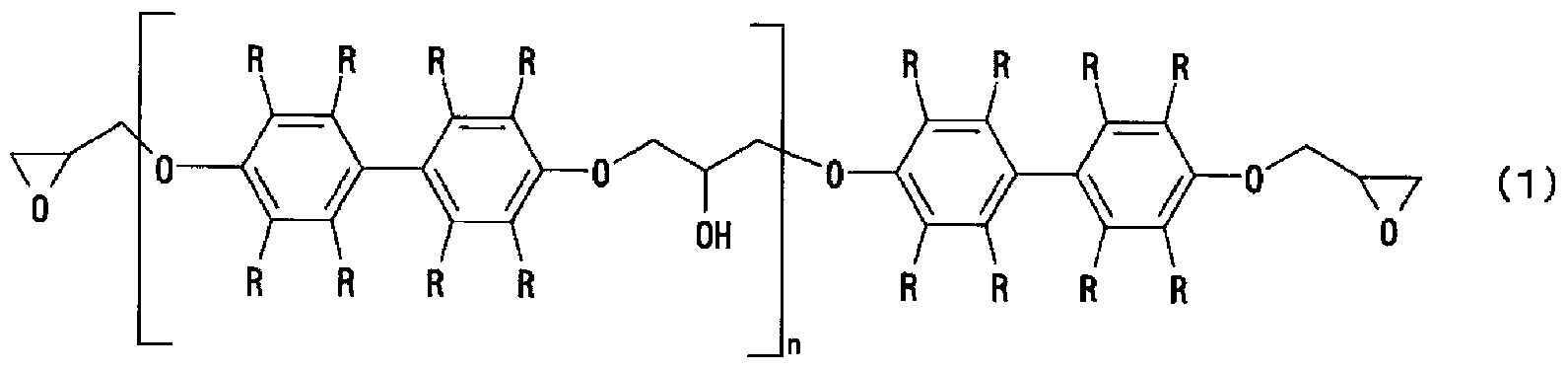

Heat-curable epoxy resin composition

InactiveUS20170037238A1Reduce thermal expansion rateImprove moisture resistance reliabilityChemistryImine

The invention provides a curable epoxy resin composition having a superior workability and capable of forming a cured product with a thermal expansion resistance, a heat resistance, an adhesiveness and a low water absorbability. The composition is a heat-curable resin composition comprising:(A) an epoxy resin;(B) a carboxyl group-free curing agent; and(C) an annular carbodiimide compound, in whichan equivalent ratio of the carboxyl group-free curing agent (B) to the epoxy resin (A) is 0.5 to 1.5, and the annular carbodiimide compound (C) is in an amount of 2 to 50 parts by mass with respect to a total of 100 parts by mass of the epoxy resin (A) and the carboxyl group-free curing agent (B).

Owner:SHIN ETSU CHEM IND CO LTD

Multilayer ceramic electronic component

ActiveUS20200126724A1Improve moisture resistance reliabilityFixed capacitor electrodesFixed capacitor dielectricDielectricElectronic component

A multilayer ceramic electronic component includes a laminated body, and first and second external electrodes respectively provided on first and second end surfaces of the laminated body. The laminated body includes an inner layer portion in which the first and second internal electrode layers oppose each other with the dielectric ceramic layers interposed therebetween, and outer layer portions sandwiching the inner layer portion in the lamination direction and a side margin portion sandwiching the inner layer portion and the outer layer portions in the width direction. The side margin portion is defined by ceramic layers laminated in the width direction, and includes, as the ceramic layers, an inner layer on an innermost side of the laminated body and an outer layer on an outermost side of the laminated body.

Owner:MURATA MFG CO LTD

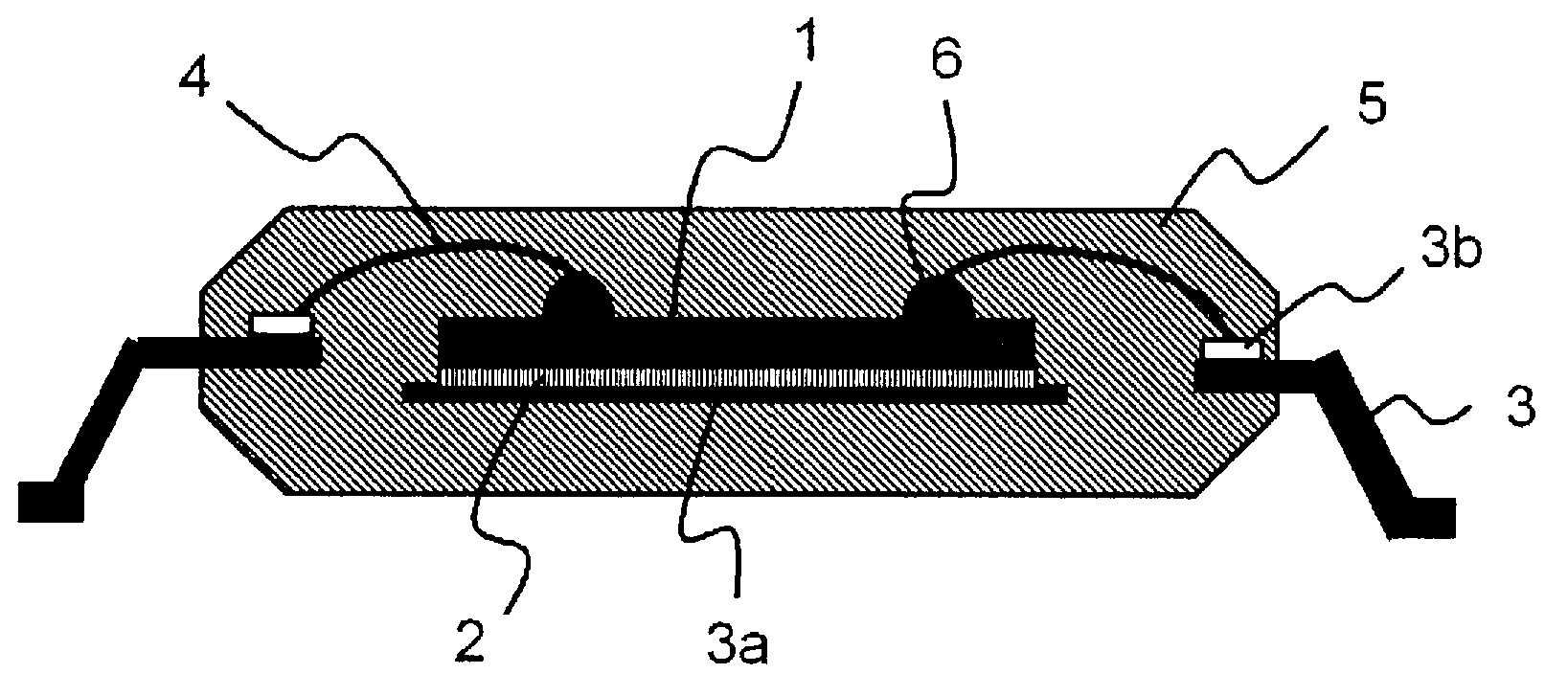

Epoxy resin composition for semiconductor encapsulation and semiconductor device

InactiveCN103221480AImprove moisture resistance reliabilityImprove reliabilityCosmetic preparationsMake-upElectrical junctionEpoxy

Disclosed is a highly reliable semiconductor device with more reliable moisture resistance. The disclosed epoxy resin composition for semiconductor encapsulation is used in the manufacture of semiconductor devices encapsulating both a semiconductor element mounted on a circuit substrate or a leadframe having a die pad unit, and a metal wire electrically connecting an electrical junction provided on the aforementioned circuit substrate or leadframe and an electrode pad provided on the aforementioned semiconductor element. The aforementioned epoxy resin composition for semiconductor encapsulation contains (A) an epoxy resin, (B) a curing agent and (C) an inorganic filler, wherein the aforementioned epoxy resin (A) has a main peak area greater than or equal to 90% of the total area of all peaks, measured by the gel permeation chromatography area method.

