Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

117results about How to "High value available" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

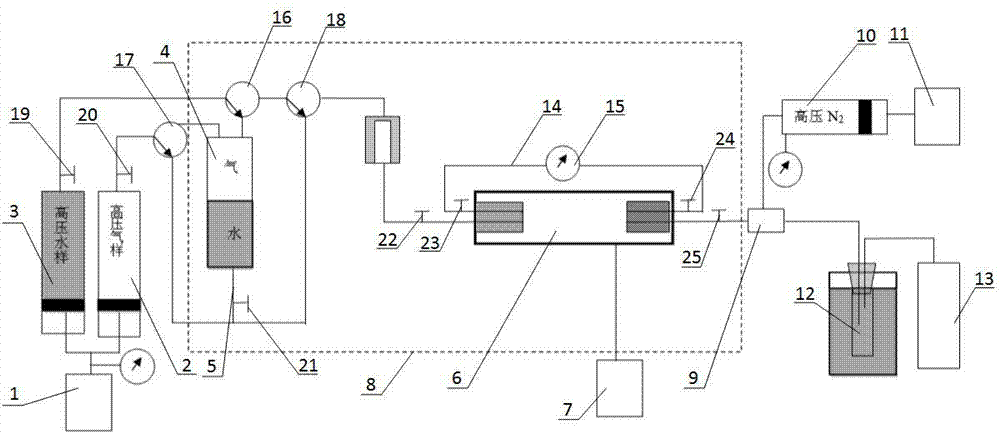

Determining method for stratum high-temperature high-pressure gas-phase and water-phase relative permeability curve

ActiveCN103645126AHigh value availableHigh precisionPermeability/surface area analysisRock coreGas phase

The invention discloses a determining method for a stratum high-temperature high-pressure gas-phase and water-phase relative permeability curve. The determining method comprises the following steps: S1, preparing a rock core; S2, preparing fluid; S3, carrying out a single separation test on balance gas and balance stratum water; S4, saturating the rock core with water; S5, carrying out a connecting flow and raising the temperature to generate a pressure; S6, carrying out a balance water-phase permeability Kw test; S7, carrying out a gas-driving-water process relative permeability test; S8, correcting an accumulated water yield amount W(t) and an accumulated gas yield amount G(t); converting a value recorded under a ground condition to a stratum condition; and S9, calculating a water-phase relative permeability rate Krw and a gas-phase relative permeability rate Krg at each moment, and a gas-containing saturation degree (Sge) of a rock sample outlet end face. The determining method for the stratum high-temperature high-pressure gas-phase and water-phase relative permeability curve has the beneficial effects that high-temperature and high-pressure conditions of a real gas deposit stratum are effectively simulated and the influences on rocks and the fluid by the high-temperature and high-pressure conditions of the stratum are sufficiently considered; a determined result meets the actual production and the usable value of experimental data is high; the disadvantages in an existing determining method are overcome.

