Wood drying method

A wood drying and wood technology, applied in the direction of humidity control wood, drying solid materials, wood processing equipment, etc., can solve the problems of unavoidable bending deformation and diameter cracking, unsuitable for small diameter logs, etc., to avoid drying defects and shorten drying time , to avoid the effect of wood damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

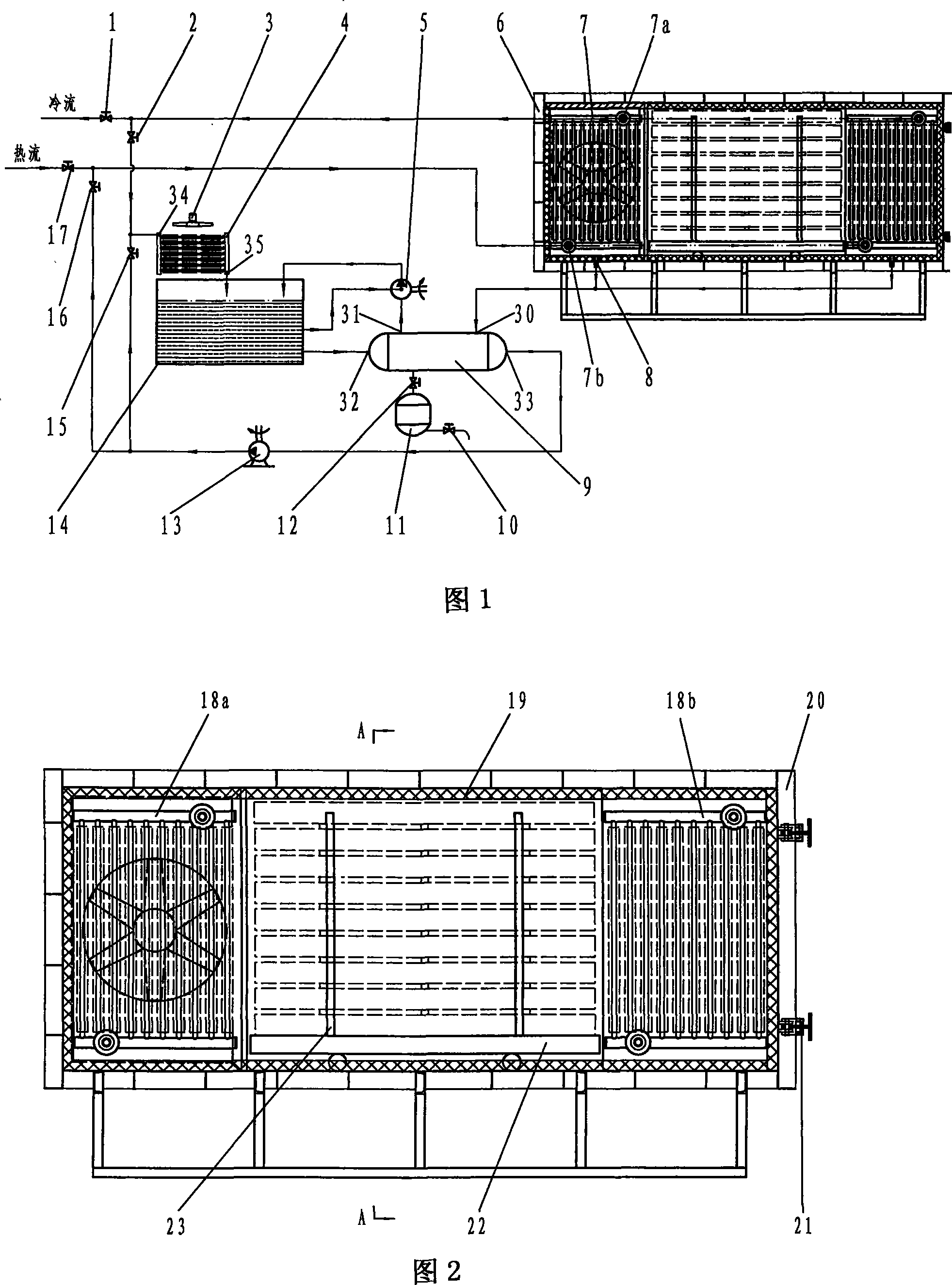

Method used

Image

Examples

Embodiment 1

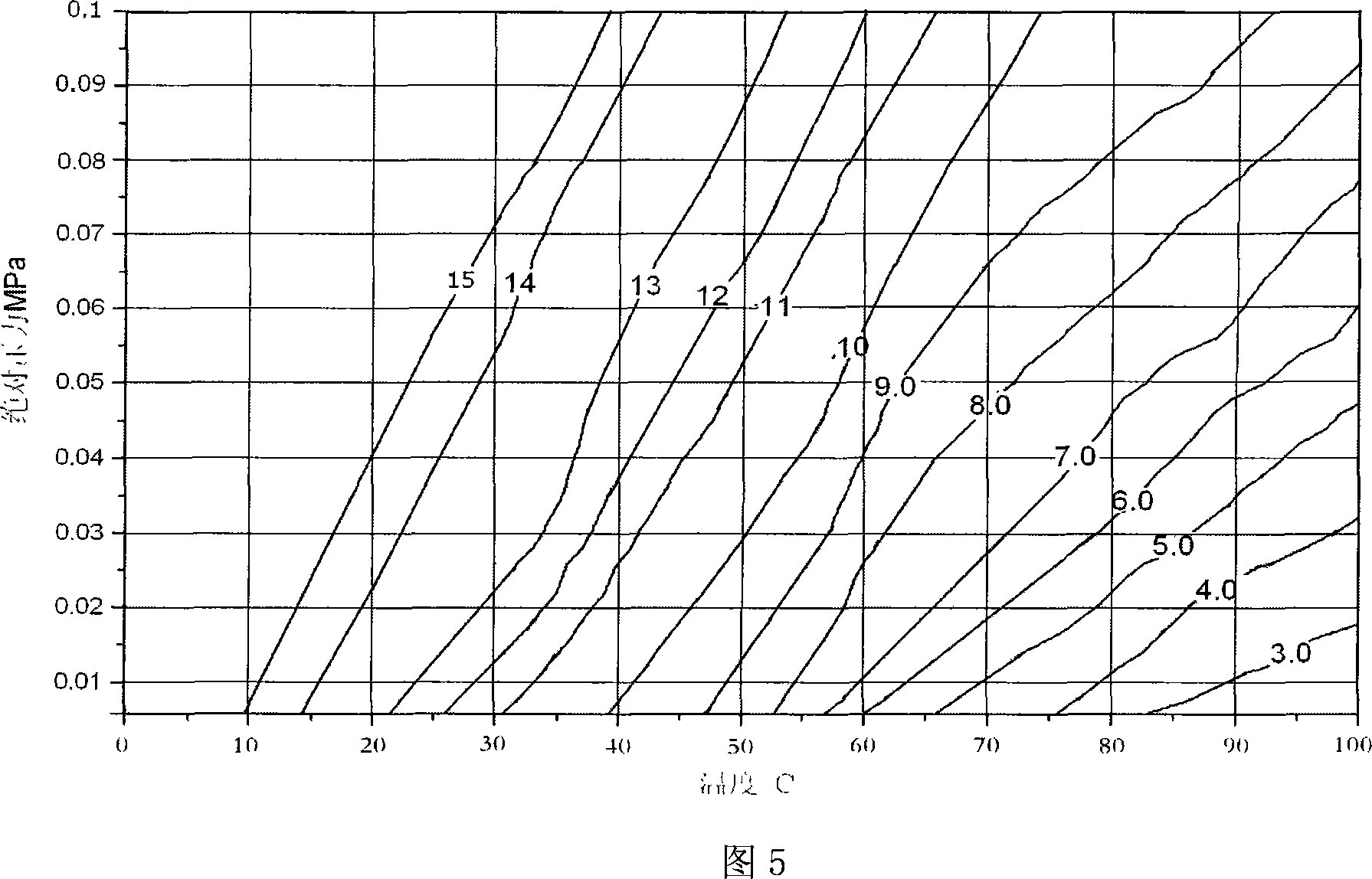

[0065] Adopt diameter scope at 6-16cm poplar small-diameter wood, it is sawed into wood section, makes the length of each wood section and its average diameter value ratio be 10, and the moisture content of wood section is 60-80%, adopts the present invention Wood vacuum drying equipment to dry it.

