Lightweight wood-plastic composite fiberboard and preparation method thereof

A wood-plastic composite and wood fiber technology is applied in the fields of wood-plastic composite materials and their manufacture, light-weight wood-plastic composite fiberboards and their preparation fields, and can solve the problems of being unsuitable for wood-plastic composite materials, damage of wood flour fibers, and high product cost. , to reduce the average density and production cost, improve the strength, improve the effect of sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1) Activation treatment of wood fiber

[0045] Mix the deionized water and the activator, use the spray nozzle and the mixer to evenly spray the activator on the wood fiber, so that the content of the activator in the wood fiber containing the activator is 5%, and the moisture content is 70%, and then put it into the drying box Inside, the wood fiber is activated when the activation temperature is 160°C, and when the wood fiber is dried to a moisture content of 1%, it is enough;

[0046] 2) Grafting treatment of wood fiber

[0047] The activated wood fiber is sprayed with dimethyltriphenylmethane isocyanate acetone solution, the sizing amount is 1.5%, and put into the drum dryer to make the isocyanate solidify;

[0048] 3) High-mix processing

[0049] The modified wood fiber, high-density polyethylene, DOP plasticizer, maleic anhydride grafted polyethylene, AC foaming agent, dibasic lead phosphite according to the ratio of 6:3:0.1:0.1:0.1:0.7 Add the ratio of the mix...

Embodiment 2

[0056] 1) Activation treatment of wood fiber

[0057] Mix the deionized water and the activator, use the spray nozzle and the mixer to evenly spray the activator on the wood fiber, so that the content of the activator in the wood fiber containing the activator is 5%, and the moisture content is 70%, and then put it into the drying box Inside, the wood fiber is activated when the activation temperature is 160°C, and when the wood fiber is dried to a moisture content of 1%, it is enough;

[0058] 2) Grafting treatment of wood fiber

[0059] The activated wood fiber is sprayed with dimethyltriphenylmethane isocyanate acetone solution, the sizing amount is 1%, and put into the drum dryer to make the isocyanate solidify;

[0060] 3) High-mix processing

[0061] The modified wood fiber, high-density polyethylene, DOP plasticizer, maleic anhydride grafted polyethylene, AC foaming agent, dibasic lead phosphite according to the ratio of 6:3:0.15:0.15:0.1:0.6 Add the ratio of the mix...

Embodiment 3

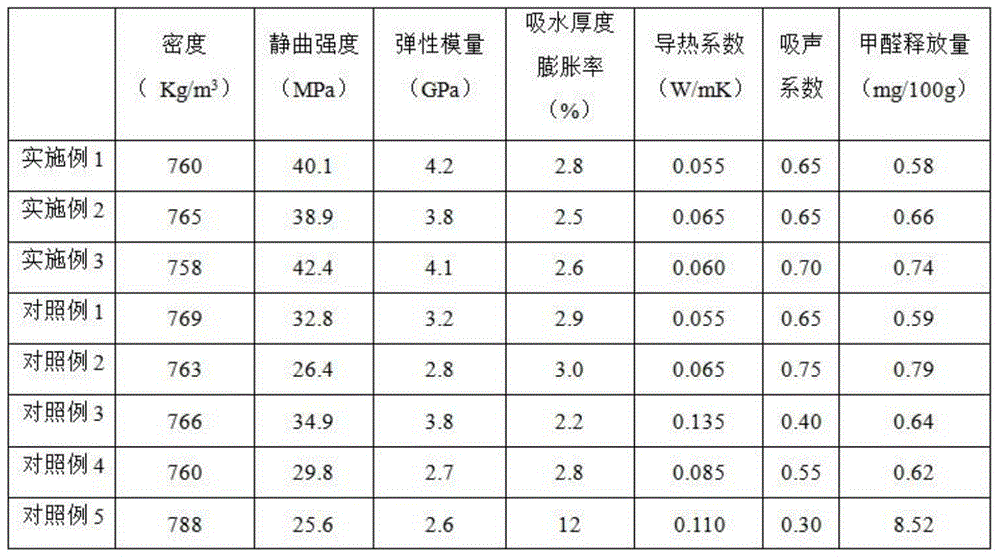

[0068] The physical and mechanical properties of the board are tested with reference to GB / T17657-1999 "Test methods for physical and chemical properties of wood-based panels and veneered wood-based panels", GB / T10294-2008 "Determination of steady-state thermal resistance and related characteristics of thermal insulation materials", GB / T18696.1 -2004 "Measurement of Sound Absorption Coefficient and Acoustic Impedance in Acoustic Impedance Tube Part I: Standing Wave Ratio Method", test results see figure 1 .

[0069] Control group 1

[0070] Compared with Example 1, the step of activation treatment of wood fiber is reduced, and other processes and formulations are consistent with Example 1.

[0071] The physical and mechanical properties of the board are tested with reference to GB / T17657-1999 "Test methods for physical and chemical properties of wood-based panels and decorative wood-based panels", GB / T10294-2008 "Determination of steady-state thermal resistance and related ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com