Process for producing cocoa polyphenol concentrate

A technology for extracting cocoa beans, which is applied in the field of obtaining cocoa products rich in cocoa polyphenols, can solve the problems of difficult control of the temperature of unfermented cocoa beans, expensive microwaves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Enzymatic browning reactions cause foods rich in phenolic compounds to darken during their transportation, storage, and processing. These undesired reactions in foods produce substances that cause unpleasant odors and tastes.

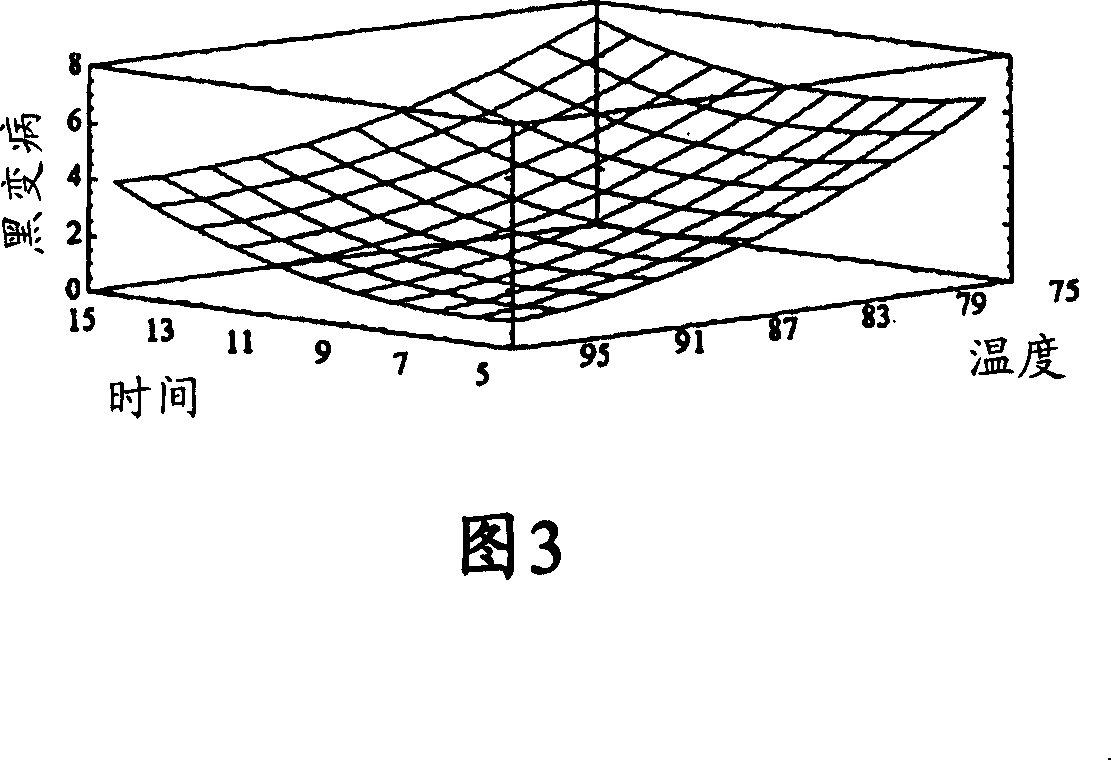

[0082] The purpose of the present invention is to inactivate polyphenol oxidase by heating, in particular, by heat treatment (bleaching) in water, and to study the inactivation conditions (time-temperature relationship) for controlling the enzymatic browning reaction, wherein the enzyme The browning response was measured by color change (perceptual color analysis).

[0083] Nine trials were performed at 3 different time and temperature combinations.

[0084] Humidity = 75°C, 85°C, and 95°C; Time = 5 minutes, 10 minutes, and 15 minutes. 1 wt% catechol was used as an agent to accelerate browning. Browning was then measured to quantify how long and what heat treatment was needed to best suppress the browning response (melanosis) of the cocoa seed...

