Reactor for preparing isophorone nitrile and method for continuously preparing isophorone nitrile by adopting reactor

A technology of isophorone nitrile and reactor is applied in the field of continuous preparation of isophorone nitrile, which can solve the problems of low product yield, poor mass transfer and heat transfer effect, etc., achieve good mass transfer performance and expand production scale , the effect of increasing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

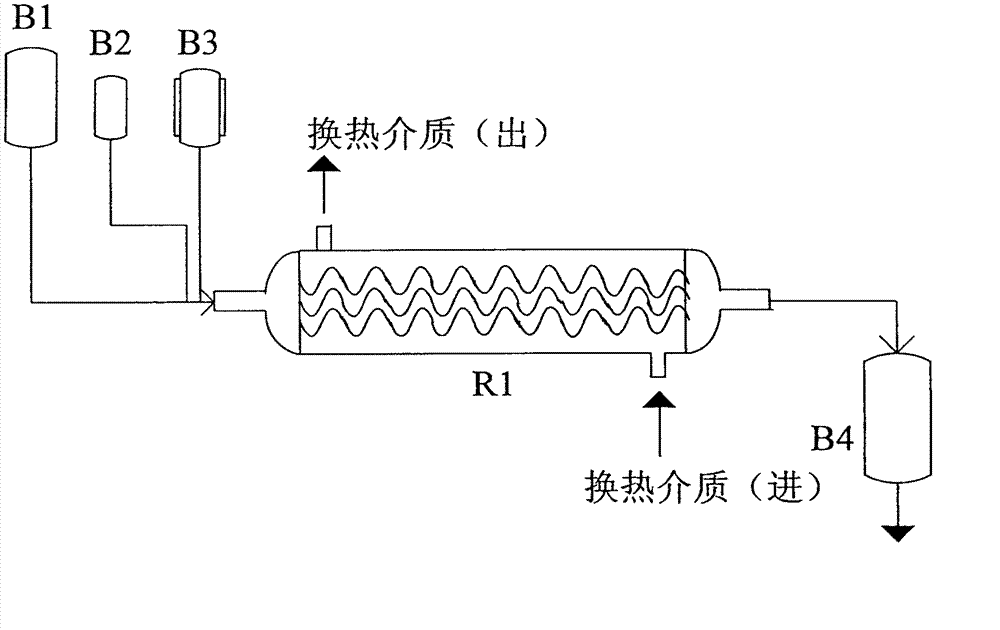

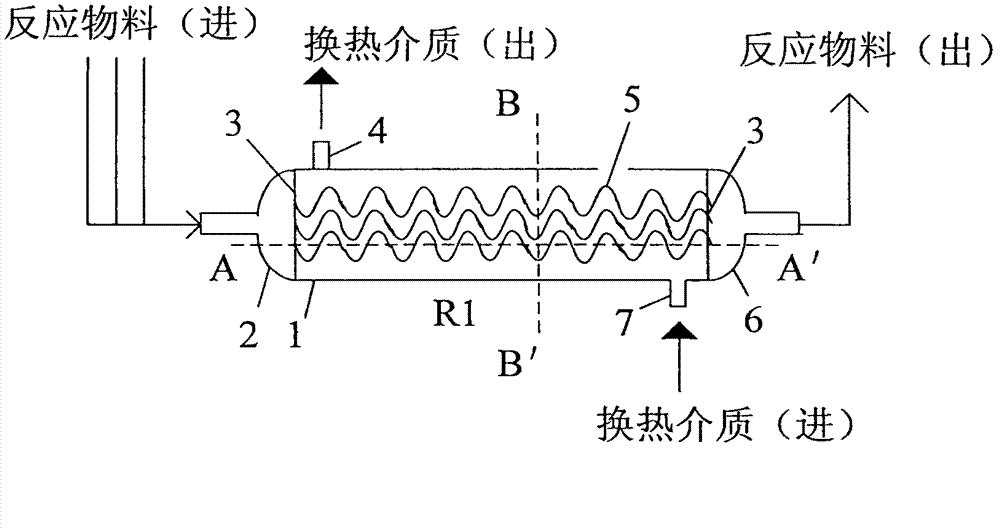

[0048] The reactor structure is as figure 2 As shown, the reactor includes a shell 1, an inlet head 2, an outlet head 6, a reaction channel 5, a shell side inlet 7, a shell side outlet 4 and a connecting plate 3, wherein 100 reaction channels 5 are arranged in parallel, and each reaction channel 5 is fixed On the connecting plate 3, and between the connecting plate 3 and the housing 1 are fixedly connected, the connecting plate 3 is installed at the inlet of the reactor and at the outlet of the reactor, between the two connecting plates 3, the outer wall of the housing 1 and the reaction channel 5 Together, they constitute the flow space of the heat exchange medium, that is, the heat exchange area. The inlet head 2 of the reactor is formed between the connection plate at the inlet and the shell at the entrance, and the connection plate at the exit and the shell at the exit. The outlet head 6 of the reactor is then constituted; the inlet head 2 is in fluid communication with t...

Embodiment 2

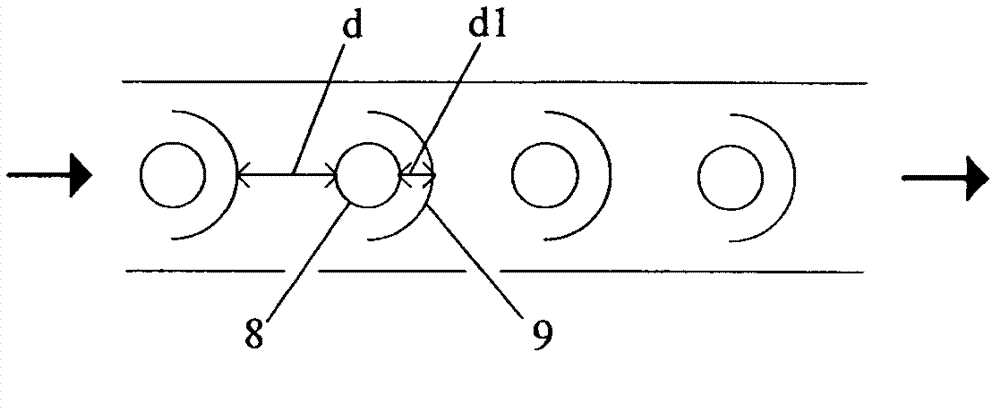