Owner:SUMITOMO BAKELITE CO LTD

Organic electroluminescent device and method for producing same

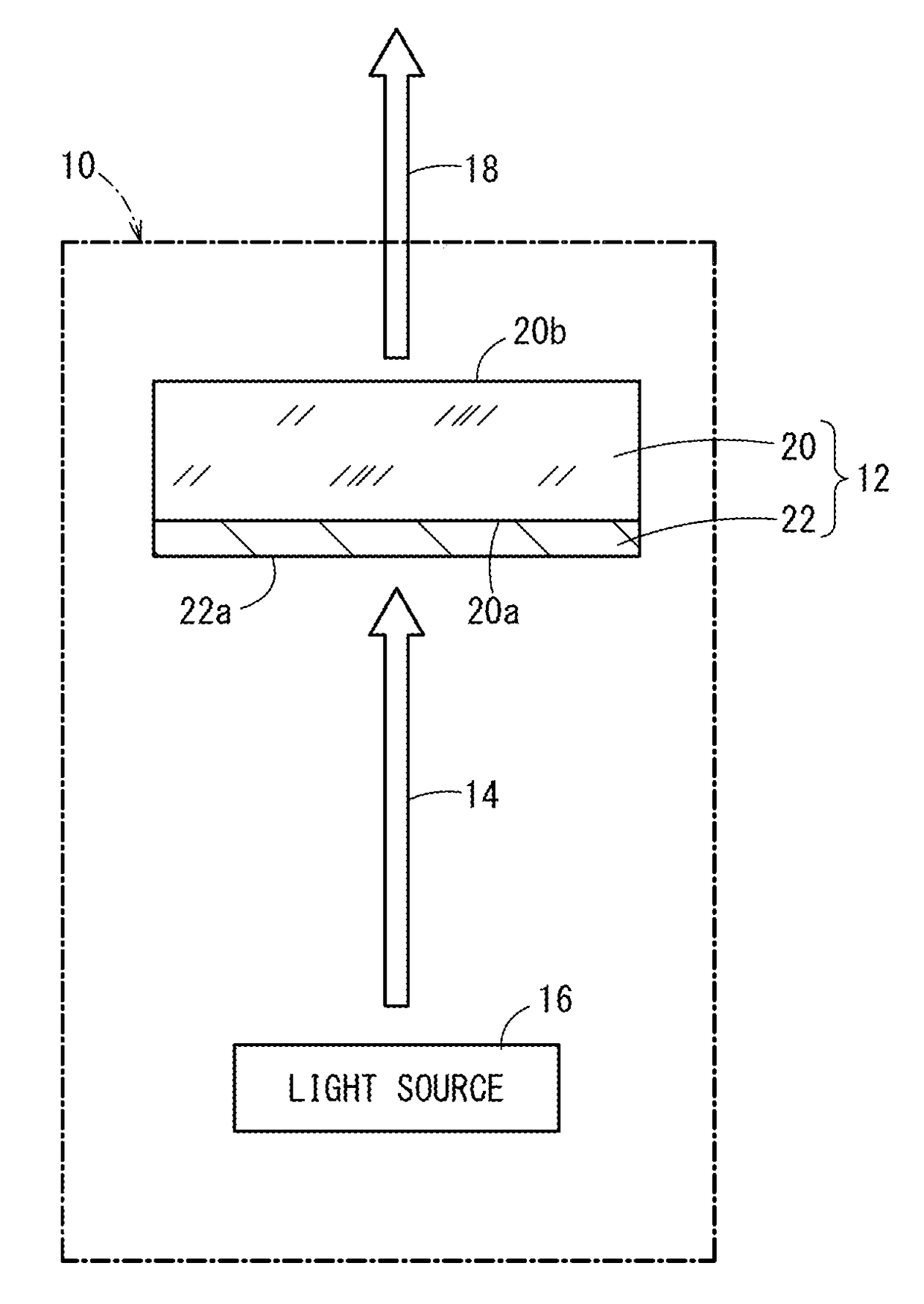