Embodiment 2

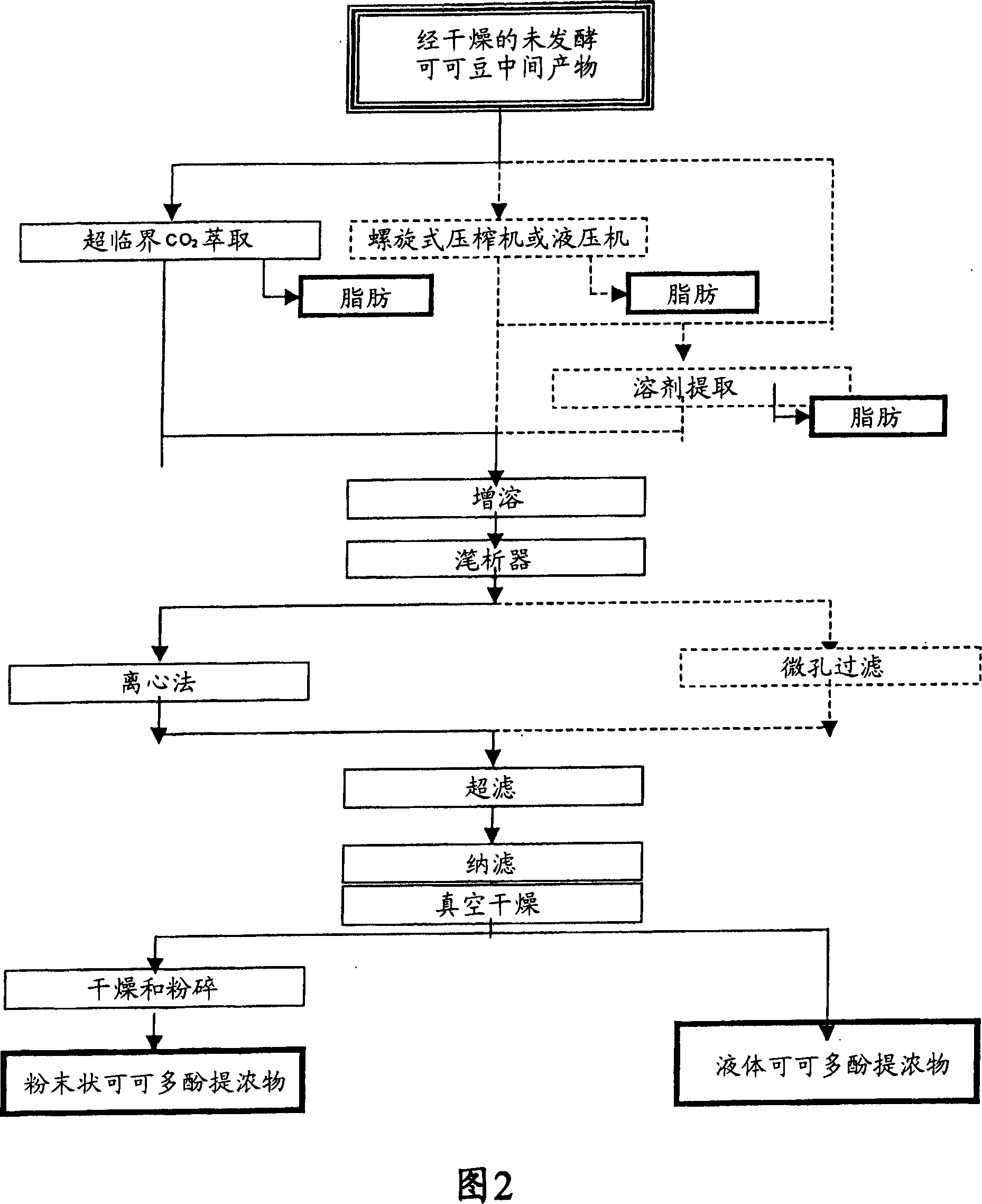

[0099] Example 2 Polyphenol Solubilization

[0100] 25 grams of dried defatted unfermented cocoa bean intermediate containing 2.31 grams of total polyphenols (9.25 wt %) were initially extracted with water at a ratio of 1:15 (cocoa:water). Extraction was performed at a temperature of 30°C for 2.5 hours.

[0101] After the first extraction, the mixture was centrifuged. Two fractions are obtained: liquid and extracted solid. The extracted solids are then subjected to the above extraction process twice. Conditions remained the same except that the solid:solvent ratio was 1:10 in the last two extractions.

[0102] The results of the experiment are shown in Table 3.

[0103] more recycled in the process

[0104] From the results shown in Table 3, it can be clearly seen that after the third extraction, 81.08 wt% of polyphenols were recovered in solution. 594 ml of solution were obtained, of which total solids (0.98%) were 5.84 g and total polyphenols were 1.42 g. T...

Embodiment 3

[0106] Unfermented fresh cocoa beans contain on average 50 wt% moisture, 24 wt% fat, 3.5% total polyphenols, 7.8% husk, and 14.7% other compounds.

