Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

144results about How to "Strong binding strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

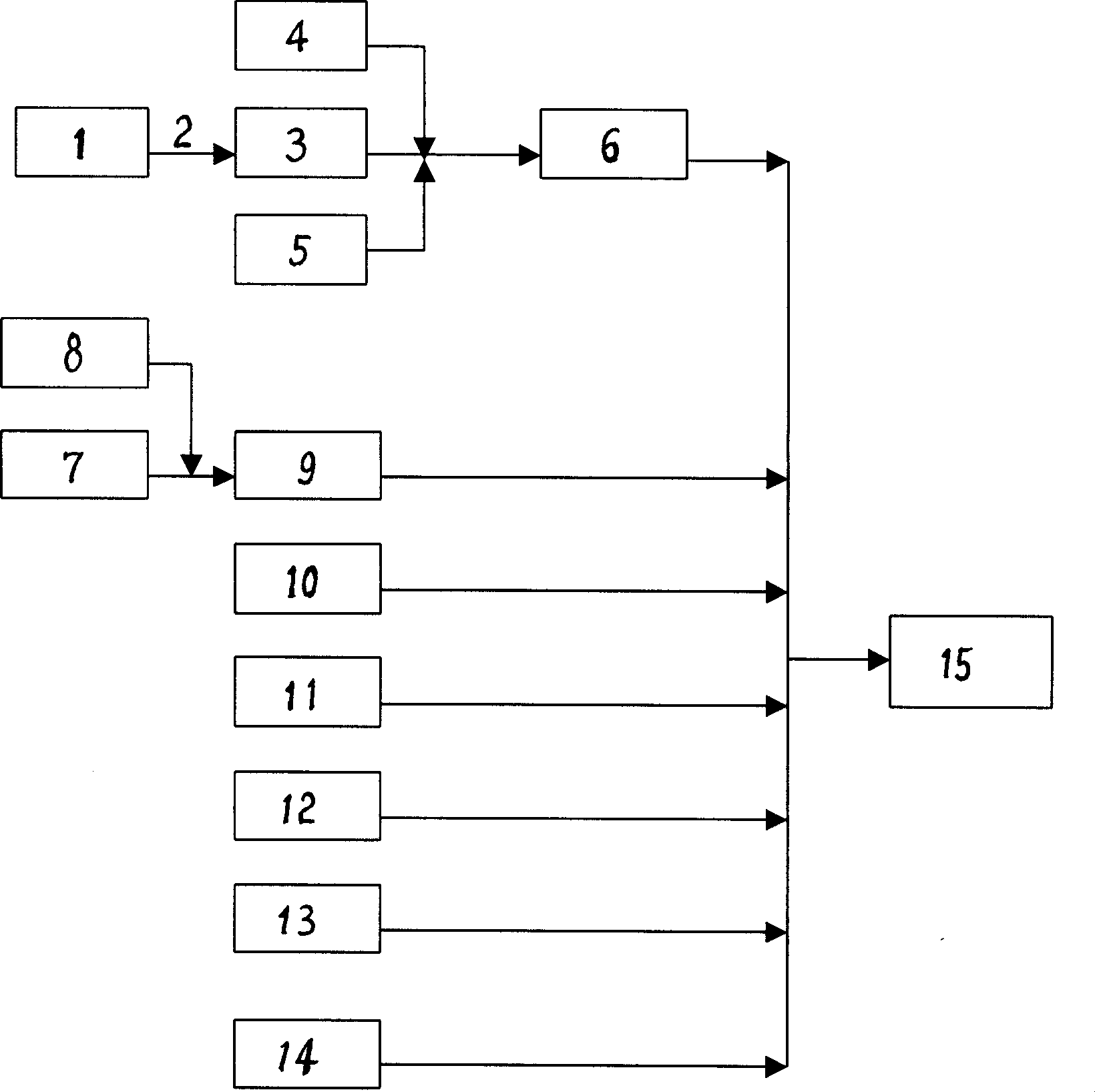

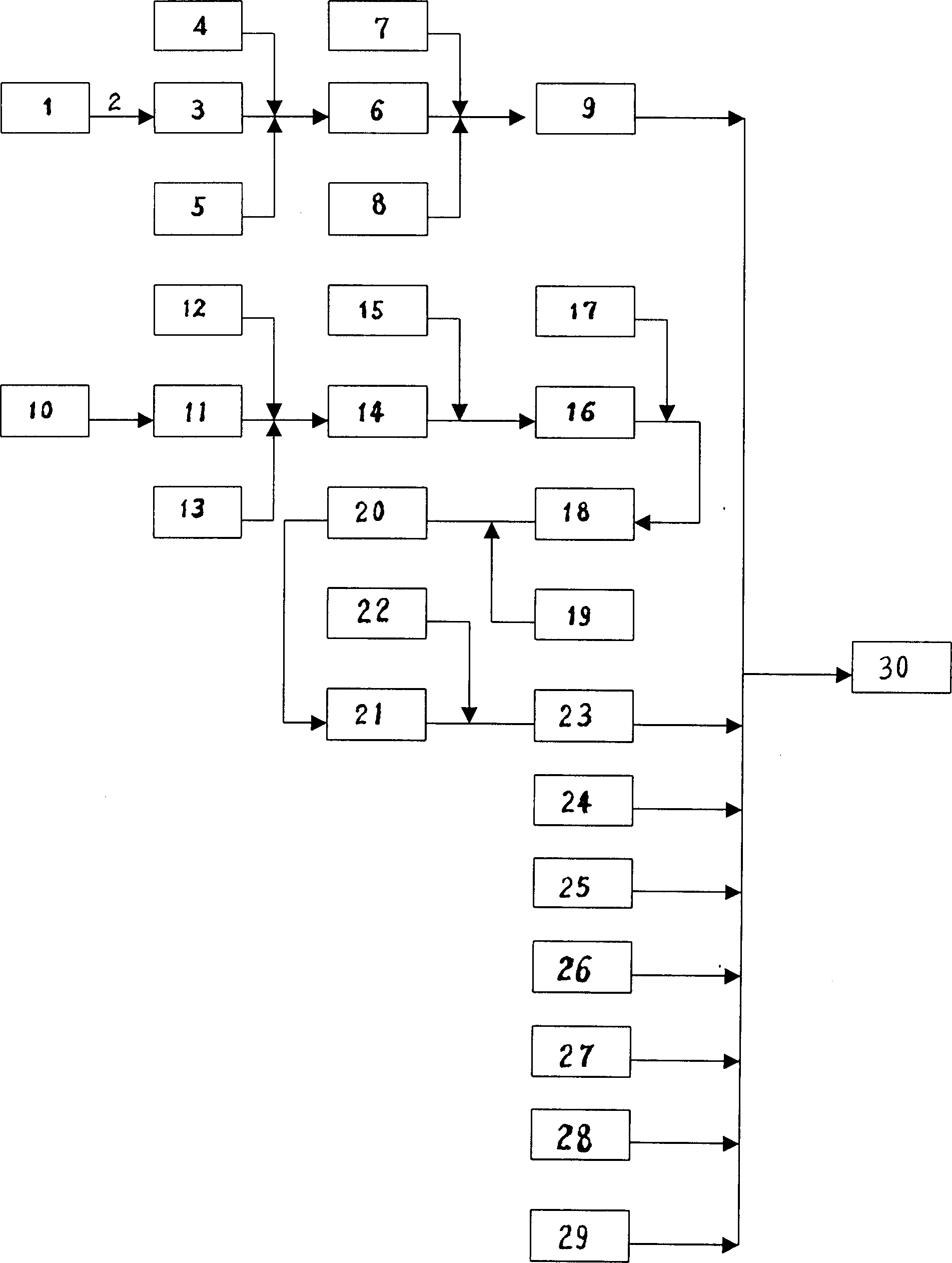

Biodegradable or compostable containers

The present invention provides an improved method and materials for forming biodegradable containers that can hold food products in dry, damp or wet conditions and provides the biodegradable containers prepared according to the disclosed process. The containers are produced through the use of a pre-gelled starch suspension that is unique in its ability to form hydrated gels and to maintain this gel structure in the presence of many other types of materials and at low temperatures.

Owner:NEW ICE LTD

Biodegradable or compostable containers

InactiveUS20050120915A1Improve bindingEffectively biodegradableWrappersBio-packagingImproved methodFood products

The present invention provides an improved method and materials for forming biodegradable containers that can hold food products in dry, damp or wet conditions and provides the biodegradable containers prepared according to the disclosed process. The containers are produced through the use of a pre-gelled starch suspension that is unique in its ability to form hydrated gels and to maintain this gel structure in the presence of many other types of materials and at low temperatures.

Owner:NEW ICE LTD

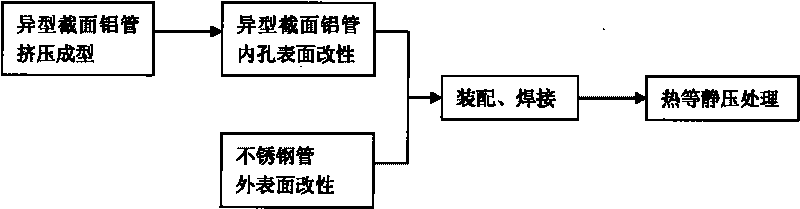

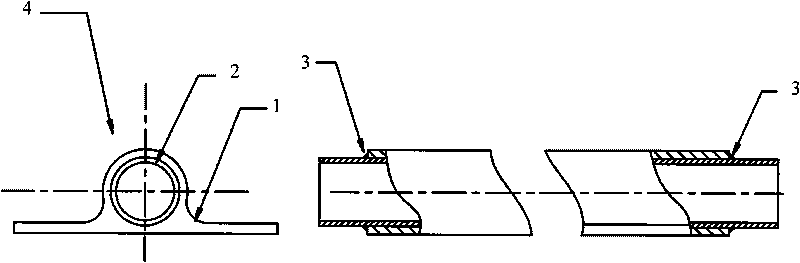

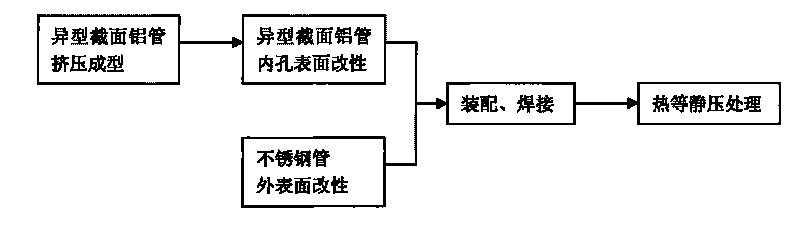

Method for producing irregular-section composite pipe

InactiveCN101745793AEfficient heat expansionHigh interface heat transfer coefficientFurnace typesLiquid/solution decomposition chemical coatingThermal expansionElectric power

