Method for producing irregular-section composite pipe

A special-shaped cross-section, composite pipe technology, applied in the direction of furnace types, manufacturing tools, heat treatment equipment, etc., can solve the problems of large thermal resistance, inability to achieve high-efficiency heat transfer, and difficult metallurgical bonding of stainless steel pipes and aluminum alloys in large areas. Achieve wide application prospects, high interface heat transfer coefficient, and long bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

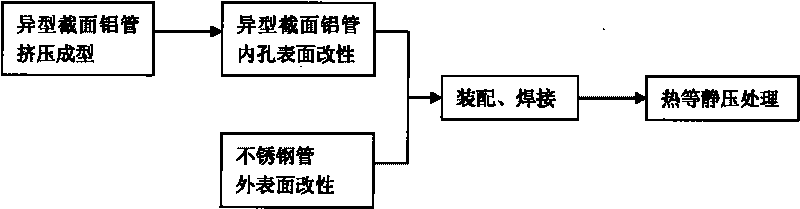

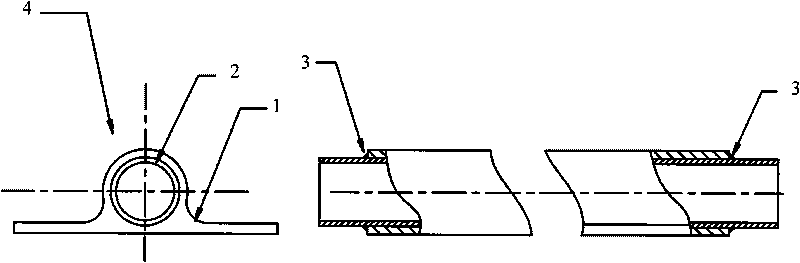

[0022] A preparation method of a special-shaped cross-section composite pipe, the method steps are as follows,

[0023] (1) Extrusion molding of special-shaped cross-section aluminum tube 1: the pure aluminum bar is put into the extrusion barrel of the extrusion machine, and the bar is preheated at 450°C for hot extrusion;

[0024] (2) Modification of the surface of the inner hole of the special-shaped cross-section aluminum tube 1: a nickel layer with a thickness of 5-10 μm is plated on the surface of the inner hole of the aluminum alloy by using the electroless plating technology.

[0025] (3) Modification of the outer surface of the stainless steel pipe 2: plating a nickel layer of 10-20 μm on the outer surface of the stainless steel pipe by electroplating technology;

[0026] (4) Assembly and welding: Insert the surface-modified stainless steel tube into the special-shaped cross-section aluminum tube with surface modification in the inner hole. The stainless steel tube is ...

Embodiment 2

[0030] A preparation method of a special-shaped cross-section composite pipe, the method steps are as follows,

[0031] (1) Extrusion molding of special-shaped cross-section aluminum tube 1: the bar material made of deformed aluminum alloy is loaded into the extrusion barrel of the extrusion machine, and the bar material is preheated at 470°C for hot extrusion molding;

[0032] (2) Surface modification of the inner hole of the special-shaped cross-section aluminum tube 1: use electroless plating technology to plate a 5-10 μm thick copper layer on the surface of the inner hole of the aluminum alloy.

[0033] (3) Modification of the outer surface of the stainless steel pipe 2: use electroplating technology to plate a layer of 10-20 μm copper layer on the outer surface of the stainless steel pipe;

[0034] (4) Assembly and welding: insert the surface-modified stainless steel tube into the special-shaped cross-section aluminum tube with surface modification in the inner hole. The ...

Embodiment 3

[0038] A preparation method of a special-shaped cross-section composite pipe, the method steps are as follows,

[0039] (1) Extrusion forming of special-shaped cross-section aluminum tube 1: the bar material made of deformed aluminum alloy is loaded into the extrusion barrel of the extrusion machine, and the bar material is preheated at 485°C for hot extrusion molding;

[0040] (2) Surface modification of the inner hole of the special-shaped cross-section aluminum tube 1: use electroless plating technology to plate a 5-10 μm thick copper layer on the surface of the inner hole of the aluminum alloy.

[0041] (3) Modification of the outer surface of the stainless steel pipe 2: use electroplating technology to plate a layer of 10-20 μm copper layer on the outer surface of the stainless steel pipe;

[0042] (4) Assembly and welding: insert the surface-modified stainless steel tube into the special-shaped cross-section aluminum tube with surface modification in the inner hole. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com