Owner:SOUTHWEST PETROLEUM UNIV

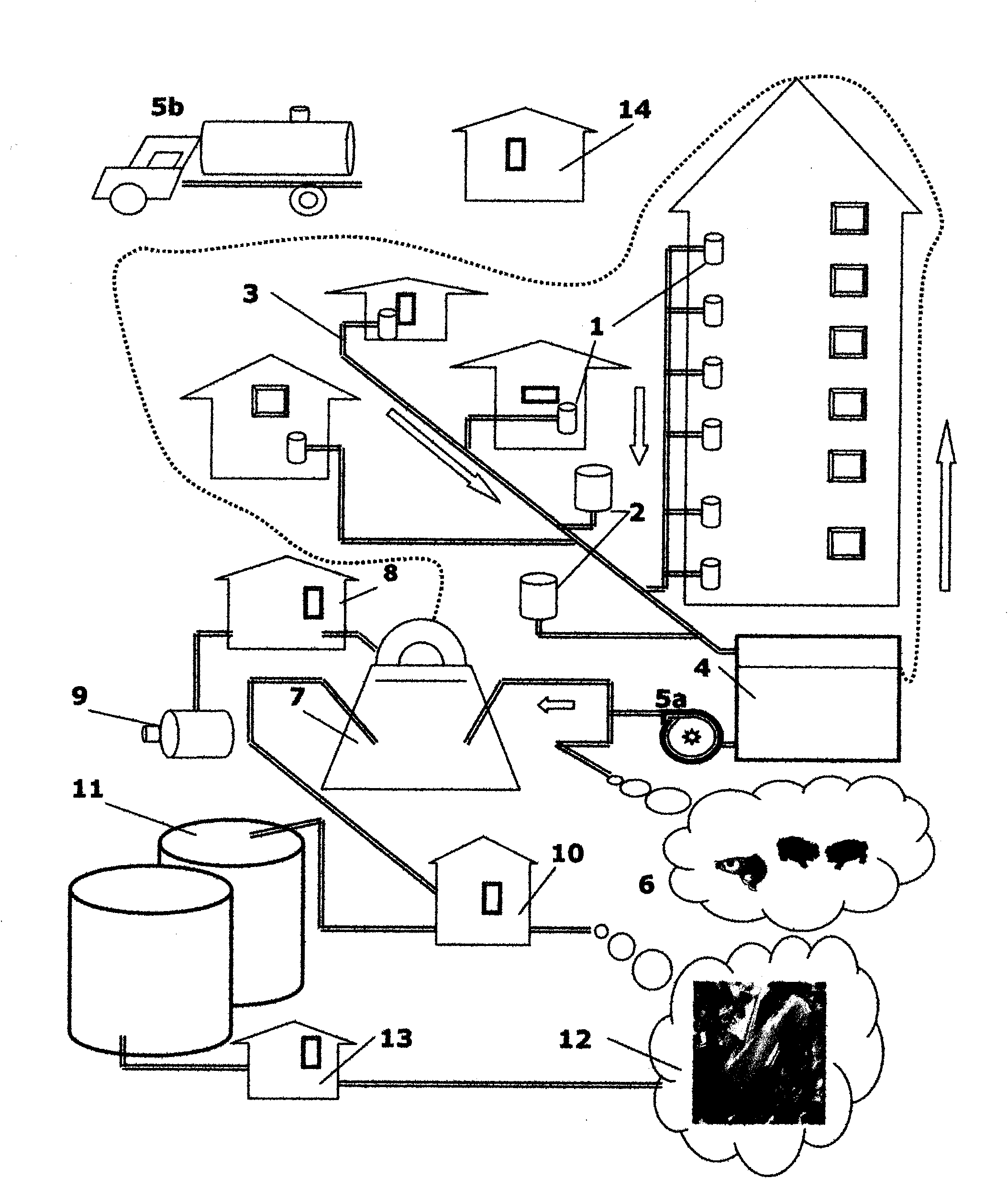

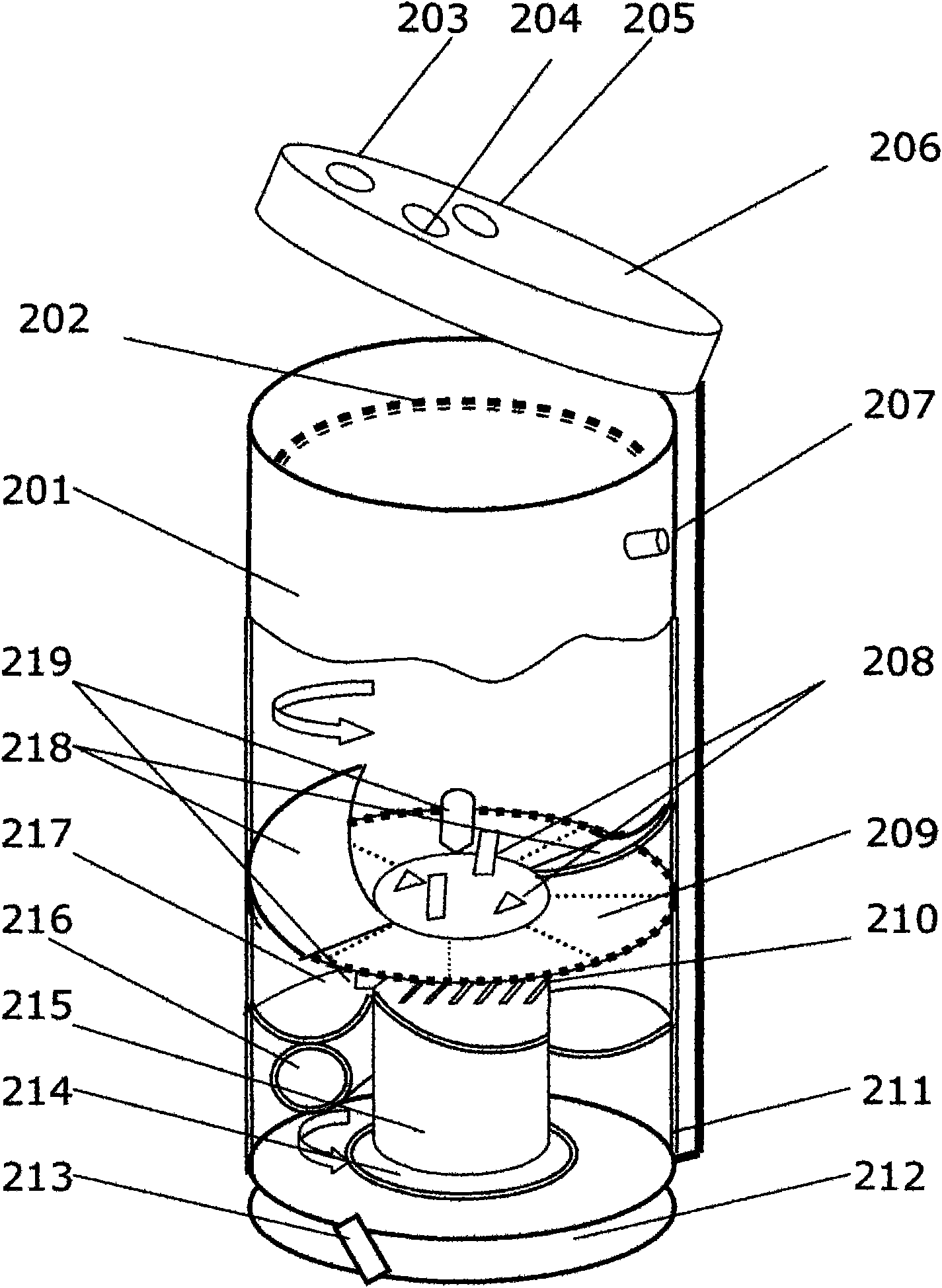

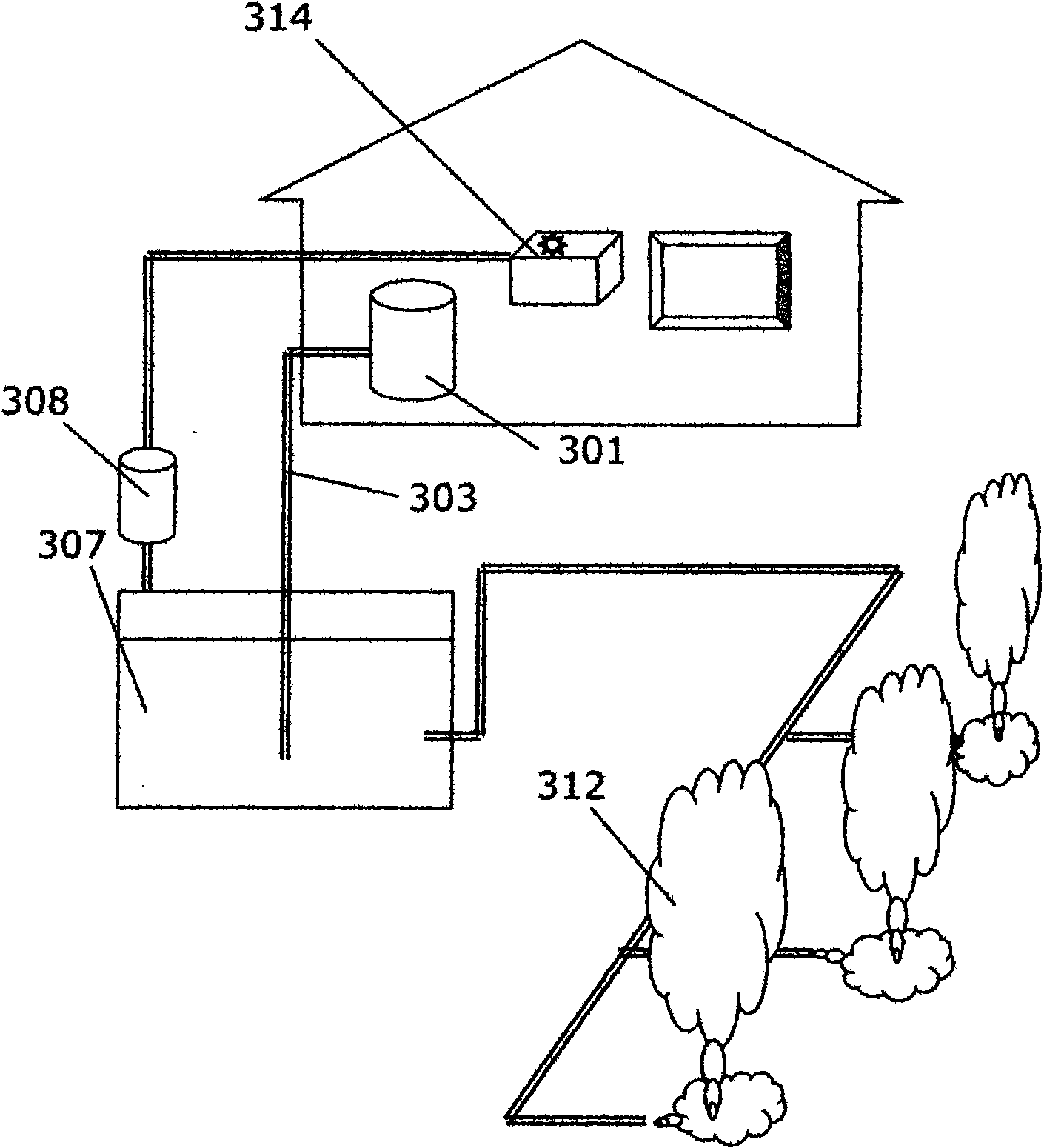

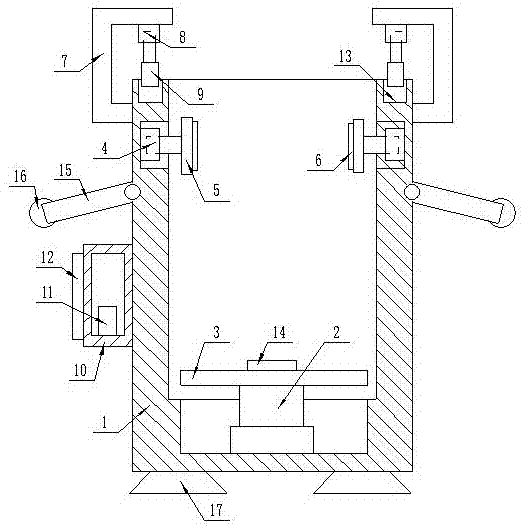

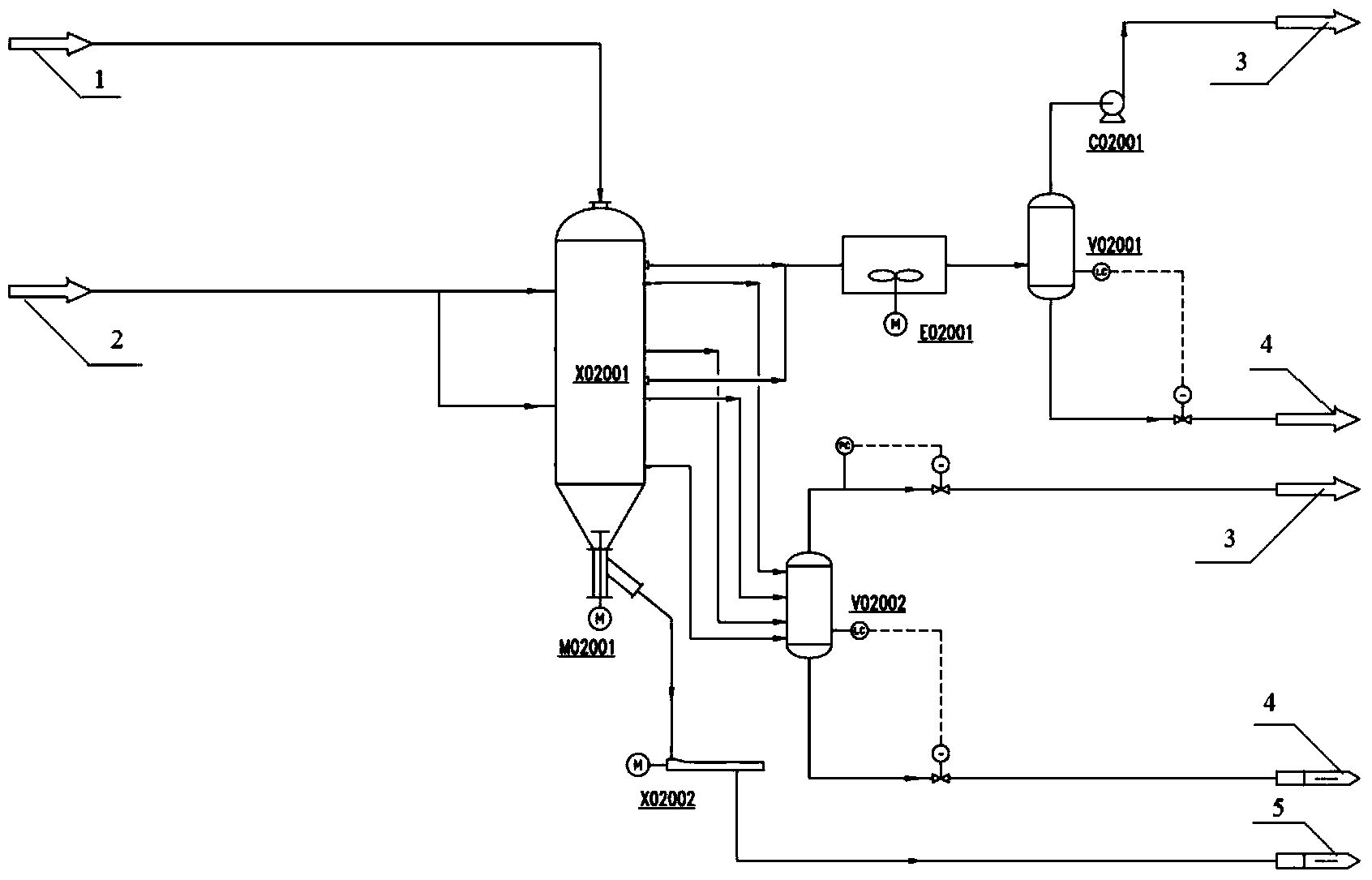

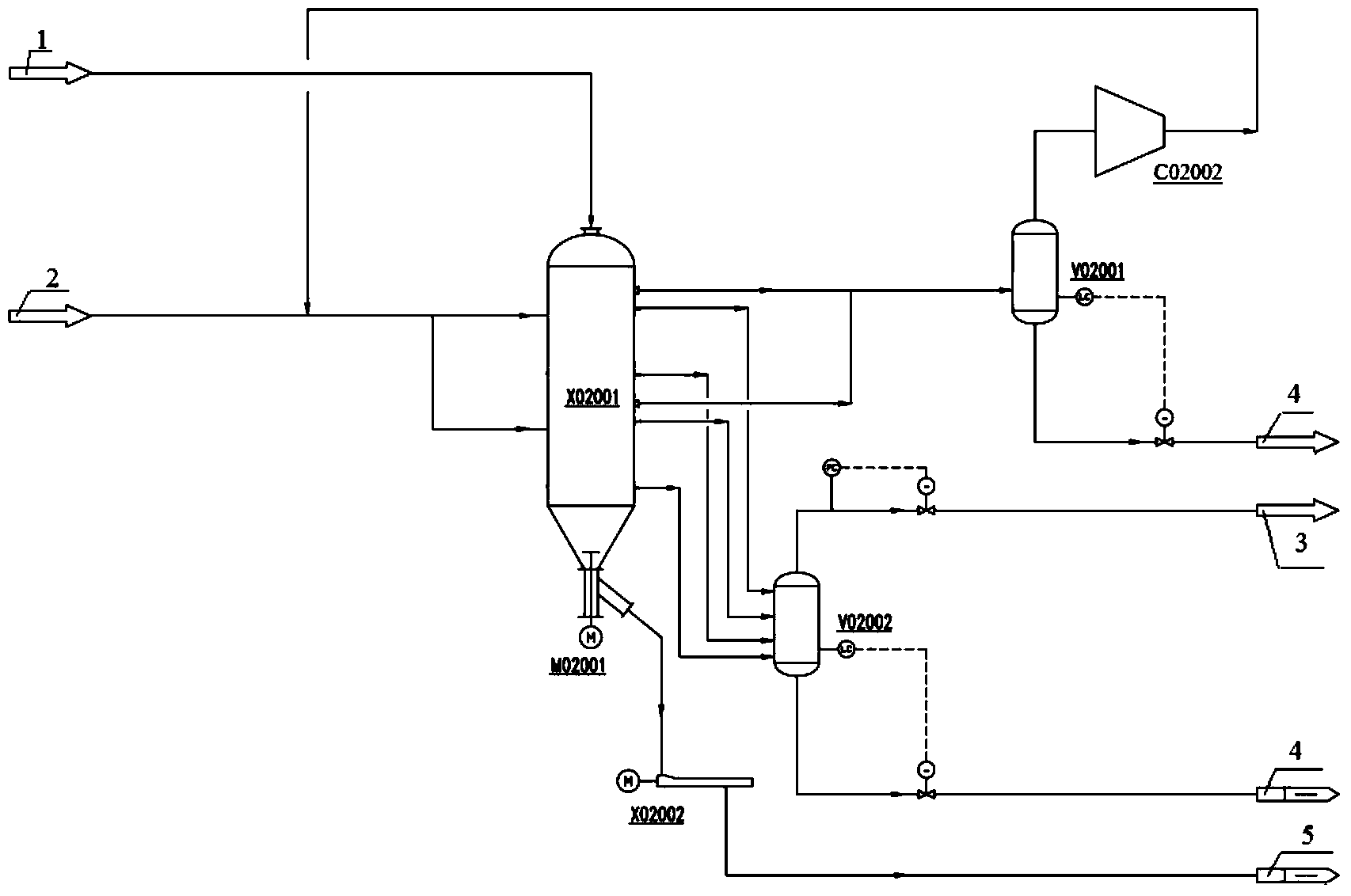

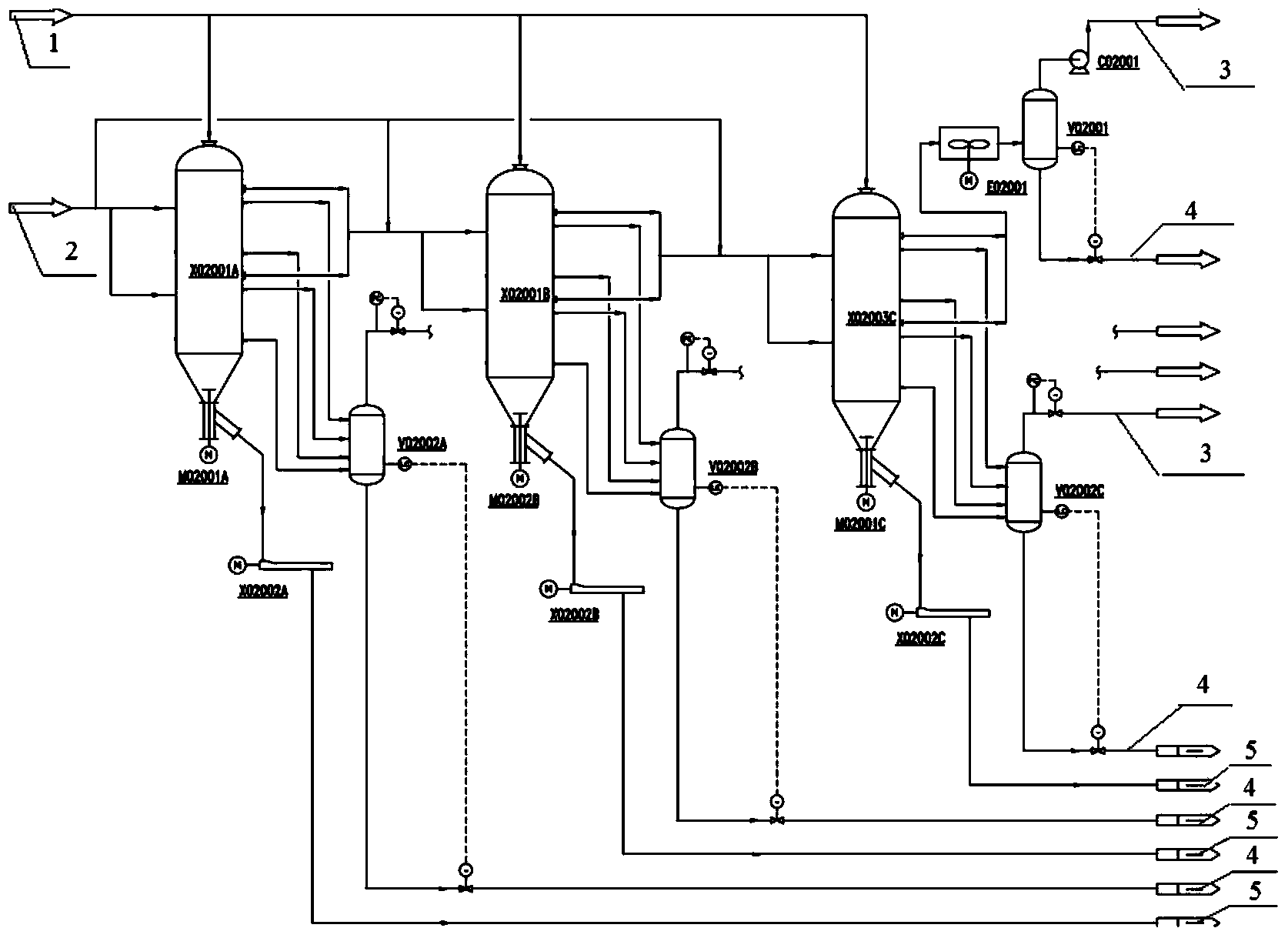

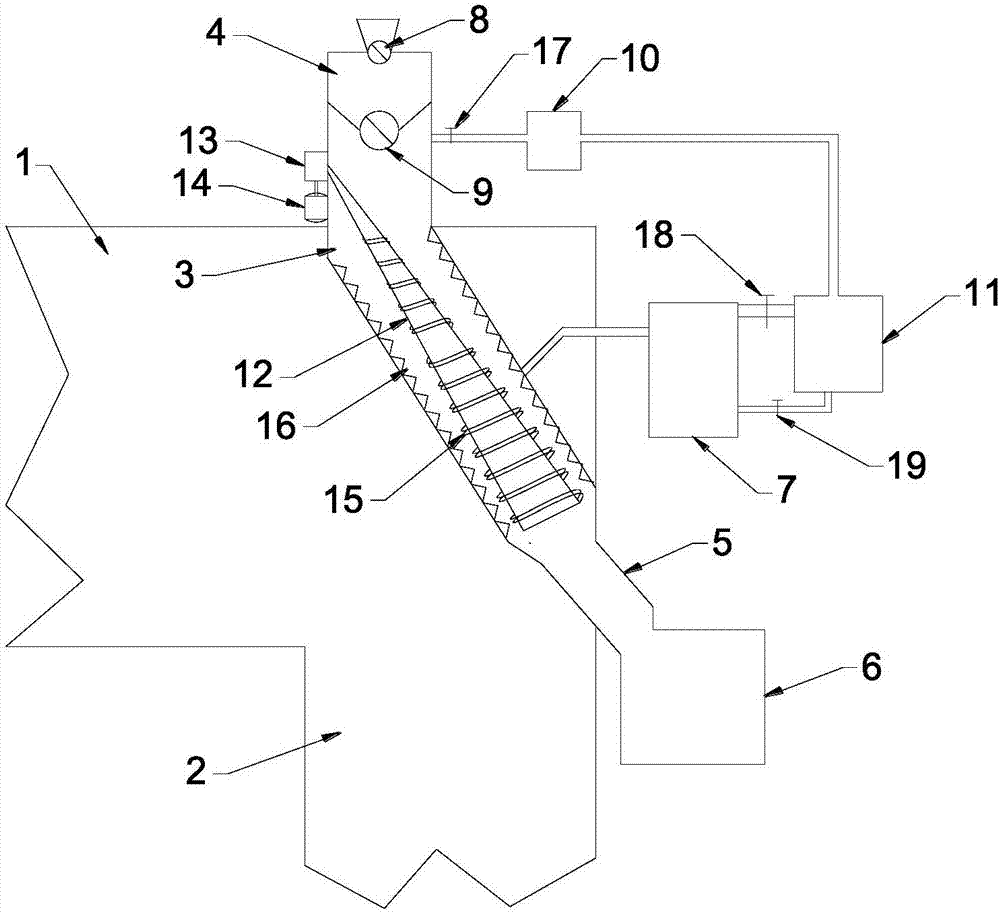

Method and apparatus for totally-closed garbage emission and transmission atomization and comprehensive utilization

ActiveCN101844144ARealize resource utilizationAchieve cleanupProductsBio-organic fraction processingLiquid stateSewage

The invention relates to a method and an apparatus for totally-closed garbage emission and transmission atomization and comprehensive utilization, in particular to the field of a method, an apparatus, a container and a facility for realizing the automation of totally-closed garbage emission, collection, concentration and transportation, no bag and comprehensive utilization. The method comprises the following steps: pulping the garbage thrown into a can with water in a certain proportion by utilizing an auto pulping liquid-state garbage can 1-2; collecting the pulped garbage into a concentrating pool 4 by utilizing a pipeline 3; transmitting the pulped garbage to a feeding farm 6 and a methane fermenting pool 7 by utilizing a water pump 5a and a carrier vehicle 5b; utilizing a purification workshop 4 and a methane recovering pipeline 9 to recover the methane; utilizing a disinfection workshop 10 and a biogas dreg dewatering device 11 to prepare the biogas dregs into organic fertilizer and fuel and discharge to be discharging into a crop irrigation and drainage land 12; purifying the sewage by utilizing a purification workshop 13 and discharging the purified sewage water; and systematically blending by utilizing a control center 14. Therefore, the invention realizes automation for totally-closed garbage emission, collection, concentration and transportation and comprehensive cyclic utilization of the garbage, and thoroughly eliminates garbage pollution caused by high polymer materials such as plastic and the like.

