Monolithic Ceramic Electronic Component

一种电子部件、层叠型的技术,应用在固定电容的零部件、电气元件、叠层电容器等方向,能够解决部件功能下降、水分浸入、金属被膜与部件本体固定力弱等问题,达到提高耐湿可靠性、增强接合力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

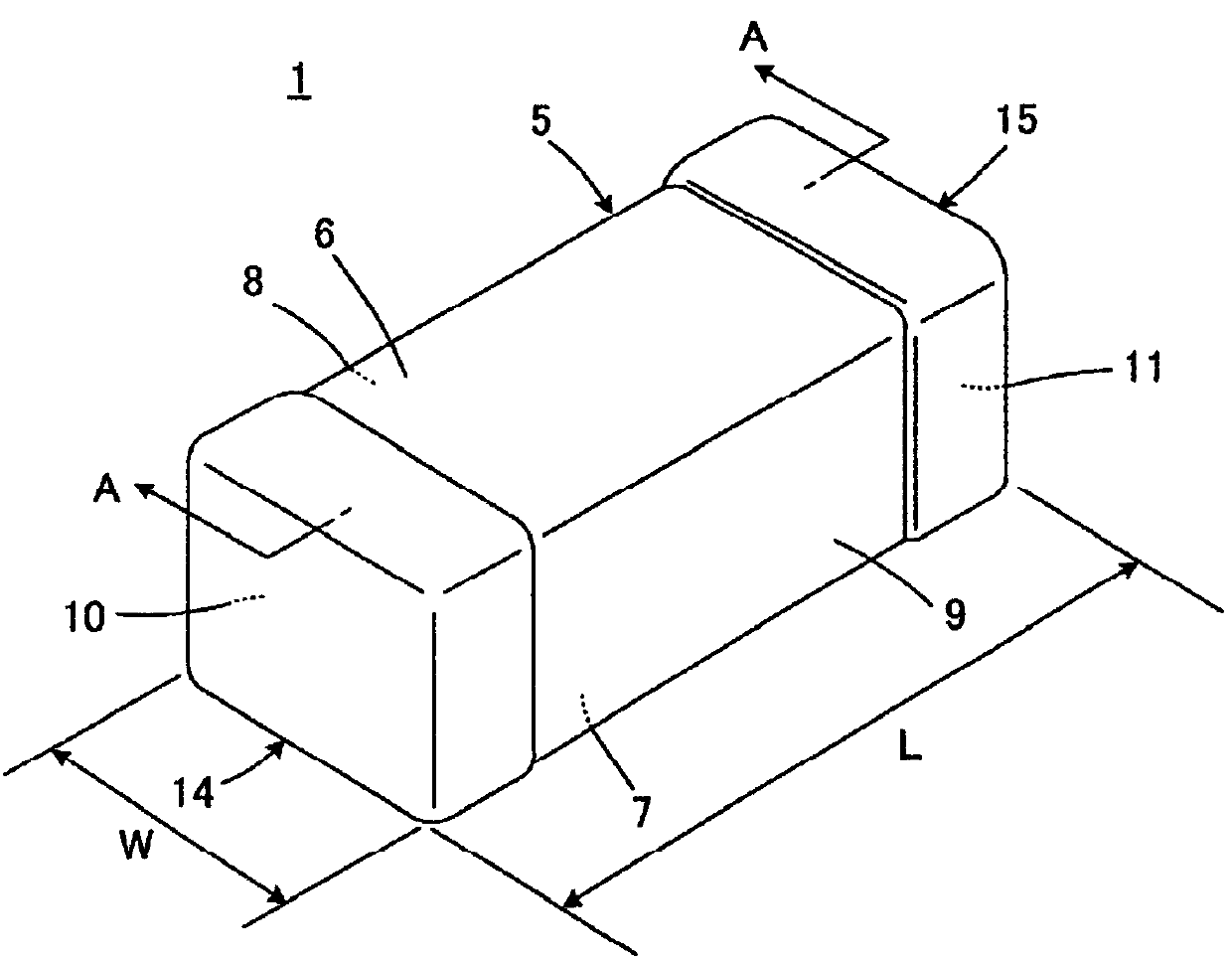

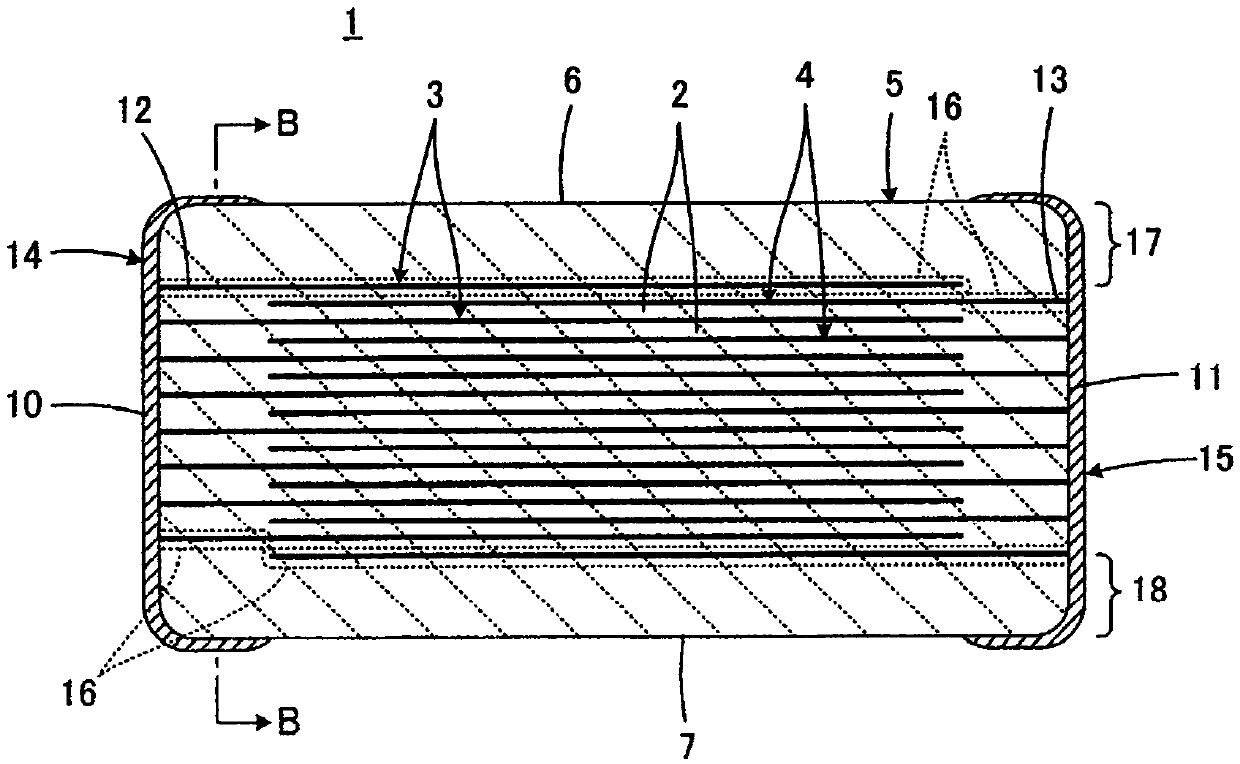

[0049] In Example 1, the effects of the Mg-Ni coexistence region 16 in which the Mg-Ni coexistence region 16 exists were confirmed by focusing particularly on image 3 The portions of the shown first internal electrodes 3 and second internal electrodes 4 that are located in the outer peripheral portion of the region where the exposed ends 12 and 13 are distributed.

[0050] As samples, the following multilayer ceramic electronic components were fabricated.

[0051] First, in order to obtain a component body included in a multilayer ceramic electronic component, an unprocessed component body having ceramic green sheets to be used as a ceramic layer and a Ni-containing layer to be used as an internal electrode is laminated. The structure obtained by the conductive paste film. A barium titanate-based dielectric ceramic raw material to which Mg was added was used as the ceramic raw material contained in the ceramic green sheet.

[0052] Next, the above-mentioned unprocessed comp...

Embodiment 2

[0066] In Example 2, the effects of the Mg-Ni coexistence region 16 in which the Mg-Ni coexistence region 16 exists in the figure 2 Among the regions where the illustrated plurality of first internal electrodes 3 and second internal electrodes 4 are distributed, the outermost first internal electrodes 3 and second internal electrodes 4 are located when viewed in the stacking direction.