The invention discloses a method for producing irregular-section composite pipes, belonging to the technical field of metal composite materials. The method comprises the following steps: an irregular-section aluminum pipe is extruded and formed, the surface of the inner hole of the irregular-section aluminum pipe is modified, the external surface of a stainless steel pipe is modified, the surface-modified stainless steel pipe is inserted into the inner-hole-surface-modified irregular-section aluminum pipe, the assembling end parts of the stainless steel pipe and the irregular-section aluminum pipe are sealed after the assembling is completed, and the welded part of the irregular-section aluminum pipe and the stainless steel pipe is put into a hot isostatic pressure furnace for heat treatment to obtain an irregular-section composite pipe. The irregular-section composite pipes produced through the invention have the advantages that the weight is light, the strength is high, the thermal expansion efficiency is high, the interfacial metallurgical bonding ratio is close to 100 percent, the interfacial heat exchange coefficient is high, the bonding strength is high, the service life in severe cold-and-hot-alternation environment and the like, can be used in heat pipe systems which are key technical hardware of aircrafts, aerospacecrafts and other spacecrafts, and can be widely used in fields such as power, electronics, ships, nuclear energy and the like.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Display panel and display device

PendingCN112599535AReduced trace routing rangeProblems affecting splicing effectCasings with display/control unitsSolid-state devicesDisplay deviceThin membrane

The invention discloses a display panel and a display device, a binding layer is arranged between a thin film transistor layer and a substrate, and a metal wire of the thin film transistor layer is electrically connected with a binding lead through a via hole, so that the range of a peripheral area can be reduced, narrow bonding can be realized, and the purpose of reducing a frame is realized.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

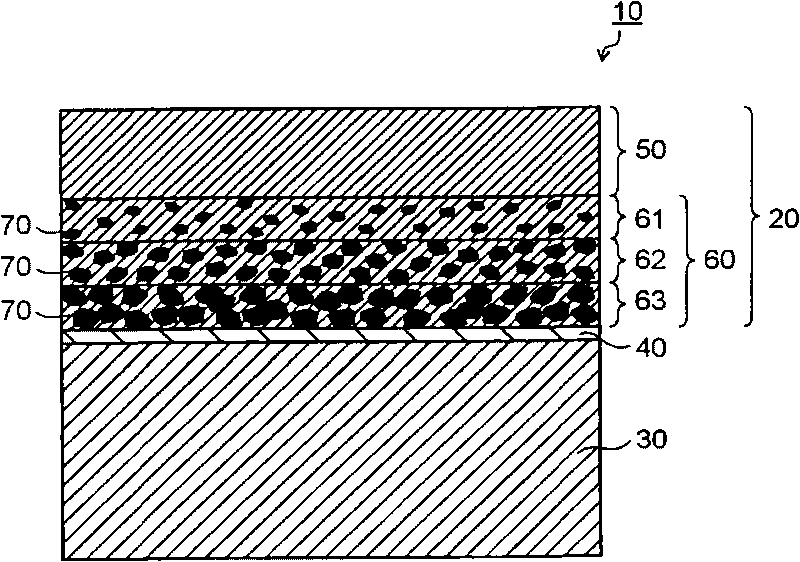

Super-hybrid composite laminate for neutron shield and preparation method of super-hybrid composite laminate

ActiveCN107955332AStrong binding strengthImprove shielding effectSynthetic resin layered productsLaminationInterlaminar shearComposite laminates

The invention provides a super-hybrid composite laminate for neutron shield. The super-hybrid composite laminate comprises a metal plate and a fiber enhanced resin-based composite layer which are alternately laminated, wherein the fiber enhanced resin-based composite layer is prepared from basalt fiber, epoxy resin, modified boron carbide, a curing agent, a moderator and a neutron absorber. The provided fiber enhanced resin-based composite layer has excellent shielding performance and mechanical performance, has the density of 2.36-2.42 g / cm<3>, the tensile strength of 1,120-1,160 MPa, the tensile modulus of 82-85 GPa and the interlaminar shear strength of 78-85 MPa, has the <252>CF neutron source shielding factor Kf (15 mm) of 2.65-3.02 and the neutron shield rate Ath10 (10mm) of 99.88%-99.89%. The invention further provides a preparation method of the composite laminate. The preparation method is simple and convenient to operate and easy to implement.

Owner:BEIHANG UNIV +1

Nano cellulose glass fiber composite filter material as well as preparation method and application thereof

InactiveCN111467875AHigh precisionImprove breathabilitySynthetic cellulose/non-cellulose material pulp/paperMembrane filtersGlass fiberPlant fibre

The invention belongs to the field of filtration, and particularly relates to a nano cellulose glass fiber composite filter material and a preparation method and application thereof. The method comprises the following steps: (1) defibering fibrillable plant fibers by a defibering machine, and dispersing in water to obtain slurry; (2) performing treatment by a physical or chemical method to obtainnanocellulose, and washing and ultrasonically treating to obtain a nanocellulose solution; (3) adding water and a dispersing agent into the glass fiber raw material, uniformly dispersing to obtain slurry, and sequentially deslagging, diluting, forming and dehydrating to form wet paper sheets with uniform thickness; (4) coating the surface of glass fiber paper with the nano-cellulose solution in acoating manner to form a nano-fiber coating; (5) drying and forming. The nano cellulose solution prepared from the plant fibers is compounded with the glass fiber base material in a coating manner, sothat the obtained fiber material has the advantages of high precision, high air permeability, low resistance, long service lifetime and the like, and is particularly suitable for the field of filtering of air, water and the like.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD +1

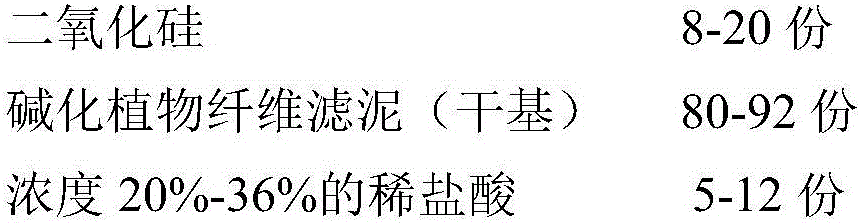

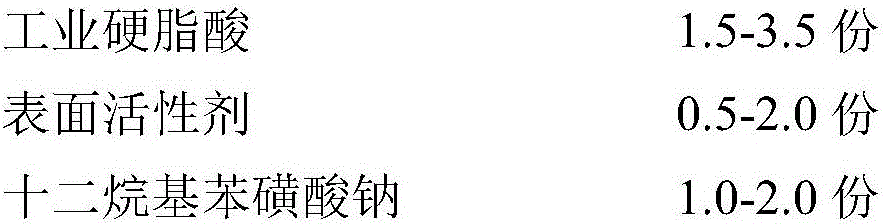

Degradable lightweight polyolefin composite for injection molding and preparation method of composite

The invention provides a degradable lightweight polyolefin composite for injection molding and a preparation method of the composite. The polyolefin composite is prepared from secondarily modified fiber mixed filler, polyolefin resin, a toughening agent, a compatilizer, a lubricant and the like through blending and extrusion granulation by a tri-screw extruders which are arranged triangularly and meshed in the same direction, wherein the modified fiber mixed filler is prepared as follows: a natural plant fiber material such as rice husks, chaff and the like are mixed with a nano-silica colloidal solution, a dispersant and a surfactant are added and a blending reaction, drying and other technologies processes are performed; then the modified mixed fiber filler is subjected to secondary surface coupling hydrophobic treatment and blended with polyolefin resin, the toughening agent, the compatilizer and the lubricant. The polyolefin composite has degradability specific to the natural plant fiber filler, has lower density than inorganic mineral filler and has excellent thermoplastic processing characteristics and mechanical properties in the injection molding process.