Owner:邱泽国

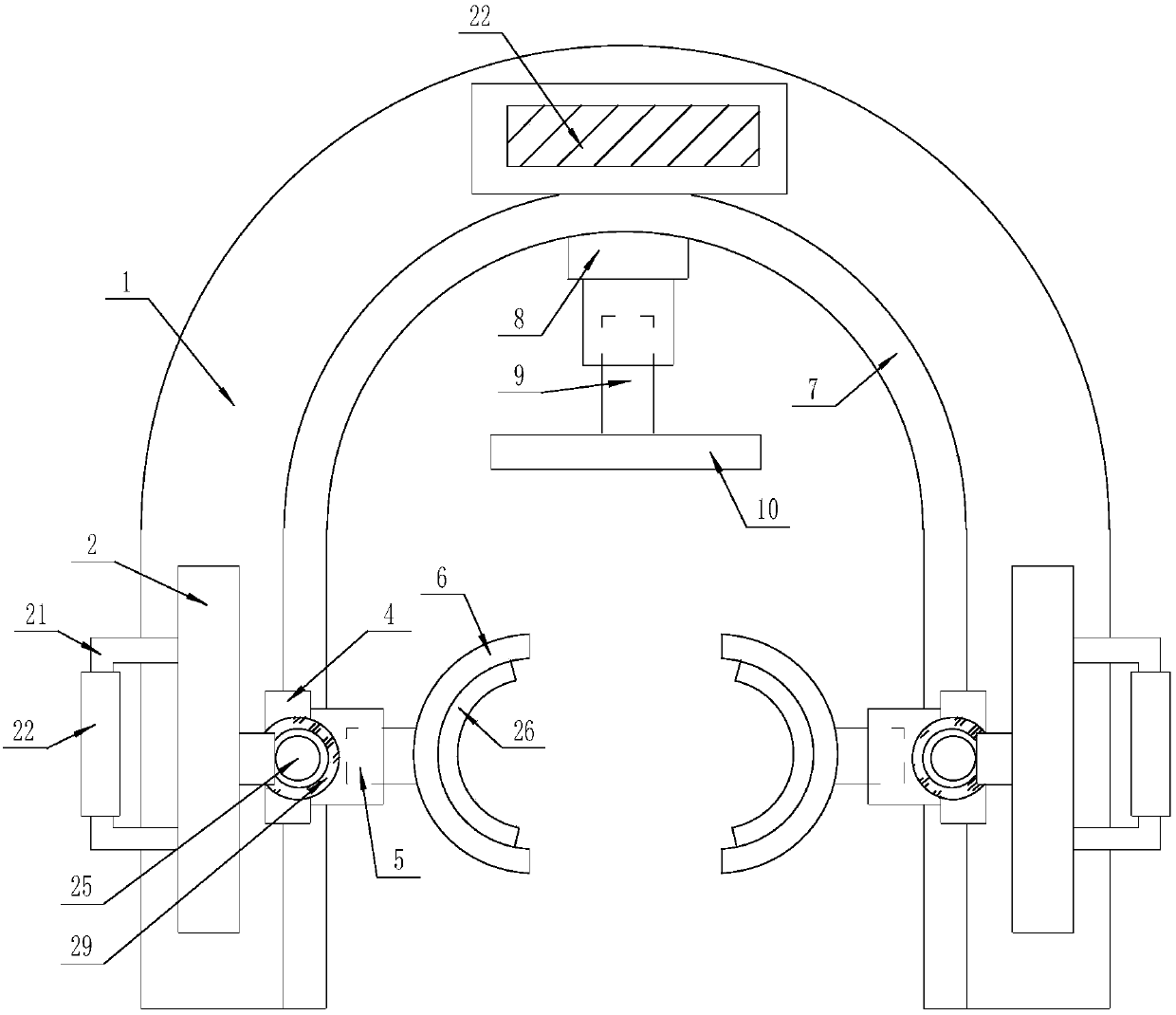

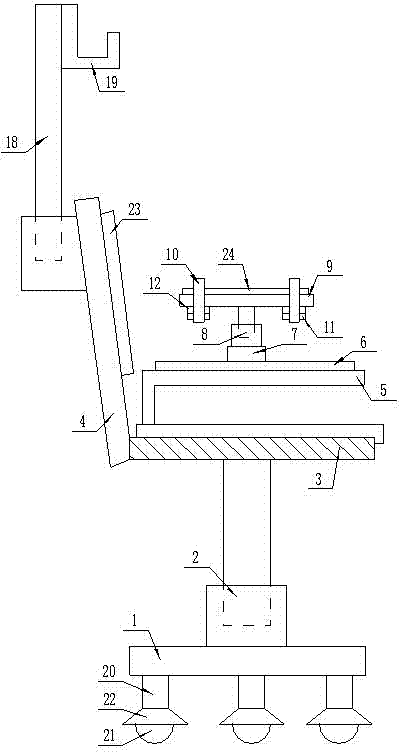

Landscaping tree planting device convenient to move

The invention discloses a landscaping tree planting device convenient to move. The landscaping tree planting device includes a U-shaped base. The landscaping tree planting device is characterized in that the two ends of the upper surface of the U-shaped base are fixedly connected with a pair of vertically-arranged vertical plates, the inner side surface of each vertically-arranged vertical plate is fixedly connected with a vertically-arranged sliding rail, an electrically controlled trolley is mounted on each vertically-arranged sliding rail, the side surface of each electrically controlled trolley is fixedly connected with an electrically controlled telescopic cross rod with the telescopic end being in the horizontal direction, the telescopic end of each electrically controlled telescopiccross rod is fixedly connected to an arc-shaped fixing clamping hand matched with a trunk, the inner side surface of the U-shaped base is fixedly connected with a U-shaped sliding rail, an electrically controlled moving block is mounted on the U-shaped sliding rail, the side surface of the electrically controlled moving block is fixedly connected with an electrically controlled telescopic push rod with the telescopic end being in the horizontal direction, and the telescopic end of the electrically controlled telescopic push rod is fixedly connected with a bulldozing plate. The landscaping tree planting device has the advantages of being simple in structure and high in practicality.