[0067] As a sample, a multilayer ceramic electronic component different from that of Example 1 in that it was not an LW inversion type was produced.

[0068] First, a raw component body having the same composition as in the case of Example 1 was prepared. Next, the unprocessed part body is fired. In this sintering step, the oxidizing atmosphere in the heating process before sintering of the ceramic green sheet is controlled, thereby obtaining a sintered component body in which the amount of Mg diffused into the internal electrodes is varied in various ways. The amount of Mg was determined b...

Embodiment 3

[0080] In Example 3, in the same manner as in Example 2, the Mg-Ni coexistence region 16 in which the Mg-Ni coexistence region 16 exists in the figure 2 Among the regions where the illustrated plurality of first internal electrodes 3 and second internal electrodes 4 are distributed, the outermost first internal electrodes 3 and second internal electrodes 4 are located when viewed in the stacking direction.

[0081] As a sample, a multilayer ceramic electronic component was prepared. The multilayer ceramic electronic component was manufactured by electrolytic Cu plating on the component body, followed by electrolytic Ni plating, and then electrolytic Sn plating to form external electrodes. It was manufactured by the same method as in the case of Example 2 except that.

[0082] And, as shown in Table 3, similarly to the case of Example 2, the "region where Mg / Ni=0.1 or more in the outermost layer" and the "peeling occurrence rate" were obtained.

[0083] [table 3]

[0084] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com