Carbonizing meshy fire retardant felt and method for preparing same

A network and flame retardant technology, applied in the direction of non-woven fabrics, fiber types, textiles and papermaking, etc., can solve the problems of melting dripping, burning through, corrosion, environmental pollution, etc., and achieve high tensile strength, beneficial to human health, Effect of improving moisture resistance reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

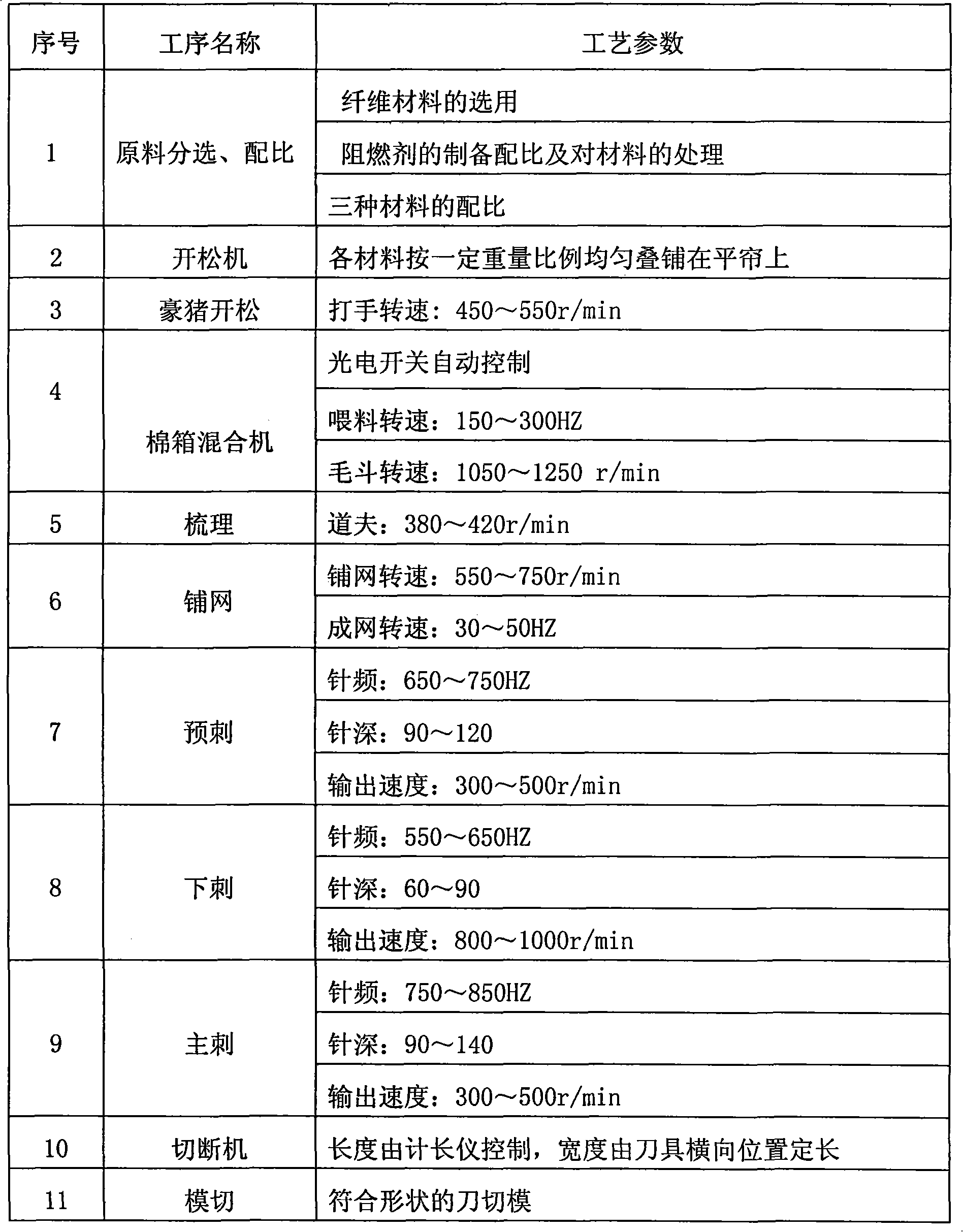

Method used

Image

Examples

Embodiment 1

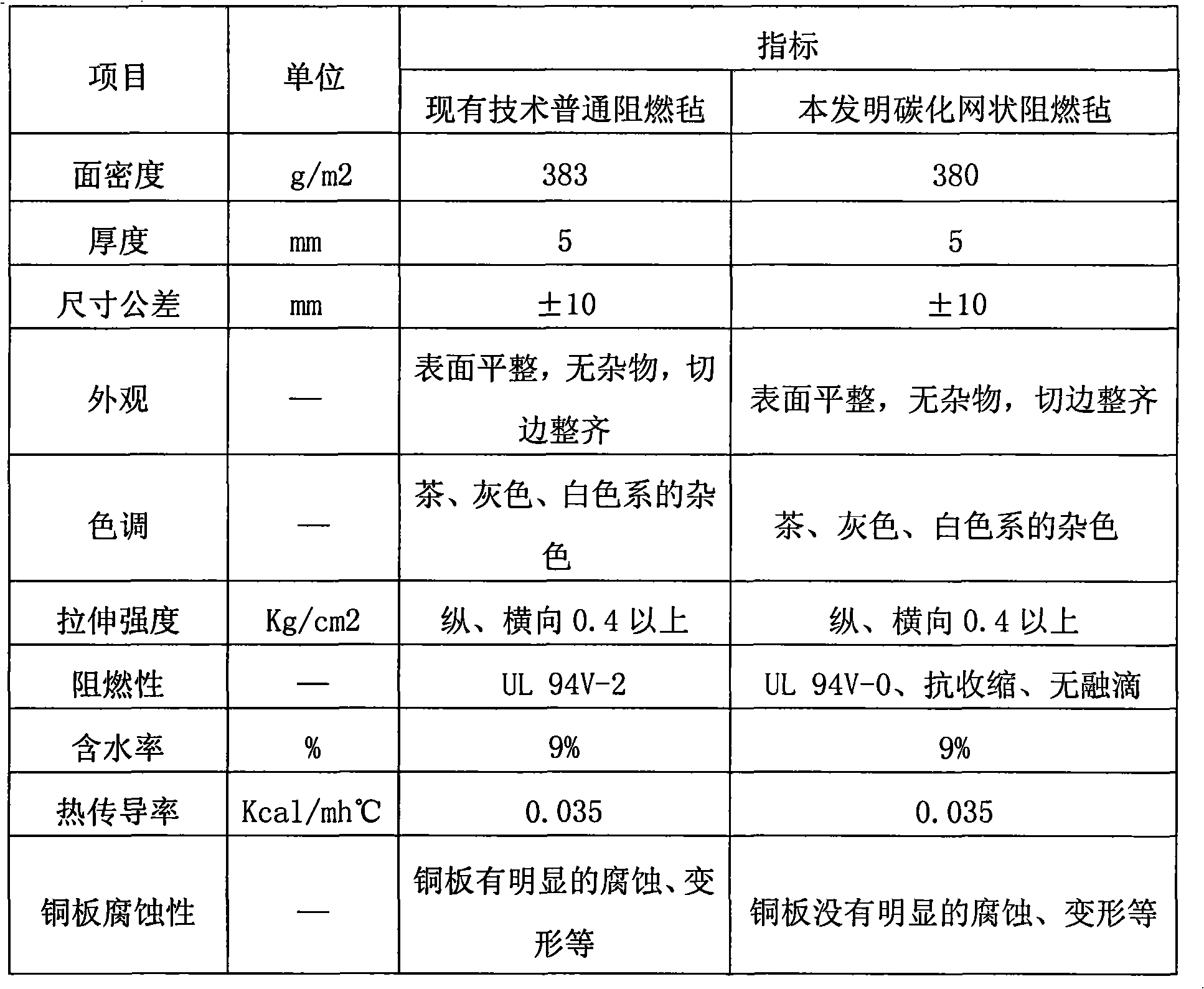

[0025] Example 1: By weight, 32% of high temperature resistant fiber, 40% of flame-retardant and shrink-proof polyester fiber, 25% of flame-retardant treated cellulose fiber and 3% of flame retardant are blended to form a carbonized reticular flame-retardant felt. Among them, the high temperature resistance of the high temperature resistant fiber should reach above 265°C, and the flame retardant treated cellulose fiber acts as a carbonized network after burning. The composition ratio of the flame retardant per unit weight is: microencapsulated red phosphorus P with red phosphorus content ≥ 83%: 12.7%, antimony trioxide Sb 2 o 3 : 7%; zinc borate ZnBO 3 : 71.5%; Magnesium Oxide MgO: 5%; Aluminum Hydroxide AL(OH) 3 : 4.5%; the rest is an appropriate amount of water.

Embodiment 3

[0026] Example 3: By weight, 36% of high temperature resistant fiber, 30% of flame-retardant and shrink-proof polyester fiber, 30% of flame-retardant treated cellulose fiber and 4% of flame retardant are used to blend to form a carbonized reticular flame-retardant felt. Among them, the high temperature resistance of the high temperature resistant fiber should reach above 265°C, and the flame retardant treated cellulose fiber acts as a carbonized network after burning. The composition ratio of the flame retardant per unit weight is: microencapsulated red phosphorus P with red phosphorus content ≥ 83%: 12.9%, antimony trioxide Sb 2 o 3 : 7.2%; zinc borate ZnBO 3 : 71.9%; Magnesium Oxide MgO: 5.2%; Aluminum Hydroxide AL(OH) 3 : 4.6%. The rest is an appropriate amount of water.

[0027] Embodiment 3: By weight, 37% of high temperature resistant fiber, 25% of flame-retardant and shrink-resistant polyester fiber, 33% of flame-retardant treated cellulose fiber and 5% of flame ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com