Owner:陈志军

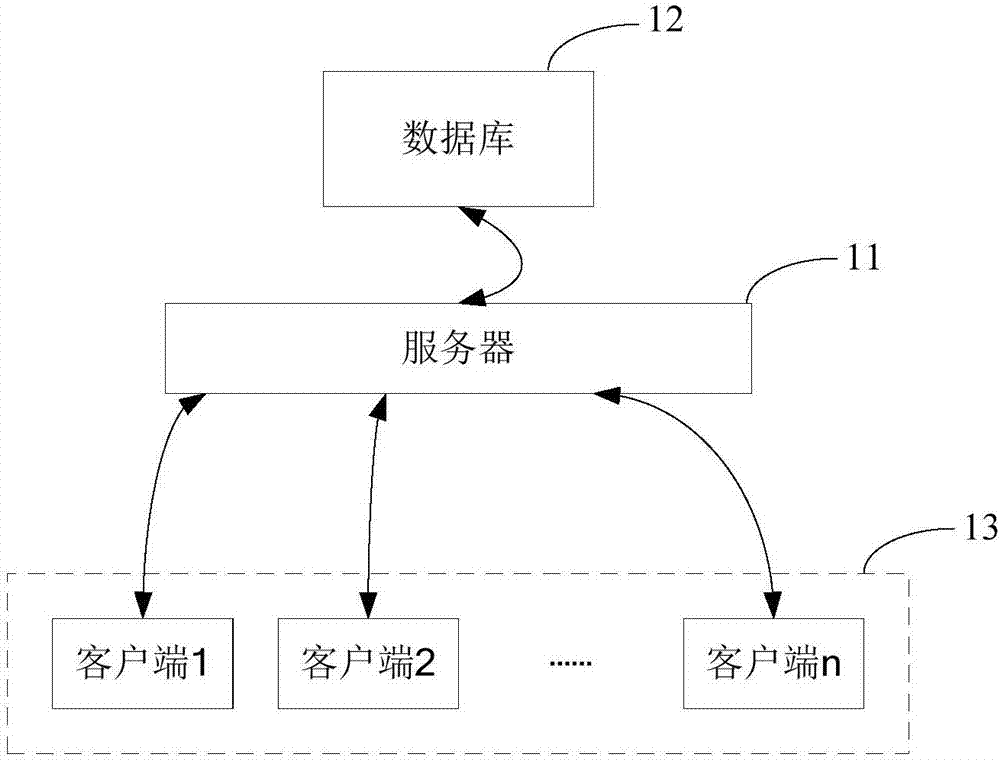

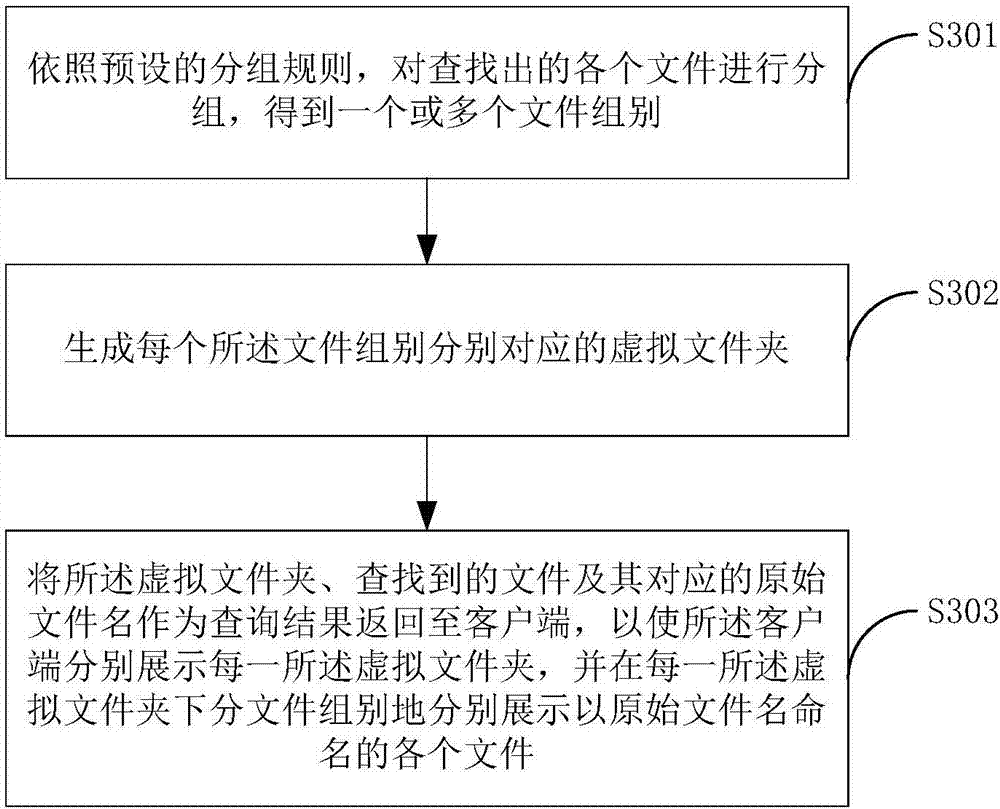

File management method and apparatus

InactiveCN107291796AHigh value availableReduce the level of disclosureDigital data protectionFile access structuresConfidentialityData management

The present invention is applicable to the technical field of data management and provides a file management method and apparatus. The method comprises: generating a corresponding file identifier according to an original file name of a file uploaded by a client at the time of uploading; renaming the file as the file identifier and storing the file in a preset storage directory; storing the mapping relationship between the file identifier of the file, the original file name and the storage directory to a database; when receiving a keyword-based file query instruction sent by the client, searching for the original file name associated with the keyword in the database and searching for the file identifier and the storage directory that have a mapping relationship with the original file name; based on the file identifier and the storage directory in the search result, searching for the file named by the file identifier under the storage directory, and taking the searched file and the corresponding original file name as a query result to return to the client. According to the method and apparatus provided by the present invention, the confidentiality of the file is improved and the risk of file leakage is reduced.

