Laminate having moisture barrier properties

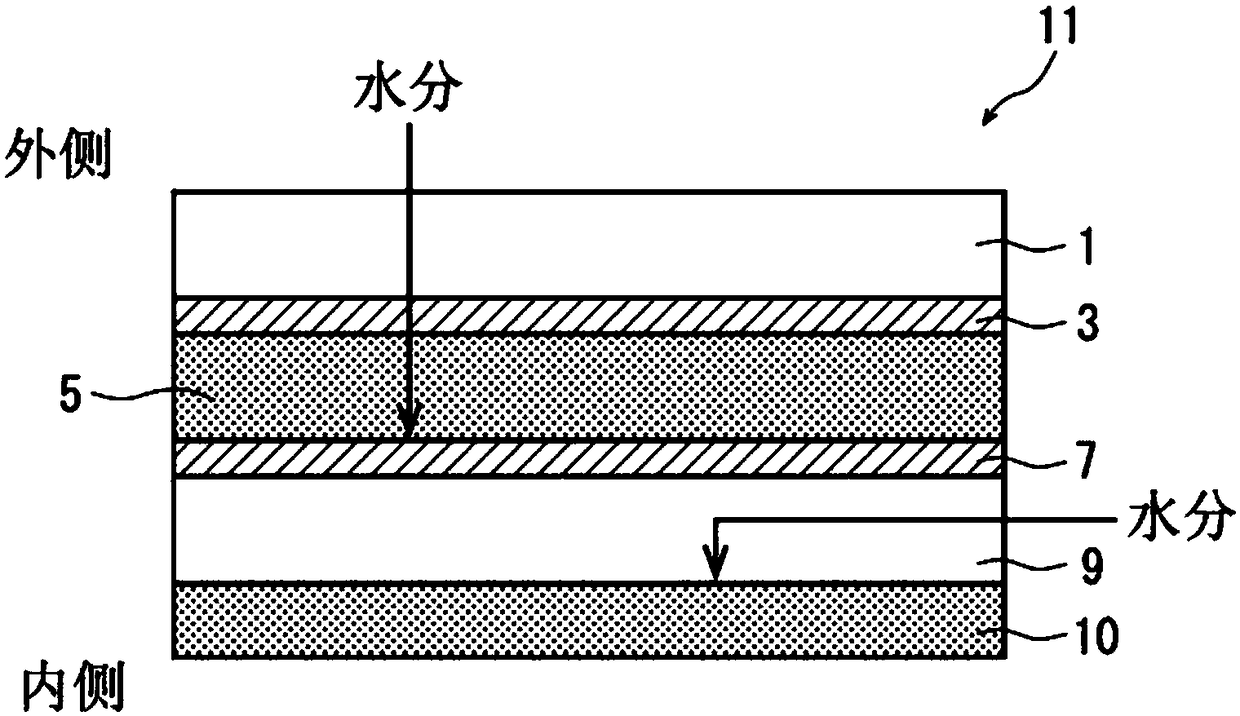

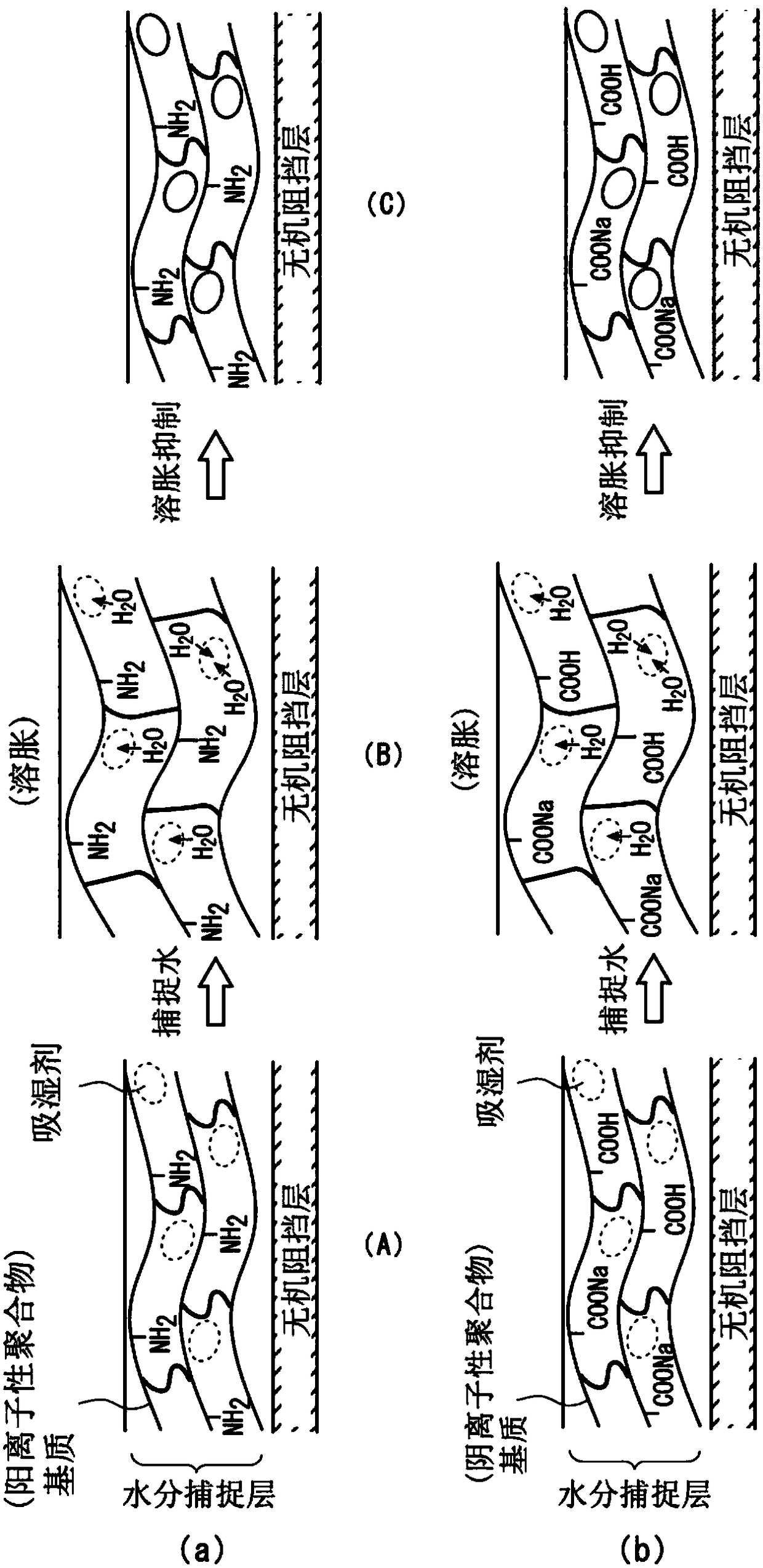

一种层压体、无机阻挡层的技术,应用在分层产品、涂层、导体等方向,能够解决没有水分研究、不能够显示水分充分程度的阻挡性等问题,达到寿命延长的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0342] An aqueous solution of polyallylamine as an ionic polymer was prepared.

[0343] Polyallylamine aqueous solution;

[0344] PAA-15C, manufactured by Nittobo Medical Co.

[0345] Solid content, 15%

[0346] In addition, as a hygroscopic agent, the following cross-linked product of polyacrylic acid Na was prepared.

[0347] The cross-linked product of polyacrylic acid Na;

[0348] TAFTIC HU-820E (water dispersion), manufactured by Toyobo Co.

[0349] Solid content, 13%

[0350] The above polyallylamine aqueous solution was diluted with water so that its solid content was 5% by weight to obtain a polymer solution.

[0351] Further, a crosslinking agent solution was prepared by dissolving γ-glycidoxypropyltrimethoxysilane (crosslinking agent) in water so that the amount thereof was 5% by weight.

[0352] Next, the polymer solution and the crosslinking agent solution were mixed together such that the amount of γ-glycidoxypropyltrimethoxysilane was 15 parts by weight rel...

