Milk pudding and preparation method thereof

A milk pudding and milk technology, which is applied in food preparation, application, food science and other directions, can solve the problems of single variety, reduced nutritional value, and can not meet the consumer demand of the masses, and achieves extended shelf life, increased protein content, and reduced whey precipitation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

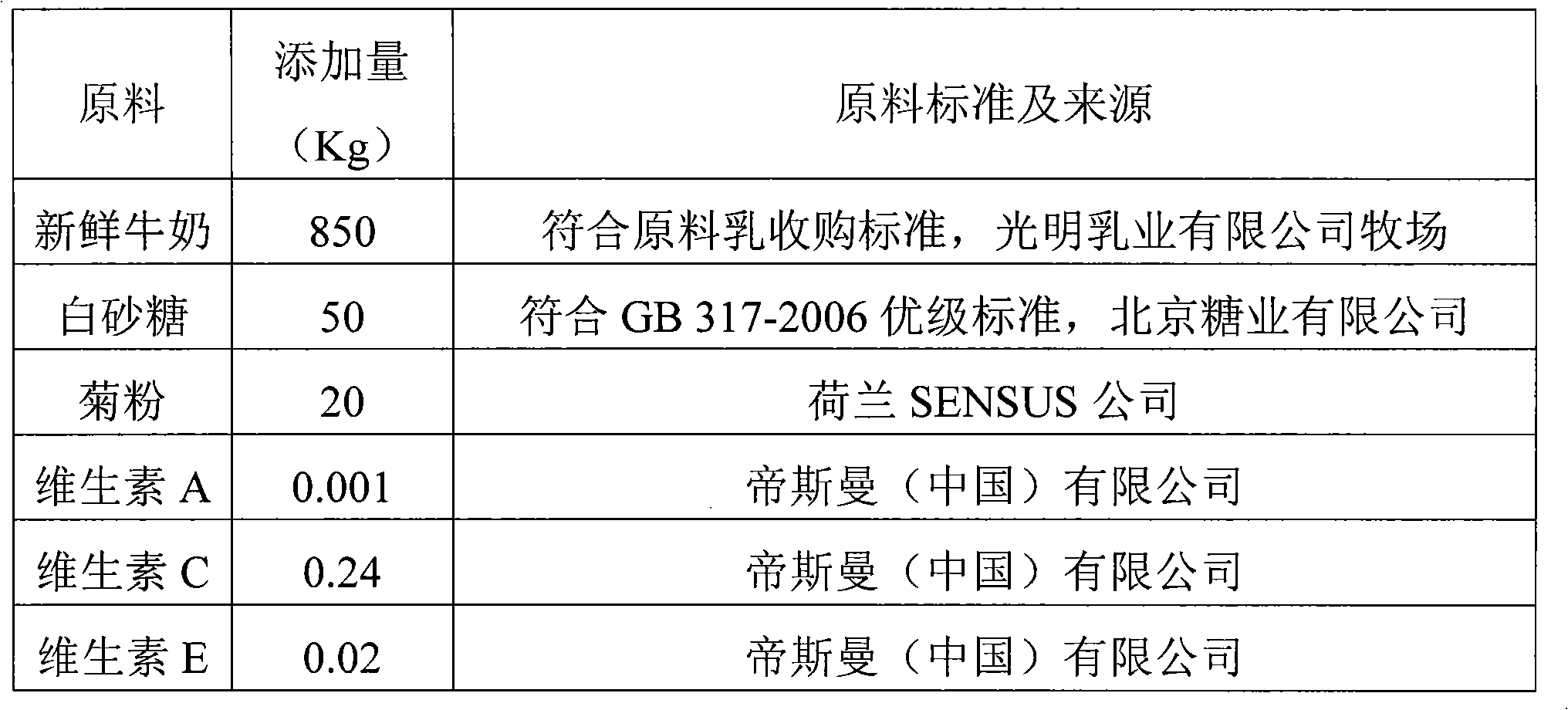

[0049] 1. Formula (see Table 1)

[0050] Table 1. Raw materials, addition amount, standards and their sources (calculated on the basis of 1 ton of product)

[0051]

[0052]

[0053] Note: The performance indicators of each raw material meet the requirements of relevant quality standards.

