Manufacturing method for printed circuit board covered with coating copper layers

A technology for printed circuit boards and manufacturing methods, applied in the directions of printed circuit manufacturing, printed circuits, manufacturing printed circuit precursors, etc., can solve problems such as difficulty, thickness of copper on circuit boards, unfavorable fine lines, etc., and increase the contact area. , the effect of strong bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

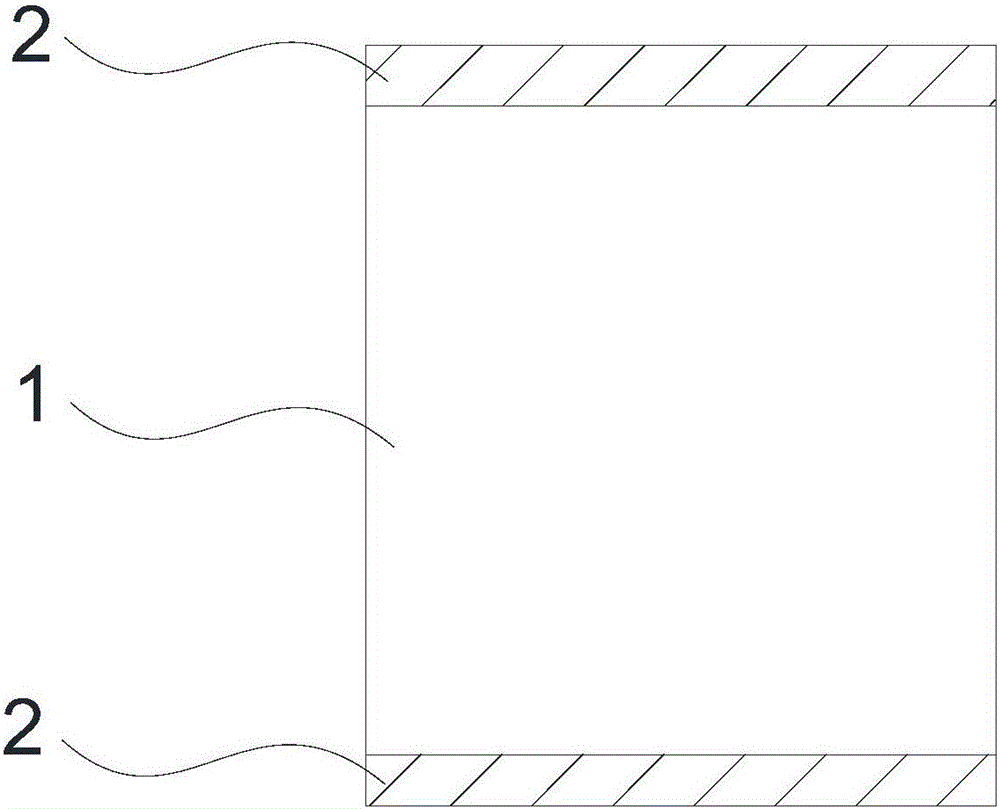

[0026] The anti-wrinkle method is used for typesetting and laminating the multi-layer board, and the following is obtained: figure 1 As shown in the circuit board, the circuit board includes a substrate 1 and copper foils 2 located on opposite surfaces of the substrate;