Owner:水发信达(山东)再生资源科技有限公司

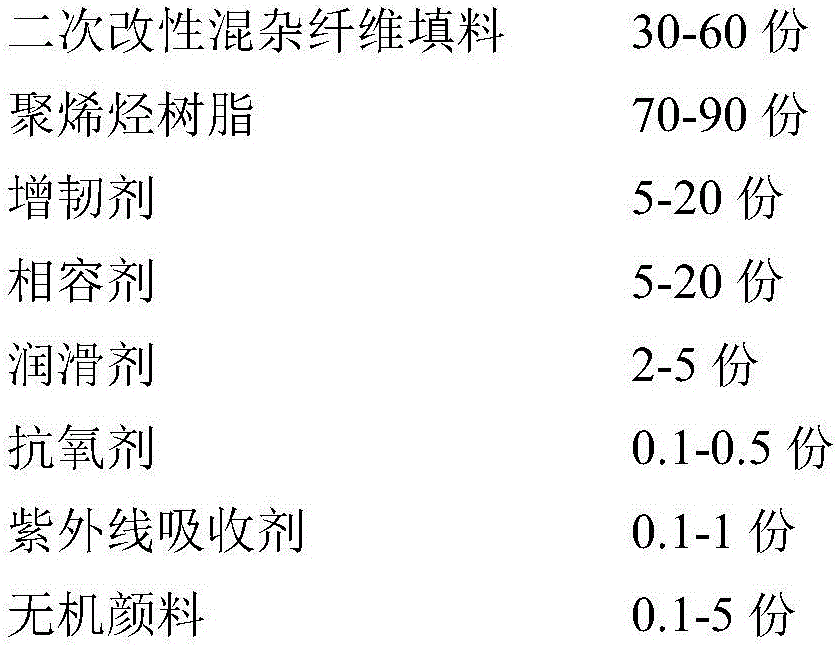

Polyethylene film for automatic packaging and preparation method thereof

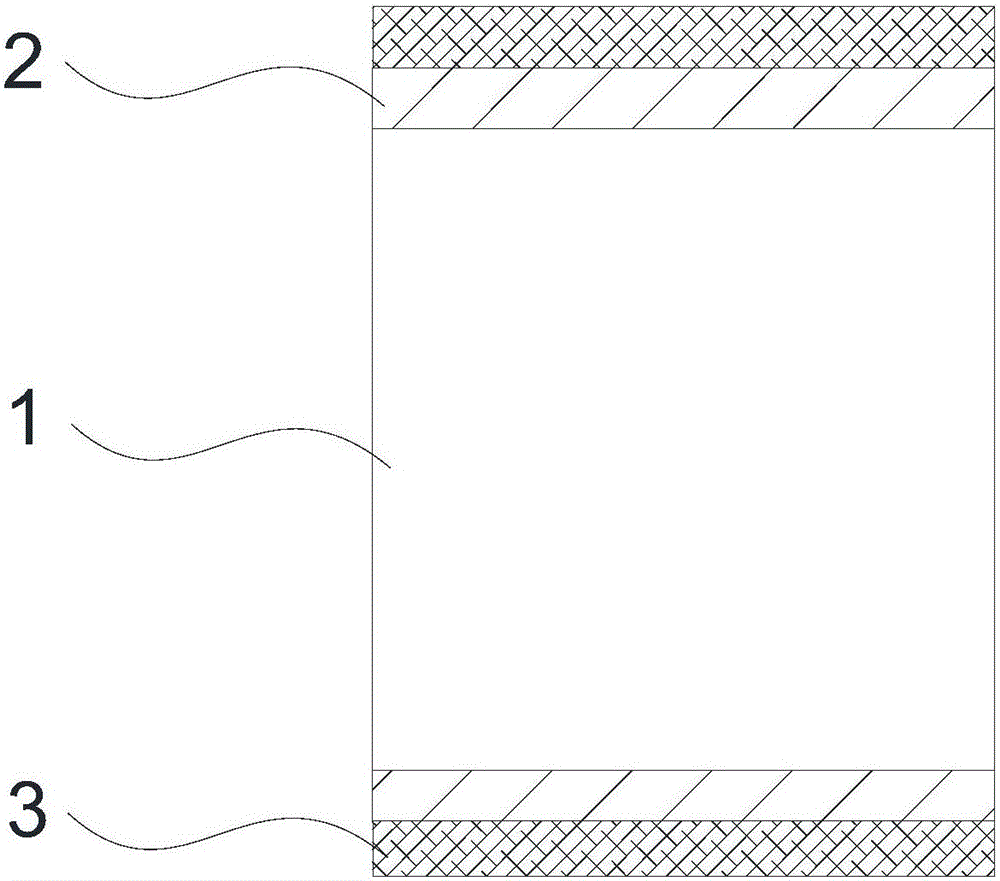

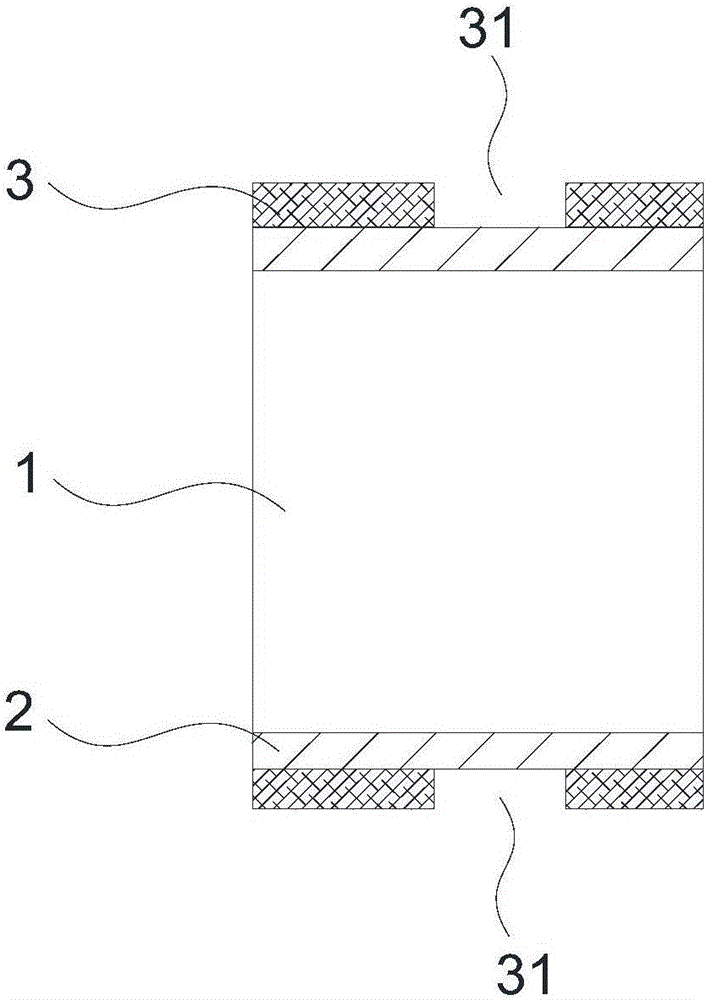

ActiveCN108773137AAnti-pollutionComposite strongSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a polyethylene film for automatic packaging. The polyethylene film comprises an outer layer, an intermediate layer and an inner layer which are sequentially laminated. The outer layer is prepared from the following substances in parts by weight: 20-40 parts of low density polyethylene (LDPE), 30-50 parts of linear low density polyethylene (LLDPE), and 20-40 parts of LLDPE with melt index of 1.1 g / 10 min and density of 0.920 g / cm<3>. The intermediate layer is prepared from the following substances in parts by weight: 10-30 parts of LDPE, 30-50 parts of LLDPE with melt index of 1.1 g / 10 min and density of 0.920 g / cm<3>, and 30-50 parts of LLDPE with melt index of 2.4 g / 10 min and density of 0.921 g / cm<3>. The inner layer is prepared from the following substances in parts by weight: 10-30 parts of LDPE, 30-50 parts of LLDPE, and 10-30 parts of LLDPE. The invention solves the problem that the polyethylene film has lower thermal viscosity and higher bag breaking rate.

Owner:青岛东海包装产业有限公司

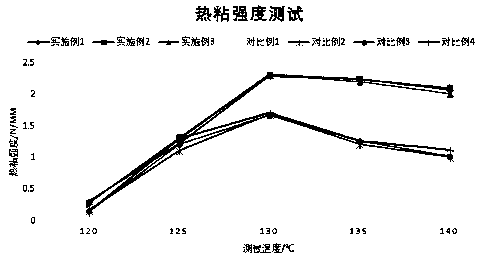

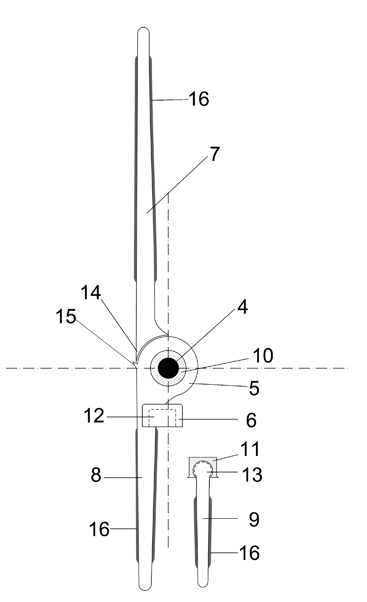

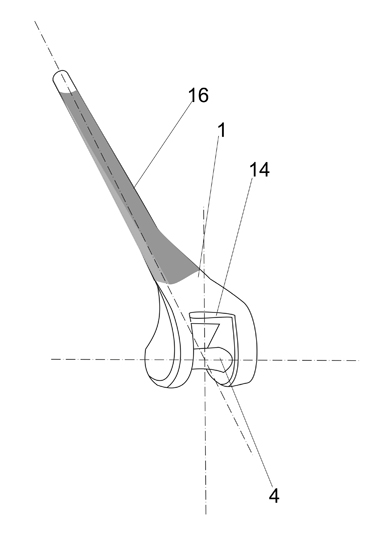

Design method of artificial elbow joint prosthesis with tantalum coating

InactiveCN101984939AIncrease bone ingrowthImprove stabilityJoint implantsCoatingsProximal radiusProximal ulna

The invention relates to an artificial elbow joint prosthesis, in particular to a design method of the artificial elbow joint prosthesis which is provided with a tantalum microporous coating on the surface, the artificial elbow joint prosthesis comprises a humeral component used for being implanted into a marrow cavity of distal humerus, an ulnar component for being implanted into the marrow cavity of proximal ulna and a radial component for being implanted into the marrow cavity of proximal radius, each component consists of a joint part and a handle body part, the joint parts have the rotary motion function with different degrees for ensuring the motion of a joint after implanting the prosthesis, and the handle body parts are the parts for being inserted into the marrow cavity, thereby achieving a role of fixing the prosthesis. The joint parts of the humeral component and the ulnar component are connected by relying on a crankshaft which can rotate for chimerism, and a joint ball head of the radial component is connected by chimeric sleeve joint through a joint mortar groove connected at the proximal end of the ulnar component. The artificial elbow joint prosthesis is characterized in that a tantalum surface is wrapped on the outer surface of each handle body, and each tantalum surface is in the microporous structure, thereby improving the fixing effect of the artificial prosthesis in a human body and prolonging the service life of the artificial prosthesis.

Owner:XIAN FUAN INNOVATION CONSULTATION

Refractory composite heat insulating sprayed material

InactiveCN1740240ALow costImprove sealingFireproof paintsAlkali metal silicate coatingsHeat conductingRefractory

The refractory composite heat insulating sprayed paint suitable for high temperature furnace, kiln and other thermal apparatus is powder comprising base material sepiolite, brucite, blue asbestos, basalt, apyre and quartz and high temperature adhering material. In the construction site, the powder is mixed with water to form heat insulting paint. The heat insulting paint has low heat conducting coefficient, high adhering strength, capacity of being used for both cold and hot construction, low comprehensive cost and other advantages.

