Direction-variable linkage type plug seedling cuttage gripper

A linkage type, plug seedling technology, applied in planting methods, applications, agriculture, etc., can solve the problems of inability to adjust the state of flower seedlings, low economic benefits, high labor intensity of workers, etc., to ensure consistent growth and high institutional coordination. , the effect of high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

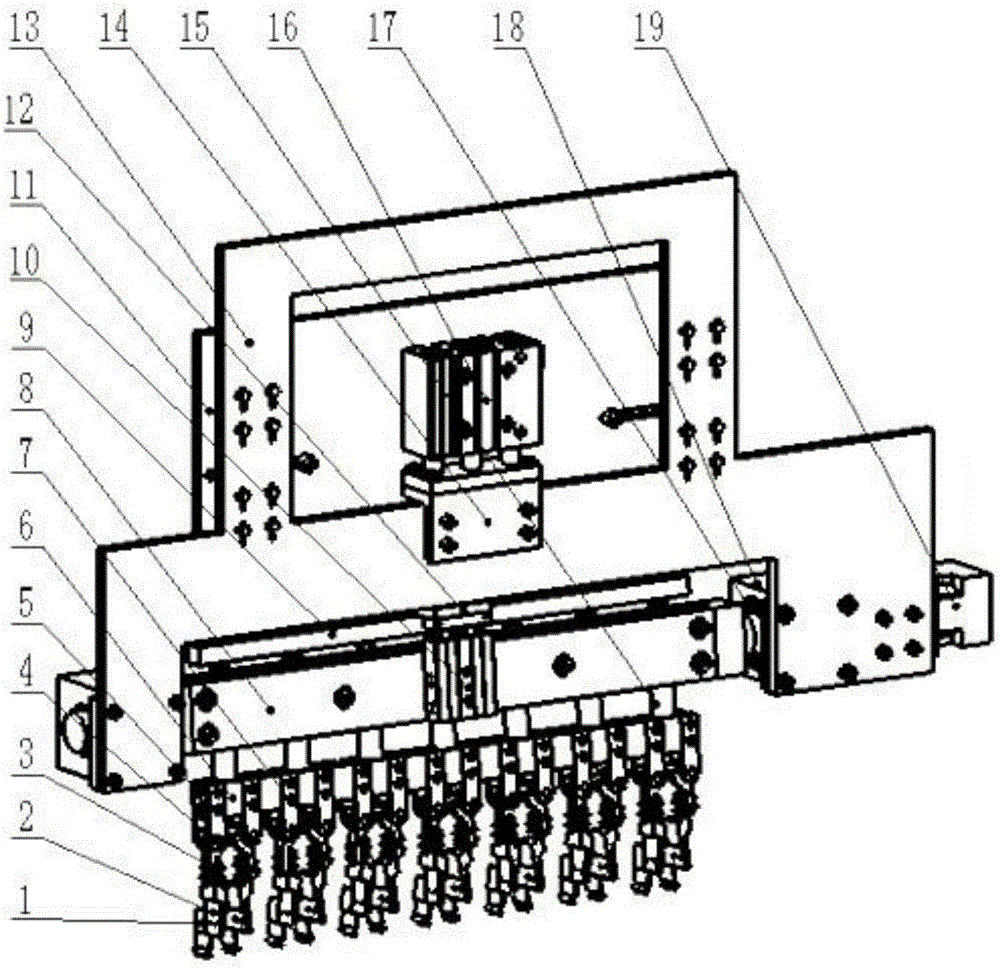

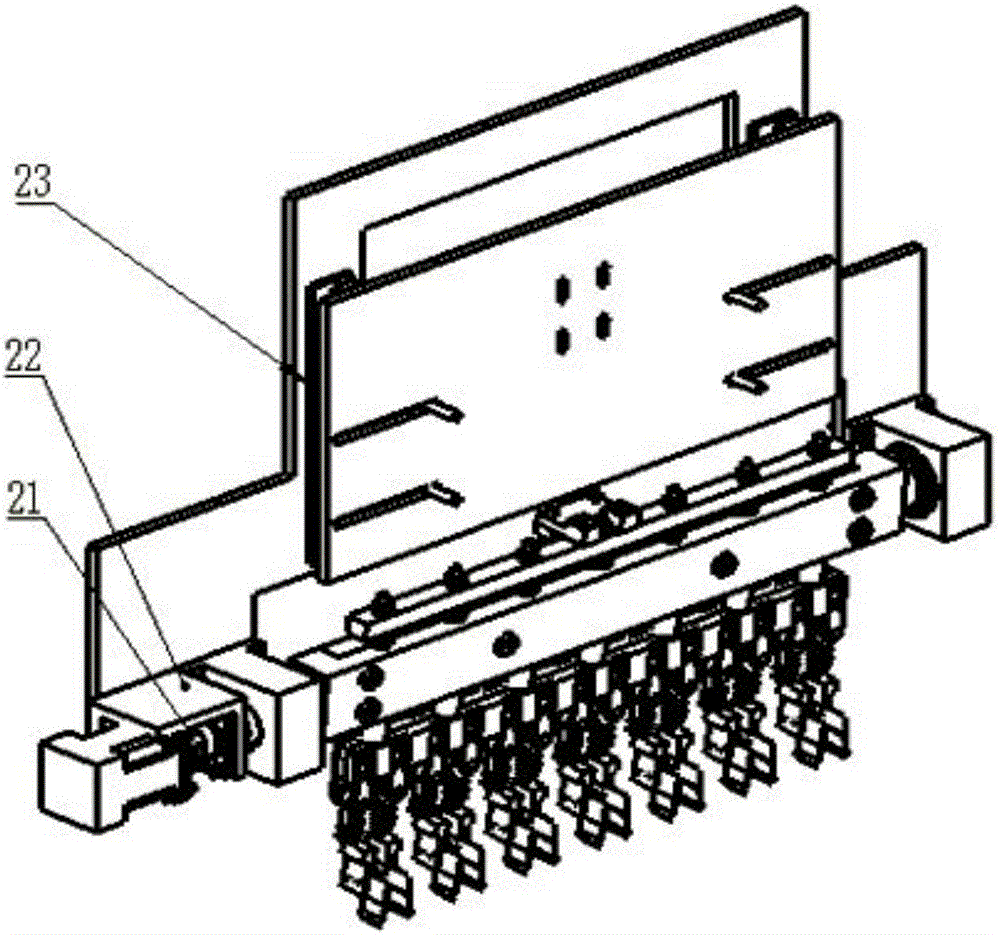

[0019] The present invention is described further in conjunction with accompanying drawing:

[0020] Such as Figure 1-Figure 9 As shown, a variable-direction linkage type plug seedling cutting hand claw, the hand claw includes a spring piece 1, a spring piece installation block 2, a claw clamping block 3, a claw support plate 4, an ejector rod 5, and a claw Support plate mounting frame 6, rod claw mounting block 7, rotating shaft block 8, top plate 9, lower cylinder 10, seedling transporting plate mounting block 11, ejector rod mounting block 12, seedling transporting plate 13, cylinder-seedling transporting plate mounting block 14, Sleeve 15, upper cylinder 16, linear bearing 17, bearing 18, bearing mount 19, rotating motor 20, shaft coupling 21, motor mount 22, linear guide rail 23; The claw structure is a clamping structure for grabbing cutting seedlings. Each claw structure is composed of two spring pieces 1 left and right symmetrically connected. The small clamping for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com