Ferment for tobacco fermentation and use thereof

A technology of starter and tobacco, applied in the direction of tobacco, application, and preparation of tobacco, can solve the problems of single action effect, little improvement of aroma, great influence on the overall quality of tobacco leaves, etc. The effect of shortening the alcoholization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

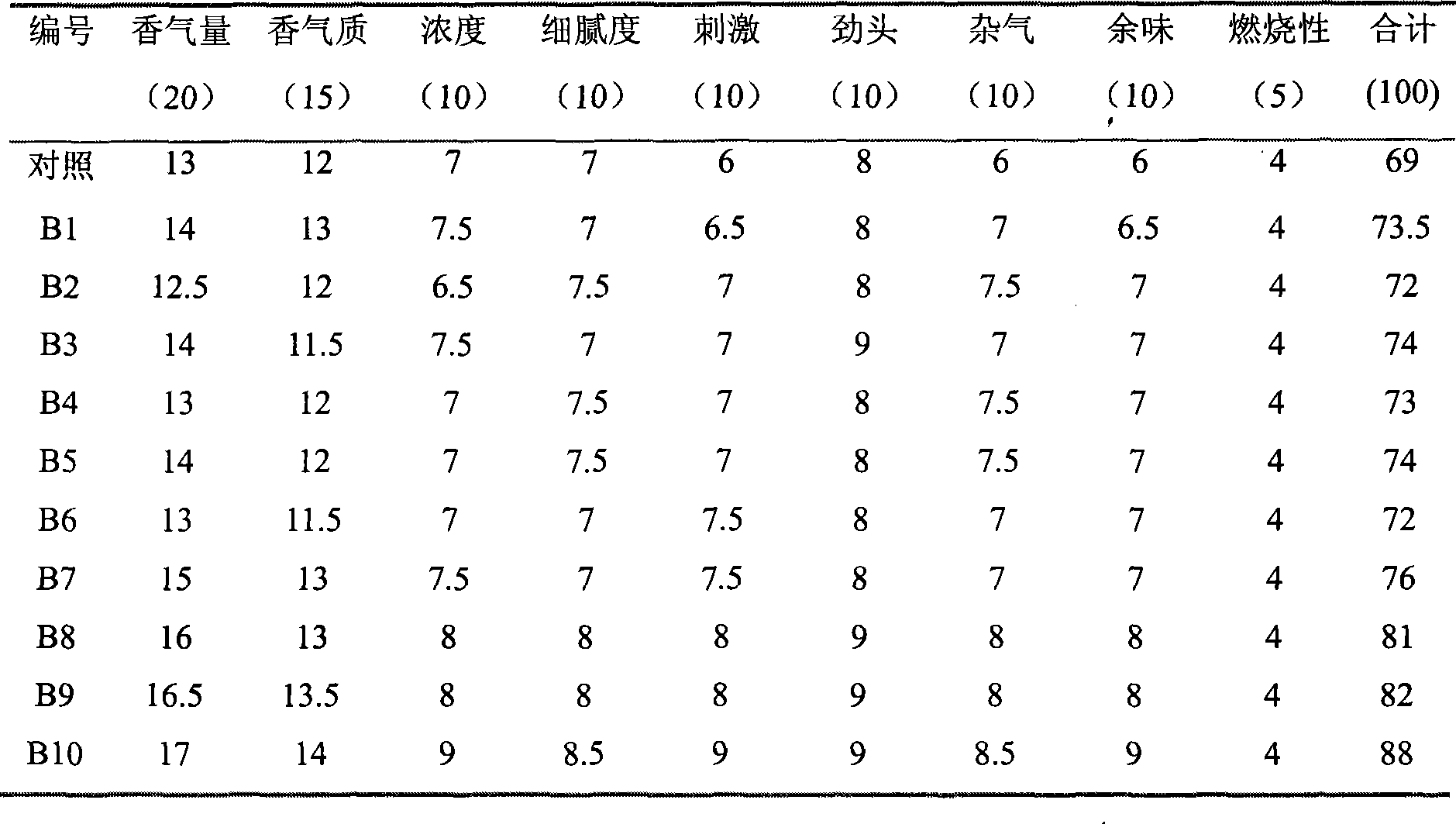

Embodiment 1

[0021] Bacillus subtilis (purchased from Shandong Institute of Light Industry, strain No. 1007) was inoculated into beef extract peptone medium, and cultured to the late logarithmic phase after being fully activated. The culture medium was centrifuged and the supernatant was discarded to collect the bacteria sludge, 18% sucrose solution of 10% of the volume of the culture medium before centrifugation was added as a protective agent, and it was freeze-dried to powder to obtain the starter 1. Crush 100g of tobacco leaf fragments to 100 mesh, add water 4 times the weight of tobacco leaves, mix and sterilize at 90°C for 30 minutes, add 2% of tobacco leaf weight starter 1 after cooling, ferment in a 30°C constant temperature box for 4 days, add 6 times the amount of fermentation mash The weight of the tobacco leaf was reflux extracted with water for 1.5 hours, and the extract was concentrated under reduced pressure to obtain the natural tobacco flavor 1.

Embodiment 2

[0023] Lactobacillus delbrueckii (purchased from Shandong Institute of Light Industry, strain No. 1026) was fully activated in MRS medium and cultured to the late logarithmic phase. The culture medium was centrifuged and the supernatant was discarded to collect the bacteria sludge, and 18% sucrose solution of 10% of the volume of the culture medium before centrifugation was added as a protective agent, and then freeze-dried to powder to obtain the starter 2. Add starter 2 according to the method for preparing natural tobacco flavor in Example 1 to prepare natural tobacco flavor 2.

Embodiment 3

[0025] Aroma yeast (purchased from Shandong Institute of Light Industry, strain No. 2041) was fully activated in wort medium and cultured to the late logarithmic growth phase. The culture medium was centrifuged and the supernatant was discarded to collect the bacteria sludge, and 18% sucrose solution of 10% of the volume of the culture medium before centrifugation was added as a protective agent and freeze-dried to powder to obtain the starter 3. Add starter 3 according to the method for preparing natural tobacco flavor in Example 1 to prepare natural tobacco flavor 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com