Owner:信阳天意节能技术股份有限公司

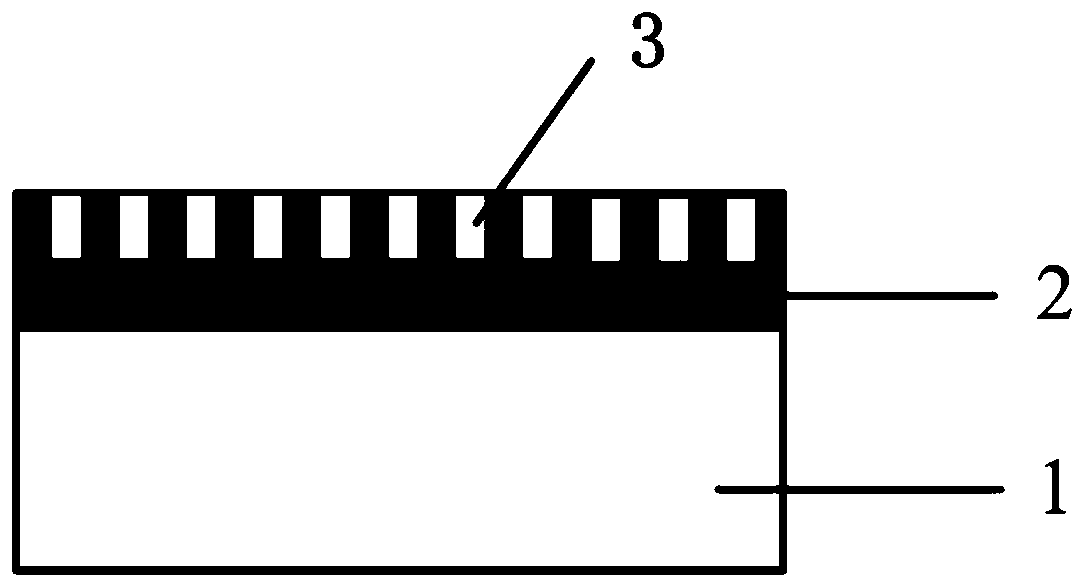

Strengthened and toughened in-site reaction-type micro-structure self-lubricating bearing and preparation method thereof

ActiveCN110318017AImprove toughnessHigh hardnessMolten spray coatingBearing componentsMicro structureCarbon nanotube

The invention discloses a strengthened and toughened in-site reaction-type micro-structure self-lubricating bearing and a preparation method thereof. A matrix of the bearing is made from chromium-containing alloy steel, a cubic boron nitride coating containing PbO, Mo, TiB2, BNNTs, CNTs and graphene is arranged on the surface of the matrix, and the surface of the coating is of a micro-structure; and the coating is prepared through a plasma vacuum spaying method. The self-lubricating bearing prepared through the method has good toughness on the whole, the binding force between the matrix and the coating is high, and boron nitride nanotubes (BNNTs) and carbon nanotubes (CNTs) are added, so that the cubic boron nitride coating on the surface has good toughness and high hardness and wear resistance; and in the working process, the graphene can achieve a lubricating effect when the temperature is low, and when the temperature is high, PbO, Mo and TiB2 are subjected to an in-site reaction togenerate PbMoO4, TiO2 and B2O3 to cooperatively work with the micro-structure to achieve a lubricating effect, so that frictional wear is reduced, and the life of the bearing is prolonged.

Owner:SOUTHEAST UNIV

Method for manufacturing shoe composition

InactiveCN101637976AStrong binding strengthSolve pollutionDomestic articlesBonding strengthHot-melt adhesive

The invention relates to a method for manufacturing a shoe composition. The method comprises the following steps: selecting a rubber blank to be formed; coating hot melt adhesives on the blank; cutting the coated blank into a preset shape; putting the cut blank into a mold cavity; closing a mold, heating and pressurizing the mold so as to ripen rubber in the mold; combining the hot melt adhesivesand rubber outsoles after rubber ripening is completed so as to form a footwear outsole with a hot melt adhesive layer by one-step forming; and then, after the temperature of a hot melt adhesive filmis increased by ultraviolet ray or radiofrequency, directly processing the attachment to midsole or a vamp. The method can improve the bonding strength of the hot melt adhesive and the outsole or themidsole, enables the subsequent processing step to be simpler, quicker and easier, and avoids the risk or environmental pollution caused by coating combustible addition agents with volatility.

Owner:张廷源

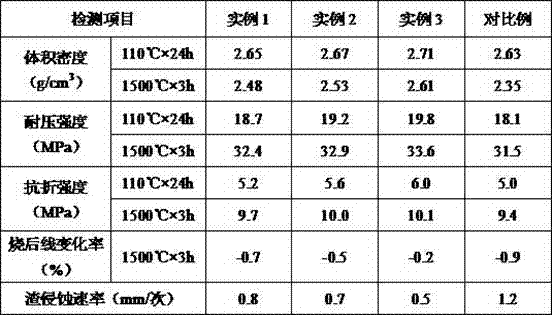

Boron-containing additive for carbide refractory and preparation thereof

The invention provides a boron-containing additive for carbon refractory, which is characterized in that the boron-containing ingredients including metal boride, B4C or amorphous boron powder are directly compounded in spongy basal body of Al2O3 or MgO by the in-situ synthesis technology so as to form Al2O3-base or MgO-base boron-containing additive. The product takes loose sponge shape. The invention adopts the boric anhydride and metal oxide, or the boric anhydride and graphite, or the boric anhydride as raw materials, and adopts the aluminum powder or magnesium powder as a reducing agent; the materials and the reducing agent are mixed, activated and are then placed in a self-spreading reacting furnace; the partial ignition mode is adopted to initiate the combustion synthesis reaction so as to produce the Al2O3-base or MgO-base boron-containing additive. The boron-containing additive for carbon refractory has the advantages of simple technique, low production cost and high product purity and does not have secondary pollution caused by crashing in the traditional production technique.

Owner:NORTHEASTERN UNIV

Cubic boron nitride self-lubricating coated tool and preparation method thereof

ActiveCN108950537AImprove toughnessHigh surface hardnessMetallic material coating processesBoron nitrideAlloy

The invention discloses a cubic boron nitride self-lubricating coated tool and a preparation method thereof. A substrate material of the cutting tool is high speed steel or a hard alloy. The surface of the substrate is a cubic boron nitride coating including CsF, Mo and ZrO2. The coating is prepared by means of an electron beam cladding method. The preparation method comprises the following steps:(1) pre-treatment; (2) boron nitride layer presetting; (3) boron nitride layer cladding; and (4) post-treatment. The tool has integral good toughness, and the surface coating has relatively high hardness and wear resistance. In the cutting process, an in-situ reaction happens on CsF, Mo and ZrO2 under the action of high temperature to generate Cs2MoO4, so that a lubricating role can be played ata relatively high cutting temperature. Meanwhile, the cubic boron nitride self-lubricating coated tool is prepared by means of the electron beam method, so that the coating and the substrate have relatively high bonding strength, the preparation efficiency is high, and oxidization in the preparation process is avoided. The tool can be widely applied to dry cutting and cutting process of hardly processed materials.

Owner:SOUTHEAST UNIV

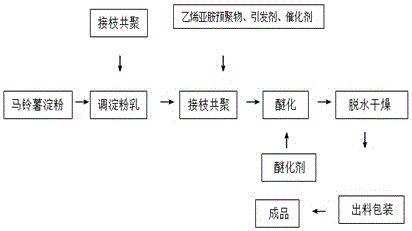

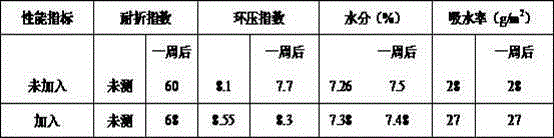

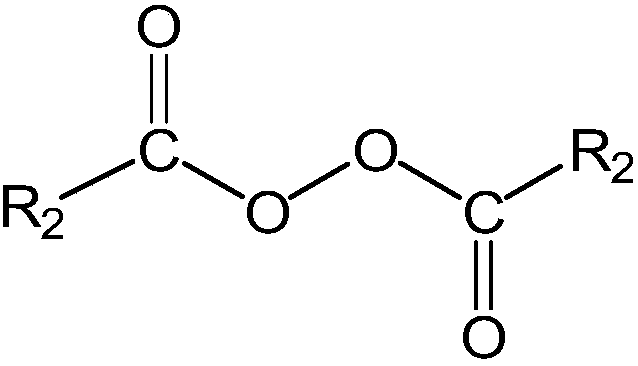

Papermaking enhancer and preparation method thereof

ActiveCN105061774AReduce consumptionImprove water filtration performanceReinforcing agents additionPolymer sciencePapermaking

The invention discloses a papermaking enhancer and a preparation method thereof. The papermaking enhancer is white or faint yellow powder, and has the water content of 15% or below and cation substitution degree of 0.03 or above, and the main effective component of the papermaking enhancer is a starch-polymine graft copolymer. Compared with the common papermaking enhancer, the papermaking enhancer is wide in application field, excellent in property, reduced in starch dosage in the papermaking production process, and lowered in production cost of paper plants.

