A processing technology of a sports protective gear, its production equipment and its control system

A technology of production equipment and control system, which is applied in the field of processing technology and its production equipment and the control system for controlling the production equipment, can solve the problems of inability to realize automatic production, low production efficiency, high production cost, etc., and achieve improved cooling forming effect, Improved productivity and shortened heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

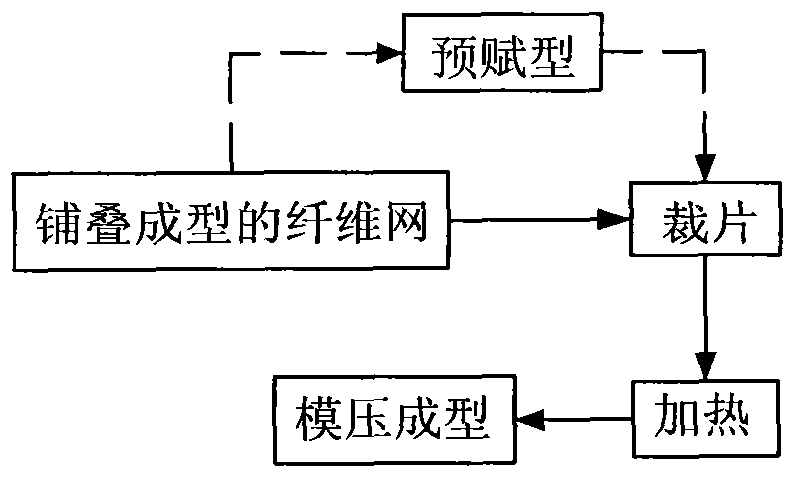

[0026] Such as figure 1 As shown, a processing technology of a sports protective gear is carried out according to the steps of fiber web laying, cutting, heating, molding and mold release;

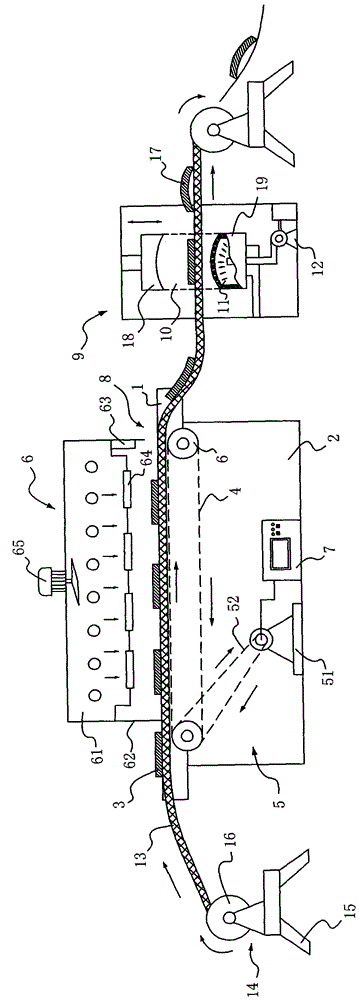

[0027] (1) Laying of fiber webs: laying up multiple layers of hot-melt bonded fiber materials through mixing, loosening, and carding into a web to form a fiber web;

[0028] Mixing and opening refers to the uniform mixing of hot-melt bonding fibers and bonded fibers in proportion before carding into a web. The mixing method can be manual mixing or mechanical mixing. The mixing machine can be a single cotton bin blender, or a multi-cotton bin blender, such as a six-cotton bin blender. After the fibers are evenly mixed, they are fed into the opening equipment, and the fiber blocks are mechanically struck and torn to be loosened into small fiber bundles, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com