[0066] During the drying process, the control of the drying process is based on the poplar small-diameter wood drying standards listed in Table 1 below:

[0067] Table 1

[0068] Wood moisture content stage (%)

temperature(℃)

Equilibrium moisture content of drying medium

(%)

>40

40

14

[0069] 40~30

30~20

20~10

<10

50

60

70

80

12

10

6

4

[0070] The specific steps are as follows:

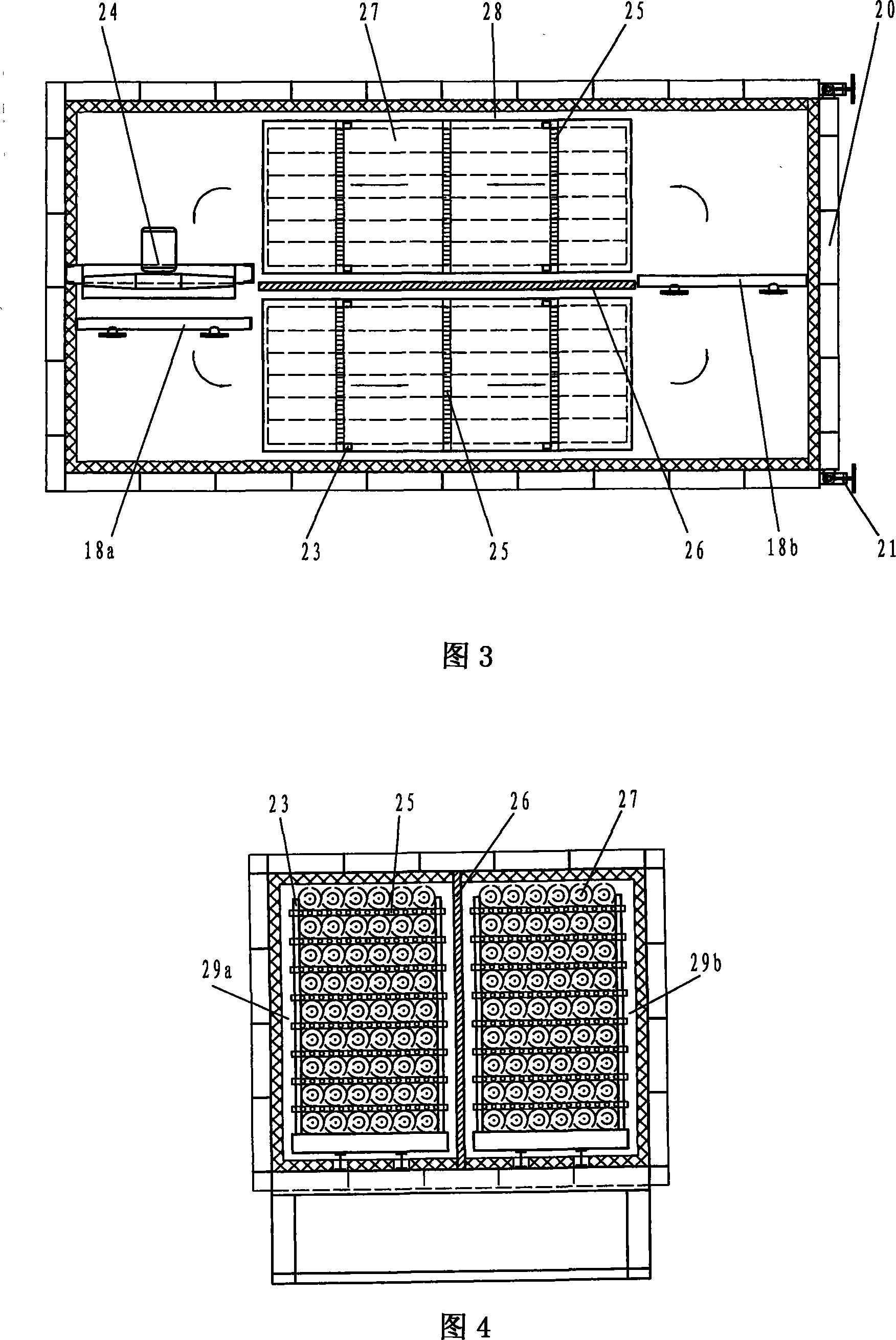

[0071] Wood sections are piled up vertically and horizontally one by one on the bottom plate of the loading vehicle 22, and each layer is separated by a drilling spacer ...

Embodiment 2

[0078] Adopt thickness 20cm poplar plank, it is sawed into 100cm long wood section, makes the length of each wood section and its thickness ratio be 5, and the moisture content of wood section is 90-100%, adopts wood vacuum drying equipment of the present invention to It is dried.

[0079] During the drying process, the control of the drying process is based on the poplar small-diameter wood drying standards listed in Table 2 below:

[0080] Table 2

[0081] Wood moisture content stage (%)

temperature(°C)

Equilibrium moisture content of drying medium (%)

>50

50~35

35~25

25~15

<15

50

55

60

70

85

12

10

8

6

4

[0082] The specific steps are as follows:

[0083] Wood sections are piled up vertically and horizontally one by one on the bottom plate of the loading vehicle 22, and each layer is separated by a drilling spacer 25, and then the loading vehicle 22 that is placed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com