Owner:DONGXIANG HEDA IND CO LTD

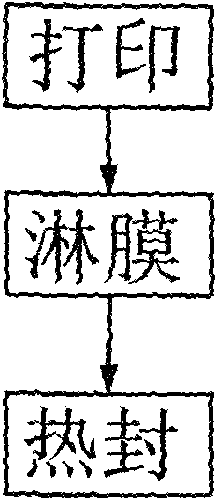

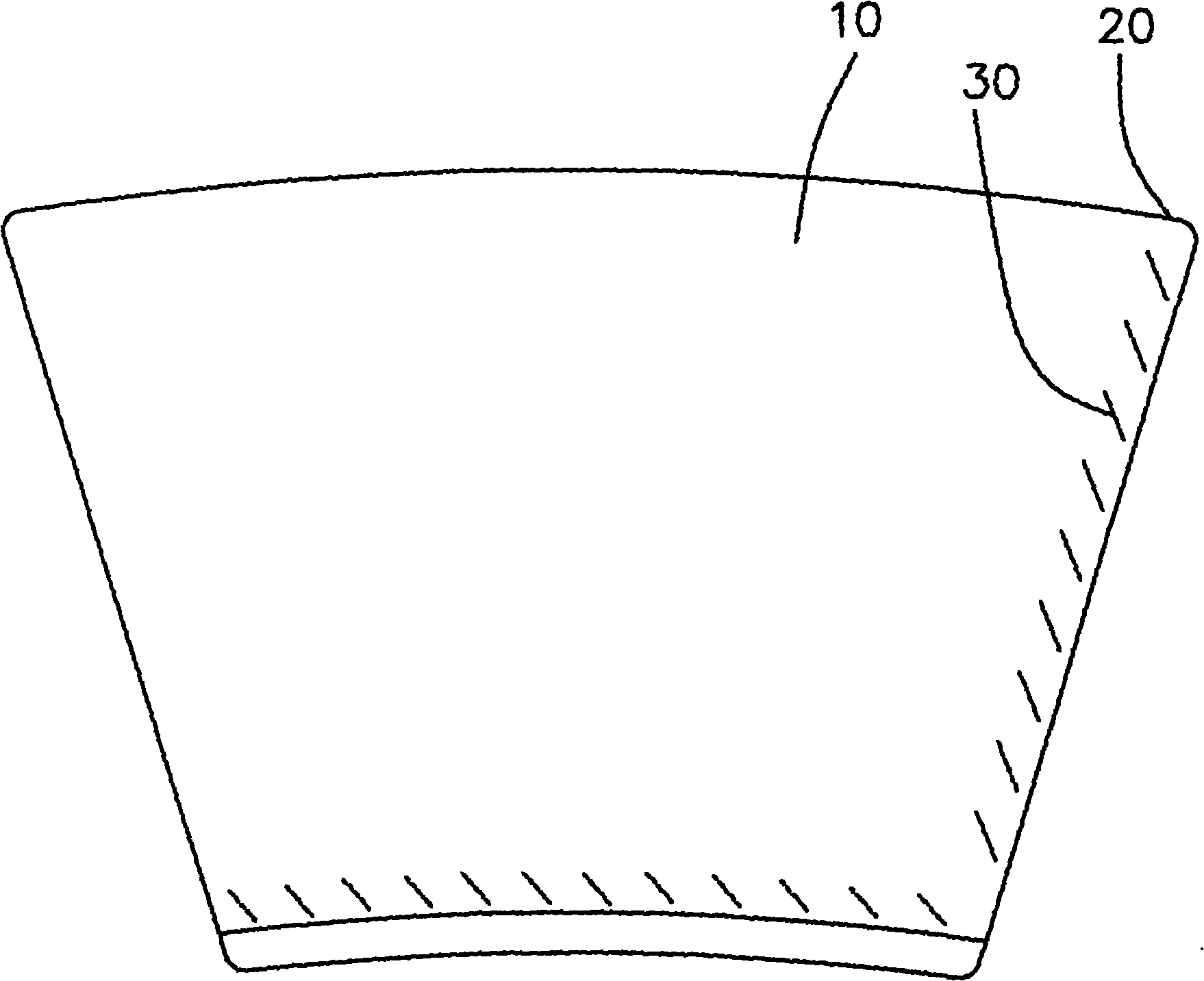

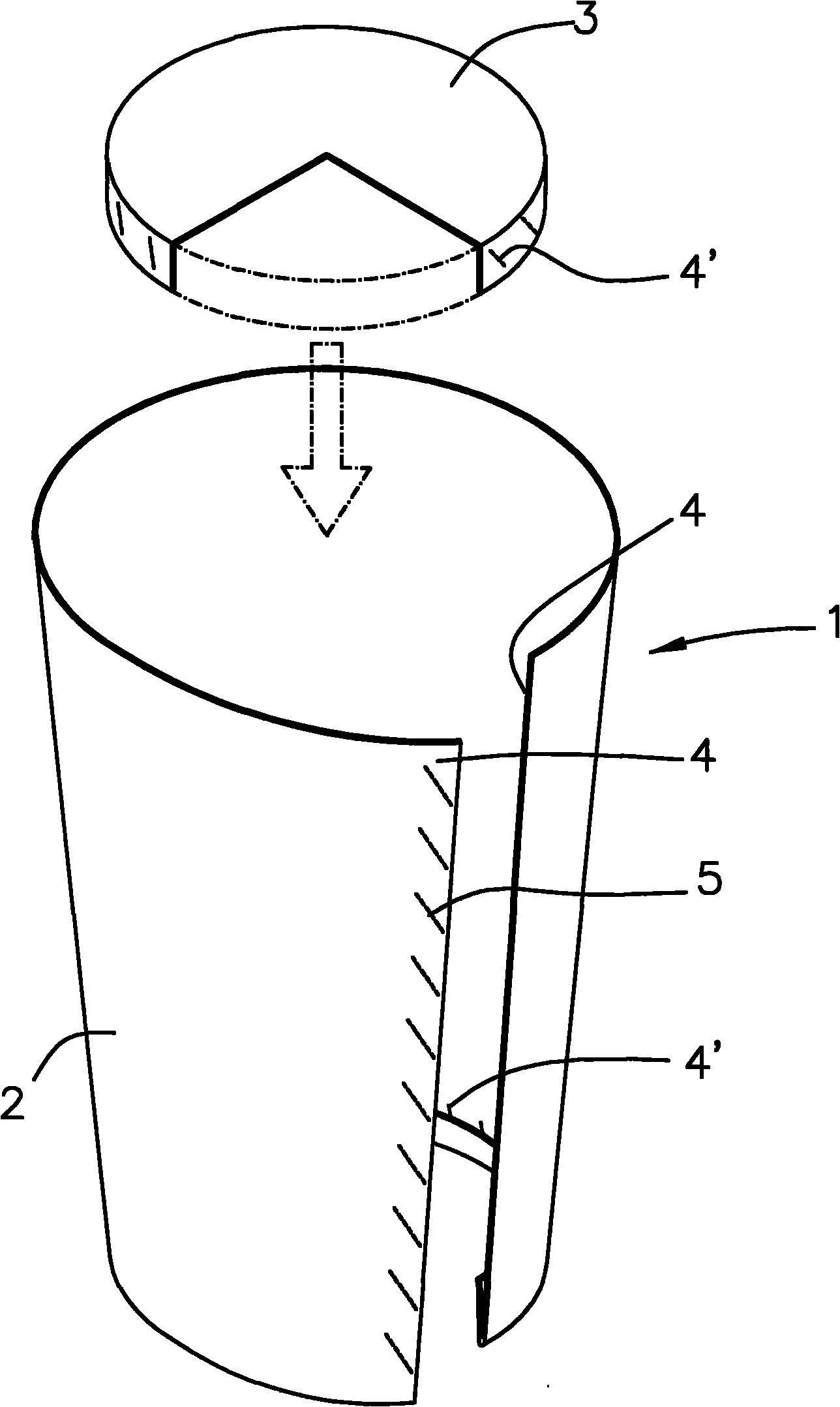

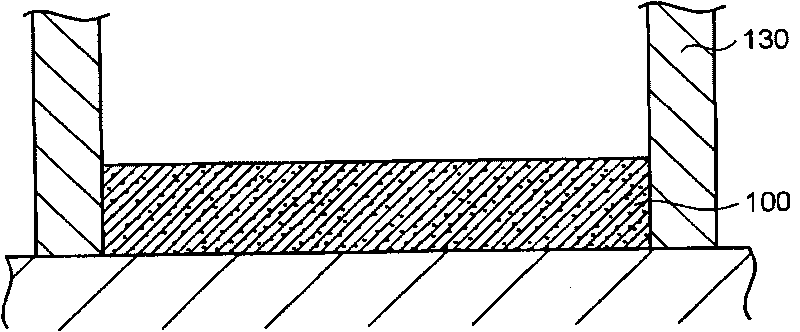

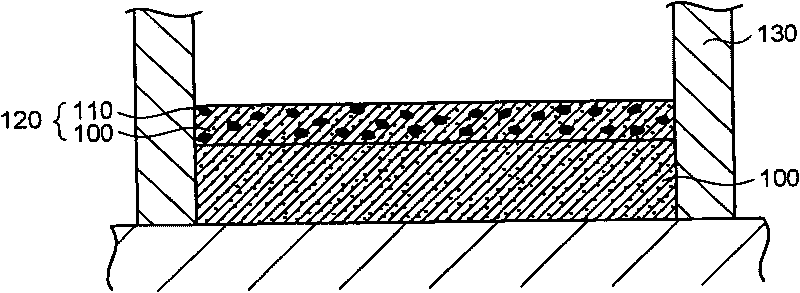

Method for manufacturing paper container and paper container

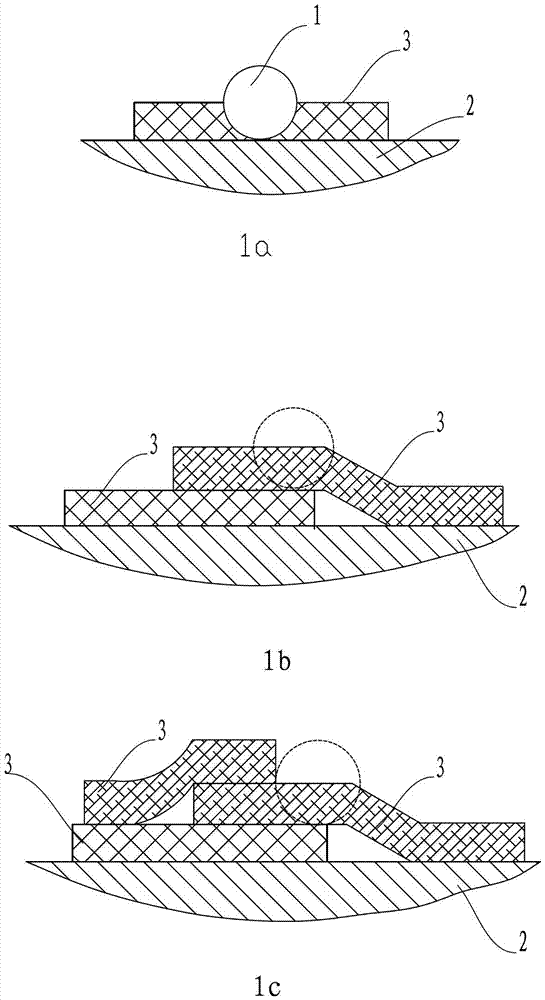

InactiveCN101875248AStrong binding strengthFast productionBio-packagingBox making operationsPulp and paper industryViscosity

The invention discloses a method for manufacturing a paper container and the paper container. The manufacturing method comprises the steps of printing, laminating and heat sealing, and comprises the following specific steps of: printing a paper substrate, wherein the paper substrate comprises at least one pair of jointing edges, and at least one of the pair of the jointing edges is provided with one or more grooves; in the paper substrate, paving and laminating a waterproof thermally-bonded film on at least one side with the groove; and under the heating condition, making the waterproof thermally-bonded film generate viscosity, and bonding the jointing edge with the groove and the corresponding jointing edge under increased pressure subsequently. The paper container comprises a body part and a bottom plate positioned at the bottom end of the body part. The manufacturing method can slow down the degree of temperature reduction of the waterproof thermally-bonded film during the heat sealing, additionally provides an unsmooth surface required by increasing bond strength, achieves the prospective bond strength, and reduces overall time required by the heat sealing step; and the paper container has the advantages of high manufacturing speed and high bond strength.

