Composite bearing member, manufacturing method of composite bearing member, bearing device and rotary electrical machine

一种复合轴承、制造方法的技术,应用在轴承元件、轴承、轴和轴承等方向,能够解决功率限制、生产成本增加、昂贵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

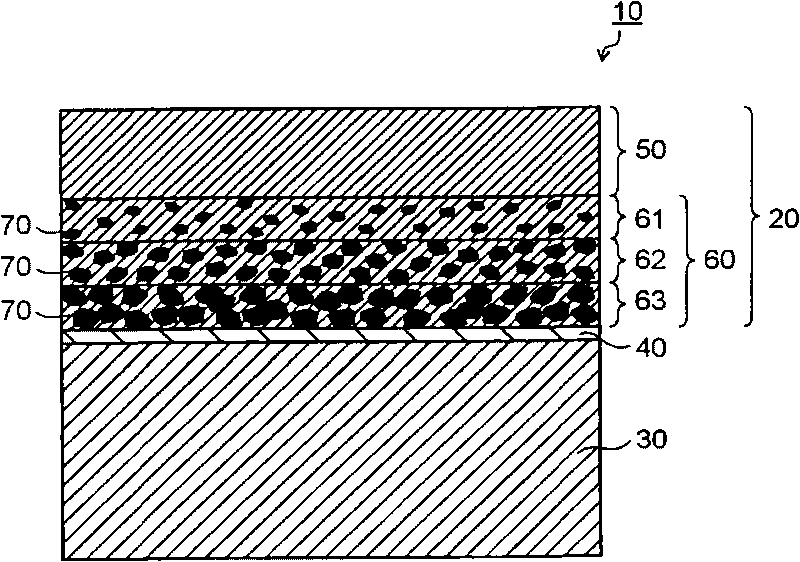

[0095] In the actual embodiment 1, the composite bearing member 10 is combined with Figure 2A-2E Fabricated in a similar manner to the first fabrication method shown in .

[0096] In the following, reference will be made to Figure 2A-2E A method of manufacturing the composite bearing member 10 used in Practical Example 1 will be described.

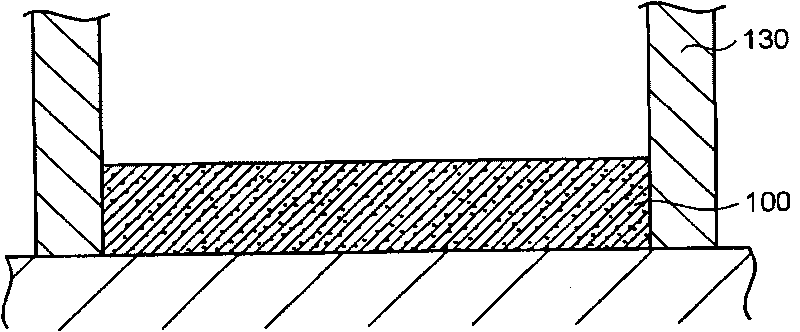

[0097] First, prepare resin particles 100 made of PTFE resin with an average particle diameter of 5 μm. It should be noted that the average particle size mentioned refers to the median value of the particle size. The average particle size is measured by a laser diffraction particle size distribution measurement method. Hereinafter, the meaning and measuring method of the average particle diameter are the same as those indicated above.

[0098] In addition, metal particles 110 made of a tin-copper-silver alloy (Sn-0.5 wt. % Cu-3.0 wt. % Ag) are prepared to be included in the composition-graded layer 60 . Here, the average particle di...

Embodiment 2

[0115] In the actual example 2, using the Figures 3A-3G The second manufacturing method shown produces composite bearing member 10 similar to the manufacturing method.

[0116] In the following, reference will be made to Figures 3A-3G A method of manufacturing the composite bearing member 10 used in Practical Example 2 will be described.

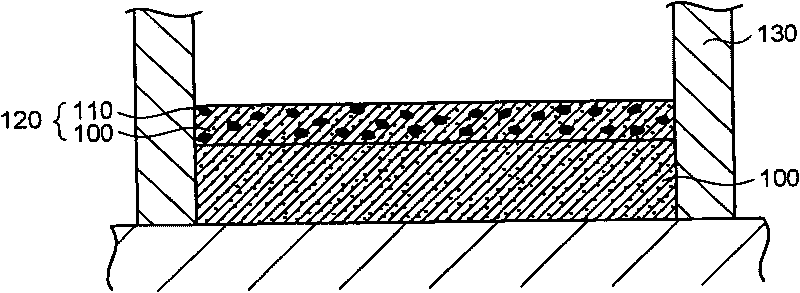

[0117] First, resin particles 100 made of PTFE resin having an average particle diameter of 5 μm are prepared. In addition, metal particles 111 made of a first metal material having a melting point lower than a sintering point at which resin particles 100 are sintered are prepared. The metal particles 111 are used to form pores to be contained in the composition-graded layer 60 into which the second metal material penetrates.

[0118] Here, the average particle diameter of the metal particles 111 used to form the metal material containing layer 61 is 25um, the average particle diameter of the metal particles 111 used to form the metal m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com