[0054] 2. Preparation process:

[0055] a) Dry mix white granulated sugar, inulin, WPC-80, functional food gum and modified starch as described in the ingredient list, dissolve in 500Kg standardized milk at 50°C, stir for 20 minutes, and then use Quantify the remaining milk or purified water to 1000Kg, add vitamins A, C and E when the temperature drops to 25°C, and cool to 10°C before sterilization;

[0056] b) After the semi-finished product passes the test, it enters the homogenization and sterilization stage. The material is heated to 50°C, homogenized under the pressure of 18MPa, and sterilized at 110°C for 900s;

[0057] c) Pour the sterilized material into the milk buffer tan...

Embodiment 2

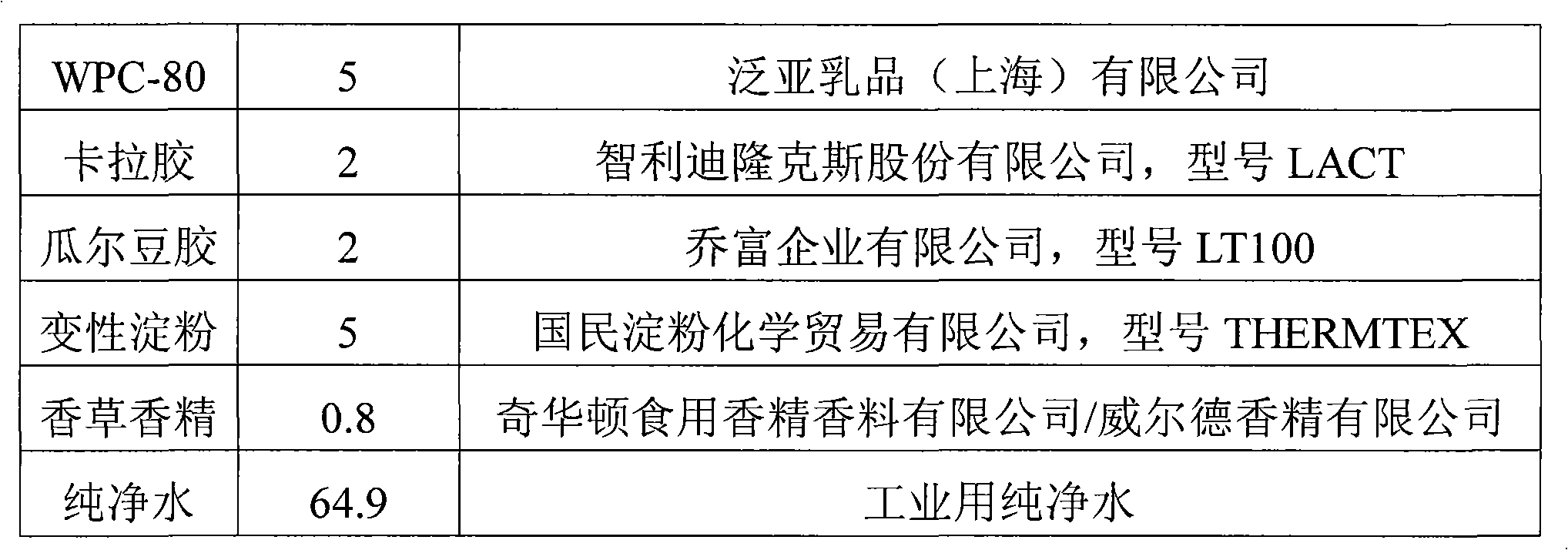

[0061] 1. Formula (see Table 2)

[0062] Table 2. Raw materials, additive amounts, standards and their sources (calculated on the basis of 1 ton of product)

[0063]

[0064]

[0065] Note: The performance indicators of each raw material meet the requirements of relevant quality standards.

