Preparation technique of carbon-based material having energy-storage property

A preparation process and carbonaceous technology, which is applied in the field of energy storage carbonaceous materials, and can solve problems such as the inability to produce carbonaceous materials that absorb and store natural gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

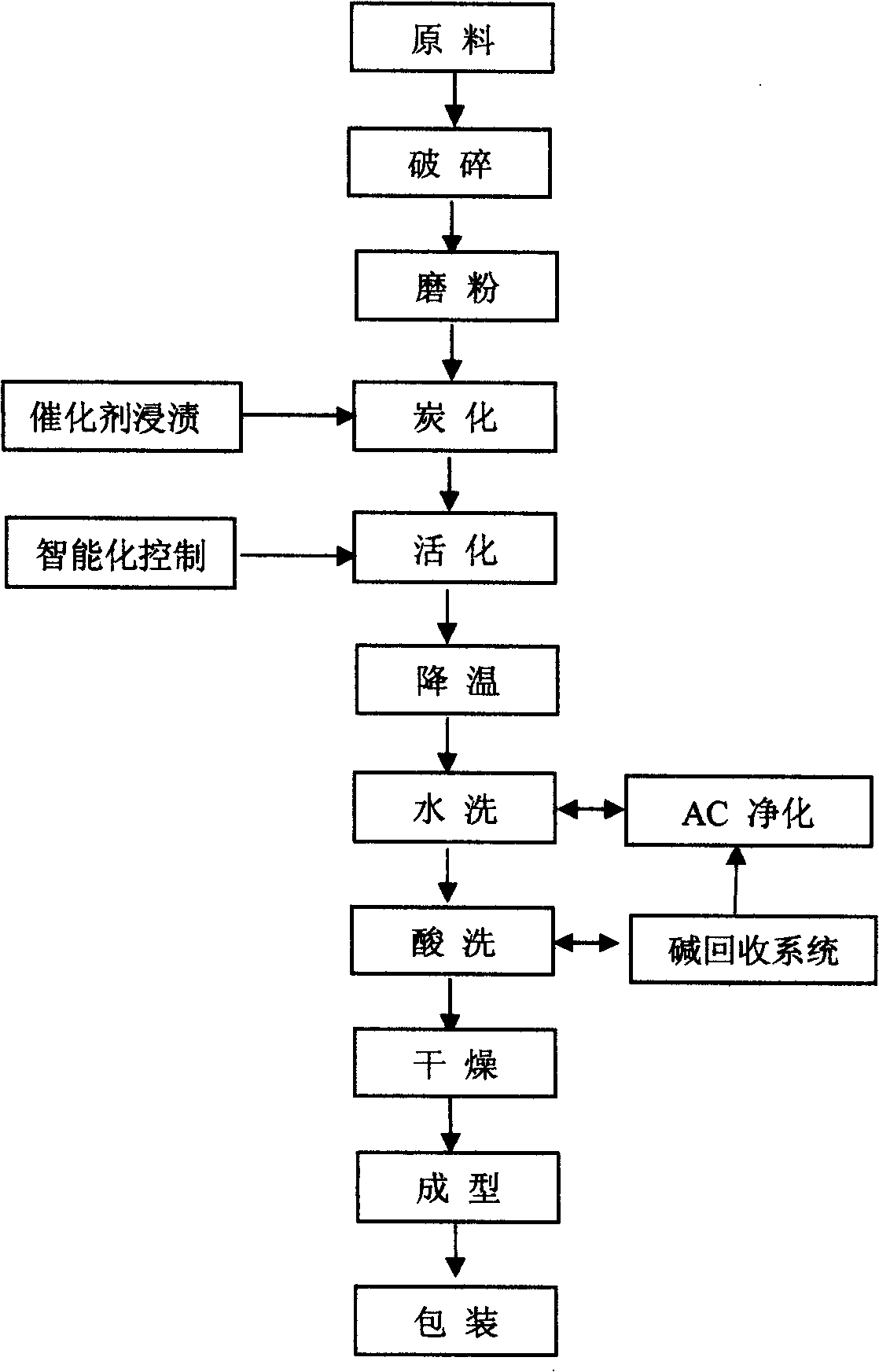

Method used

Image

Examples

Embodiment 1

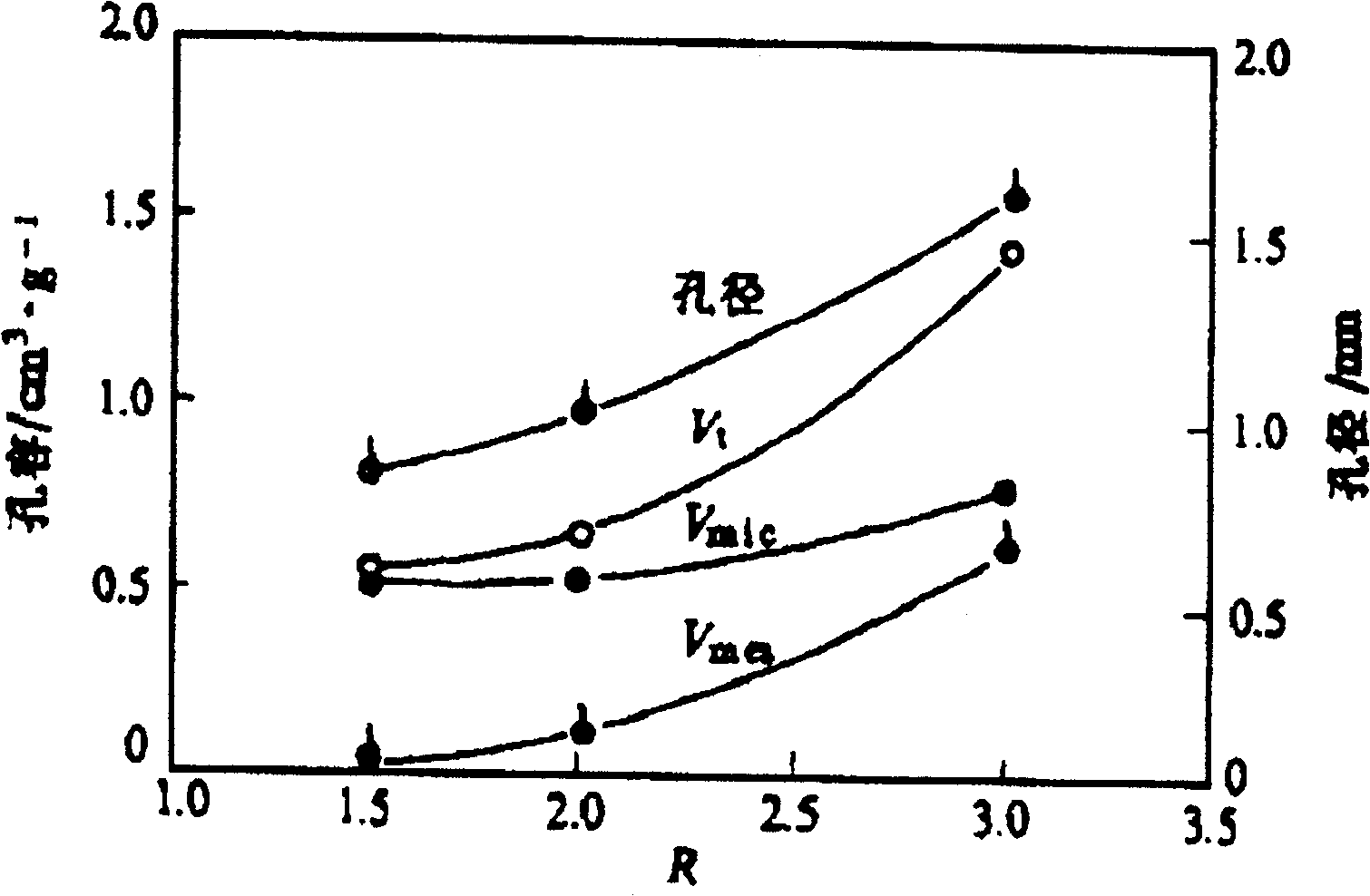

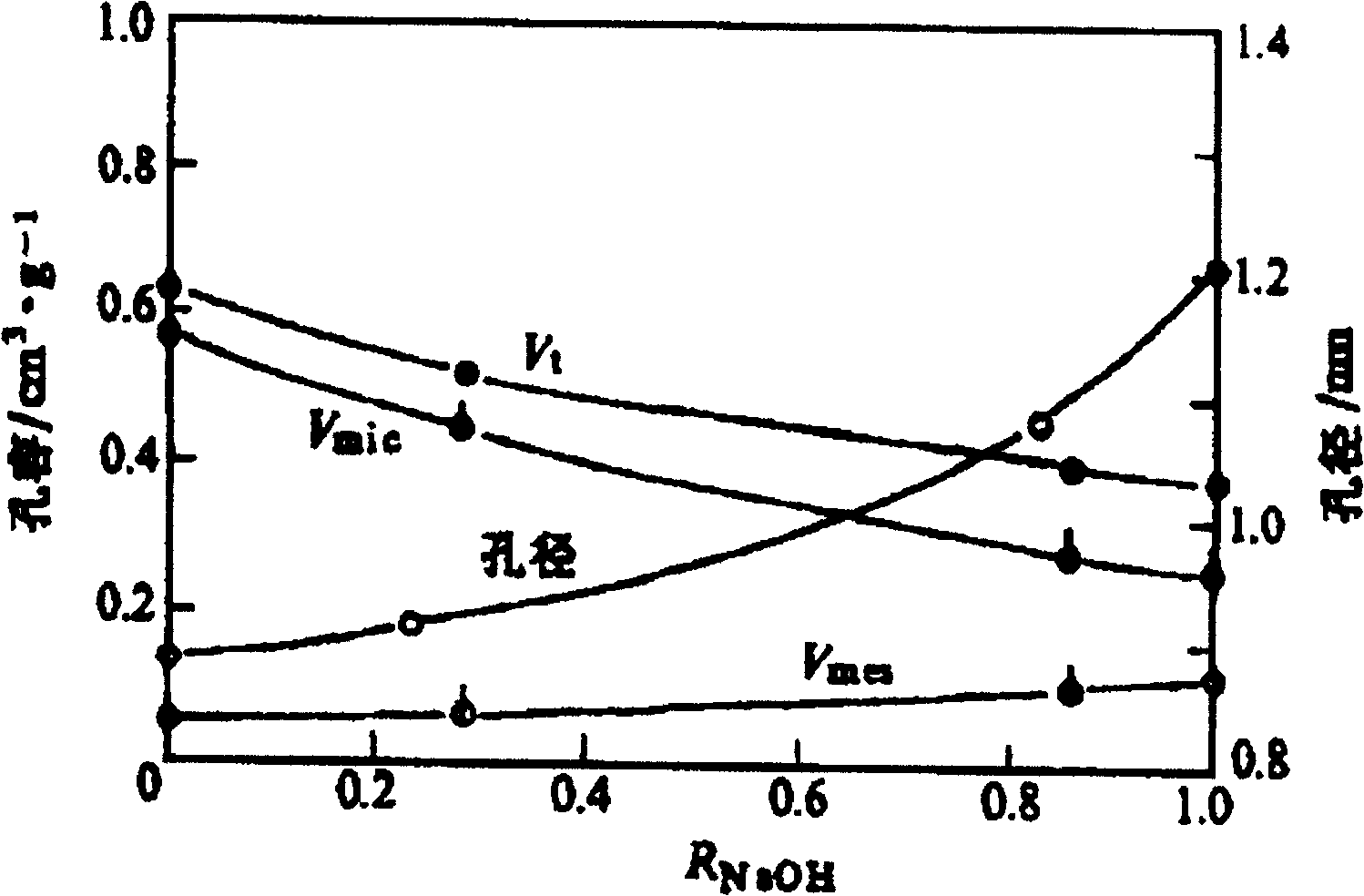

[0033]Take the petroleum pitch coke and grind it to 100~160um, use (KOH:NaOH is 75:25): carbon at 6:1, soak for 2h, transfer to the activation furnace and input the set time and temperature at one time through the electronic intelligent program controller The change program is carried out according to the following heating and constant temperature steps: 750℃~770℃ / 30min, then 800℃~850℃ / 30min, then heating to 870℃ / 30min, in N 2 Activated under protection, and then fully washed to neutrality to obtain a specific surface area of 3887m 2 / g, the iodine absorption value is 3750mg / g, the methylene blue value is 750mg / g, the nanometer pore size is 0.5-1.82nm, and the pore volume accounts for 80-90% of the total pore volume.

Embodiment 2

[0035] Take petroleum pitch coke and grind it to 100~120um, use (KOH:NaOH is 60:40): charcoal 5:1, impregnate for 2h, transfer to activation furnace according to the following heating and constant temperature steps: 770℃ / 30min, then heating 820℃ / 30min, then heat up to 870℃ / 30min, at N 2 Activated under protection, and then fully washed to neutrality to obtain a specific surface area of 3578m 2 / g, the iodine absorption value is 3350mg / g, the methylene blue value is 550mg / g, the nanometer pore size is 1~1.92nm, and the pore volume accounts for 75~85% of the total pore volume. The adsorption capacity of methane is inferior to the effect of experiment 1. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| methylene blue value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com