Functional oil microencapsulation and manufacturing method thereof

A functional, microcapsule technology, which is applied in the field of pharmaceuticals, health food additives, and feed, can solve the problems of re-demulsification, unfavorable oil embedding, and disadvantages, and achieve stable demulsification, good anti-oxidation effect, and improved stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

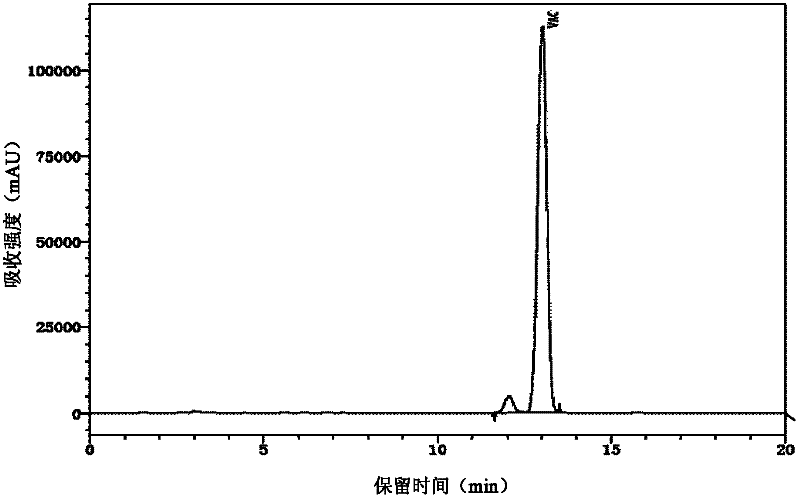

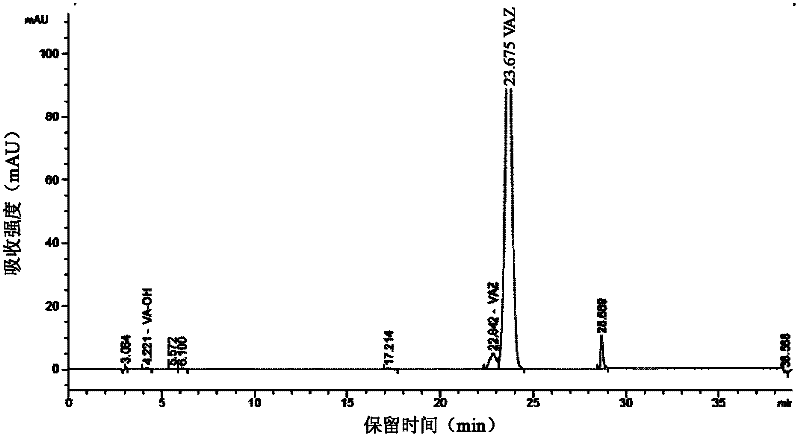

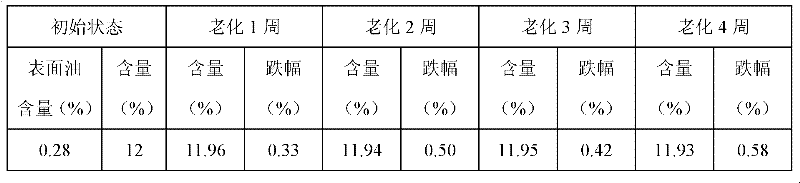

Embodiment 1

[0037] Step 1. Weigh 100g of sodium caseinate, 100g of lactose, 25g of mannose, and 100g of sucrose, mix well, then add 500g of water to stir and dissolve in a water bath at 50°C; weigh VA acetic acid with a content of 2.78 million IU / G 100g of ester crystals, 75g of soybean oil, 0.6g of antioxidants (containing 0.20g of rosemary extract, 0.05g of vitamin C palmitate, and 0.35g of natural vitamin E), were dissolved in a 60°C water bath while stirring while heating; After the oxidant is completely dissolved, add the oil-phase core material to the water-phase wall material solution, use a shearing machine to shear and emulsify initially, and use 30MPa high-pressure homogenization twice.

[0038] Step 2. Heat the obtained emulsion in a water bath at 35°C, add 1000 U of Tg enzyme while stirring, and stir for 4 hours; after the reaction is completed, quickly raise the temperature to 80°C and keep it for 5 minutes to inactivate the Tg enzyme, and then cool down to 50°C .

[0039] S...

Embodiment 2

[0042] Step 1. Weigh 100g of sodium caseinate, 100g of lactose, 25g of mannose, and 75g of sucrose, mix well, then add 500g of water, stir and dissolve in a water bath at 55°C; weigh VA palm with a content of 1.75 million IU / g 165g of ester oil, 35g of soybean oil, 0.5g of antioxidant (containing 0.12g of rosemary extract, 0.03g of vitamin C palmitate, and 0.35g of natural vitamin E), were dissolved in a 60°C water bath while stirring while heating; After the antioxidant is completely dissolved, add the oil-phase core material to the water-phase wall material solution, use a shearing machine to shear and emulsify initially, and use 35MPa high-pressure homogenization twice.

[0043] Step 2. Heat the obtained emulsion in a water bath at 50°C, add 500 U of Tg enzyme while stirring, and stir for 2 hours; after the reaction is completed, the temperature is rapidly raised to 80°C and kept for 5 minutes to inactivate the Tg enzyme, and then cooled to 55°C .

[0044] Step 3, dehydrat...

Embodiment 3

[0047] Step 1. Weigh 125g of whey protein, 20g of modified starch, 75g of lactose, 25g of maltose syrup, 70g of sucrose, 20g of trehalose, and 10g of cyclodextrin, mix well, then add 500g of water, stir and heat to dissolve in a 50°C water bath; Weigh 150g of microalgae oil with DHA content of 40%, 25g of rapeseed oil, 0.6g of antioxidant (containing 0.16g of rosemary extract, 0.04g of vitamin C palmitate, and 0.40g of tea polyphenols), at 45°C Stir and dissolve while heating in a water bath; after the antioxidant is completely dissolved, add the oil-phase core material to the water-phase wall material solution, use a shearing machine to shear and emulsify initially, and use 40MPa high-pressure homogenization twice.

[0048] Step 2. Heat the obtained emulsion in a water bath at 35°C, add Tg enzyme 1875U while stirring, and stir for 2 hours; after the reaction is completed, quickly raise the temperature to 75°C and keep it for 10 minutes to inactivate the Tg enzyme, and then coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com