Tail gas continuous processing device utilizing alkaline activation to prepare activated carbon and tail gas continuous processing method thereof

A treatment device and treatment method technology, applied in chemical instruments and methods, separation methods, alkali metal oxides, etc., can solve problems such as no safe treatment, casualties, and exhaust pipes blowing up, to solve safety problems, eliminate Safety hazard, eliminate the effect of burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

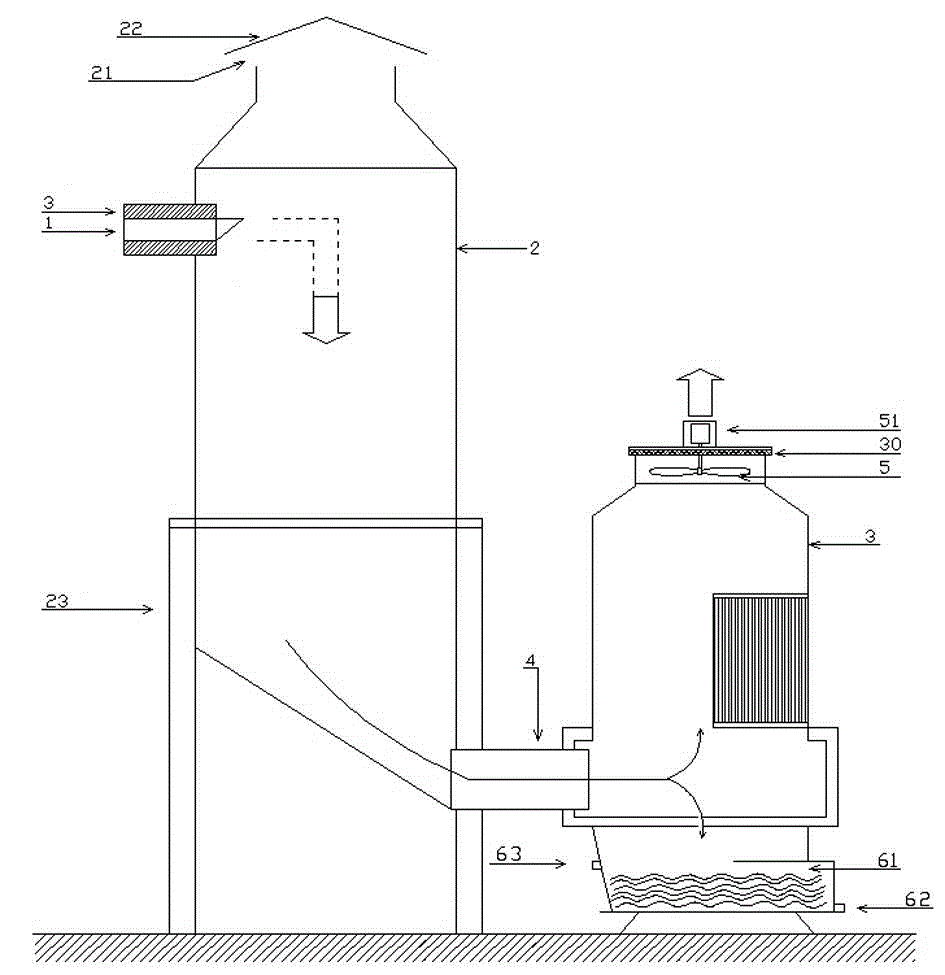

[0044] The device of the present invention is used to process the generated gas during the production of activated carbon by alkali activation, and the gas discharged from the activation furnace encounters air combustion in the oxidation tower to reduce or remove harmful organic components in the exhaust gas. According to the calculation results of measuring the alkali metal concentration in the recovered aqueous solution in the recovery chamber and the amount of residual alkali metal in the activated product, it can be confirmed that the alkali metal vapor generated during activation is completely recovered after being treated by the device, and there is no gas in the exhaust pipe 1. Residual alkali metal, this device is effective and feasible.

