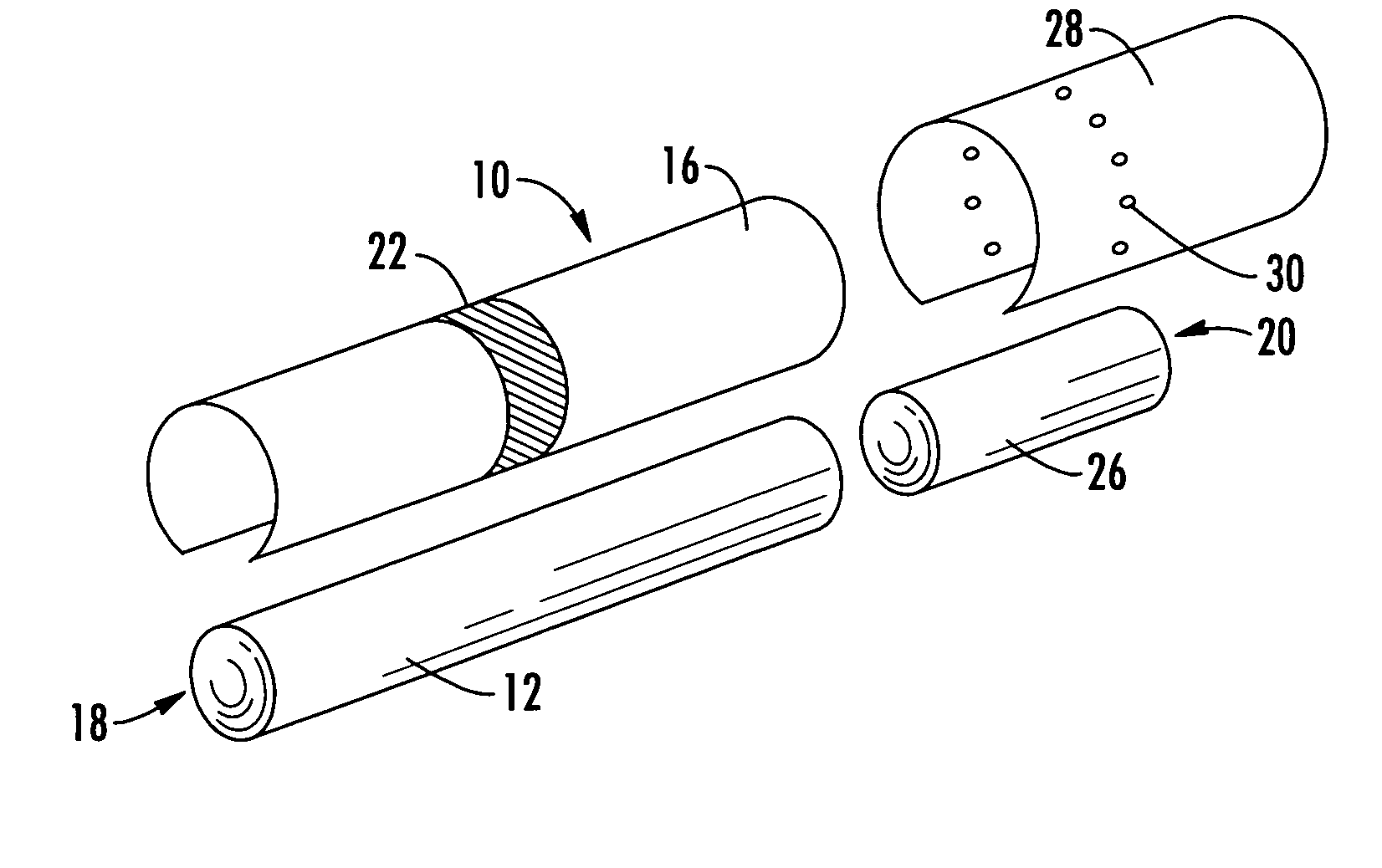

Smoking articles comprising inner wrapping strips

a technology of inner wrapping strips and smoking articles, which is applied in the field of tobacco products, can solve the problems of higher self-extinction rates and increase in alkali metal content of inner wrapping strips, and achieve the effect of greater control of the bum characteristics of smoking articles and higher self-extinction rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