Owner:PING AN TECH (SHENZHEN) CO LTD

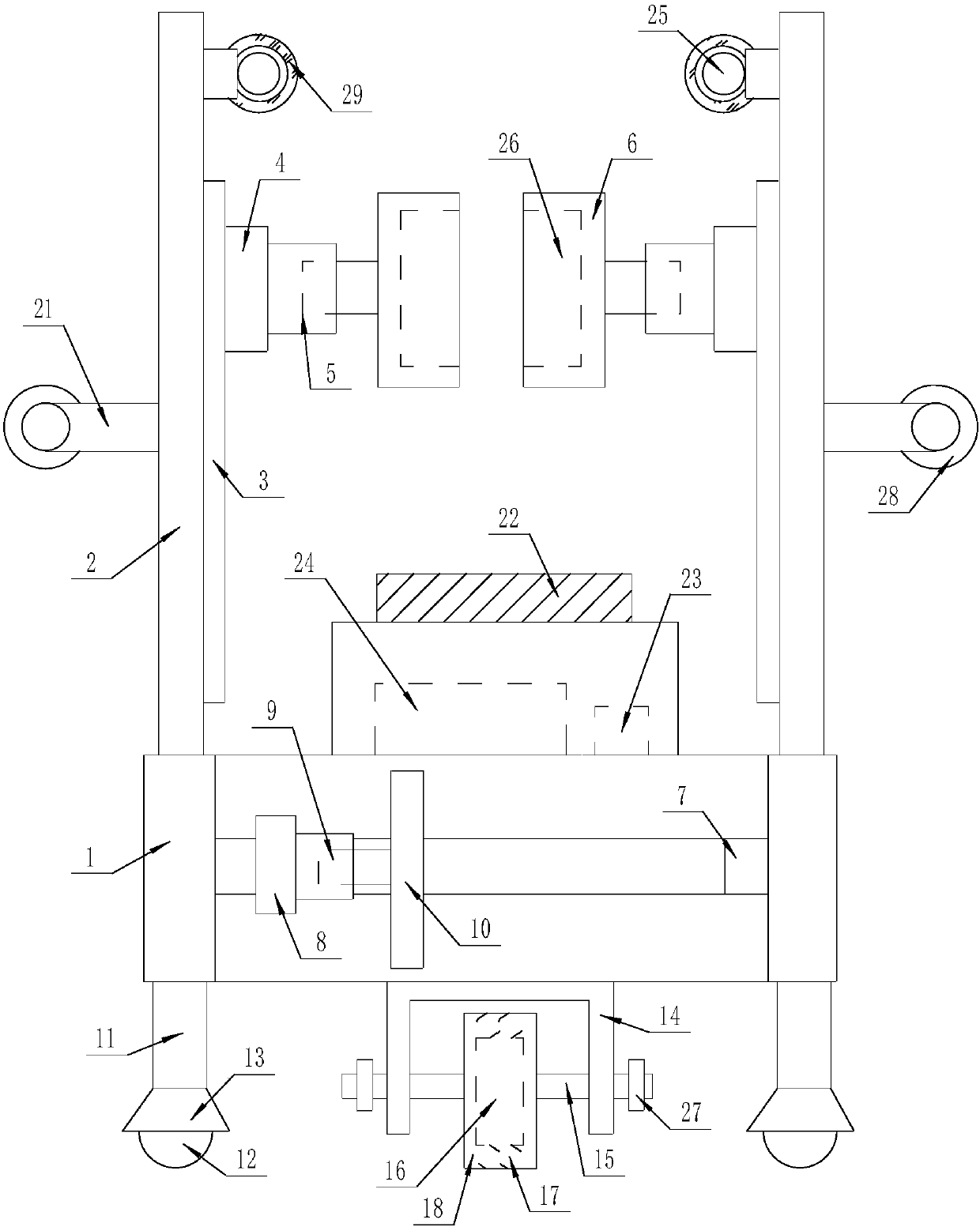

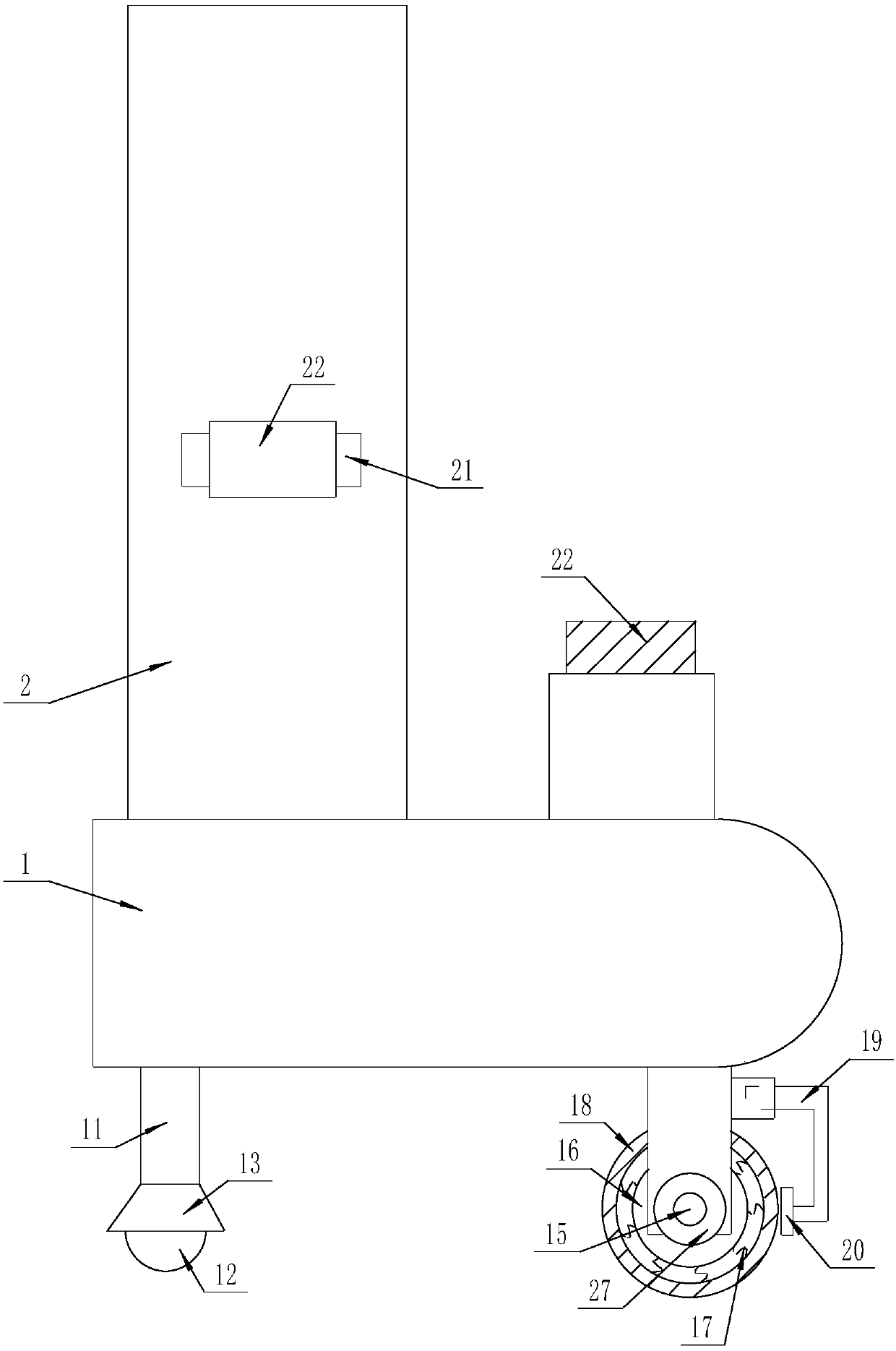

Novel pruning device for greenbelt plants

InactiveCN107278642AEasy to operateEasy to moveCuttersCutting implementsArchitectural engineeringEngineering

The invention discloses a novel pruning device for greenbelt plants. The device comprises a strip-shaped base. The center of the upper surface of the strip-shaped base is fixedly connected with a transversally-arranged sliding rail. An electric-control dolly is arranged on the transversally-arranged sliding rail. The upper surface of the electric-control dolly is fixedly connected with a pair of electric-control telescopic columns with upward telescopic ends. The telescopic ends of the pair of electric-control telescopic columns are fixedly connected with an L-shaped box body. The lower surface of the L-shaped box body is fixedly connected with an electric-control telescopic pushing rod with a downward telescopic end. The telescopic end of the electric-control telescopic pushing rod is fixedly connected with a first miniature rotary motor with a downward rotary end. A rotary end of the first miniature rotary motor is provided with a first circular pruning cutter in a sleeving manner. The surface on the right side of the L-shaped box body is fixedly connected with a vertically-arranged sliding rail, on which an electric-control movable block is arranged. The surface on the right side of the electric-control movable block is fixedly connected with an electric-control telescopic transverse rod with the telescopic end in the horizontal direction. The novel pruning device for greenbelt plants has the following beneficial effects: the novel pruning device for greenbelt plants is simple in structure and high in practicability.

Owner:夏周阳

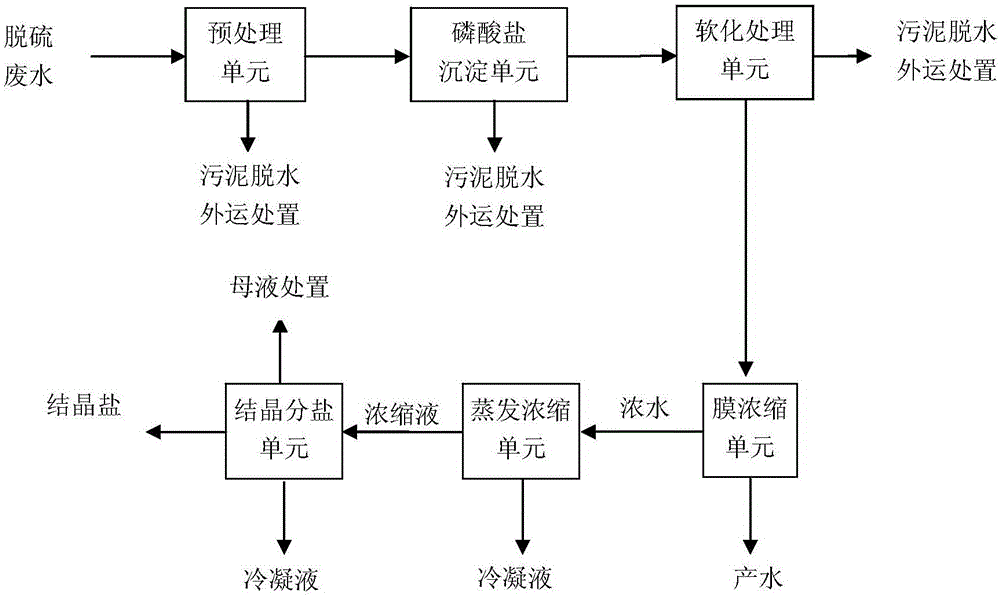

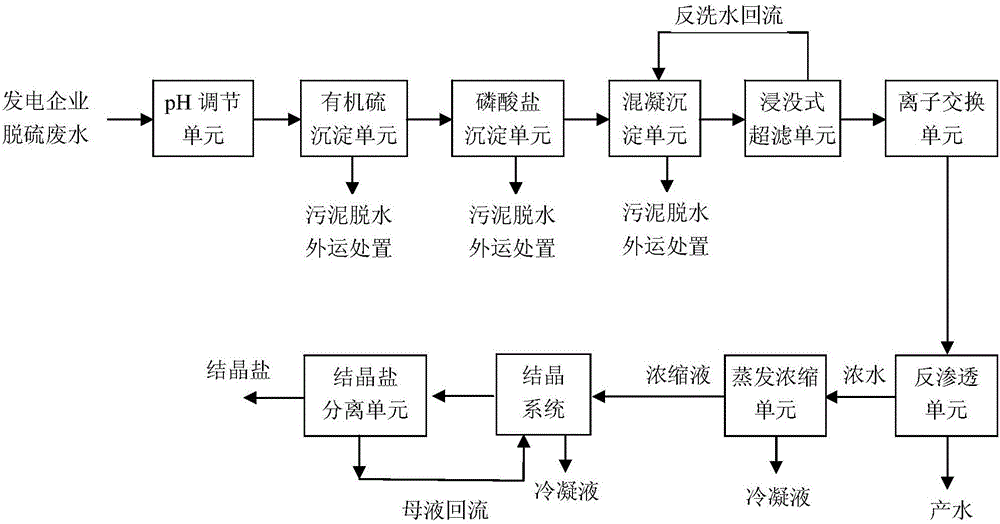

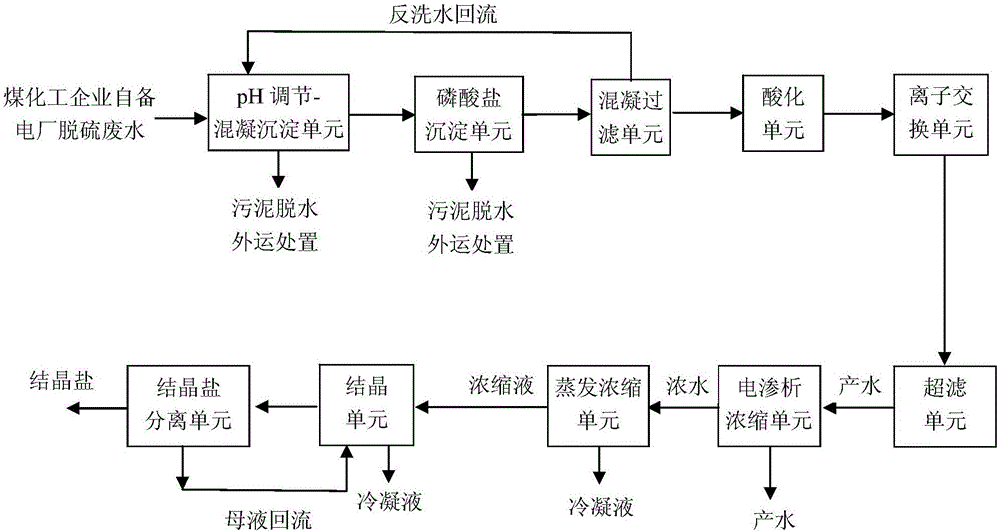

Desulfurated waste water resourceful treatment method and treatment system

InactiveCN106746115AHigh value availableHigh purityWater/sewage treatment by centrifugal separationWater contaminantsPhosphateFiltration

The invention provides a desulfurated waste water resourceful treatment method. The method includes the steps that desulfurated waste water is pretreated to remove suspended matter and / or colloid and heavy metal ions; 2, pretreated effluent obtained in the step 1 is subjected to phosphate precipitation; 3, phosphate precipitation effluent obtained in the step 2 is softened, wherein softening comprises the procedures of ion exchange and / or coagulation, and optionally, softening further comprises the procedures of acidification and / or filtration; 4, softened effluent obtained in the step 3 is subjected to membrane concentration; 5, membrane concentration concentrated water obtained in the step 4 is subjected to evaporation and concentration, and evaporation and concentration liquid and evaporation and condensation liquid are obtained; 6, the evaporation and concentration liquid obtained in the step 5 is subjected to crystallization salt separation, and crystallized salt, the evaporation and condensation liquid and crystallized mother liquor are obtained. The invention further provides a treatment system implementing the method.

Owner:DATANG INT CHEM TECH RESINST

Optimal cutting method for wood surface defects

ActiveCN108943179AAvoid it happening againMaximize yieldProfiling/shaping machinesEconomic benefitsWaste material

The invention discloses an optimal cutting method for wood surface defects, and relates to the technical field of wood processing. The cutting method specifically comprises the following steps that S1, firstly, rubber wood undergoes manual blind cutting from raw material, transverse polishing and vertical polishing, then a wood block with the length of about 300 mm, the width of about 80 mm and the thickness of about 25 mm is cut, the wood usually has the defects such as black knots, white joints, tree centers, missing edges, cracks, inclined heads and damage, the wood is cut according to thedistribution rule of the defects, and the cut wood is divided into four types namely, an AA material, an AB material, a C material and a waste material. According to the optimal cutting method for thewood surface defects, the effects that a deep learning analysis algorithm is adopted to accomplish the defection on the surface detects of the wood, the yield of the wood can reach the maximum economic benefit, the labor cost is greatly saved, the production efficiency is improved, the utilization value of the wood is improved, and the problems that the cutting position is prone to be misjudged manually and the manual line drawing efficiency is low are solved can be achieved.

