Camera on-field calibration method in measuring system

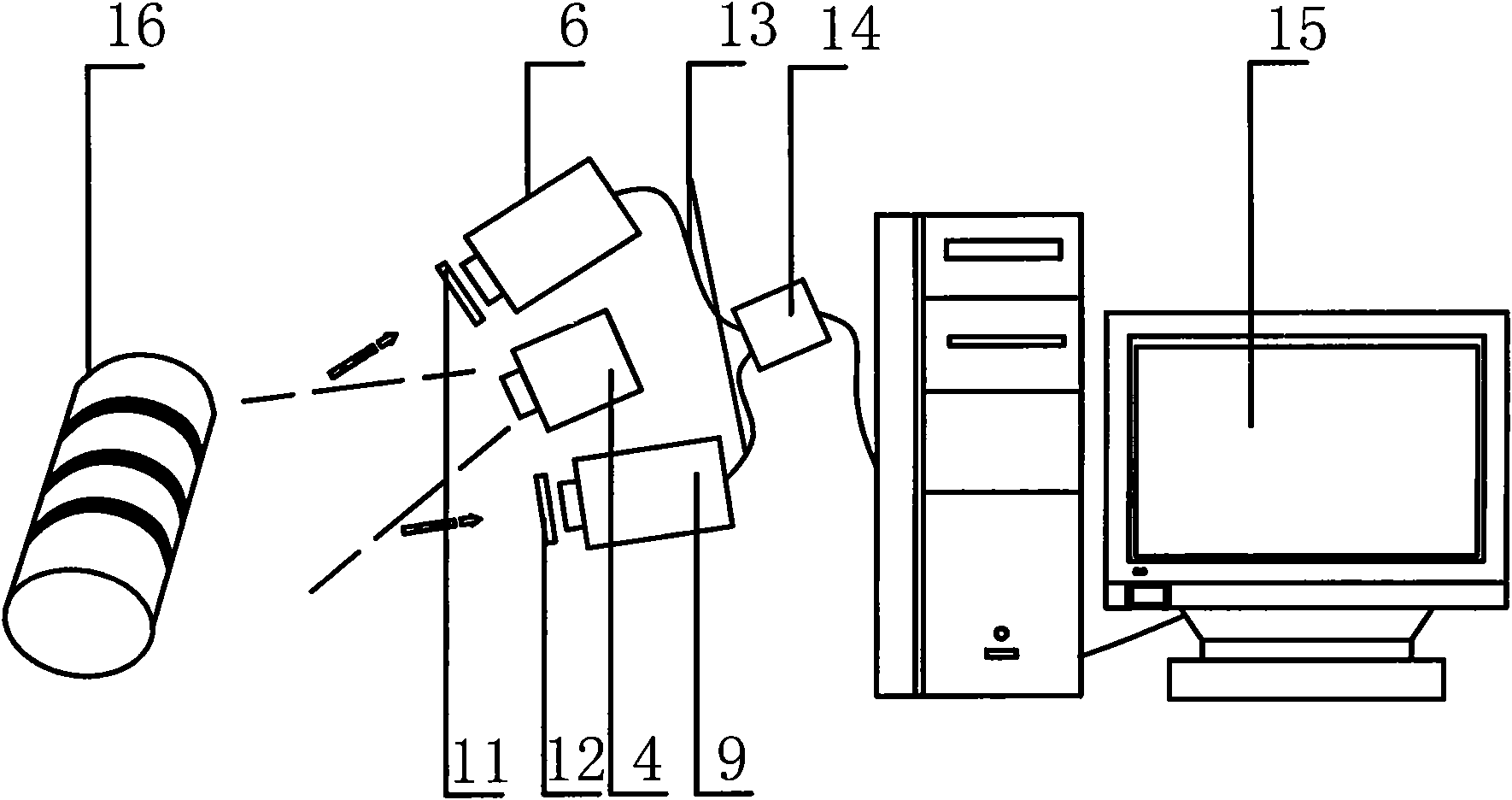

A measurement system and on-site calibration technology, which is applied in the direction of measurement devices, image analysis, image data processing, etc., can solve the problems of insufficient imaging clarity, achieve the effects of overcoming opaque imaging, strong on-site adaptability, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions, and the steps of the method for calibrating the internal and external parameters of the camera of the binocular stereo measurement system for the size of large forgings will be further described.

