Laminate type ceramic electronic component and manufacturing method therefor

一种电子部件、制造方法的技术,应用在固定电容的零部件、叠层电容器、固定电容器电极等方向,能够解决层叠型陶瓷电子部件可靠性降低、部件主体易产生间隙、镀膜产生裂纹等问题,达到固定力优良、固定力或者密封性提高、耐湿可靠性提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

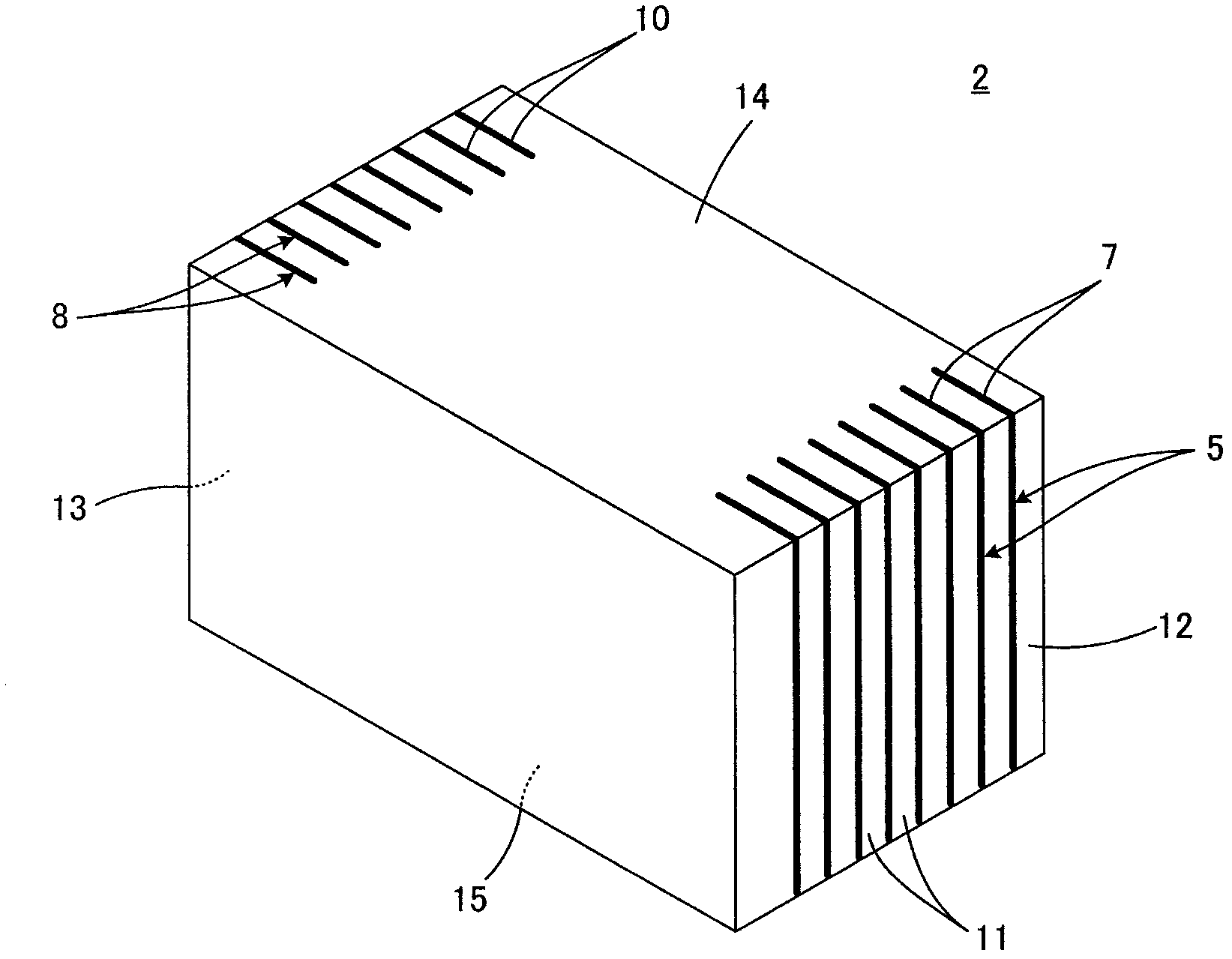

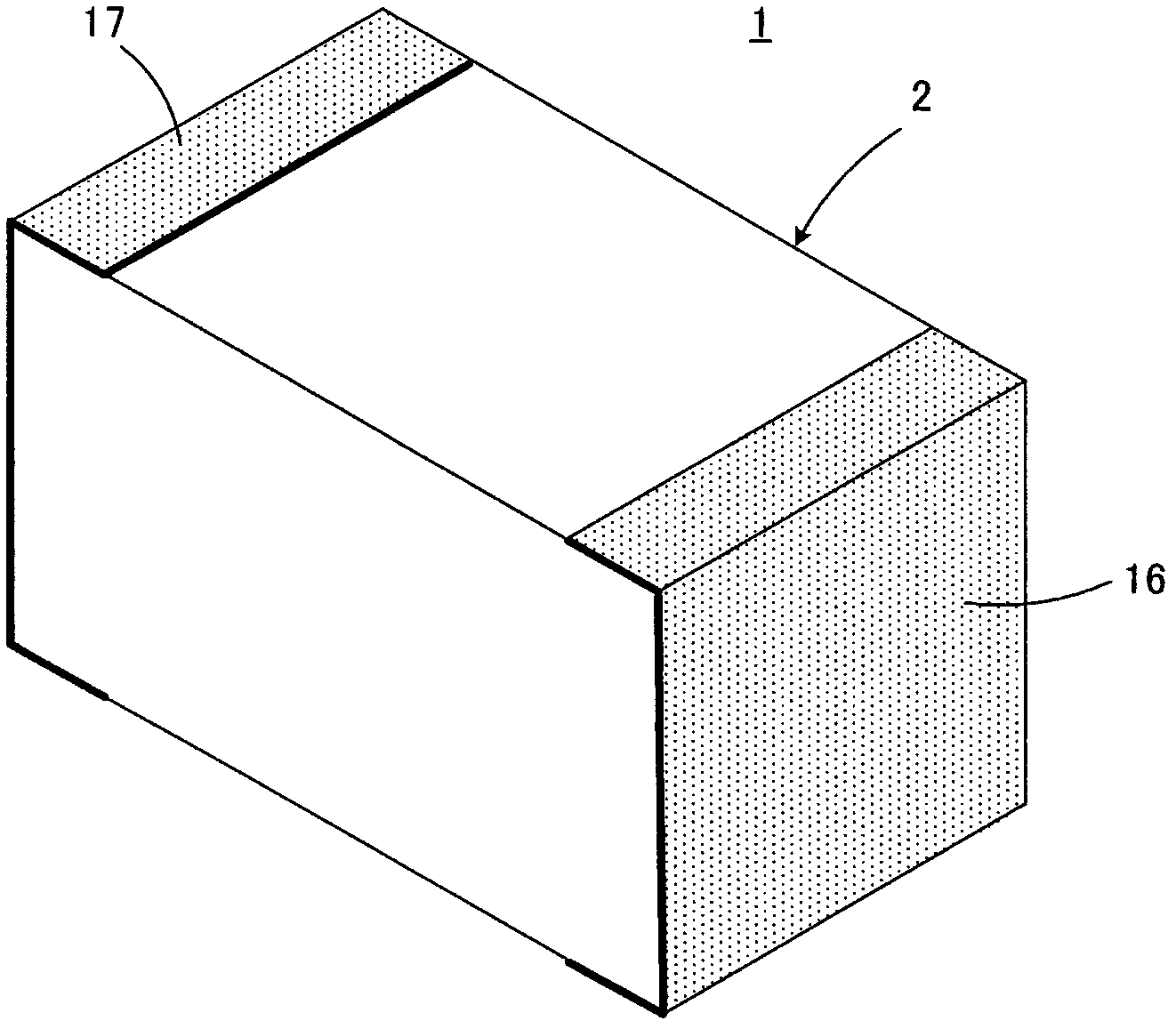

[0041] For the structure of a multilayer ceramic capacitor as a multilayer ceramic electronic component according to one embodiment of the present invention, refer to Figure 1 to Figure 4 And it demonstrates by its manufacturing method.

[0042] for manufacturing image 3 Multilayer ceramic capacitors shown in 1, prepare the figure 2 Part body 2 shown. Additionally, in order to get figure 2 The parts shown in Body 2, prepare the figure 1 Two kinds of ceramic green sheets 3 and 4 are shown.