Owner:RICH CUP BIO CHEM TECH

Electrostatic spraying type high abrasion-resistant powder coating and preparation method thereof

InactiveCN106833324AGood storage stabilityGuaranteed low temperature curingAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyAcrylic resin

The invention relates to an electrostatic spraying type high abrasion-resistant powder coating and a preparation method thereof. The electrostatic spraying type high abrasion-resistant powder coating is prepared from the following raw materials in parts by weight: 45 to 95 parts of polyurethane, 5 to 25 parts of hydroxy acrylic resin, 1 to 5 parts of epoxy resin, 5 to 15 parts of multiwall carbon nanotube, 2 to 8 parts of titanium dioxide, 1 to 4 parts of aluminum nitride, 5 to 15 parts of mica powder, 5 to 10 parts of talcum powder, 10 to 30 parts of titanium dioxide, 1 to 20 parts of pigment filler, 0.5 to 2 parts of dibutyltin dilaurate, 0.5 to 3 parts of benzoin, 1 to 3 parts of flatting agent, 0.1 to 1 part of anti-precipitating agent, and 2 to 40 parts of curing agent. The electrostatic spraying type high abrasion-resistant powder coating has the advantage that at the premise of ensuring good conductivity of the powder coating, the corrosion-resistant property of the coating is greatly improved.

Owner:TIANCHANG JINLING ELECTRONICS

Nano environmental protection liquid aluminium foil and its preparation method and use method

InactiveCN1429871ACorrosion resistance exceedsSufficient sourceLiquid surface applicatorsCoatingsSolventNanometre

An environmental-protection type nano-class liquid aluminium foil as a chemicoplating material on the surface of metal is prepared from pure coster oil, TDI, epoxy resin, aluminium powder and nano-class filler through a special process. It has solvent type and water type. Its advantages are low cost, excellent anticorrosion performance, and no environmental pollution.

Owner:程新华

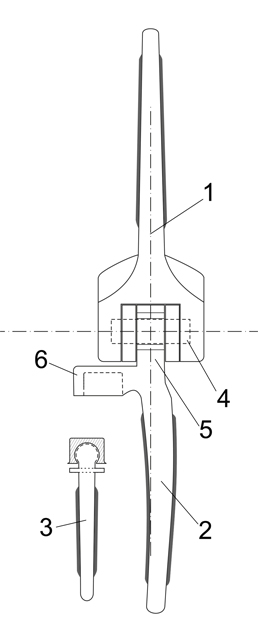

Anti-erosion gunning mix

The invention belongs to the technical field of unshaped refractory materials, and in particular relates to an anti-erosion gunning material. In the present invention, clay, glass fiber, and quartz stone are mixed and sieved to obtain a mixed powder, and then acrylic acid and sodium hydroxide solution are mixed and stirred with mixed powder and sodium dodecylbenzenesulfonate to obtain an emulsified mixed liquid, and the emulsified The mixed solution is reacted with Tween-80, ammonium persulfate, etc. to prepare a binder, and then the graphite, alumina and rice husk are crushed and sieved, and then calcined to obtain a calcined product, which is mixed with zirconium boride, aluminum-magnesium tip After the spar is ball milled and sieved, it is fully stirred evenly with magnesia, high-alumina bauxite, binder, etc. to obtain an anti-erosion gunning material. The gunning material prepared by the present invention has good high-temperature strength, good Volume stability and excellent corrosion resistance make it an ideal material for hot repair of refractory parts.

Owner:常州市泰英物资有限公司

Alloy powder for manufacturing high-entropy alloy coatings, and manufacturing method and application for alloy powder

InactiveCN103394685BHigh bonding strengthAccelerated corrosionMetallic material coating processesHigh entropy alloysCobalt

The invention discloses alloy powder for manufacturing high-entropy alloy coatings, and a manufacturing method and application for the alloy powder. The alloy powder comprises raw material powder including, by mole percent, 10%-20% of molybdenum, 10%-20% of iron, 10%-20% of chromium, 0-15% of titanium, 10%-20% of tungsten, 5%-20% of silicon, 0-10% of boron, 10%-20% of cobalt and 0-15% of aluminum. The alloy powder, the manufacturing method and the application have the advantages that the alloy powder is applicable to surface laser cladding modification for iron-based materials, heat cracking cannot occur easily in cladding procedures, cladding layers which is fine in structure, free of holes and high in bonding strength can be effectively formed, and structural stress and heat stress on the cladding layers in the laser cladding procedures can be reduced; after the alloy powder is subjected to cladding, the laser cladding layers are fine in structure and free of holes and cracking, and the bonding strength between each cladding layer and a base material is high; the formed cladding layers are high in hardness, abrasion resistance, corrosion resistance and fatigue resistance.

Owner:GUIZHOU UNIV

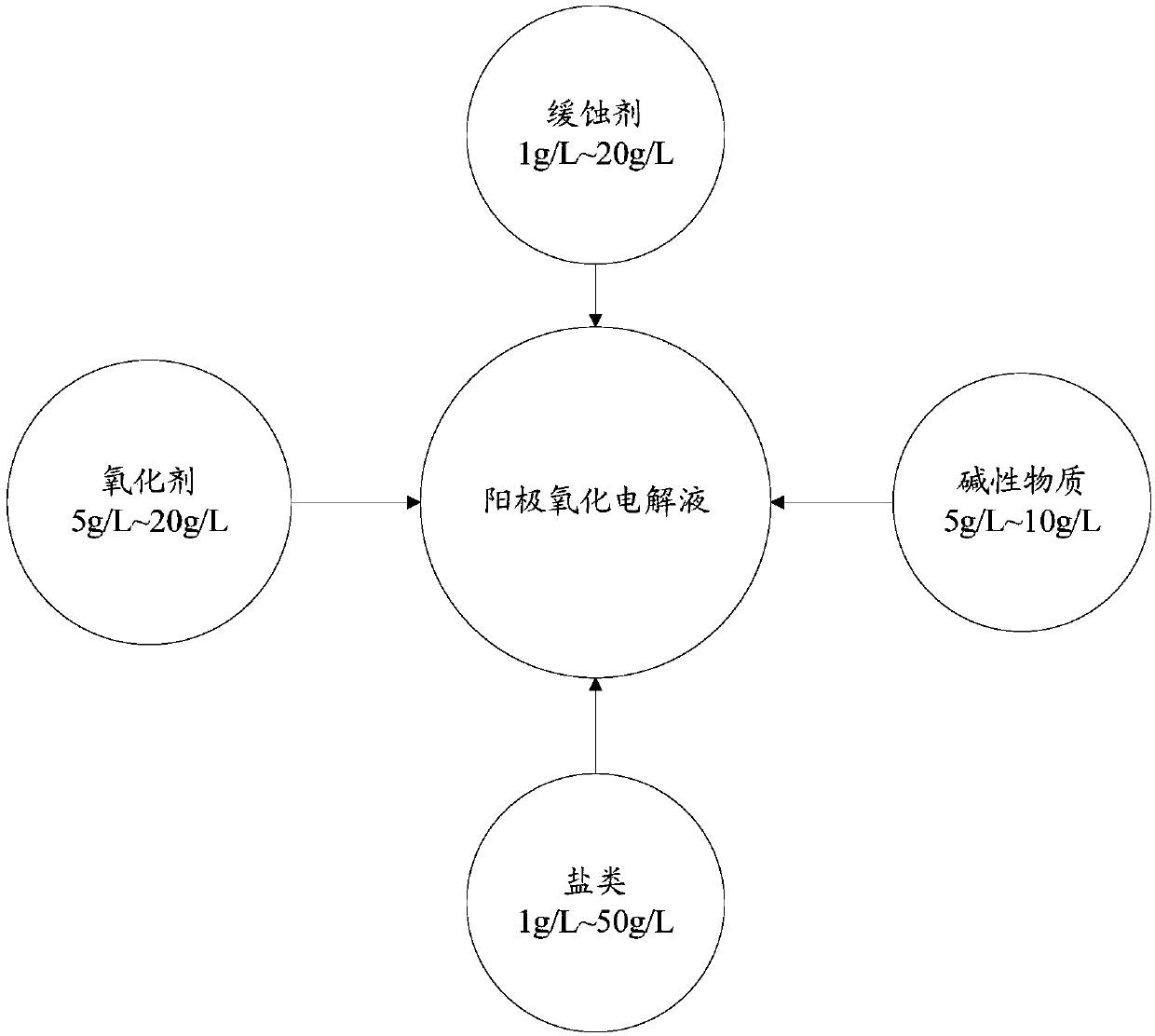

Anodizing electrolyte and preparation method of magnesium alloy and resin complex

InactiveCN107779931AStrong binding strengthHigh bonding strengthAnodisationSodium bicarbonatePhosphate

The invention provides an anodizing electrolyte and a preparation method of a magnesium alloy and resin complex, wherein the anodizing electrolyte is prepared from the following components with mass concentration: an inhibitor of which the mass concentration is 1g / L-20g / L, an oxidizer of which the mass concentration is 5g / L-20g / L, salts of which the mass concentration is 1g / L-50g / L, and alkaline matters of which the mass concentration is 5g / L-10g / L, wherein the salts include at least one of phosphate, molybdate and sulfate; and the alkaline matters include at least one of sodium hydroxide, sodium carbonate, sodium bicarbonate, potassium hydroxide, potassium carbonate, potassium bicarbonate, hydrazine hydrate and ammonia water. Because alkaline liquor is added to the anodizing electrolyte,in the process of anodizing magnesium alloy, a nano-scale porous membrane formed on the surface of the magnesium alloy is more uniform, so that when the magnesium alloy is subjected to subsequent injection molding treatment, resin enters nano-scale pores and troughs during injection molding, and then, the magnesium alloy and the resin part have higher bonding strength.

