Moist snuff non-tobacco composition and a method for producing thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

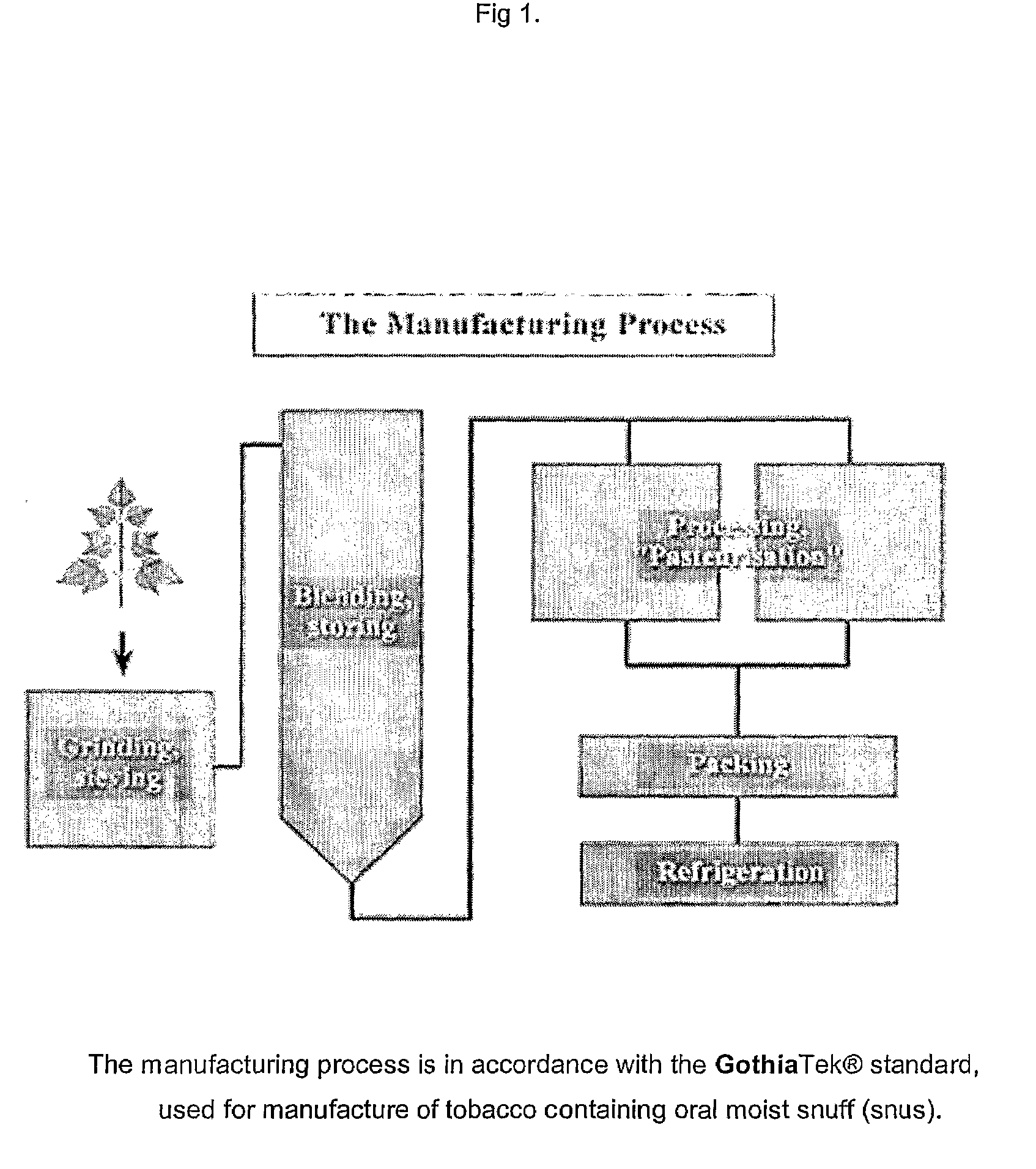

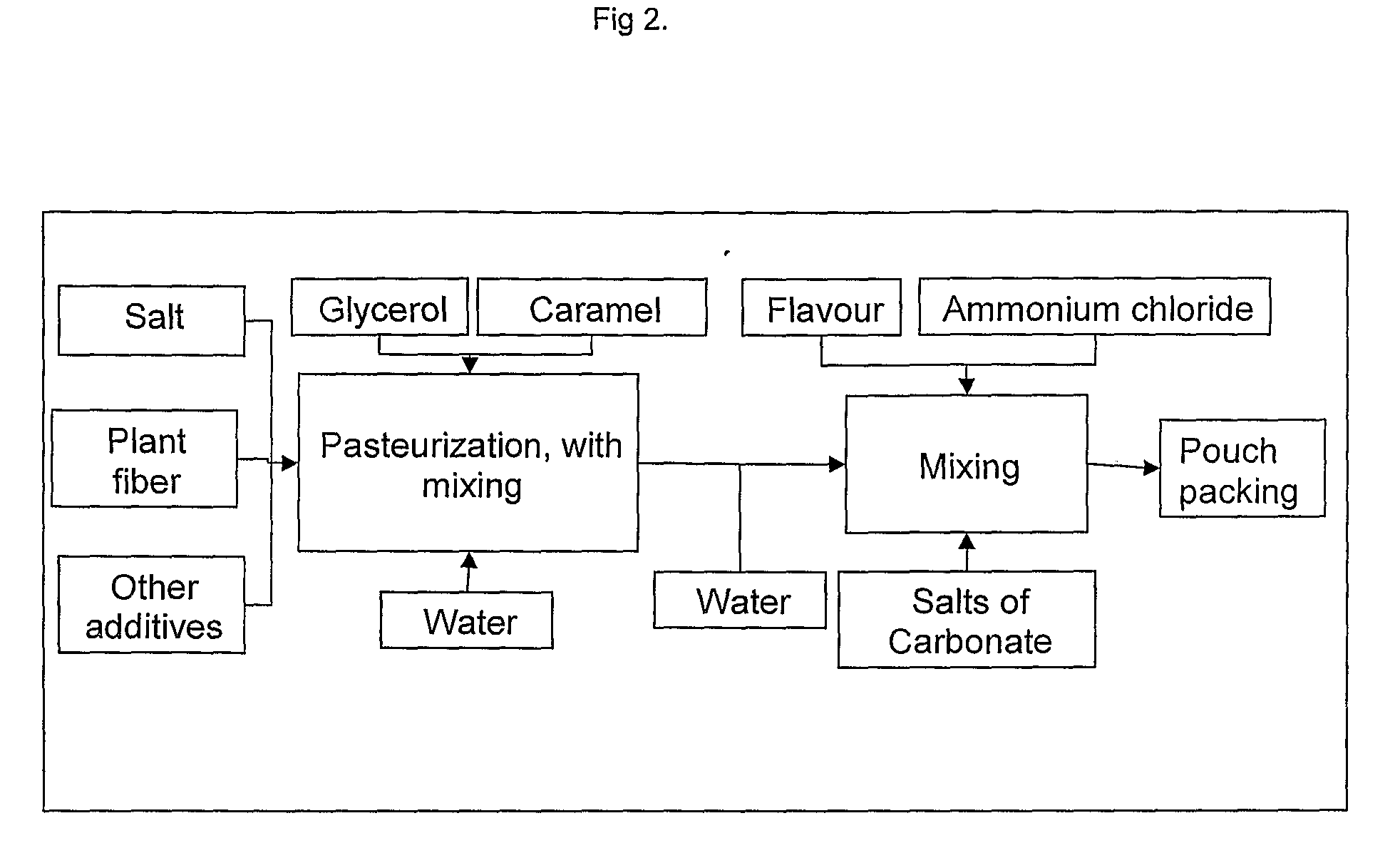

[0050]Moist snuff in accordance with the second aspect of the invention was manufactured in accordance with the GothiaTek® standard, here adapted for a non-tobacco containing product as set out above, and said snuff was filled into pouches. The fibers that were used were:

[0051]Buckwheat fibers (SOFABRAN F 170 (buckwheat))

[0052]Maize fibers (SOFABRAN F 184-80 (maize))

[0053]Apple fibers (Vitacel® Bio-Apple Fiber AF 12).

[0054]The buckwheat and maize fibers were obtained from AB R. Lundberg, while the Apple fibers were obtained from LCH Kemiflor AB.

[0055]The buckwheat fibers and the maize fibers were finely ground (as set out below).

[0056]The proportions were

Buckwheat fibers60%(approx. 90% of the fibers with a size μm)Maize fibers20%(approx. 90% of the fibers with a size μm; “fine maize”)Apple fibers20%(approx. 60% of the fibers with a size μm)(approx. 20% of the fibers with size μm)

[0057]The fibers were pasteurized in a heat process in accordance with the GothiaTek® standard (which nor...

example 2

[0060]Moist snuff in accordance with the second aspect of the invention was manufactured in accordance with the GothiaTek® standard as set out above, and said snuff was not filled into pouches. The fibers that were used in this example were:

[0061]80% Buckwheat fibers (SOFABRAN F 170 (buckwheat))

[0062]20% Maize fibers (fine maize), (SOFABRAN F 184-80 (maize))

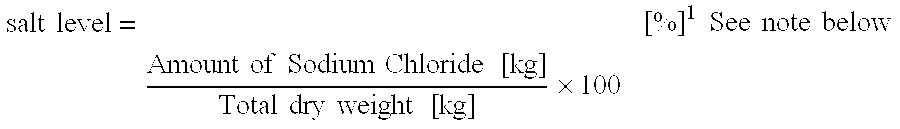

[0063]NaCl was added to 6-16%, preferably 8-10%

[0064]Glycerol was added to 2-15%, preferably 8-12%.

[0065]The calculations were in accordance with the above mentioned formulas (I) and (II). The buckwheat and maize fibers were obtained from AB R. Lundberg

example 3

[0066]Moist snuff in accordance with the second aspect of the invention was manufactured in accordance with the GothiaTek® standard as set out above, and said snuff was not filled into pouches. The fibers that were used were

[0067]Buckwheat fibers (SOFABRAN F 170 (buckwheat))

[0068]Maize fibers (SOFABRAN F 184-80 (maize)).

[0069]Oat fibers (Vitacel 401)

[0070]NaCl was added to 6-16%, preferably 8 10%

[0071]Glycerol was added to 2-15%, preferably 8-12%.

[0072]The calculations were in accordance with the above mentioned formulas (I) and (II). The buckwheat and maize fibers were obtained from AB R. Lundberg. The oat fibers were obtained from LCH Kemiflor AB.

[0073]The buckwheat fibers and the maize fibers were finely ground (as set out below).

[0074]The proportions were

Buckwheat fibers60%(approx. 90% of the fibers with a size μm)Maize fibers20%(approx. 90% of the fibers with a size μm; “fine maize”)Oat fibers20%(approx. 60% of the fibers with a size μm)

[0075]The three examples 1 to 3 gave as r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com