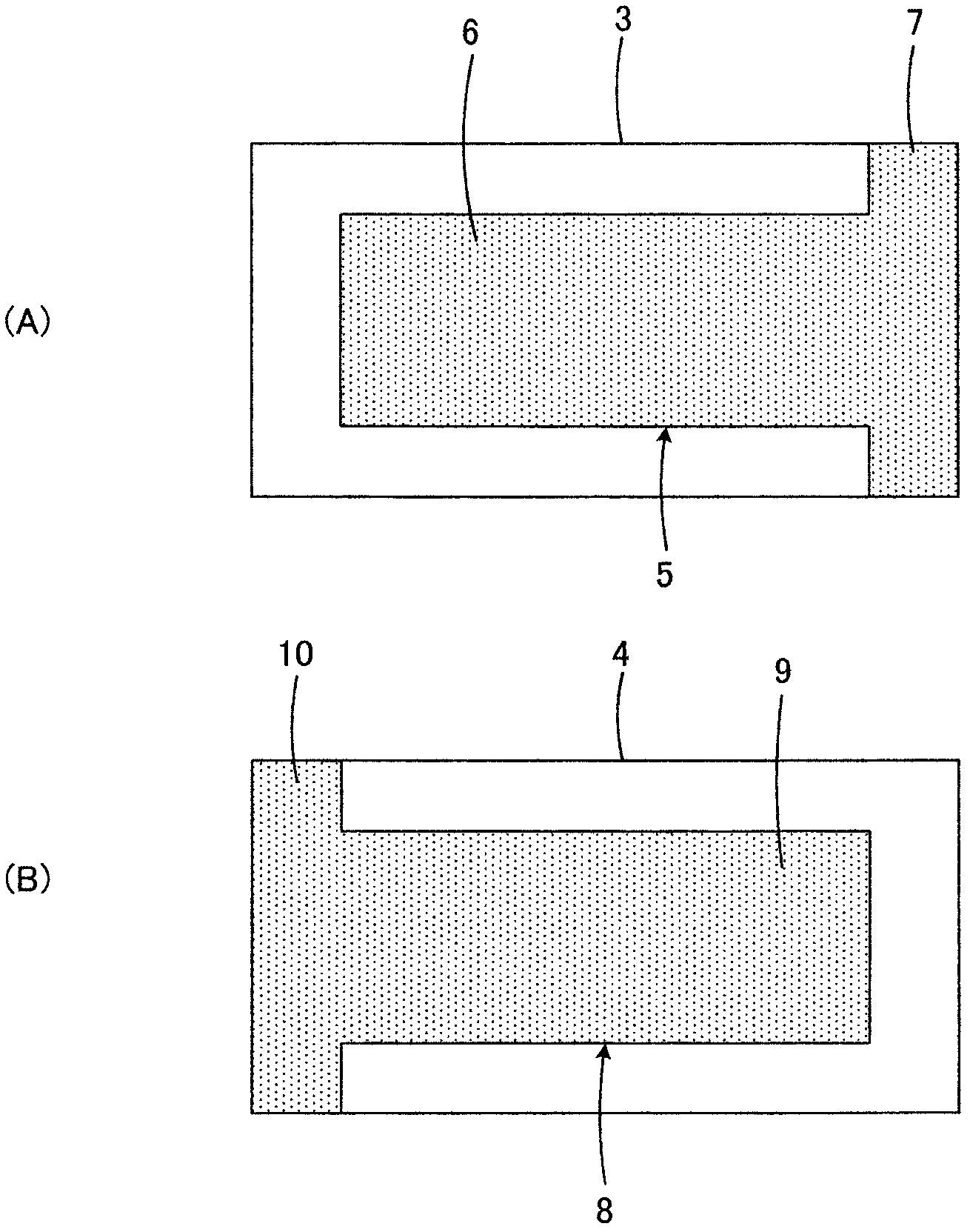

[0043] exist figure 1 The first internal electrodes 5 are formed on the ceramic green sheet 3 shown in (A). The first internal electrode 5 has a capacitance forming portion 6 and a lead portion 7 constituting its main parts. The lead-out portion 7 extends so as to reach one short side of the ceramic green sheet 3 and a part of two long sides adjacent thereto, and constitutes an exposed end there.

[0044] On the other hand, in figure 1 The second internal electrode 8 is form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com