Papermaking enhancer and preparation method thereof

A papermaking strengthening agent and initiator technology, applied in the field of papermaking, can solve problems such as single function, toxicity, and unsuitable for large-scale use, and achieve the effects of wide application fields, improved surface strength, and improved quality grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

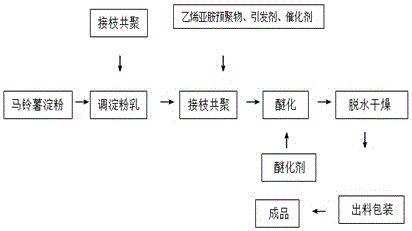

Method used

Image

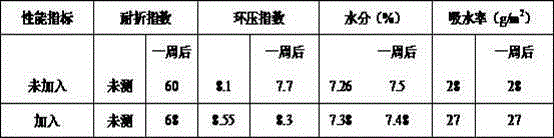

Examples

Embodiment Construction

[0034] The present invention will be further described in conjunction with specific examples below.

[0035] Example:

[0036] Step 1: Add 100g of ethyleneimine monomer powder to the three-necked bottle, and spray 20g of distilled water at the same time (it must be sprayed into a mist) and stir, and add initiator 0.1g ammonium persulfate and 0.02g sulfurous acid while stirring Sodium hydrogen, in a water bath, prepolymerized at 56°C for 1 hour, dried to obtain 10.2g of crystalline powder prepolyethyleneimine, and its molecular weight was below 500,000.

[0037] Step 2: Equip a 500ml four-necked flask with a stirrer, a constant pressure dropping funnel and a thermometer, and heat it in an oil bath filled with silicone oil. Add 140g of potato starch to the equipped flask, start stirring, add 60g of pre-polyethyleneimine, spray 50g of deionized water in the form of mist, add initiator 0.5g of ammonium persulfate and 0.3g of sodium bisulfite, and add Self-made catalyst ferric ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com