Environment-friendly geopolymer-based foaming material

A technology of foam materials and geopolymers, applied in the field of geopolymer-based foam materials and their preparation, can solve the problems of bulk density, high thermal conductivity, poor fire resistance, etc., achieve simple process, avoid high temperature sintering, reduce pollution and air pollution pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

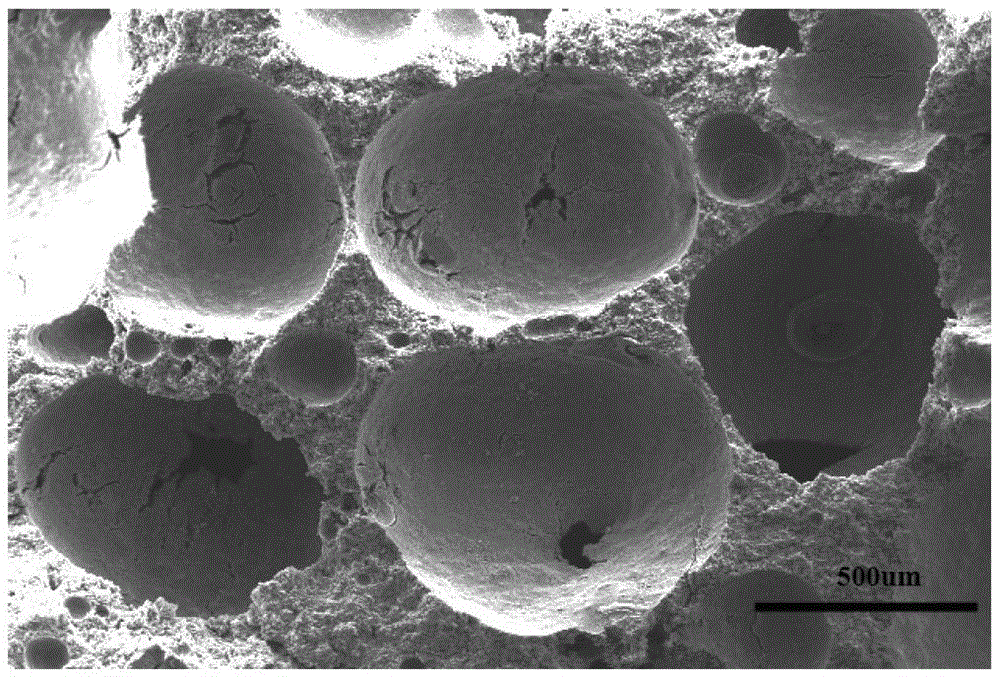

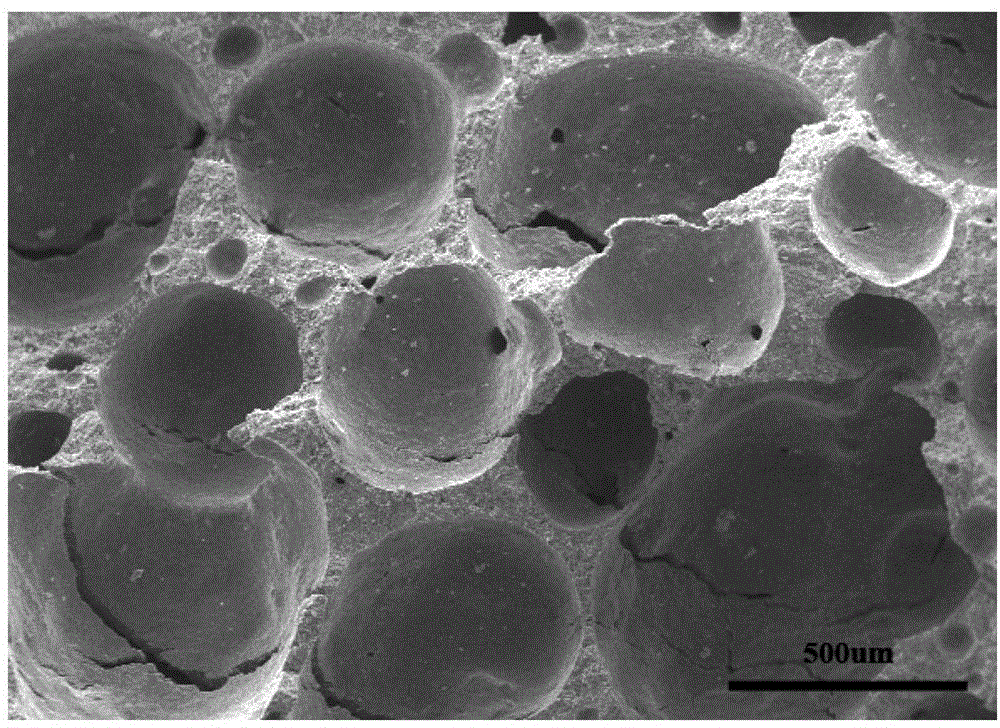

Embodiment 1

[0020] Prepare a sodium hydroxide solution with a mole fraction of 10%, weigh the fly ash and silicon dioxide according to the Si:Al molar ratio of the silicon-aluminum element in the fly ash and silicon dioxide is 1.8:1, and stir the silicon dioxide Slowly add sodium hydroxide solution under the condition of stirring to obtain sodium silicate solution, then add fly ash into the sodium silicate solution under stirring condition to make a slurry with a solid phase content of 62%, and ball mill for 10 minutes . After ball milling, add 0.04wt% aluminum powder for foaming, and add 0.01v% foam stabilizer at the same time, inject the fully foamed slurry into a cylindrical mold with d×h of 50mm×125mm, and place it at room temperature for 6 hours to fully After foaming, it is cured by heating at 70°C, and after demoulding, it is kept in a cool place at room temperature for 7 days. The shape of the obtained ceramic foam is a regular cylinder, its density is measured by the mass / volume...

Embodiment 2

