Modified cellulose diacetate as well as preparation method and application thereof

A modified technology of cellulose diacetate, applied in the direction of additive processing, etc., can solve the problems of weak layer-to-layer adhesion, yellowing of product color, high melt viscosity, etc., and achieve bright surface, good chroma, Effect of increasing melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

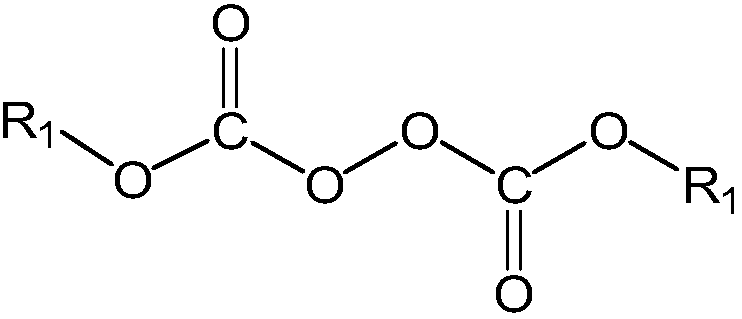

Method used

Image

Examples

Embodiment 1

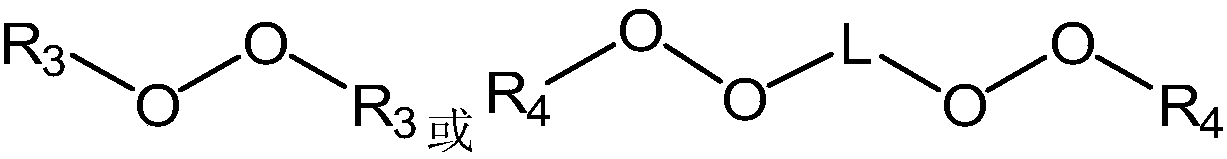

[0041] In terms of weight percentage, according to the total amount designed in the test, weigh 0.2% hindered phenolic stabilizer 1076 and 0.2% phosphite stabilizer 626 in 20% plasticizer DOP according to the following proportions, and the dispersed The stabilizer solution was mixed with 77.8% cellulose diacetate in a high-speed mixer for 40 minutes, and after 12 hours of aging at room temperature, 1.8% dialkyl peroxide was added. The peroxide R 4 It is a tert-butyl group, L is a C straight chain containing 6 C atoms, mix evenly and extrude and granulate on a twin-screw machine. ℃, 205°C, 210°C, 215°C, 225°C, the head temperature is 225°C, the host speed is 120r / min, and the feeding speed is 40r / min to obtain transparent rubber particles, which are finally dried and packaged.

Embodiment 2

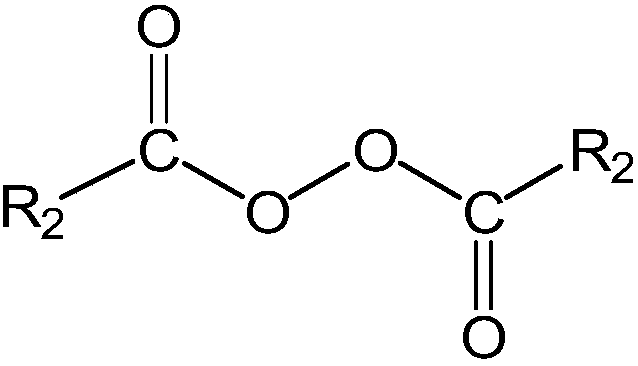

[0043] In percent by weight, according to the total amount designed in the test, weigh 0.2% hindered phenolic stabilizer 1098 and 0.5% phosphite stabilizer 626 and dissolve them in 32% plasticizer DMP according to the following proportions, and the dispersed The stabilizer solution was mixed with 67.2% cellulose diacetate in a high-speed mixer for 40 minutes, and after aging at room temperature for 15 hours, 0.1% acyl peroxide was added. The peroxide R 2 For acetyl, mix evenly and extrude and granulate on the twin-screw machine. The twin-screw machine starts from the feeding section, and the temperature settings are 160°C, 185°C, 200°C, 205°C, 205°C, 210°C, 215°C, and 225°C. , the head temperature is 225°C, the host speed is 120r / min, and the feeding speed is 40r / min to obtain transparent rubber particles, which are finally dried and packaged.

Embodiment 3

[0045] In terms of weight percentage, according to the total amount designed in the test, weigh 0.5% hindered phenolic stabilizer 1010 and 0.3% phosphite stabilizer 168 in 45% plasticizer DEP according to the following proportions, and the dispersed The stabilizer solution was mixed with 54.199% cellulose diacetate in a high-speed blender for 40 minutes, aged at room temperature for 12 hours and added with 0.001% dialkyl peroxide, the peroxide R 3 It is tert-butyl, and after mixing evenly, it is extruded and granulated on a twin-screw machine. The twin-screw machine starts from the feeding section, and the temperature settings are 160°C, 185°C, 200°C, 205°C, 205°C, 210°C, 215°C, 225°C, the temperature of the head is 225°C, the speed of the main machine is 120r / min, and the feeding speed is 40r / min to obtain transparent rubber particles, which are finally dried and packaged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com