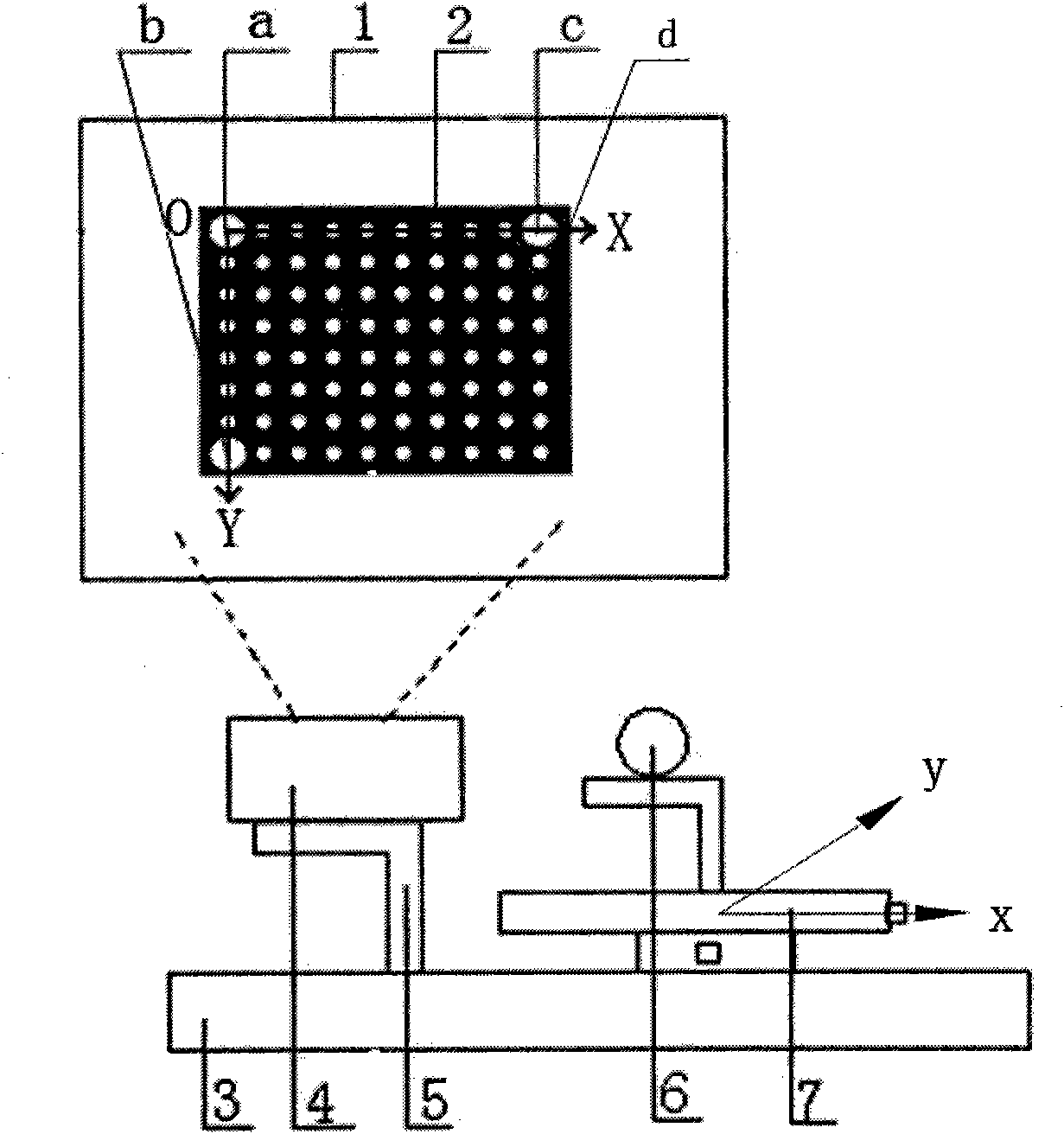

[0030] Step 1: Formulate the calibration target of internal and external parameters of the camera