[0053] Reactor structure is the same as embodiment 1, and difference is that reaction channel 5 quantity is 1, and length is 1 meter, as Figure 5 As shown, the reaction channel 5 is in the form of a continuous semicircle, and the cross-sectional form is a square. The hydraulic diameter of the reaction channel 5 is 5 mm, and the specific surface area is 1000 m 2 / m 3 ,like Figure 6 As shown, a spherical mixing element 8 and a concave semicircular arc mixing element 9 are installed in the reaction channel 5, and three first holes 11 are opened on the spherical mixing element 8, and the first holes 11 are evenly distributed in the spherical mixing element 8 in the incoming material direction. on the hemisphere, and fan-shaped distribution inside the hemisphere, and finally gather in a linear second channel 12 with a diameter of 80 microns at the center of the sphere. The opening ratio of the spherical mixing element 8 is 30%, of which the first The aperture of the channel 11 ...

Embodiment 3

[0057] Reactor structure is the same as embodiment 1, and difference is that reaction channel 5 quantity is 20, and length is 50 meters, as Figure 7 As shown, the reaction channel 5 is in the form of a bow, and the cross-sectional form is elliptical. The hydraulic diameter of the reaction channel 5 is 500 microns, and the specific surface area is 6000m 2 / m 3 ,like Figure 8As shown, a spherical mixing element 8, a concave semicircular arc mixing element 9 and a deflector 13 are installed in the reaction channel 5, and 30 first channels 11 are opened on the spherical mixing element 8, and the first channels 11 are distributed before the incoming material. The contacted hemispheres are integrally formed in an umbrella shape inside the hemisphere, and finally gather in a linear second channel 12 with a diameter of 50 microns at the center of the sphere. The opening ratio of the spherical mixing element 8 is 60%, of which the first The diameter of the holes 11 is 5 microns, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com