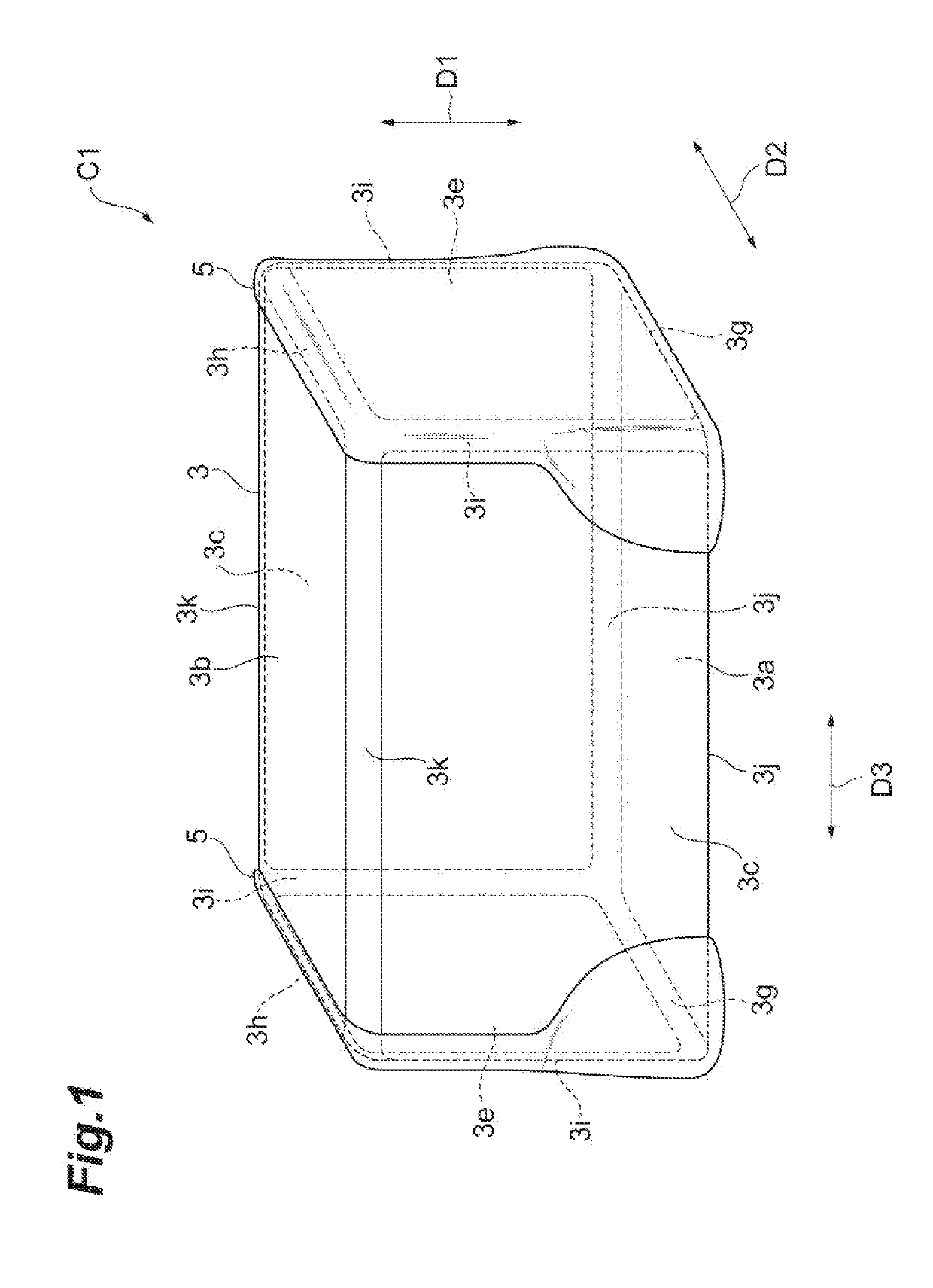

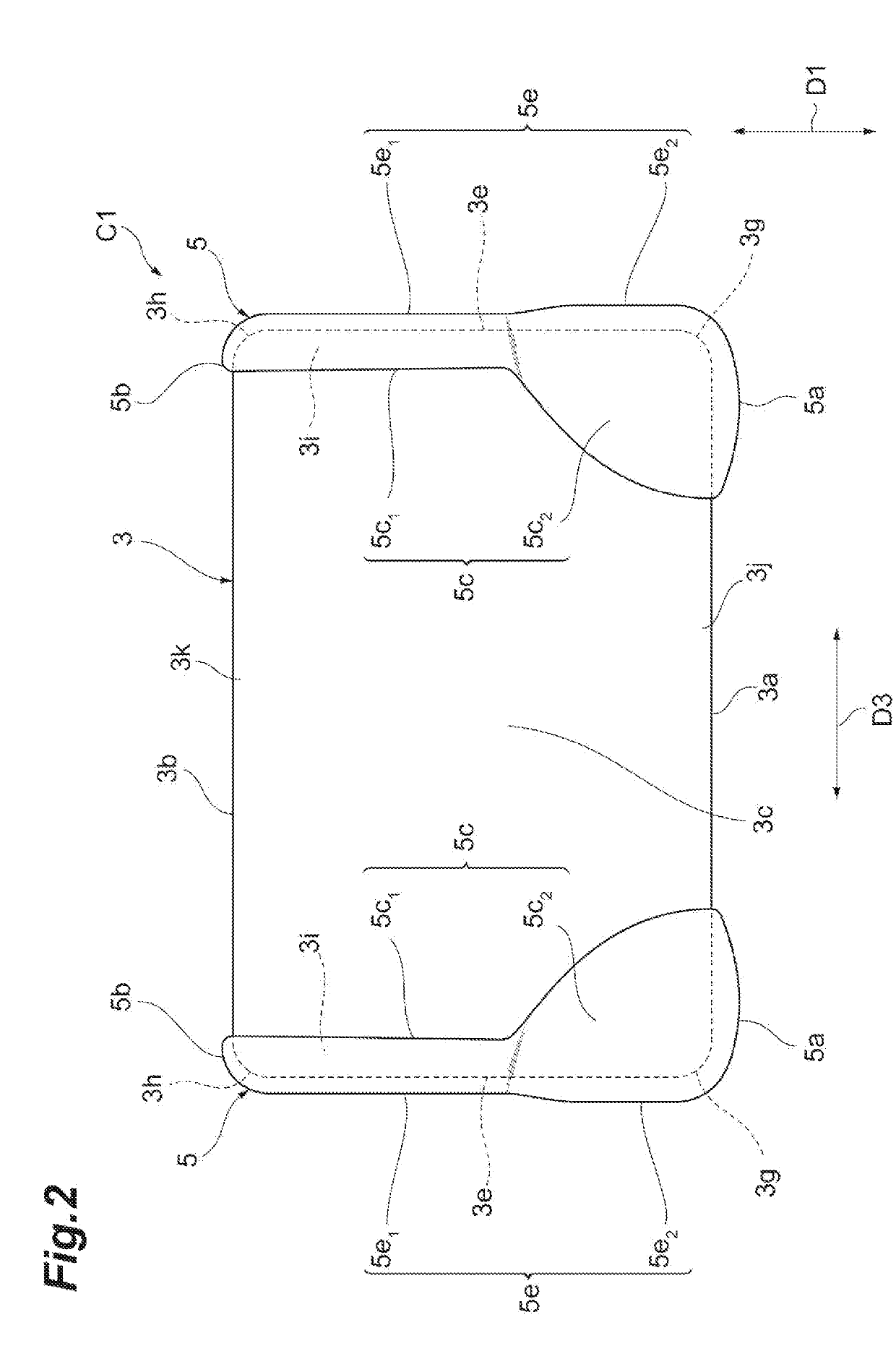

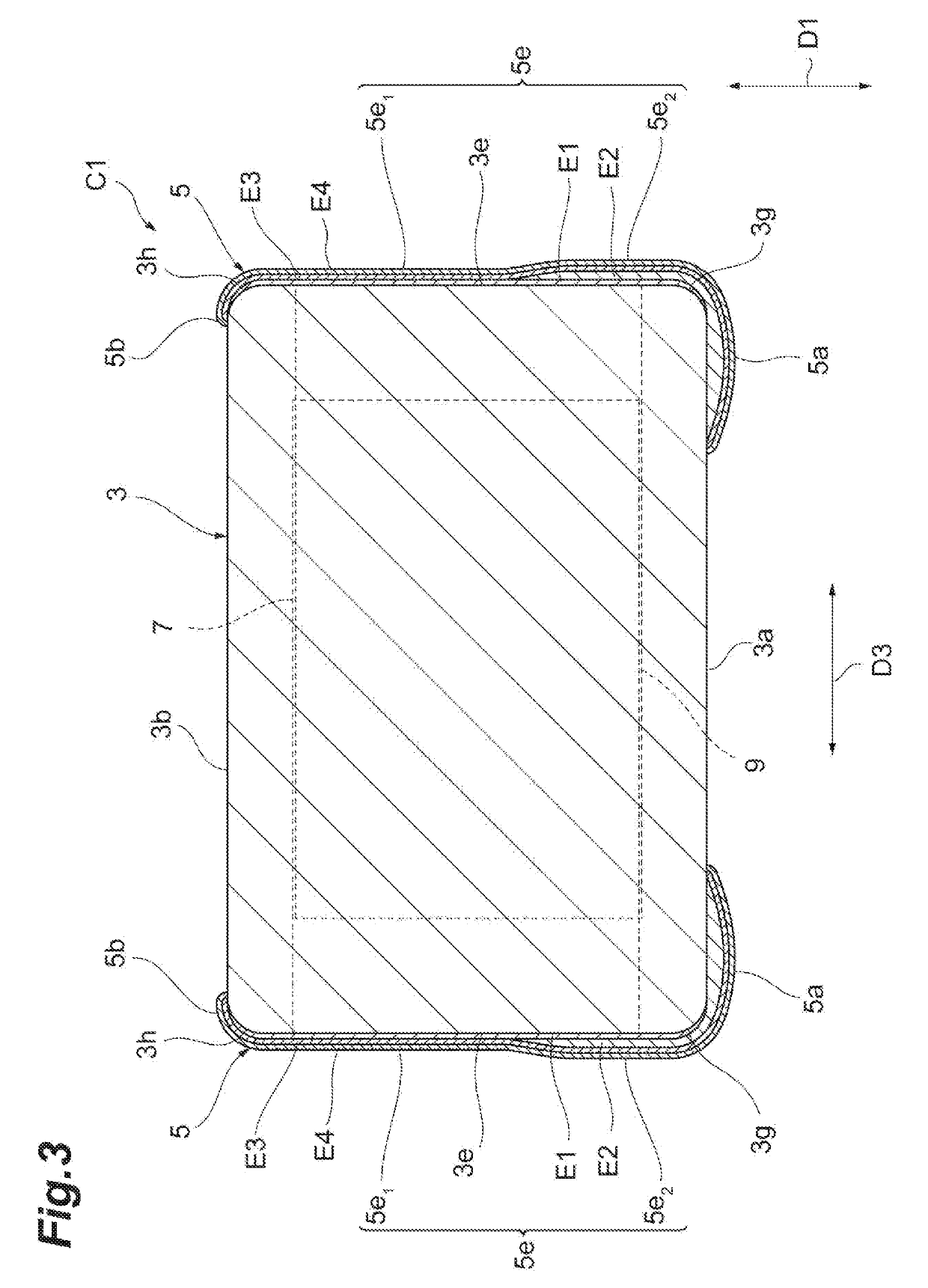

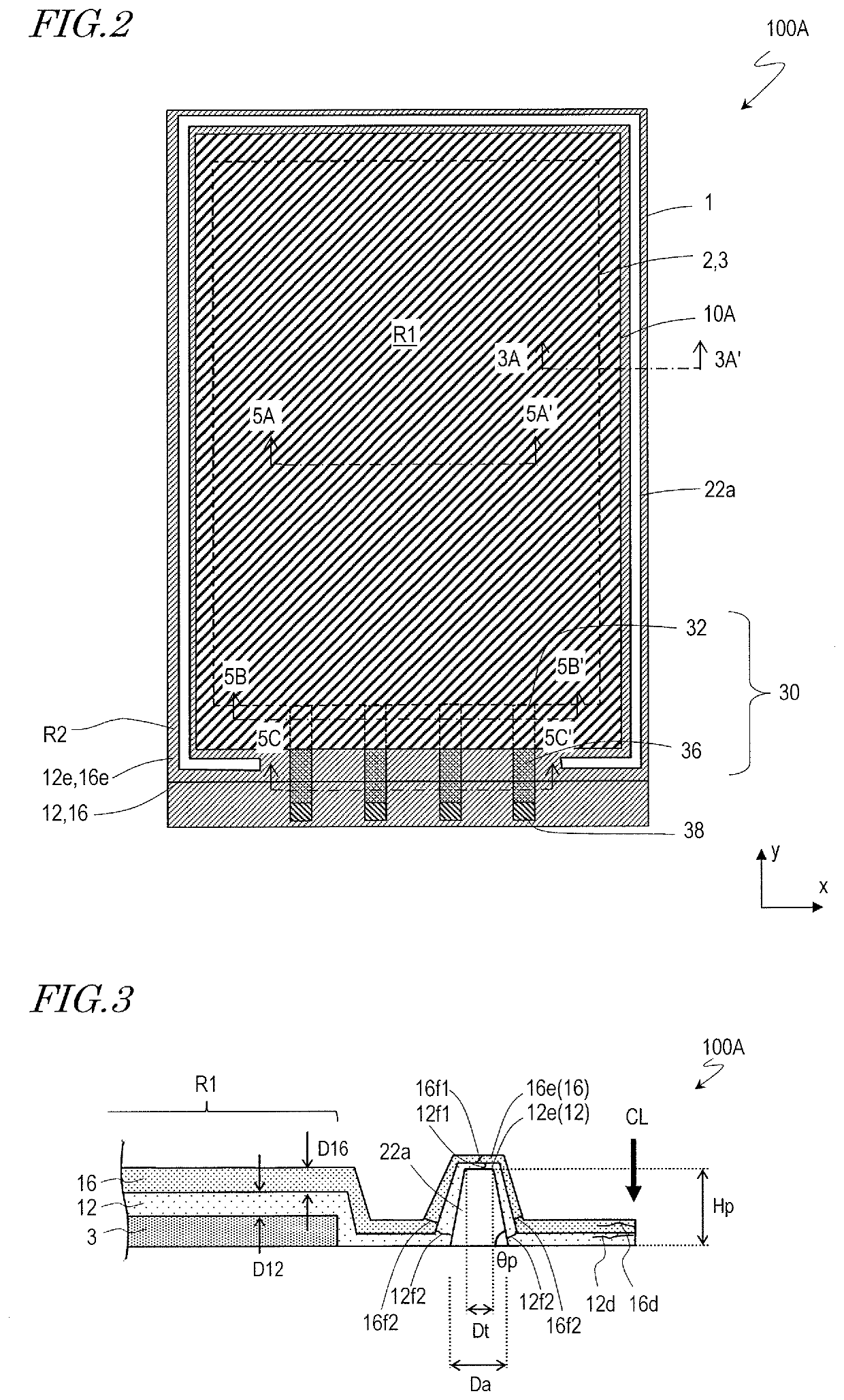

ActiveUS20190363292A1Improve moisture resistance reliabilityElectroluminescent light sourcesSolid-state devicesEngineeringOrganic electroluminescence