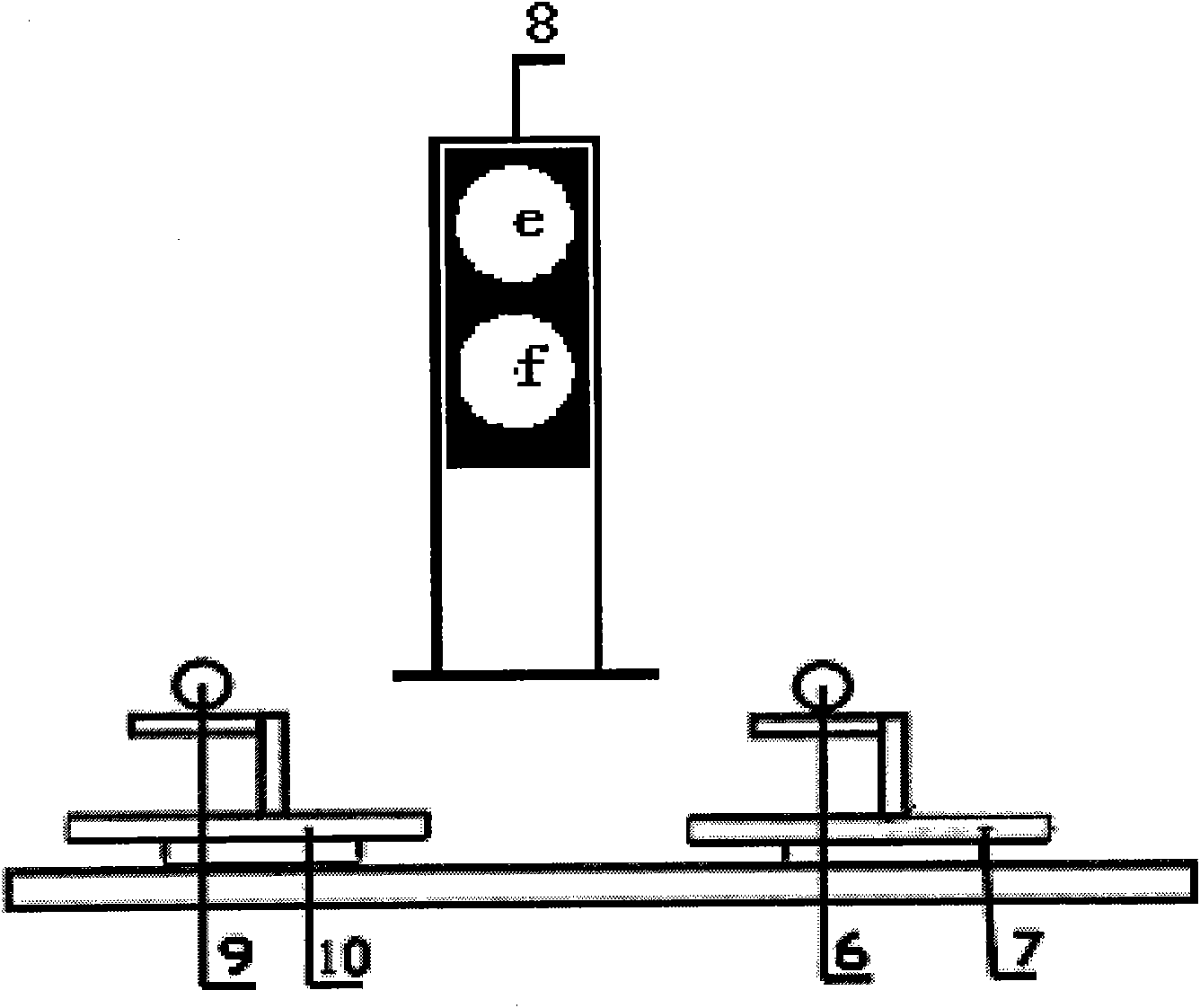

[0031] First make the calibration target of the internal parameters of the camera, such as figure 2 As shown, there are N rows and M columns of easily identifiable characteristic dots distributed on the target 2 of camera internal parameter calibration, where: the diameters of the first, second, and third positioning circles a, b, and c at the three corners of the array It should be larger than the diameter of other characteristic circles d; establish coordinate system XOY, take O point as the reference, determine the arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com