[0066] 2. Preparation process:

[0067] a) Dry mix white sugar, inulin, WPC-34, functional food glue, modified starch, cocoa powder and other materials according to the ingredients list, dissolve in 68°C, 400Kg standardized milk, and stir for 18 minutes , and then use the remaining milk or purified water to quantify to 1000Kg, and cool to 8°C before sterilization;

[0068] b) After the semi-finished product passes the test, it enters the homogenization and sterilization stage. The material is heated to 68°C, homogenized under the pressure of 20MPa, and sterilized at 135°C for 5s;

[0069] c) Pour the sterilized material into the milk buffer tank, and the cooling temperature is 68°...

Embodiment 3

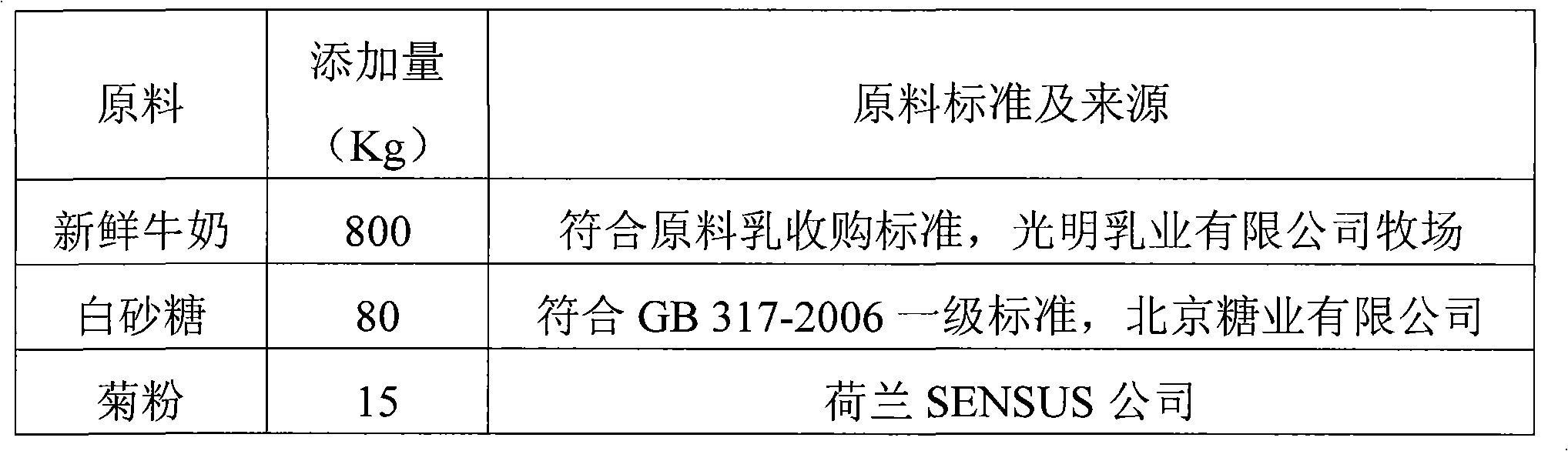

[0073] 1. Formula (see Table 3)

[0074] Table 3. Raw materials, additive amounts, standards and their sources (calculated on the basis of 1 ton of product)

[0075]

[0076]

[0077] Note: The performance indicators of each raw material meet the requirements of relevant quality standards.

[0078] 2. Preparation process:

[0079] a) Dry mix acesulfame-K, aspartame, inulin, WPC-34, functional food gum, modified starch and other materials according to the ingredient list, dissolve in 70°C, 300Kg standardized milk, and Stir for 10 minutes, then use the remaining milk or purified water to measure to 1000Kg, and cool to 4°C before sterilization;

[0080] b) After the semi-finished product passes the test, it enters the homogenization and sterilization stage. The material is heated to 70°C, homogenized under the pressure of 10MPa, and sterilized at 120°C for 10s;

[0081] c) Pour the sterilized material into the milk buffer tank, and the cooling temperature is 65°C;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com