[0107] 1000 Kg of fresh unfermented cocoa beans were bleached in hot water at 95° C. for 7 minutes to inactivate the PPO enzyme. After blanching, the cocoa beans are rinsed in cold water. Next, the cocoa beans having a moisture content of 44 wt% were dried in the sun for one week to reduce the moisture content to 6 wt%. After drying, 532 Kg of dried unfermented cocoa beans with greatly reduced and / or inactivated PPO activity were obtained. This by-product contains 6.57% polyphenols.

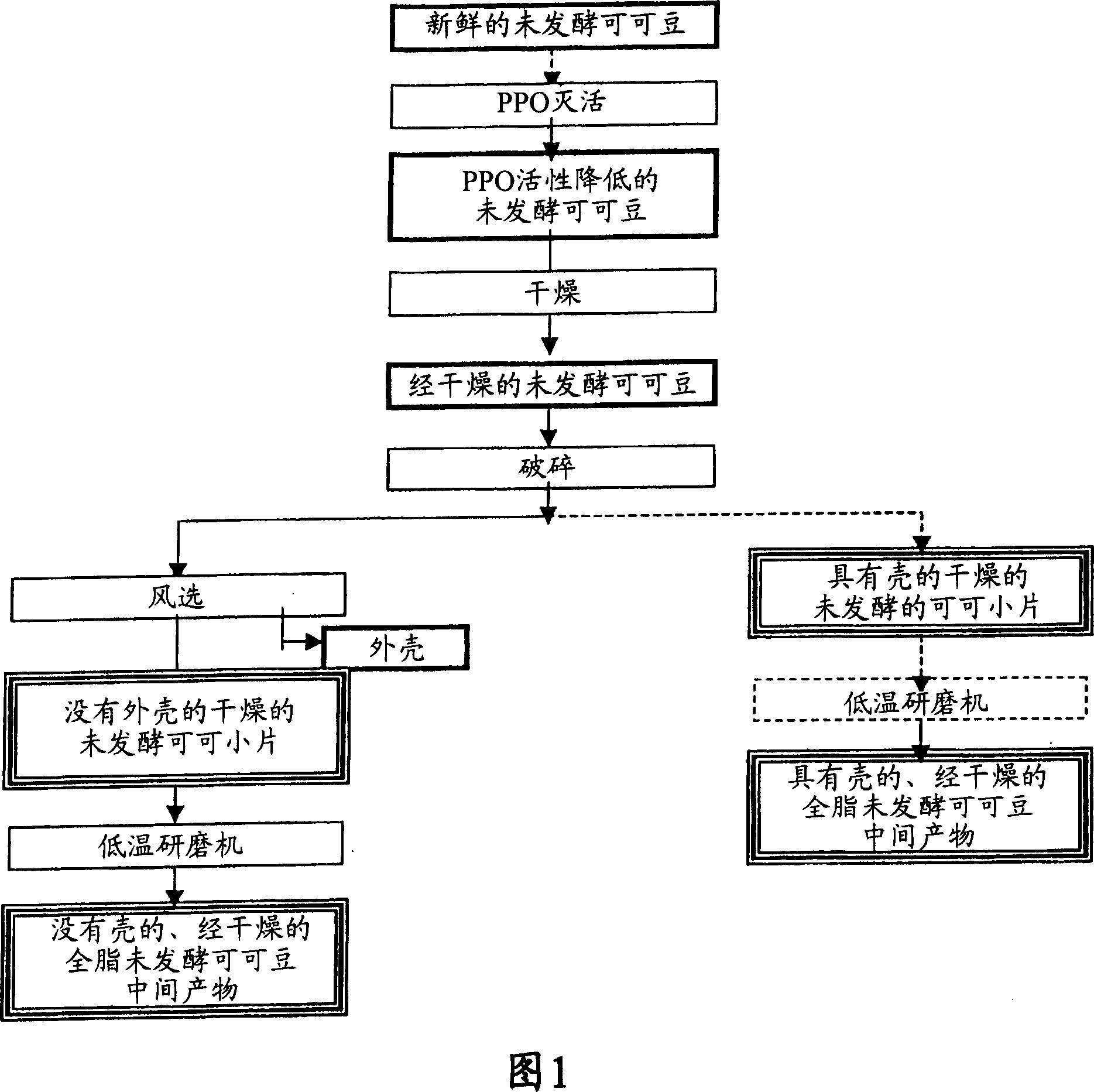

[0108] In the next step, the dried cocoa beans are reduced in particle size by crushing followed by pulverization. Crush with a hammer mill to obtain small pieces. After crushing, the flakes were ground with a cryogenic pin mill using nitrogen as cooling medium to avoid fat melting. During cryogenic milling, by-products were frozen at -5 °C. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com