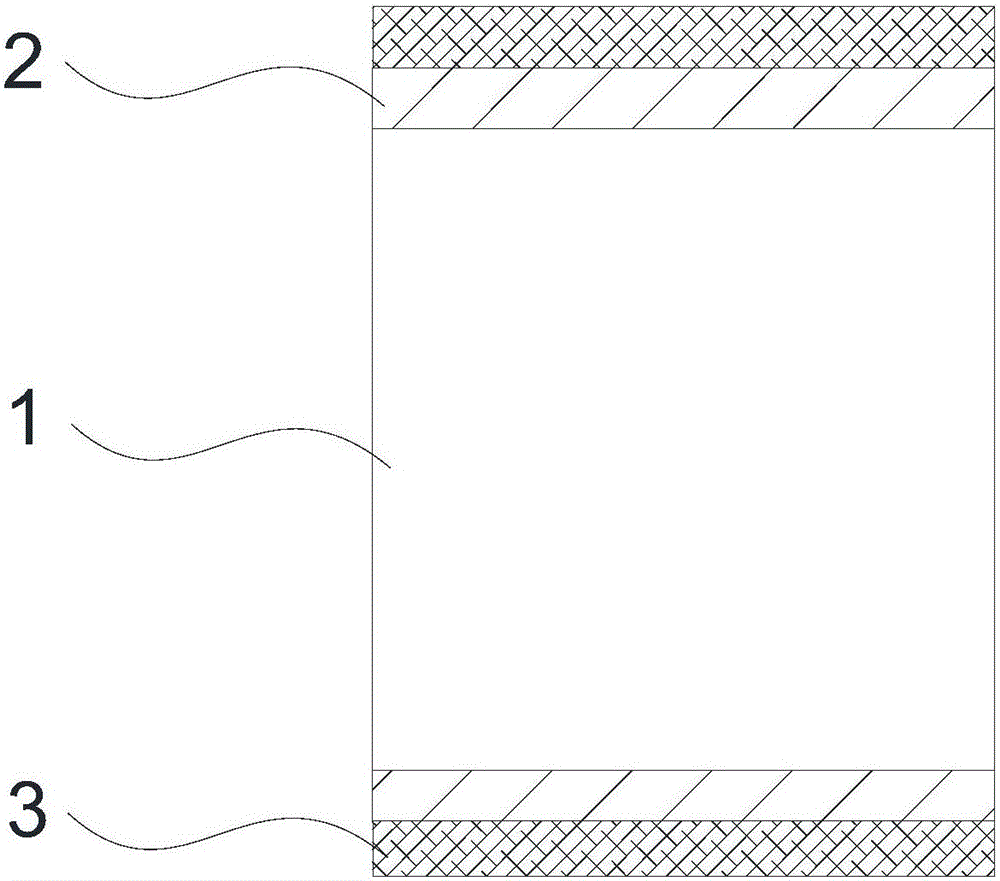

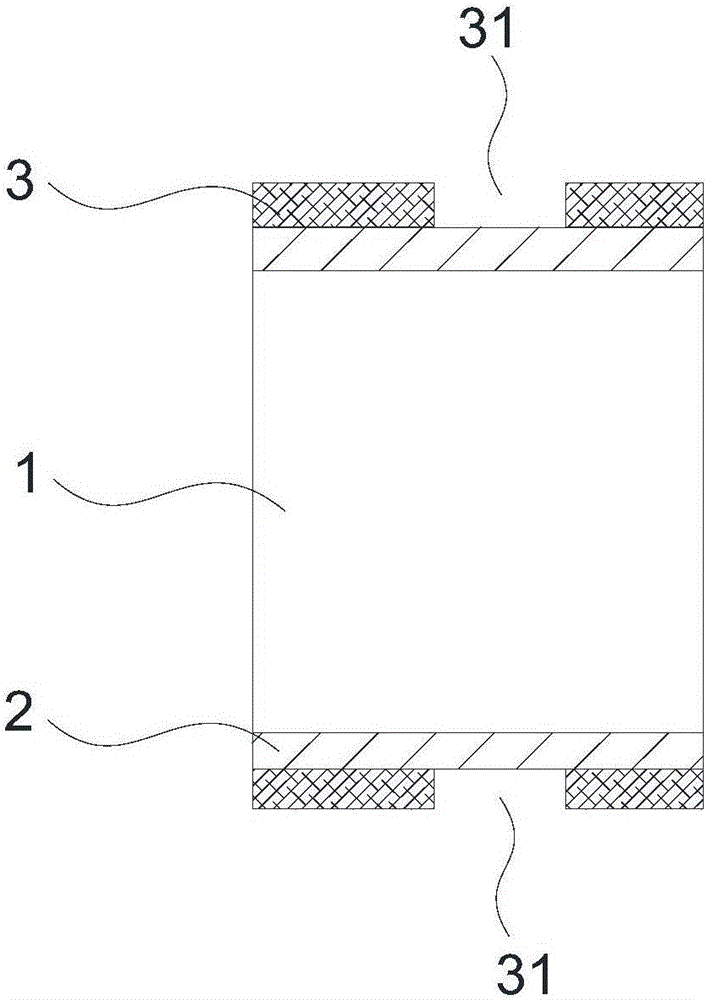

[0027] like figure 2 As shown, the circuit board is coated with dry film 3 on both sides after super-roughening treatment; image 3 As shown, after exposure and development, the dry film is made to form a circular window 31 corresponding to the position where the groove needs to be formed to expose the bottom copper. ).

[0028] Place the circuit board after the above treatment on the copper foil of a certain depth etched by the copper wire; control the Cu in the etching cylinder 2+ The concentration is 110-150g / L, the specific gravity is 1.23-1.33, the acidity is 1.5-3.8N, the temperature is 48-52°C, and the upper pressure is controlled at 0.8-2.0kg / cm 2 , the downforce is controlled at 0.8-1.5kg / cm 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com