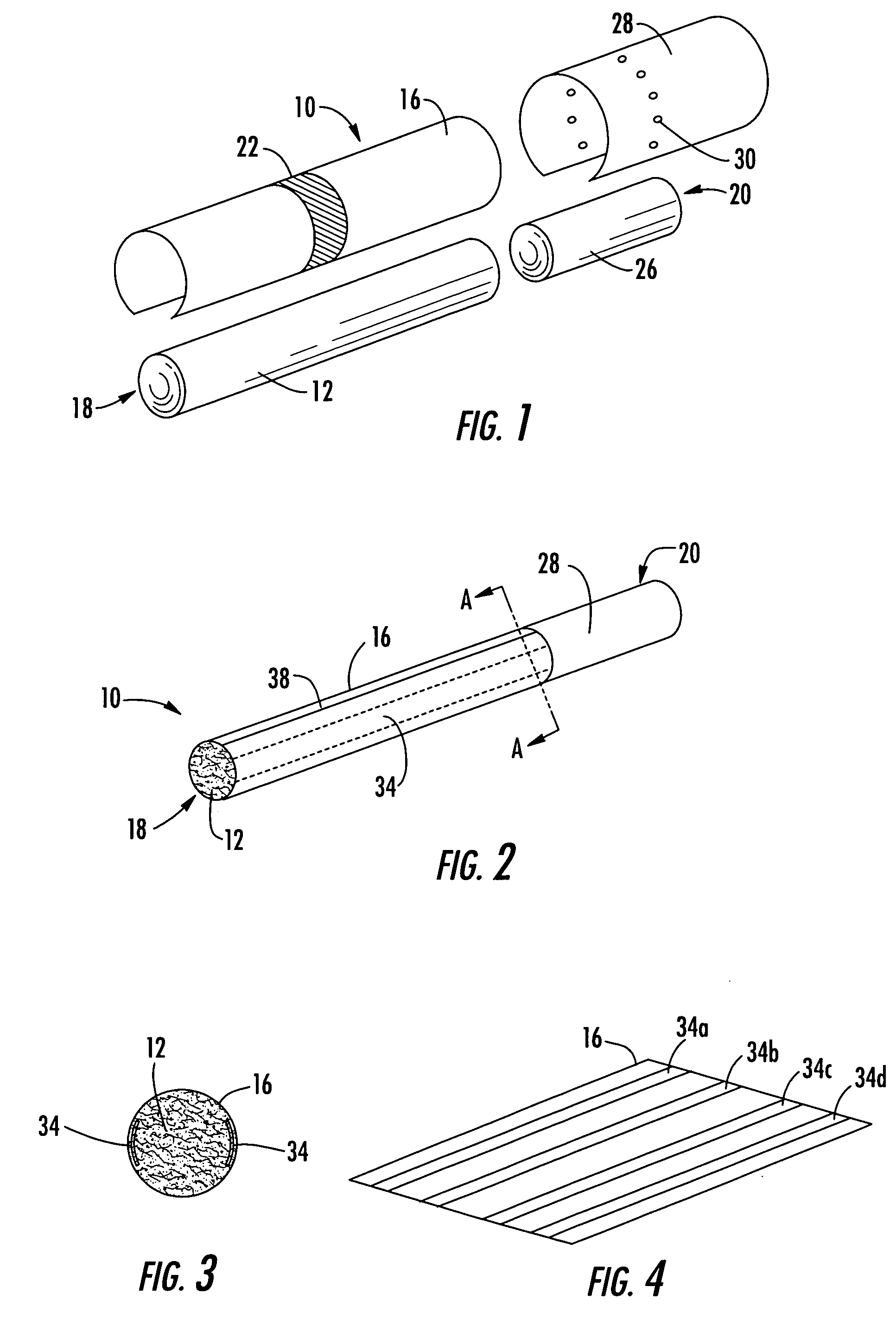

[0050] Reconstituted tobacco cast sheet materials with target sodium alginate content ranging from 15% to 35% are made. Cigarettes are made with each sheet material with two split inner wrap strips of 4 mm width. The strips are located longitudinally along the tobacco rod opposite one another and oriented 90 degrees from the side seam. All other cigarette construction details are held constant.

[0051] The sheet materials are tested for sodium content and for ignition temperature (as measured by differential scanning calorimetry). Self-extinction (SE) rates are measured for finished cigarettes by the ASTM E 2187-02b test procedure (20 cigarettes per test). The results from these tests are set forth in Table 1 below, and show a fairly strong correlation between the split inner wrap sodium content and the cigarette self-extinction rate. That is, as the sodium content increases, self-extinction rates increase. The results in Table 1 also show a strong correlation between the sodium cont...

example 2

[0052] This experiment determines if the “alginate anion” content causes some (or all) of the self-extinction rate variation found in Example 1. In this experiment, sheet materials are made with 15% sodium alginate, with additions of 1.5%, 2.5% and 3.5% sodium phosphate. The resulting materials are tested for sodium content and cigarettes are made as described above. The results from these tests are set forth in Table 2 below, and show a small increase in self-extinction rate with the amount of added sodium phosphate. This suggests that the sodium content of the sheet material is moderating the cigarette self-extinction rate. Analysis of the sodium content and self-extinction data in Tables 1 and 2 suggests that the split inner wrap sodium content should exceed about 30,000 μg / g to yield acceptable cigarette self-extinction rates and, thus, reliably conform to current regulations for low ignition propensity cigarettes. The requisite sodium content can be obtained by the use of sodiu...

example 3

[0053] An experiment is conducted to investigate the relationships between cigarette coal temperatures and the split inner wrap ignition temperature. For this work, six cigarette examples are chosen for testing, including five from the list shown in Table 1. Three of these have low self-extinction rates (18%-30%), and low split inner wrap ignition temperatures (558° C.-603° C.). The other three have high self-extinction rates (85%-100%), and high split inner wrap ignition temperatures (649° C.-686° C.). A control cigarette without split inner wrap is also tested.

[0054] Cigarette coal temperatures are measured during smolder while suspended in air, and while resting on the ASTM test substrate (ten layers of Whatman filter paper) using a thermal imaging system comprising an infrared camera (Agema Thermovision 900). The results of these measurements are summarized in Table 3 below. As is evident from the data in Table 3, the coal temperatures are higher during free-air smolder than du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| ignition temperature | aaaaa | aaaaa |

| ignition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com