Embodiment 2

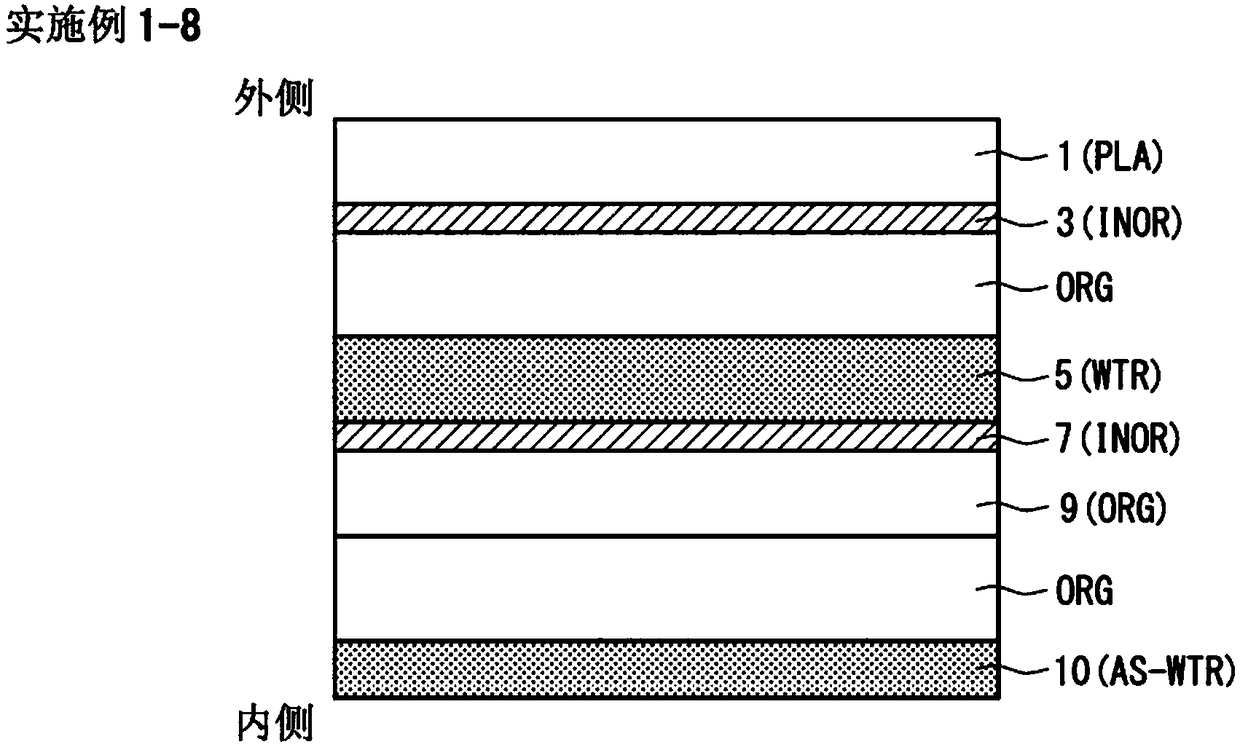

[0360] In the same manner as in Example 1, except for forming an AS-WTR layer with a thickness of 8 μm, image 3 Moisture barrier laminate (2) of the layer structure shown.

Embodiment 3

[0362] An ion exchange resin (Amberlite 200CT, produced by Organo Co.) was prepared.

[0363] The Na salt type carboxyl group of polyacrylic acid Na crosslinked product (HU-820E) is converted into H type carboxyl group by using ion exchange resin. Thereafter, by using a 1N potassium hydroxide aqueous solution, a crosslinked product of polyacrylic acid K having a potassium salt type carboxyl group (water dispersion product, solid content: 10%, neutralization rate: 80%) was obtained.

[0364] Except using the cross-linked product of the above polyacrylic acid K as a hygroscopic agent, in the same manner as in Example 1, image 3 Gas barrier laminate (3) of the layer structure shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hygroscopic ratio | aaaaa | aaaaa |

| hygroscopic ratio | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com