Owner:广东东明新材科技有限公司 +1

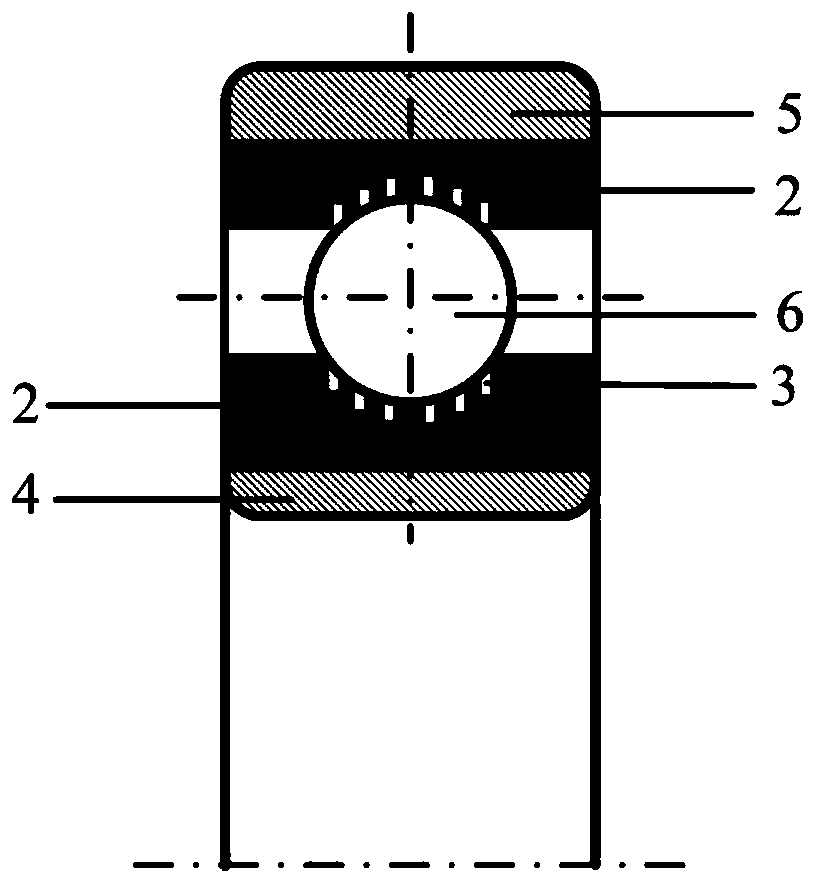

Composite bearing member, manufacturing method of composite bearing member, bearing device and rotary electrical machine

Owner:KK TOSHIBA

Preparation method of hard tissue substitute material

The invention provides a preparation method of a hard tissue substitute material, which comprises the following steps of: S1, preparation of nano-hydroxyapatite powder; S2, pretreatment of a substrate; S3, preparation of an electrophoretic deposition suspension; S4, electrophoretic deposition treatment. The hard tissue substitute material prepared by the method of the invention has good interface bonding strength; no later crystallization heat treatment is necessary; and thus phase transition and decomposition of a bio-coating during high temperature heat treatment are prevented. The method of the invention is simple and practical in operation, and the obtained coating is low in product cost.

Owner:HUIZHOU BYD ELECTRONICS

Manufacturing method for printed circuit board covered with coating copper layers

InactiveCN105050327AControl depthIncrease contact areaCircuit precursor manufactureManufacturing technologyCopper coating

The invention discloses a manufacturing method for a printed circuit board coveried with coating copper layers, and relates to the circuit board production and manufacturing technology field. The manufacturing method comprises the following steps: firstly, a circuit board with a surface covered with copper foil is provided, part of copper is etched in a position, corresponding to a position of the circuit board needing drilling of a through hole, of the copper foil surface, thus a recess groove is formed in the copper foil surface, and the size of the recess groove is more than the hole diameter of through hole; secondly, the through hole in the first step is drilled; thirdly, full plate electroplating is carried out, and thus the surface of the circuit board and the inner wall of the through hole are covered with copper layersl fourthly, the through hole is subjected to resin filling, the resin for filling is subjected to flatting processing, and thus the outer surface of the covering copper layer is flat. The manufacturing method facilitates to remove the filling resin at the dense hole, manufacturing of copper coating is carried out after part of the recess groove is subjected to electrocoppering, and electrocoppering in the recess groove leaves copper reduction allowance for board wearing, and facilities flatting processing of the hole position. In addition, the contact area of the covered copper layer and the surface copper foil of the circuit board are increased, and the bonding strength is high.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

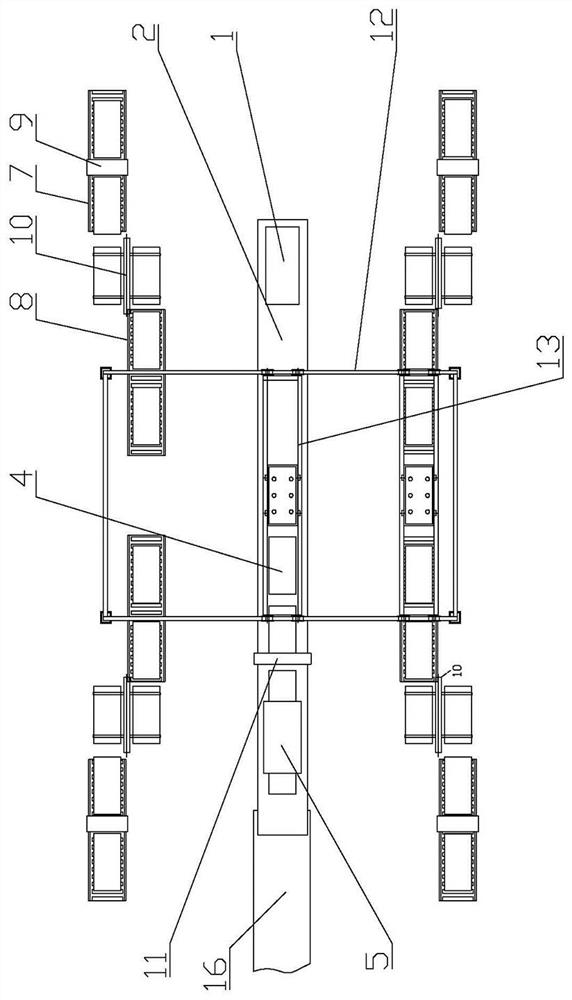

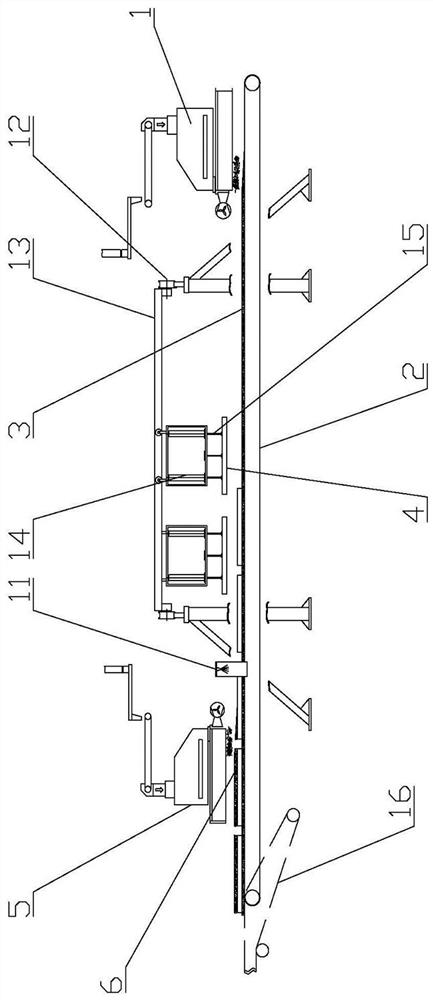

Fine material veneer processing artificial board paving process

ActiveCN112873444AIncrease productivityReduce manufacturing costPlywood pressesVeneer pressesAdhesive cementProduction line

The invention relates to the technical field of artificial board finish processing, and particularly relates to a fine material veneer processing artificial board paving process. The process comprises the following steps: S1, lower surface layer fine material paving: uniformly paving a fine material mixed with adhesives on a first conveying line running at a constant speed through a first paving machine to form a lower surface layer fine material; S2, single-side gluing of a core veneer: coating the upper surface of the core veneer placed on a second conveying line with the adhesive; and S3, blank assembling: forming a board blank through the lower surface layer fine material, the upper surface layer fine material and the core veneer. According to the process, the fine material mixed with the adhesives is directly paved on the upper layer and the lower layer of the core veneer to obtain the board blank, the veneer artificial board can be obtained through hot pressing in the later period, veneer materials do not need to be pressed and pasted after the surface of the artificial board is subjected to dust scraping and sanding treatment, the whole paving process achieves mechanical operation of a production line, all steps work cooperatively, the production efficiency of the veneer artificial board is obviously improved, and the production cost is reduced.

Owner:TREEZO NEW MATERIAL TECH GRP CO LTD

Abrasion-resisting and high-temperature-resisting power box housing and preparation method thereof

InactiveCN107686939AHigh hardnessChange the shape of the organizationSubstation/switching arrangement detailsMetallic material coating processesCeramic coatingImpurity

The invention discloses an abrasion-resisting and high-temperature-resisting power box housing and a preparation method thereof. The housing comprises a power box housing metal substrate and a ceramiccoating. Raw materials of the power box housing metal substrate comprise the following components of C, Al, B, Si, Mn, Cr, Ni, Cu, Ti, Zr, Nb, Mo, Sc, Nd, Y, La and the balance Fe and inevitable impurities. Raw materials of the ceramic coating comprise BC, SiC, Cr3C2, B2O3, ZrO2 and BN. The abrasion-resisting and high-temperature-resisting power box housing and the preparation method thereof havethe advantages of being resistant to a high temperature and creep deformation, good in tenacity, good in corrosion resistance, long in service life and the like.

Owner:芜湖锐华暖通科技股份有限公司

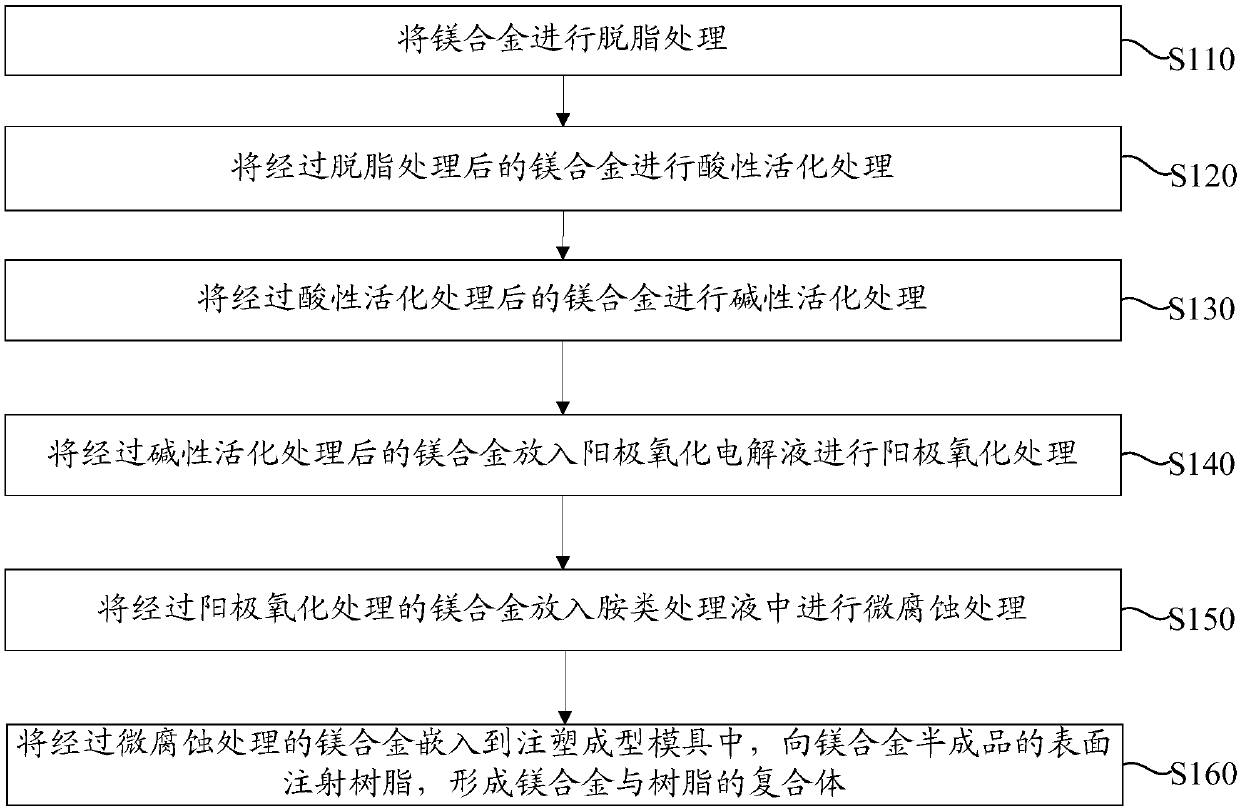

Magnesium alloy surface treatment method and preparation method of composite body of magnesium alloy and resin