[0022] Prepare a potassium hydroxide solution with a mole fraction of 8%, weigh the fly ash and silicon dioxide according to the Si:Al molar ratio of the silicon-aluminum element in the fly ash and silicon dioxide as 2.0:1, and stir the silicon dioxide Slowly add sodium hydroxide solution under the same conditions and stir evenly to obtain sodium silicate solution, then add fly ash into the sodium silicate solution under stirring conditions to prepare a slurry with a solid phase content of 62%, and ball mill for 10 minutes. After ball milling, add 0.06wt% aluminum powder for foaming, and add 0.01v% foam stabilizer at the same time, inject the fully foamed slurry into a cylindrical mold with d×h of 50mm×125mm, and place it at room temperature for 6 hours to fully After foaming, it is cured by heating at 70°C, and after demoulding, it is kept in a cool place at room temperature for 7 days. The shape of the obtained ceramic foam is a regular cylinder, its density is measured by t...

Embodiment 3

[0024] Prepare a sodium hydroxide solution with a mole fraction of 12%, weigh the fly ash and silicon dioxide according to the Si:Al molar ratio of the silicon-aluminum element in the fly ash and silicon dioxide as 2.0:1, and stir the silicon dioxide Slowly add sodium hydroxide solution into the sodium silicate solution and stir evenly to obtain a sodium silicate solution, then add fly ash into the sodium silicate solution under stirring to form a slurry with a solid phase content of 65%, and ball mill for 10 minutes. After ball milling, add 0.04wt% aluminum powder for foaming, and add 0.01v% foam stabilizer at the same time, inject the fully foamed slurry into a cylindrical mold with d×h of 50mm×125mm, and place it at room temperature for 6 hours to fully After foaming, it is cured by heating at 70°C, and after demoulding, it is kept in the shade at room temperature for 7 days. The shape of the obtained foamed ceramics is a regular cylinder, its density is measured by the mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com