Owner:慧泉智能科技(苏州)有限公司

Children infusion device convenient to fix

The invention discloses a conveniently fixed infusion device for children, which comprises a circular base, the center of the upper surface of the circular base is fixedly connected with an electronically controlled telescopic column with an upward telescopic end, and the telescopic end of the electronically controlled telescopic column is fixedly connected There is a rectangular seat, the rear surface of the rectangular seat is fixedly connected with an inclined backrest, the left and right sides of the rectangular seat are fixedly connected with a pair of L-shaped struts, and each L in the pair of L-shaped struts The upper surface of the support rod is fixedly connected with a strip slide rail, and each of the strip slide rails is equipped with an electric control trolley, and the upper surface of each electric control trolley is fixedly connected with an electric control telescopic telescopic arm with the telescopic end upward. The telescopic end of one of the electrically controlled telescopic poles is fixedly connected to a No. 1 strip-shaped supporting plate, and a pair of No. 1 elastic elastic straps are fixedly connected to the left surface of the No. 1 strip-shaped supporting plate. The invention has the advantages of simple structure and strong practicability.

Owner:夏周阳

Garbage can with garbage bag sealing function

InactiveCN107021310AEasy to collectAvoid distributingRefuse receptaclesArchitectural engineeringElectric machinery

Owner:李菊兰

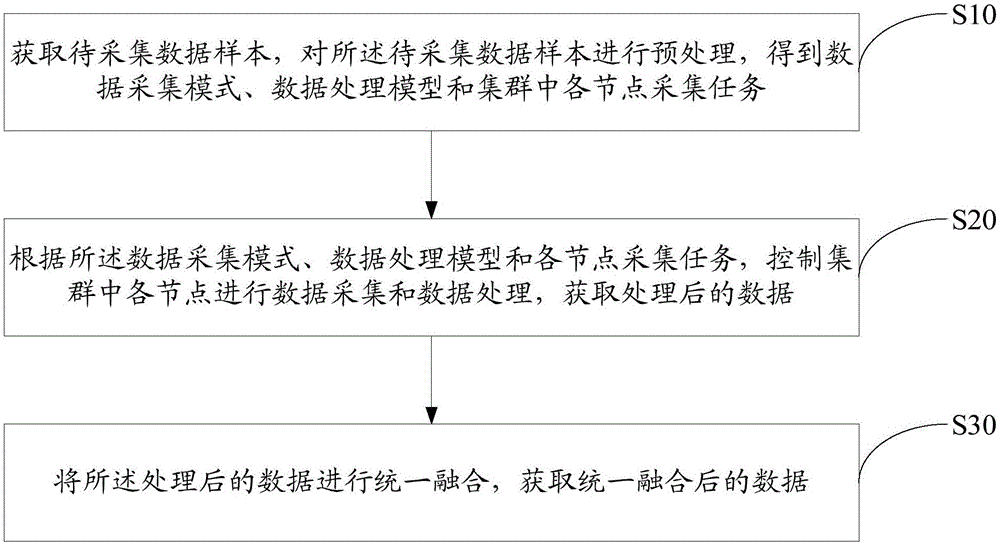

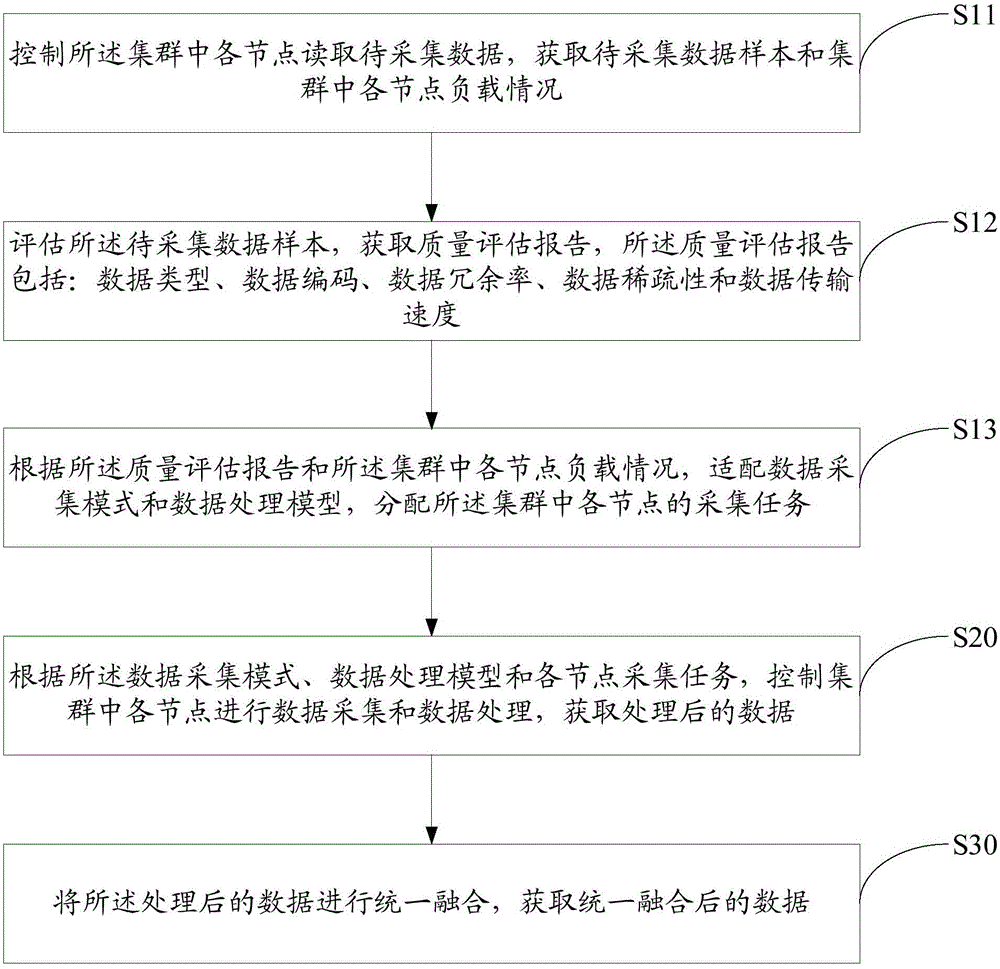

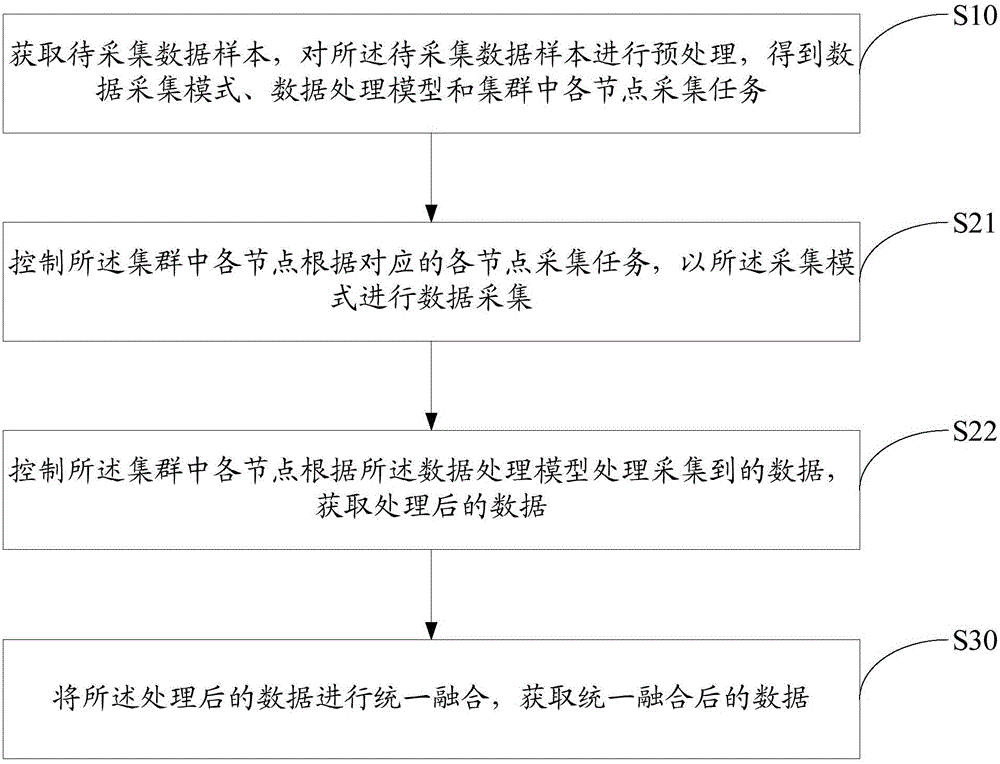

Data processing method, device and system

ActiveCN106708815AImprove data processing efficiency and data fusionEnhance usable value and practicalityOther databases queryingTransmissionData processingData acquisition

The invention discloses a data processing method. The data processing method comprises the steps of obtaining a data sample, and conducting preprocessing on the data sample to be collected to obtain a data collection mode, a data processing model and a collection task of each node in a cluster; according to the data collection mode, the data processing model and the collection task of each node in the cluster, controlling each node in the cluster to conduct data collection and data processing to obtain processed data; conducting unified merging on the processed data to obtain the data after unified merging. The invention further discloses a data processing method and a data processing system. According to the data processing method and a data processing system, the problems in the prior art that the big data processing efficiency is low and the degree of fusion is low are effectively solved, the data processing efficiency and the degree of data fusion are improved, the utilizable value of the final data is increased, the practicability of the final data is improved, and the data quality guarantee of the big data analysis and value mining is provided.