ActiveCN107881545AStrong binding strengthHigh bonding strengthAnodisationPorous membraneBonding strength

The invention discloses a preparation method of a composite body of a magnesium alloy and resin. A magnesium alloy surface treatment method comprises the following steps that a magnesium alloy base material is provided; the magnesium alloy base material is subjected to ungrease treatment; the magnesium alloy base material subjected to ungrease treatment is subjected to acid activating treatment; the magnesium alloy base material subjected to acid activating treatment is subjected to alkaline activating treatment; the magnesium alloy base material subjected to alkaline activating treatment is subjected to anodic oxidation treatment; and the magnesium alloy base material subjected to anodic oxidation treatment is placed into amine treatment liquid to be subjected to microcorrosion treatment.According to the magnesium alloy surface treatment method, a nanoscale porous membrane can be formed on the surface of the magnesium alloy, a plurality of thin and small grooves and nanoscale holes are formed in the surface of the nanoscale porous membrane, through the holes and the grooves, when the magnesium alloy base material is subjected to subsequent injection molding treatment, during injection molding, the resin enters the nanoscale holes and the grooves, and thus high bonding strength is achieved between the magnesium alloy base material and the resin part.

Owner:广东东明新材科技有限公司

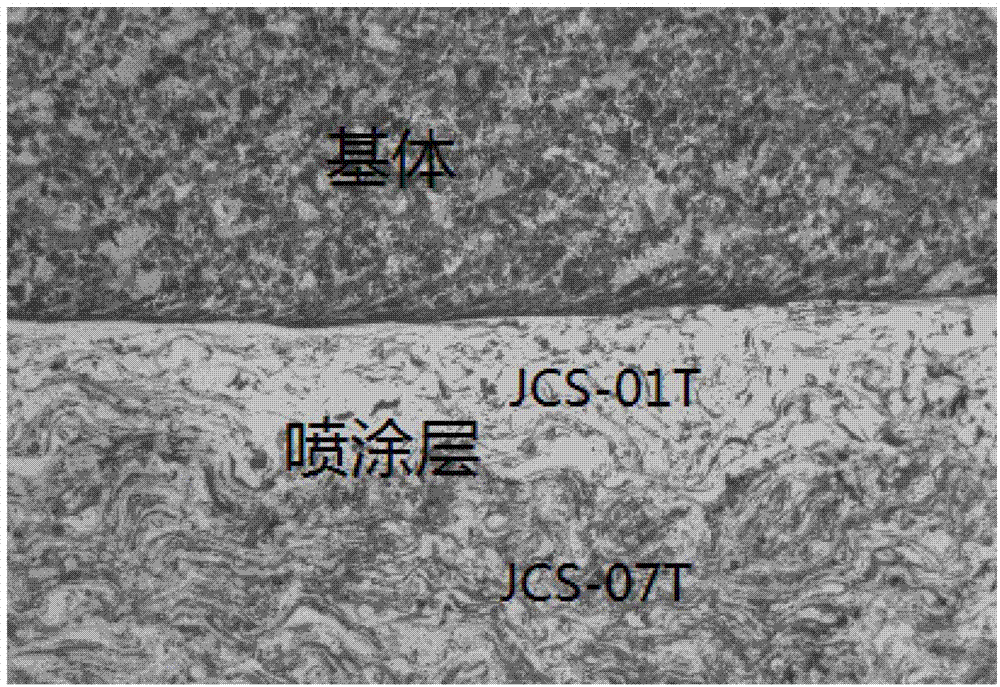

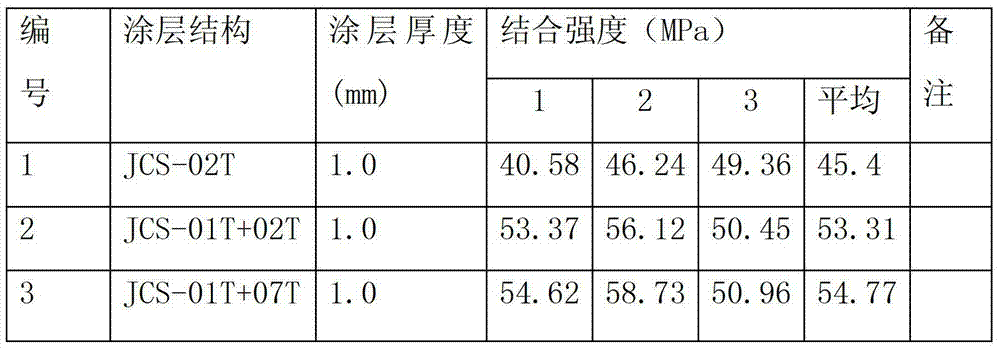

Protection method of blast furnace cooling wall and protection coating

InactiveCN103397124APerformanceExcellent high temperature mechanical propertiesMolten spray coatingCooling devicesRare-earth elementSurface cooling

The invention discloses a protection method of a blast furnace cooling wall. The protection method comprises the following steps of: (a) carrying out surface pretreatment on the blast surface cooling wall, removing attachments on the surface of the cooling wall and simultaneously roughening and activating the surface; (b) spraying and bottoming an alloy layer on the surface of the blast surface cooling wall, wherein the bottoming alloy layer comprise the alloy elements in percent by mass: 3-10% of Al, 2-5% of Fe, 80-90% of Ni and 2-5% of rare-earth elements; (c) spraying a working alloy layer on the surface of the bottoming alloy layer, wherein the working alloy layer comprises the alloy elements in percent by mass: 1-3% of Co, 18-30% of Cr, 10-20% of Mo, 2-6% of W, 2-5% of rare-earth elements and the balance of Ni; and (d) carrying out subsequent hole sealing treatment on the working alloy layer and the bottoming alloy layer. Under the premise of not influencing the capability of a base body of the cooling wall, a coating has the advantages of high hardness, high-temperature oxidation resistance, wear resistance and good thermal shock resistance.

Owner:山东金萃冶金技术有限公司

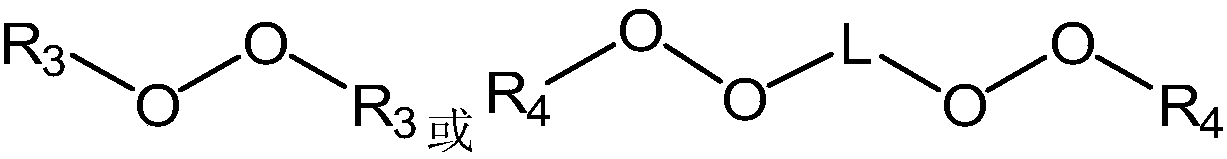

Modified cellulose diacetate as well as preparation method and application thereof

ActiveCN109503892AIncrease melt viscosityFeel comfortableAdditive manufacturing apparatusCellulose diacetateCellulose acetate

The invention belongs to the field of cellulose diacetate products, and particularly relates to a modified cellulose diacetate product as well as a preparation method and application thereof to 3D printing and other fields. The modified cellulose diacetate provided by the invention is prepared by mixing cellulose diacetate, a plasticizer, a hindered phenol antioxidant, a phosphite antioxidant andperoxide. The cellulose diacetate can be used as a 3D printing material for preparing products by adopting a 3D printing method.

Owner:SICHUAN PUSH CELLULOSE ACETATE CO LTD

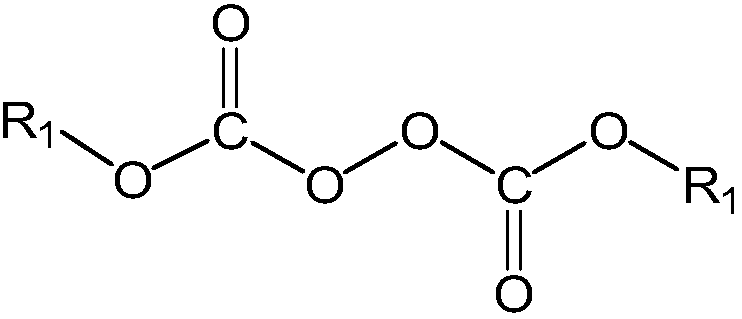

Resin adhesive with high waterproofness and high durability

InactiveCN106367001AStrong binding strengthHigh densityNon-macromolecular adhesive additivesBituminous material adhesivesMicrocrystalline waxMicrosphere

The invention discloses a resin adhesive with high waterproofness and high durability. The resin adhesive is prepared from the following raw materials in parts by weight: 40 to 90 parts of unsaturated resin 189, 5 to 15 parts of modified asphalt, 1 to 8 parts of natural gas-based slot black, 2 to 4 parts of cotton flocks, 5 to 15 parts of glass fibers, 5 to 15 parts of mica powder, 1 to 8 parts of hollow microspheres, 5 to 12 parts of titanium dioxide powder, 2 to 6 parts of calcined clay, 5 to 15 parts of organic bentonite, 2 to 7 parts of wollastonite powder, 2 to 10 parts of 1,1-di(tert-butylperoxy)cyclohexane, 5 to 15 parts of microcrystalline wax, 1 to 6 parts of hydroxyethyl methylcellulose, 2 to 8 parts of fumed silica and 50 to 120 parts of water. The resin adhesive provided by the invention is extremely high in waterproofness and high in corrosion resistance and durability.

Owner:ANHUI SKY EYE INTELLIGENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com