Machine-vision-based online dimensional measurement method of precise instrument

A machine vision and measurement method technology, applied in the field of image processing, can solve the problem of high precision requirements and achieve the effect of low hardware equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

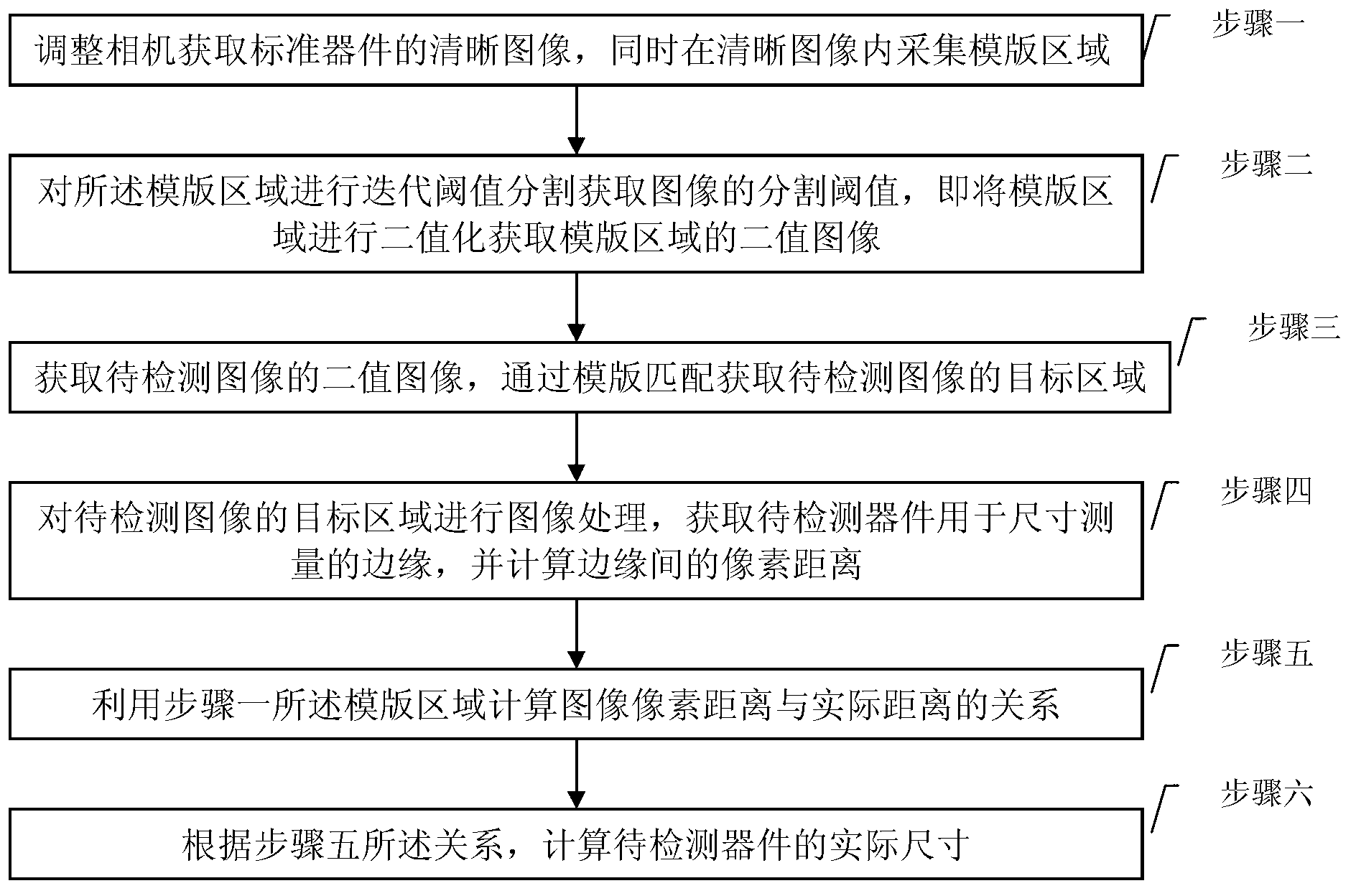

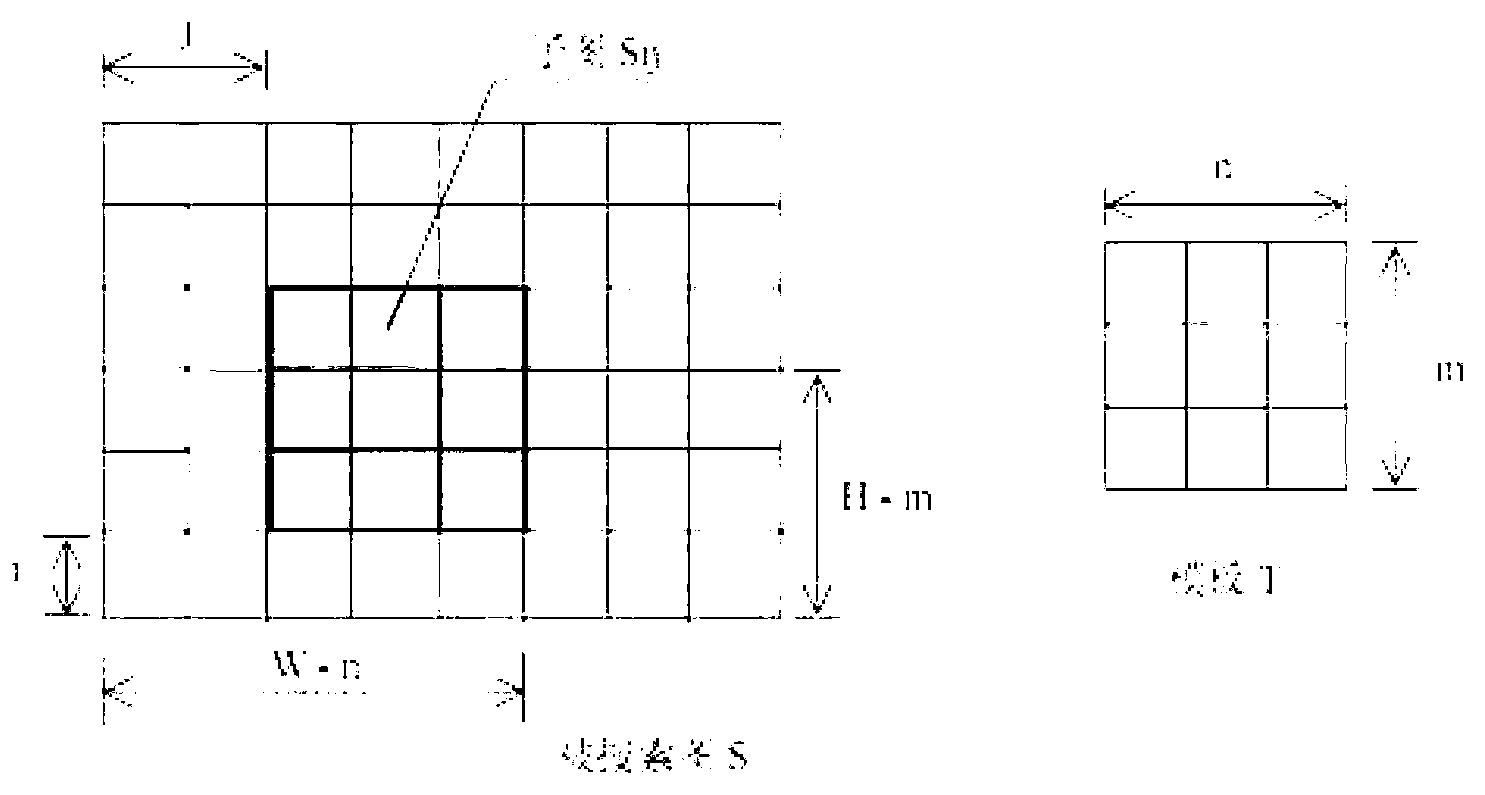

[0056] Specific implementation mode one, combining Figure 1-4 This specific embodiment will be described. An online size measurement method for precision devices based on machine vision, which includes the following steps:

[0057] Step 1: Adjust the camera to obtain a clear image of the standard device, and at the same time collect the template area in the clear image;

[0058] The template area is the image size of a standard device;

