Rapid prototyping shape memory high polymer material and preparation method and application thereof

A high-molecular material and fast technology, applied in textiles and papermaking, single-component synthetic polymer rayon, fiber chemical characteristics, etc., can solve the problem of few thermoplastic shape memory polymers, achieve low price, simple preparation process, Wide selection of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

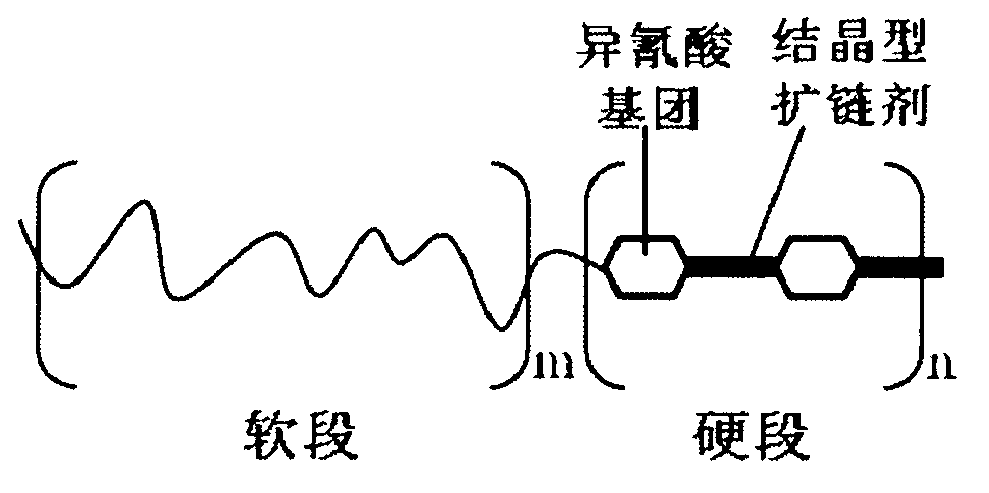

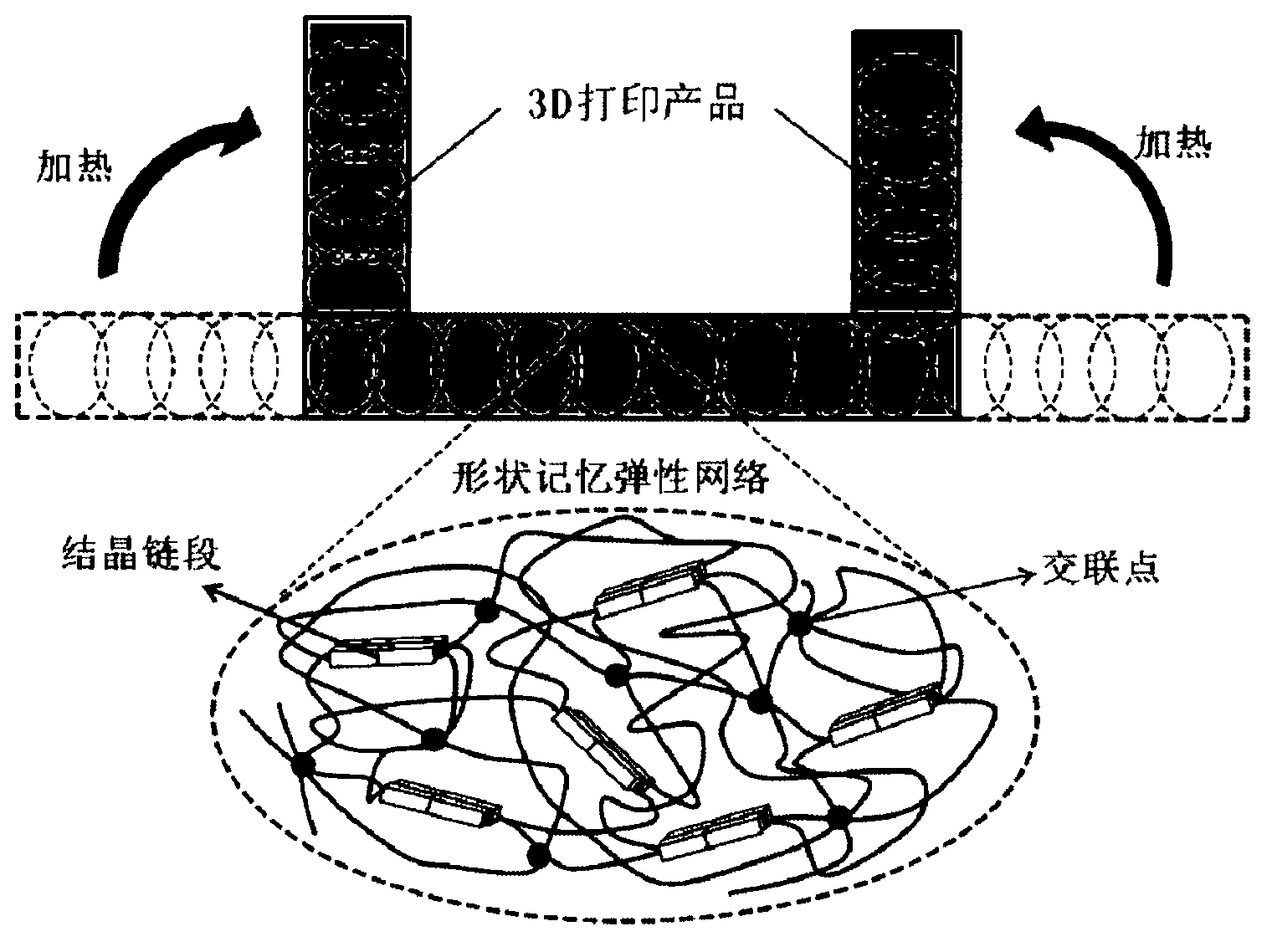

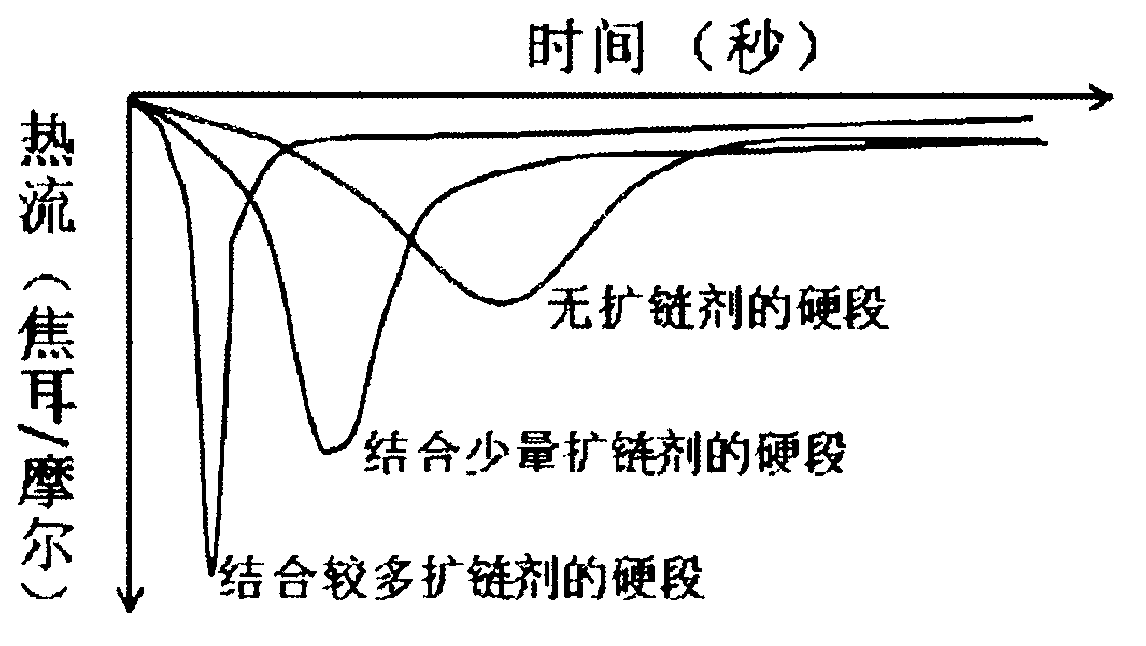

[0050] Polyether PTMG with a molecular weight of 50,000 is used as the soft segment, and 1,6-hexamethylene diisocyanate MDI is used as the hard segment to synthesize a polyurethane prepolymer. Under the action of a catalyst, the hydroxyl-terminated POSS segment is used as a chain extender, and the reaction extrusion Shape-memory polyurethane pellets were prepared. Among them, the hard segment content is 40%. The crystallinity of the hard segment is 50% within 0.5 seconds within a temperature difference range of 300°C to 120°C. The pellets were melt spun through an extruder to obtain monofilaments of uniform diameter. Use a personal 3D printer to print a rod-shaped product with a diameter of 2mm at a printing temperature of 200-250 degrees Celsius, bend the product at 80 degrees Celsius, and cool to room temperature to fix the shape. When the temperature is raised to 80 degrees Celsius, the deformation fixation rate of the rod-shaped product is 90%, and the recovery rate is 9...

Embodiment 2