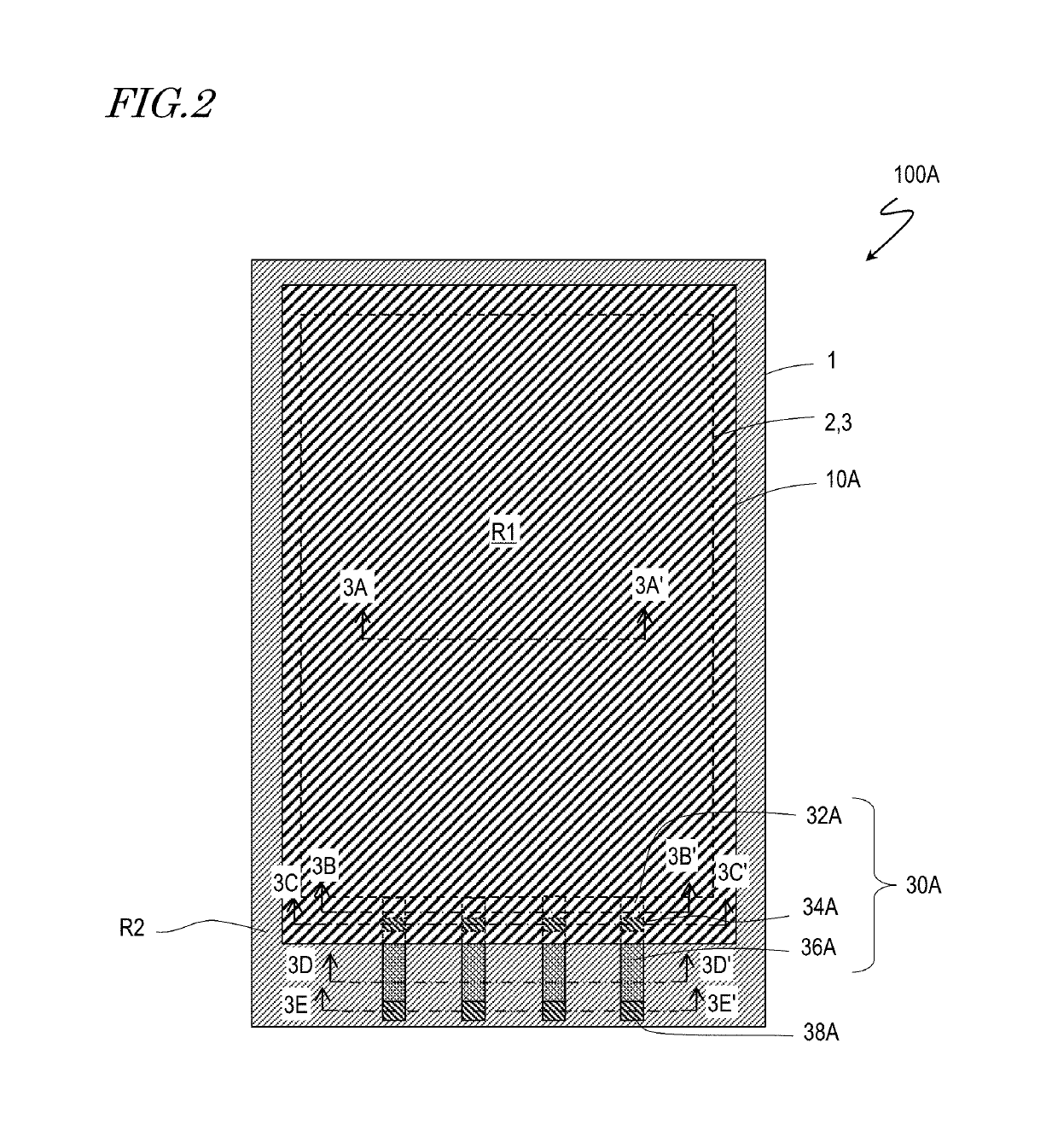

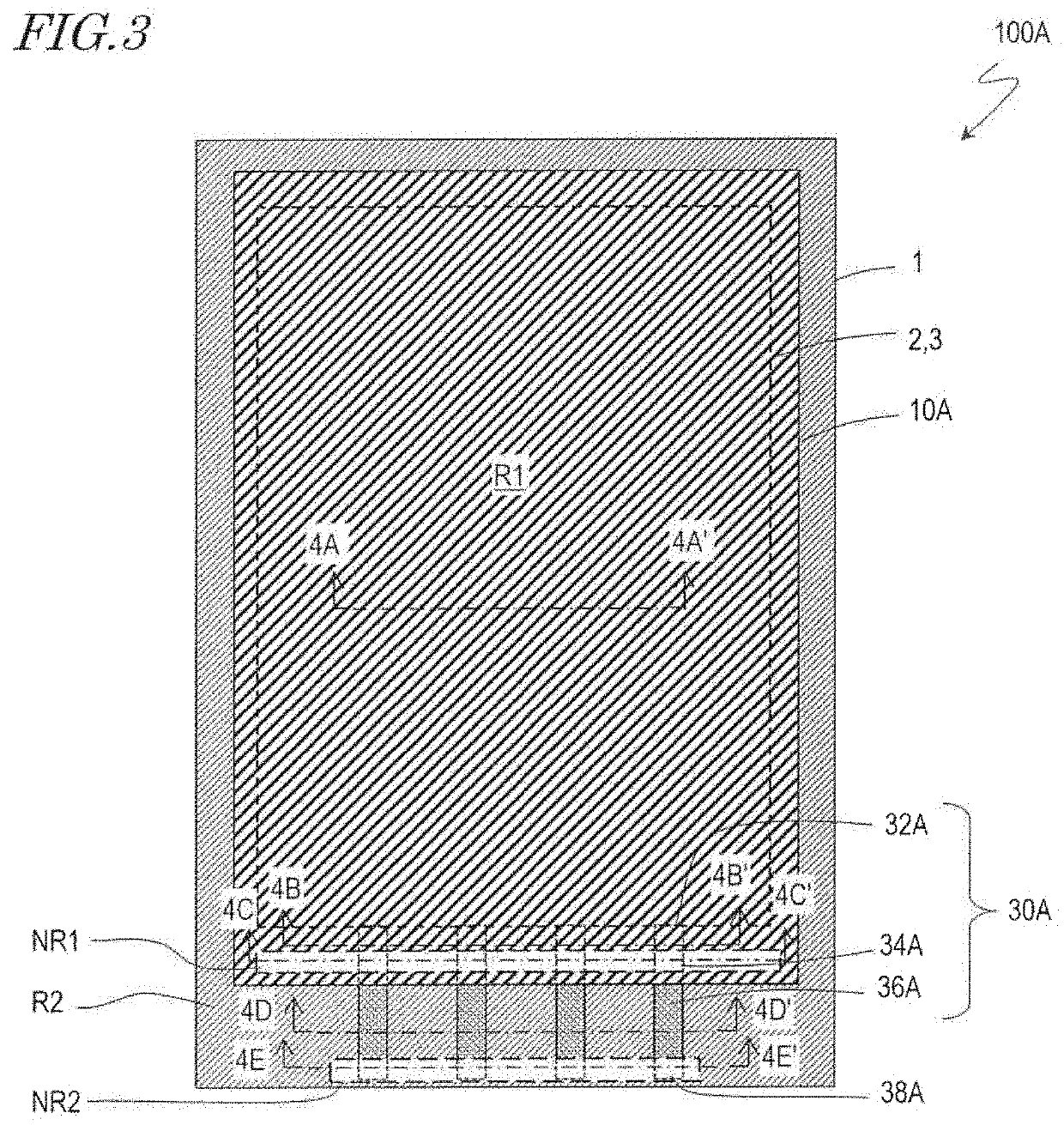

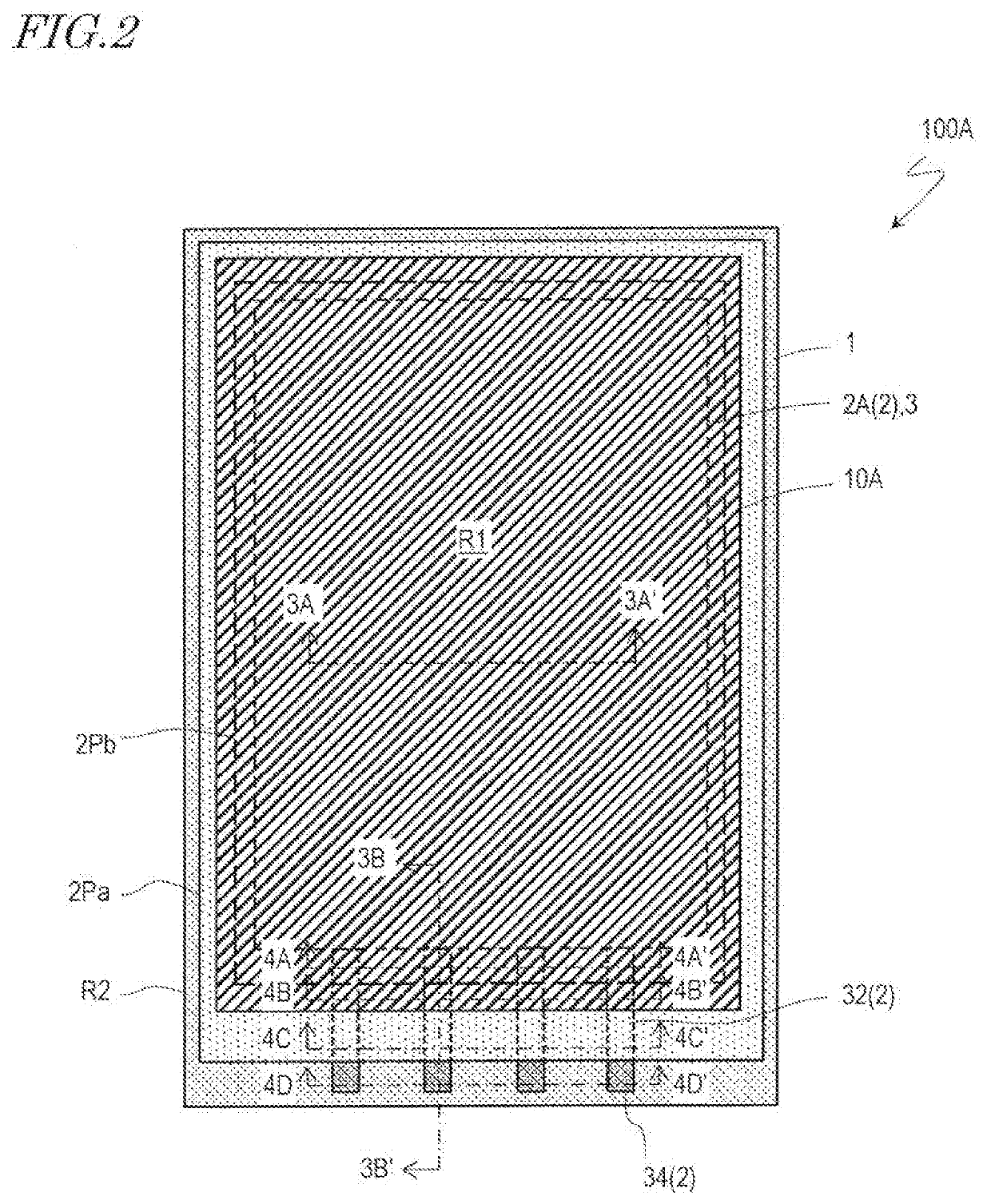

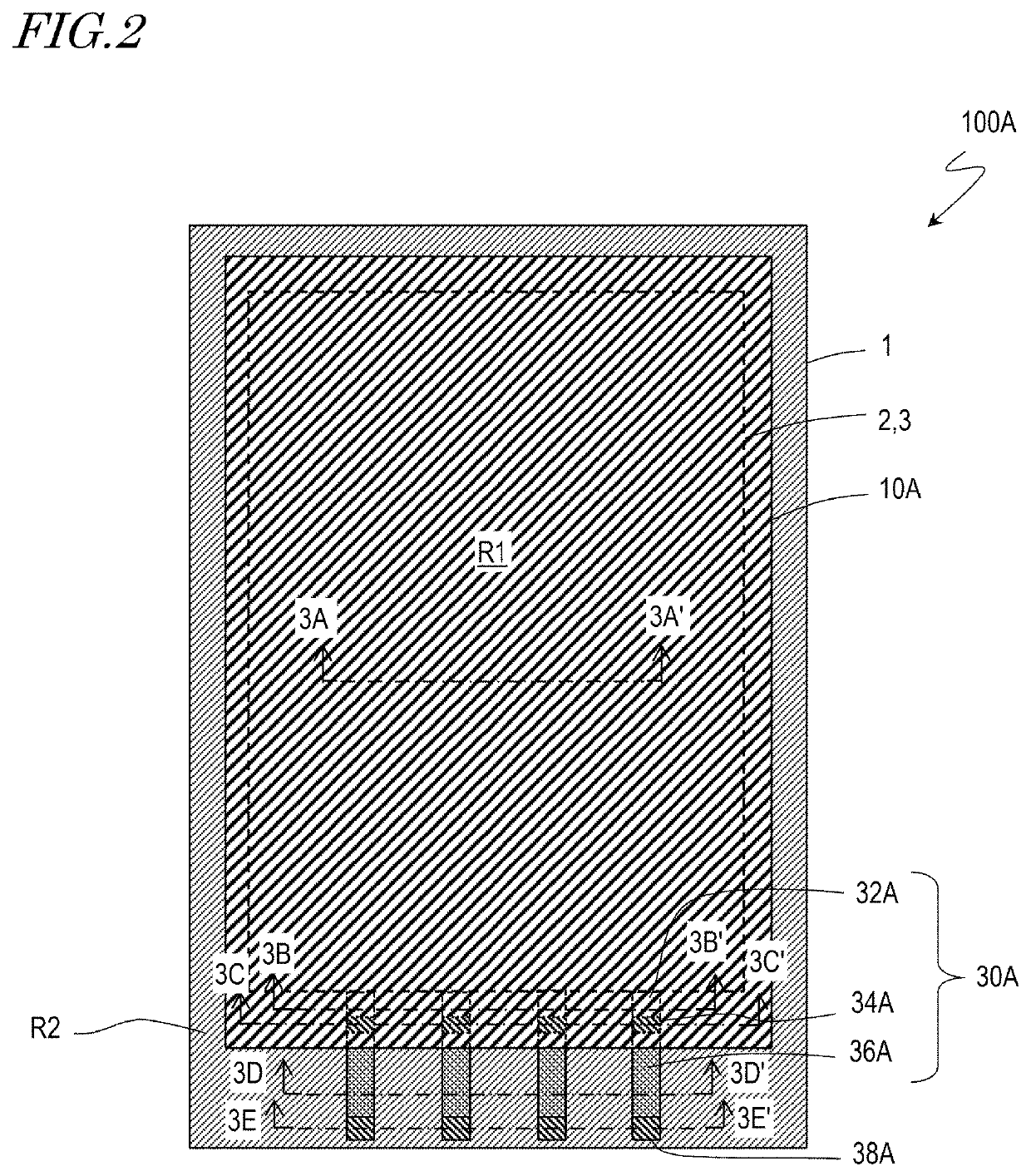

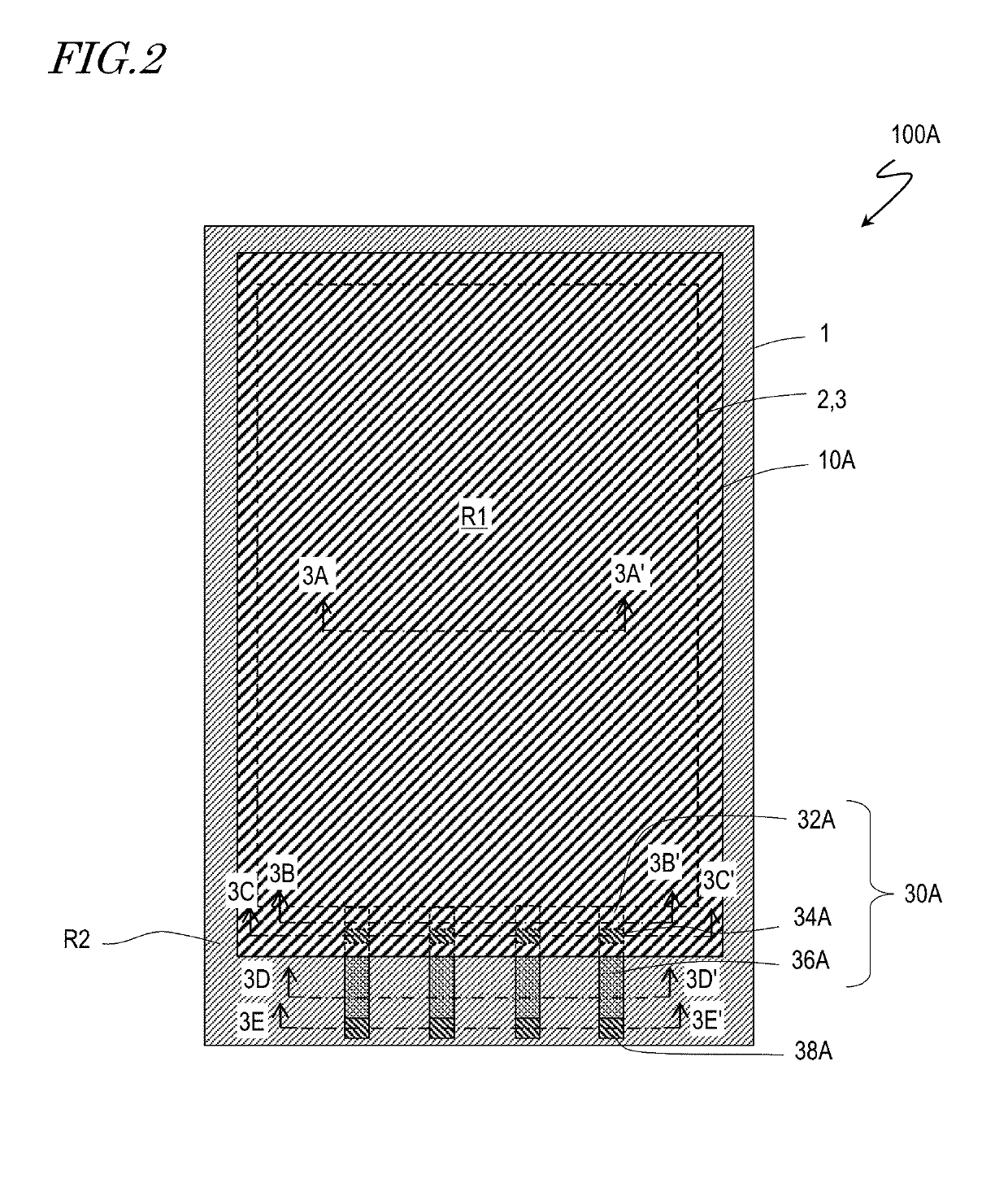

An organic EL device (100A) includes an active region (R1) including a plurality of organic EL elements and includes a peripheral region (R2) located in a region other than the active region. The organic EL device includes an element substrate (1) including a substrate, and the plurality of organic EL elements supported by the substrate; and a thin film encapsulation structure (10A) covering the plurality of organic EL elements. The thin film encapsulation structure includes a first inorganic barrier layer (12), an organic barrier layer (14) in contact with a top surface of the first inorganic barrier layer, and a second inorganic barrier layer (16) in contact with the top surface of the first inorganic barrier layer and a top surface of the organic barrier layer. The peripheral region includes a first protruding structure (22a) including a portion extending along at least one side of the active region, the first protruding structure being supported by the substrate, and also includes an extending portion (12e), of the first inorganic barrier layer, extending onto the first protruding structure, the first protruding structure having a height larger than a thickness of the first inorganic barrier layer.