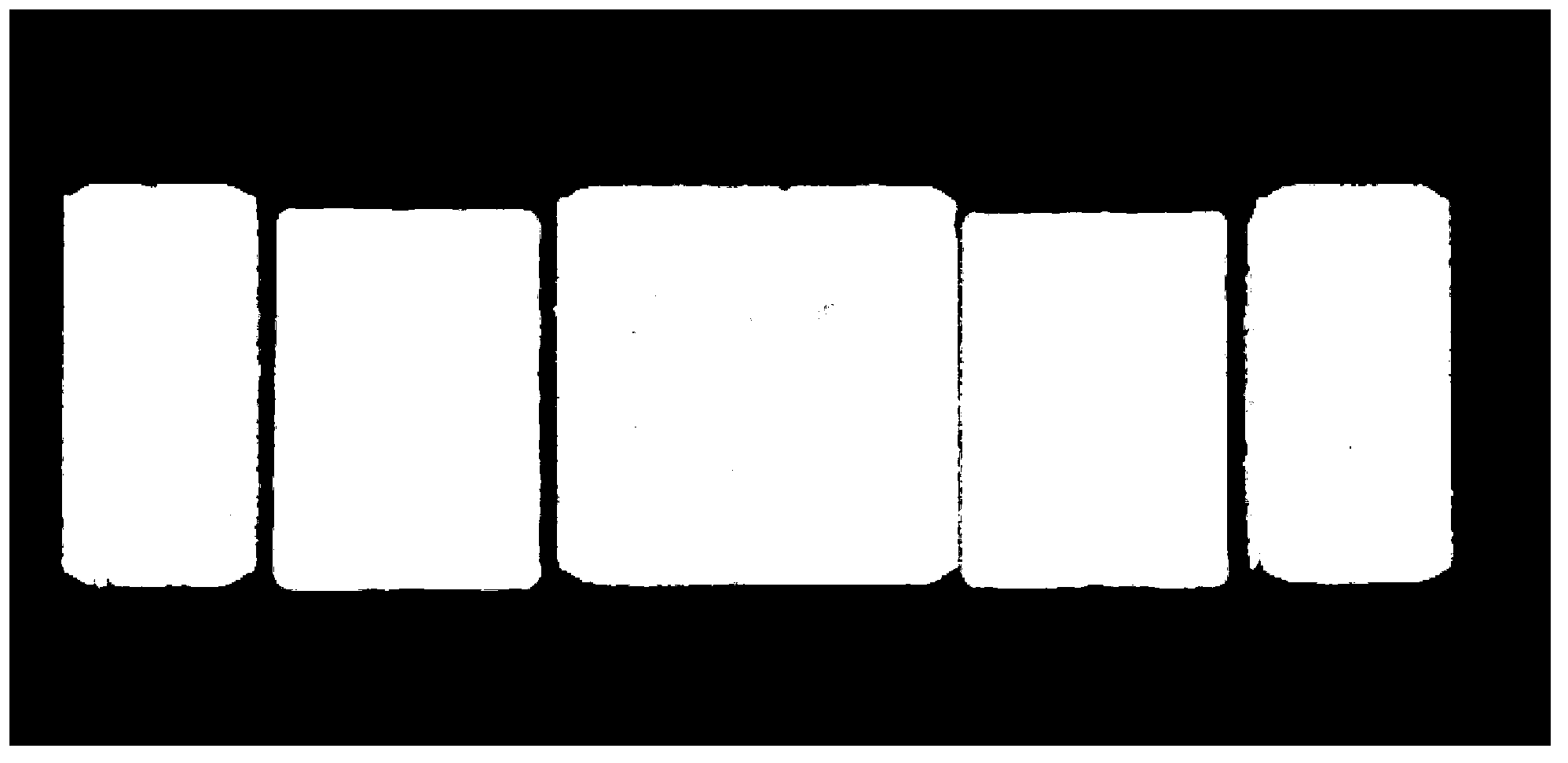

[0059] Step 2: Perform iterative threshold segmentation on the template area to obtain the segmentation threshold of the image, that is, perform binarization on the template area to obtain a binary image of the template area;

[0060] Step 3: Obtain the binary image of the image to be detected, and obtain the target area of the image to be detected by template matching;

[0061] Step 4: Perform image processing on the target area of the image to be inspected, obtain the edge of the device to be inspected for size measurement, and calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com