Embodiment 2

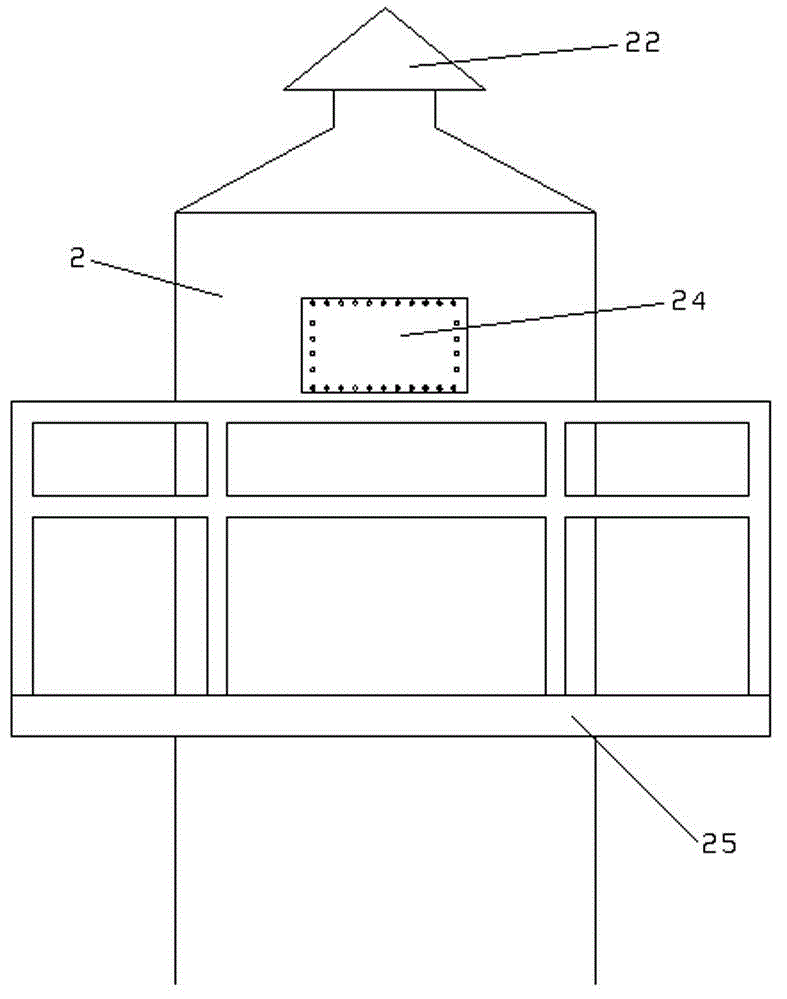

[0046] Through the transformation of the treatment device, the inside of the oxidation tower 2 and the heating exhaust pipe 1 can be observed and cleaned. Open a hole of about 40 centimeters * 30 centimeters on the cylinder body of the oxidation tower directly opposite to the exhaust pipe, and configure an openable and closable stainless steel cover 24 thereon. Open lid stainless steel cover 24, can observe the situation inside oxidation tower 2 and heating exhaust pipe 1, also can clean it if necessary. Set up an operating platform 25 equipped with steps outside the oxidation tower 2, so that personnel can operate on it (such as image 3 shown).

Embodiment 3

[0048] Mix the carbonized product of phenolic resin (800°C, 2 hours carbonization, average particle size 200-400μm) and KOH at a weight ratio of 1:3, place it in a nickel activation furnace, and raise the temperature to 550°C under stirring in a nitrogen atmosphere Keep it for 2 hours to make the reactant form powder (fine grain), then raise the temperature to 800°C, keep it for 30 minutes, discharge the product into the cooler and cool it below 50°C, wash it with hot water / hot hydrochloric acid after discharge When it reaches neutrality, the washing liquid is recovered, and the temperature of the exhaust pipe is kept at 800°C during the activation process, and the device of the present invention is used to safely process and recover metal potassium. Use ICP to measure the concentration of metal potassium in the washing recovery liquid and metal potassium treatment recovery liquid, and calculate the total amount of potassium. The results are summarized in Table 1. It can be s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com