Owner:SAKAI DISPLAY PROD

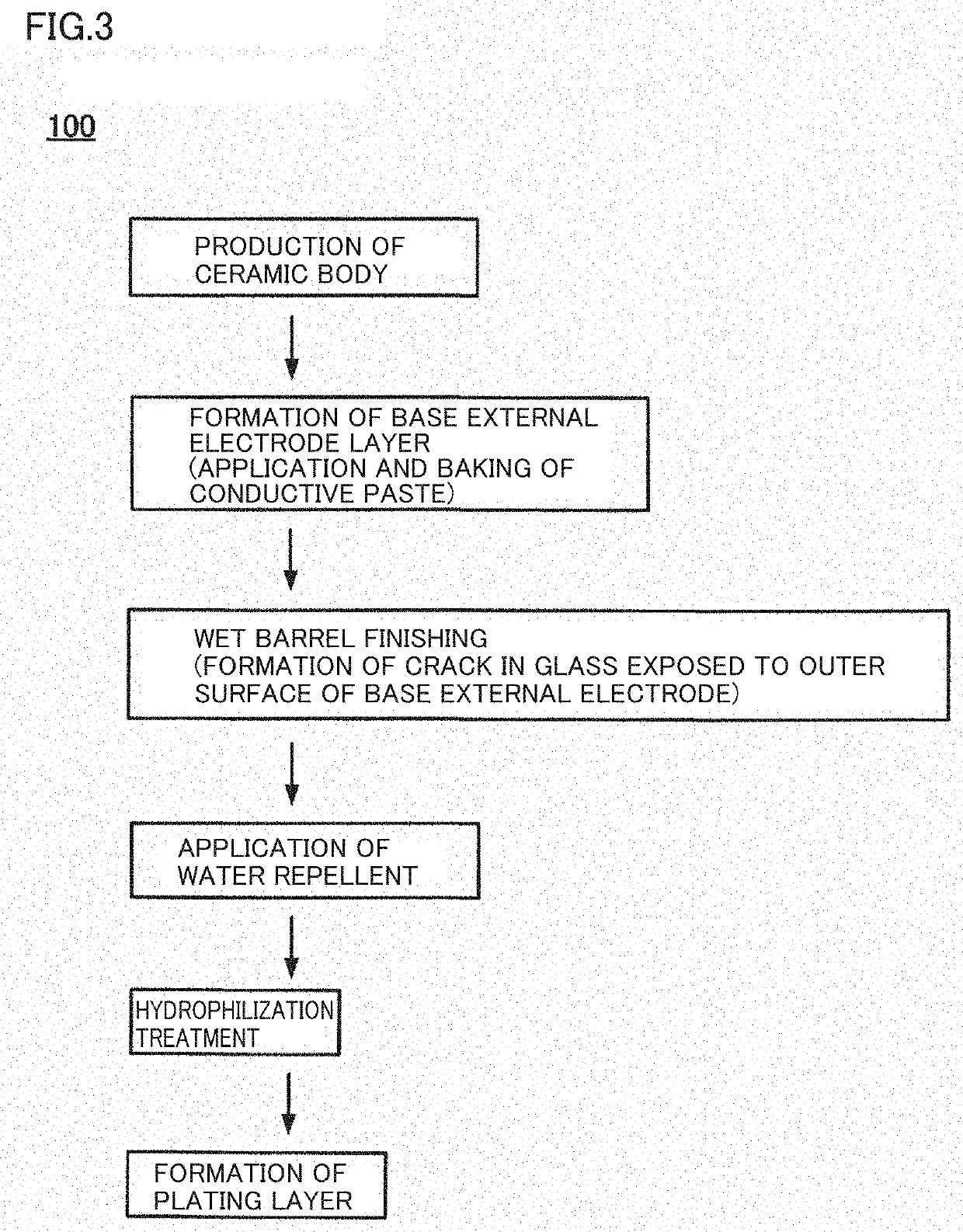

Method of manufacturing multilayer ceramic capacitor and multilayer ceramic capacitor

ActiveUS20200411247A1Sufficient distanceReduces and prevents insulation degradationFixed capacitor electrodesFixed capacitor dielectricConductive pasteFrit

A method includes producing a ceramic body including a stack of a dielectric layer and an internal electrode, applying a conductive paste including metal powder and glass frit to an outer surface of the ceramic body and baking the conductive paste to form a base external electrode layer, forming a crack in glass exposed to an outer surface of the base external electrode layer, after the formation of the crack, applying a water repellent to the base external electrode layer, and forming a Ni plating layer and a Sn plating layer on the base external electrode layer.

Owner:MURATA MFG CO LTD

Monolithic ceramic capacitor and structure for mounting the same

ActiveUS10483041B2Low costImprove moisture resistance reliabilityFixed capacitor electrodesFixed capacitor dielectricCeramic capacitorAnode potential

A first outer electrode and first inner electrodes are supplied with an anode potential and a second outer electrode and second inner electrodes are supplied with a cathode potential when a monolithic ceramic capacitor is mounted and in use. The first outer electrode supplied with the anode potential has a thickness that is greater than a thickness of the second outer electrode supplied with the cathode potential.

Owner:MURATA MFG CO LTD

Method for manufacturing organic el device, including a thin film encapsulation structure film-forming method, and film-forming apparatus for the same

ActiveUS10741800B2Improve moisture resistance reliabilityFinal product manufactureElectroluminescent light sourcesInfraredThin membrane

Owner:SAKAI DISPLAY PROD

Organic el display apparatus and manufacturing method therefor

ActiveUS20200194718A1Improve moisture resistance reliabilityFinal product manufactureElectroluminescent light sourcesThin membraneEngineering

A thin film encapsulation structure included in an organic EL display apparatus includes a first inorganic barrier layer, an organic barrier layer in contact with the inorganic barrier layer, and a second inorganic barrier layer in contact with the organic barrier layer. The thin film encapsulation structure is formed on an active region and the active region side portion of a plurality of lead wires extending from the active region to a terminal. Each of the lead wires at least partially includes, at at least the lowermost portions of two side surfaces thereof in contact with the first inorganic barrier layer, a forward tapering side surface portion having a tapering angle smaller than 90 degrees in a cross-section parallel to a line width direction thereof. The thin film encapsulation structure includes an inorganic barrier layer joint portion in which the organic barrier layer is not present, and the first inorganic barrier layer and the second inorganic barrier layer are in direct contact with each other. On the respective portions, of the lead-out wires, having the forward tapered side surface portions, the inorganic barrier layer joint portion is formed and the active region is completely enclosed by the inorganic barrier layer joint portion.

Owner:SAKAI DISPLAY PROD

Multilayer capacitor

ActiveUS20200090871A1Improve moisture resistance reliabilityIncreased Strength ReliabilityFixed capacitor electrodesHybrid capacitor electrodesStress alleviationDielectric layer

A multilayer capacitor includes a body including a stack structure of a plurality of dielectric layers, and a plurality of internal electrodes stacked with the dielectric layers interposed therebetween. A stress alleviation portion is disposed on at least one surface among surfaces of the body, and an external electrode is disposed on an external portion of the body and connected to the internal electrodes. The stress alleviation portion includes a first resin layer adjacent to the body, and a second resin layer covering the first resin layer and including a filler dispersed in a resin of the second resin layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Organic electroluminescent device and method for producing same

InactiveUS20190207162A1Improve moisture resistance reliabilityLiquid surface applicatorsSolid-state devicesOrganic electroluminescenceMolecular physics

An organic electroluminescent device according to an embodiment includes an element substrate including a substrate and a plurality of organic electroluminescent elements supported by the substrate, and a thin film encapsulation structure formed on the plurality of organic electroluminescent elements. The thin film encapsulation structure includes at least one complex stack body which includes a first inorganic barrier layer, an organic barrier layer in contact with a top surface of the first inorganic barrier layer, the organic barrier layer including a plurality of solid portions discretely distributed, and a second inorganic barrier layer in contact with the top surface of the first inorganic barrier layer and a top surface of each of the plurality of solid portions of the organic barrier layer.

Owner:SAKAI DISPLAY PROD

Organic electroluminescent device and method for producing same

ActiveUS10693104B2Improve moisture resistance reliabilityElectroluminescent light sourcesSolid-state devicesThin membraneEngineering

An organic EL device (100A) includes an active region (R1) including a plurality of organic EL elements and includes a peripheral region (R2) located in a region other than the active region. The organic EL device includes an element substrate (1) including a substrate, and the plurality of organic EL elements supported by the substrate; and a thin film encapsulation structure (10A) covering the plurality of organic EL elements. The thin film encapsulation structure includes a first inorganic barrier layer (12), an organic barrier layer (14) in contact with a top surface of the first inorganic barrier layer, and a second inorganic barrier layer (16) in contact with the top surface of the first inorganic barrier layer and a top surface of the organic barrier layer. The peripheral region includes a first protruding structure (22a) including a portion extending along at least one side of the active region, the first protruding structure being supported by the substrate, and also includes an extending portion (12e), of the first inorganic barrier layer, extending onto the first protruding structure, the first protruding structure having a height larger than a thickness of the first inorganic barrier layer.

Owner:SAKAI DISPLAY PROD

Laminate type ceramic electronic component and manufacturing method therefor

ActiveCN102376450AHigh hardnessImprove joint strengthFixed capacitor electrodesFixed capacitor dielectricMetallurgyCeramic capacitor

In a laminate type ceramic electronic component, when an external electrode is formed directly by plating onto a surface of a component main body, the plating film that is to serve as the external electrode may have a low fixing strength with respect to the component main body. In order to prevent this problem, an external electrode includes a first plating layer composed of a Ni-B plating film and is first formed such that a plating deposition deposited with the exposed ends of respective internal electrodes as starting points is grown on at least an end surface of a component main body. Then, a second plating layer composed of a Ni plating film containing substantially no B is formed on the first plating layer. Preferably, the B content of the Ni-B plating film constituting the first plating layer is about 0.1 wt % to about 6 wt %.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com