Owner:ZTE CORP

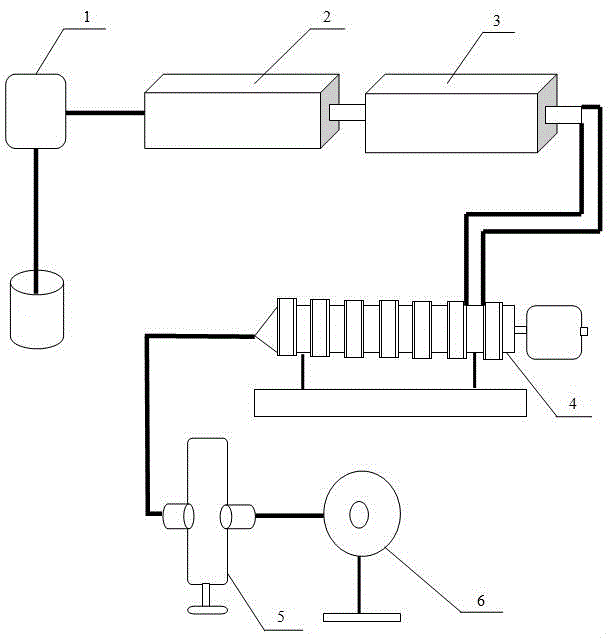

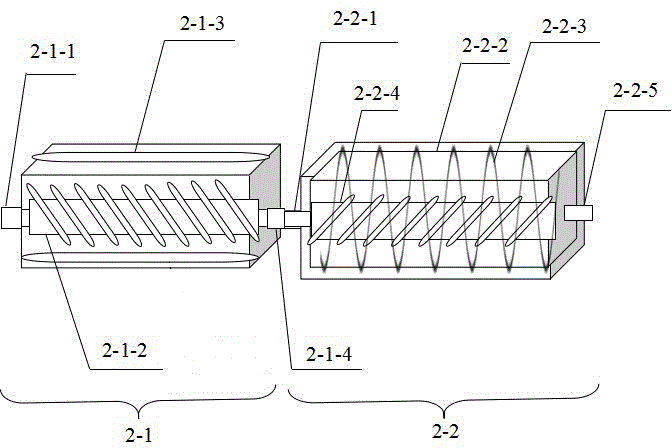

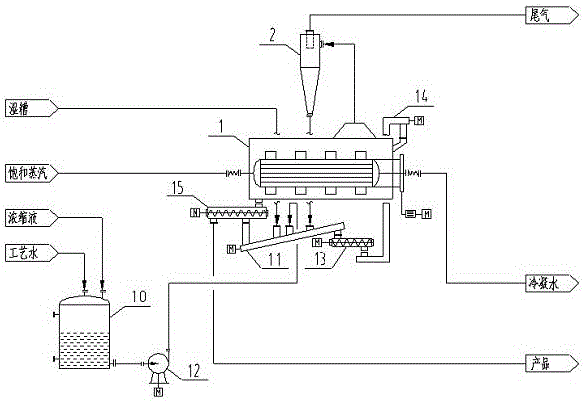

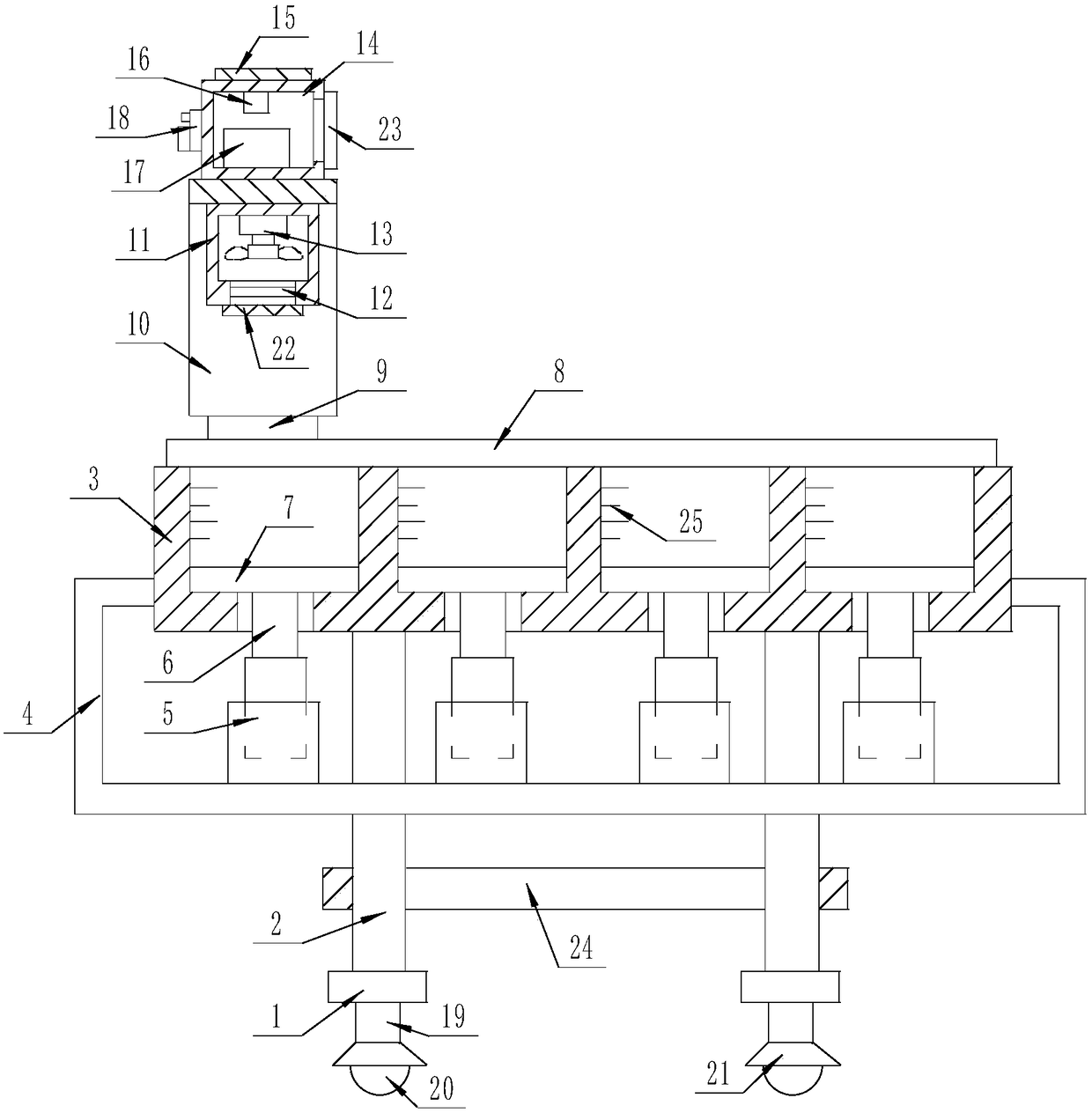

Low-energy-consumption lignite drying process for recovering lignite moisture and drying equipment

InactiveCN103453752APrevent leakageReduced inert gas contentDrying gas arrangementsDrying solid materialsResource utilizationDry heat

The invention relates to the technical field of lignite drying and comprehensive high-efficiency utilization of lignite, and discloses a low-energy-consumption lignite drying process for recovering lignite moisture and drying equipment. The drying equipment disclosed by the invention comprises a drier for realizing the indirect heating by steam. The lignite drying process comprises the steps that steam is used as heating media, and the steam enters the drier to carry out drying heat exchange with the lignite in the drier; and meanwhile, moisture removed from the lignite is heated to become secondary steam, and the secondary steam realizes the gas-solid separation through an outer sleeve made of porous gas-solid separation materials, and are discharged out of the drier to be recovered and utilized. The process and the equipment have the advantages that the moisture removed from the lignite can be recovered, and meanwhile, the energy consumption in the drying process can also be reduced, so the energy utilization efficiency, the resource utilization efficiency and the environmental protection benefit of the comprehensive utilization items of the lignite are improved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

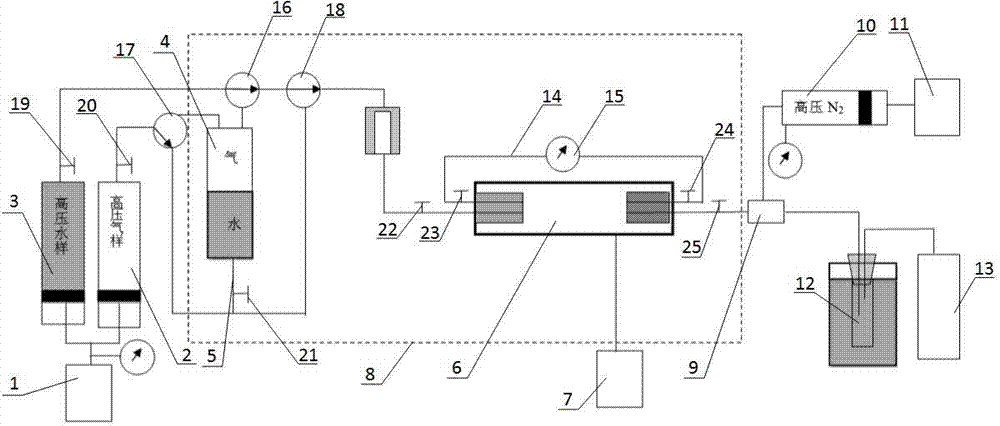

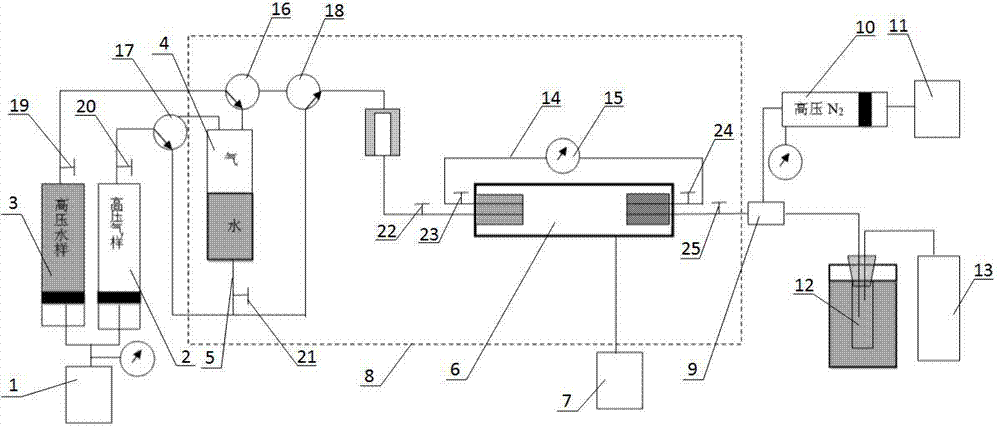

Gas reservoir stress sensitivity evaluating experiment method considering bound water under formation condition

ActiveCN110566195AHigh value availableIn line with actual productionFluid removalTemperature stressStress conditions

The invention discloses a gas reservoir stress sensitivity evaluating experiment method considering bound water under the formation condition. The gas reservoir stress sensitivity evaluating experiment method comprises the steps of core preparation, fluid preparation, establishment of formation temperature and pressure conditions, establishment of core bound water saturation, stress sensitivity evaluation experiment, calculation of permeability under all test points in the stress sensitivity experiment, experiment concluding and the like, and the gas reservoir productivity of a reservoir witha core used in the experiment is predicted according to stress sensitivity damage degree evaluation obtained through experiment concluding. The temperature and pressure conditions of a real gas reservoir formation are effectively simulated, the influence of the formation bound water is fully considered, the measurement result better conforms to actual production, and the available value of experiment data is high; and the stress sensitivity situation of the formation in the production process can be more truly simulated through the experiment, the defect that the influences of the formation bound water and the temperature on results of the gas reservoir stress sensitivity evaluating experiment are not considered in an existing measurement method is overcome, and the experiment method is provided for obtaining gas reservoir stress sensitivity evaluating experiment data with the higher available value.