[0052] Polyester PCL with a molecular weight of 100,000 is used as the soft segment, and 1,6-hexamethylene diisocyanate MDI is used as the hard segment to synthesize a polyurethane prepolymer. Under the action of a catalyst, the hydroxyl-terminated POSS segment is used as a chain extender, and the reaction extrusion Shape-memory polyurethane pellets were prepared. Among them, the hard segment content is 20%. The crystallinity of the hard segment is 60% within 0.5 seconds within a temperature difference range of 300°C to 25°C. The pellets were melt-spun through a twin-screw extruder to obtain monofilaments of uniform diameter. Use a personal 3D printer to print a rod-shaped product with a diameter of 2mm at a printing temperature of 200-250 degrees Celsius, bend the product at 80 degrees Celsius, and cool to room temperature to fix the shape. When the temperature is raised to 80 degrees Celsius, the deformation fixation rate of the rod-shaped product is 95%, and the recovery ...

Embodiment 3

[0054] Polyether PTMG with a molecular weight of 50,000 is used as the soft segment, 1,6-hexamethylene diisocyanate MDI is used as the hard segment to synthesize polyurethane prepolymer, and the hydroxyl-terminated one, tetra-butanediol is used as the chain extender under the action of the catalyst , Reactive extrusion to prepare 4D printing shape memory polyurethane pellets. Among them, the hard segment content is 40%. In the temperature range of 300°C to 60°C, the crystallinity of the hard segment is 40% within 0.2 seconds. The pellets were melt-spun through a twin-screw extruder to obtain monofilaments of uniform diameter. Use a personal 3D printer to print a rod-shaped product with a diameter of 2mm at a printing temperature of 200-220 degrees Celsius, bend the product at 75 degrees Celsius, and cool to room temperature to fix the shape. When the temperature is raised to 75 degrees Celsius, the deformation fixation rate of the rod-shaped product is 92%, and the recovery ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com