Owner:CHINA NAT OFFSHORE OIL CORP +1

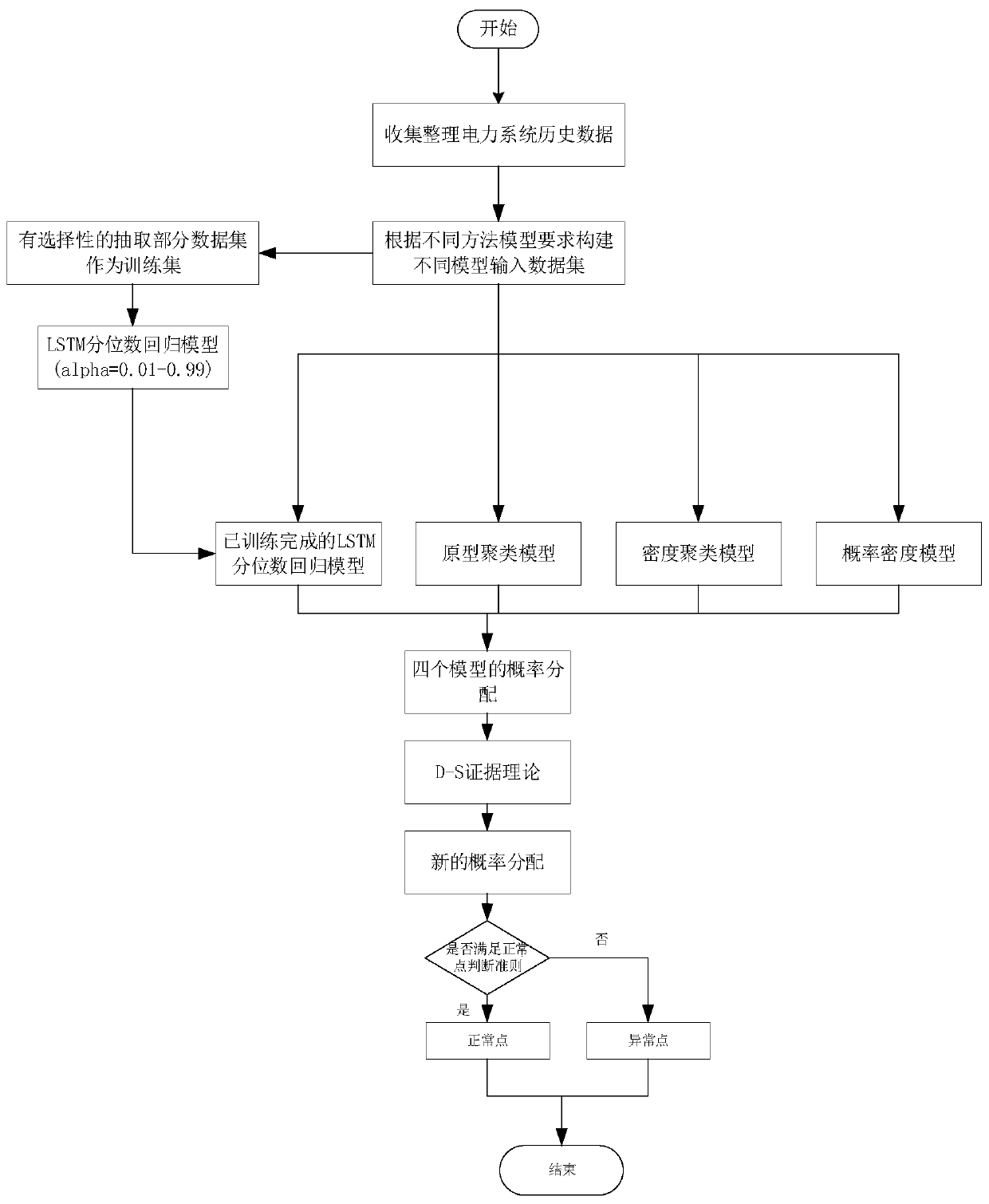

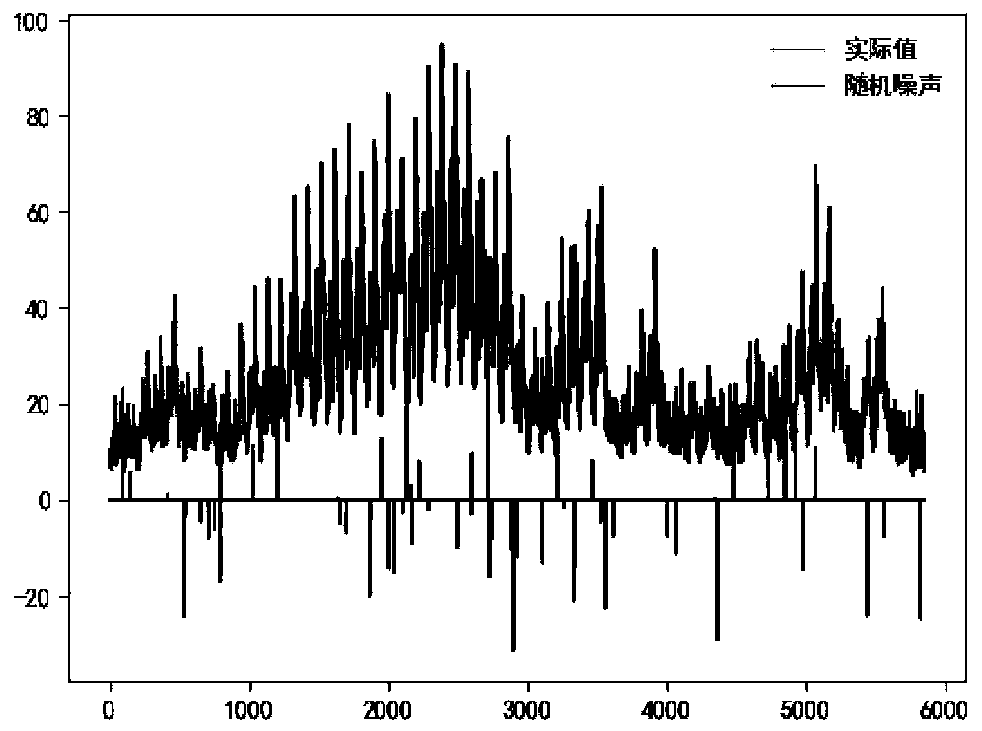

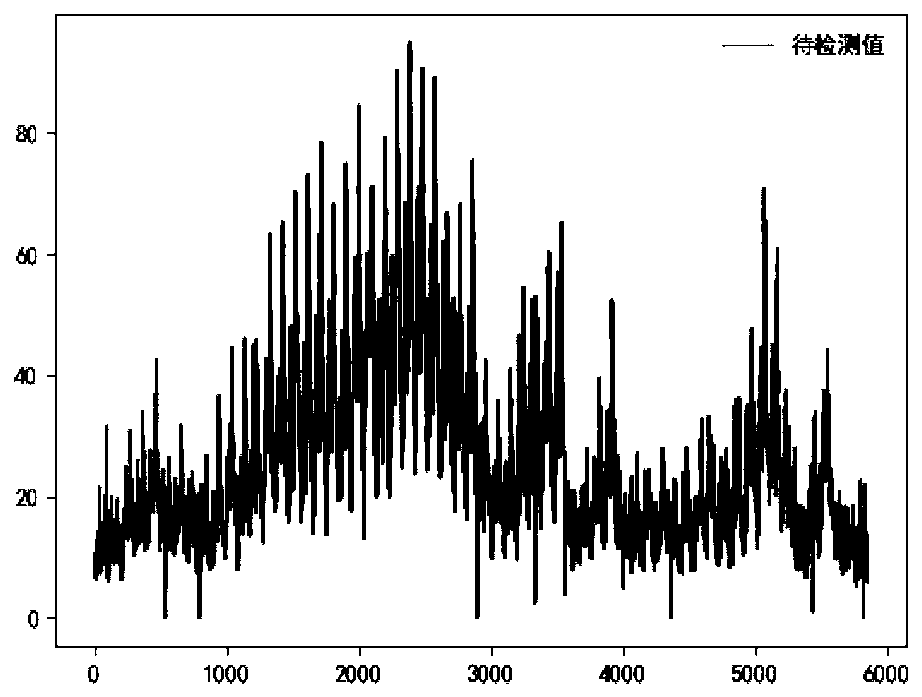

Abnormal data discrimination method based on multi-criterion fusion

ActiveCN110458195AImprove discrimination accuracyImprove reliabilityCharacter and pattern recognitionNeural architecturesData setData discrimination

The invention discloses an abnormal data discrimination method based on multi-criterion fusion. The method comprises the following steps: S1, preprocessing a sample data set; S2, according to four detection models in the abnormal data discrimination model, establishing sample data sets corresponding to the four detection models respectively; S3, inputting the input data set of the deep learning method into the long-short-term neural network model for training, and obtaining the trained long-short-term neural network model; S4, respectively inputting the sample data sets into the correspondingmodels, discriminating abnormal values, and obtaining the probability that each data point is discriminated as an abnormal point by the corresponding model; and S5, fusing the discrimination result probabilities of the data points discriminated by the corresponding models, and judging a fusion result according to a set judgment criterion to obtain a final abnormal data discrimination result. The data abnormal point discrimination precision is improved, the data accuracy and the available value are also improved, and accurate data guarantee is provided for operation detection business.

Owner:HOHAI UNIV

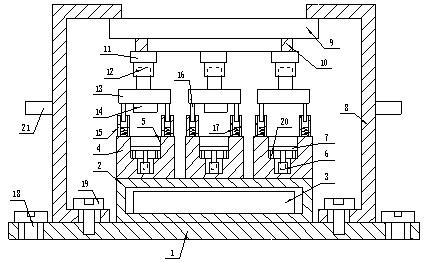

Efficient rotating stamping shaping mold

The invention discloses an efficient rotating stamping shaping mold. The mold comprises a rectangular base, the right end of the upper surface f the rectangular base is fixedly connected with a driving motor with the upward rotating end, the rotating end of the driving motor is fixedly connected with a fixed disc, multiple lower molds are fixedly connected to the upper surface of the fixed disc, the upper surface of each lower mold is provided with a stamping concave mold, rectangular grooves are machined in the lower surface in each stamping concave mold, the lower surface in each rectangulargroove is fixedly connected with an electric control telescopic push rod with the upward telescopic end, the telescopic end of each electric control telescopic push rod is fixedly connected with a stripper plate matched with the corresponding stamping concave mold, and the lower surface of the fixed disc is fixedly connected with supporting cylinders corresponding to the lower molds, and the lower surface of each supporting cylinder is fixedly connected with a semicircular sliding plate block. The mold has the beneficial effects of being simple in structure and high in practicability.

Owner:TIANJIN XINYUAN HONGDA TECH CO LTD

Active parts of wild jujube as well as preparation method and application thereof

InactiveCN102670764AHigh value availableRealize comprehensive utilizationAntinoxious agentsAntineoplastic agentsHigh-fructose corn syrupMedicine

The invention discloses the high fructose corn syrup, the dietary fiber, the anti-oxidation active parts and the anti-tumor active parts of wild jujube as well as a preparation method and application thereof. The preparation method comprises the following steps of: taking the flesh of wild jujube as a raw material, extracting by ethanol and preparing residues into the dietary fiber powder of the wild jujube; separating an alcohol extract by macroporous resin, eluting by using water and ethanol with different concentrations sequentially, and washing eluent by the water so as to obtain the high fructose corn syrup of the wild jujube; and washing the eluent by ethanol with low concentration so as to obtain the anti-oxidation active parts, washing the eluent by ethanol with high concentration, adding a low-polarity organic solvent and extracting so as to obtain the anti-tumor active parts of the wild jujube. According to the preparation method, the flesh of waste wild jujube is utilized as the raw material, the active components of the wild jujube are extracted by a method combining a modern extracting and separating means and pharmacological activity sieving, wastes are changed into valuables, and various free radicals can be removed by the anti-oxidation active parts in the hope of being developed into a medicine for oxidation resistance and senescence resistance; and the anti-tumor effective parts have clearer active components and high content, have very good functions of suppressing and killing various tumor cells and are in the hope of being developed into a novel anti-tumor medicine.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

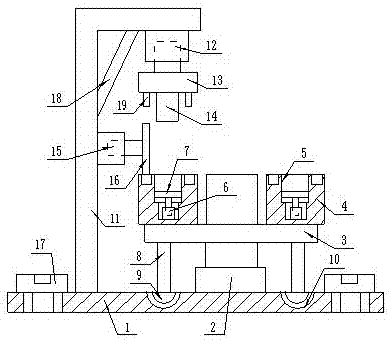

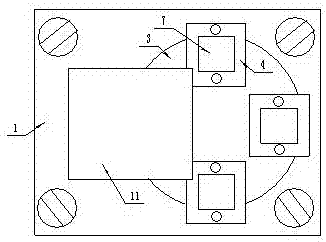

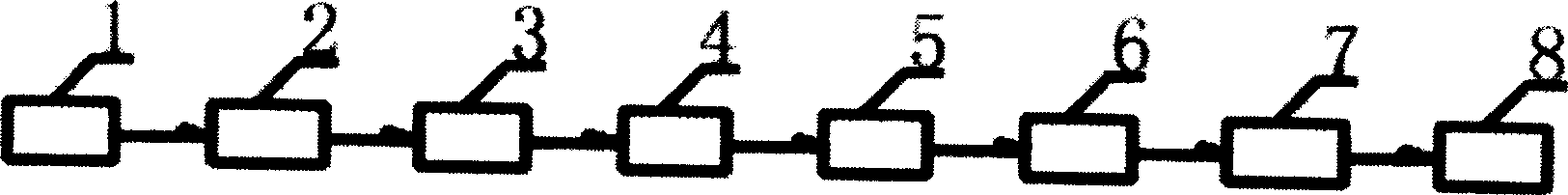

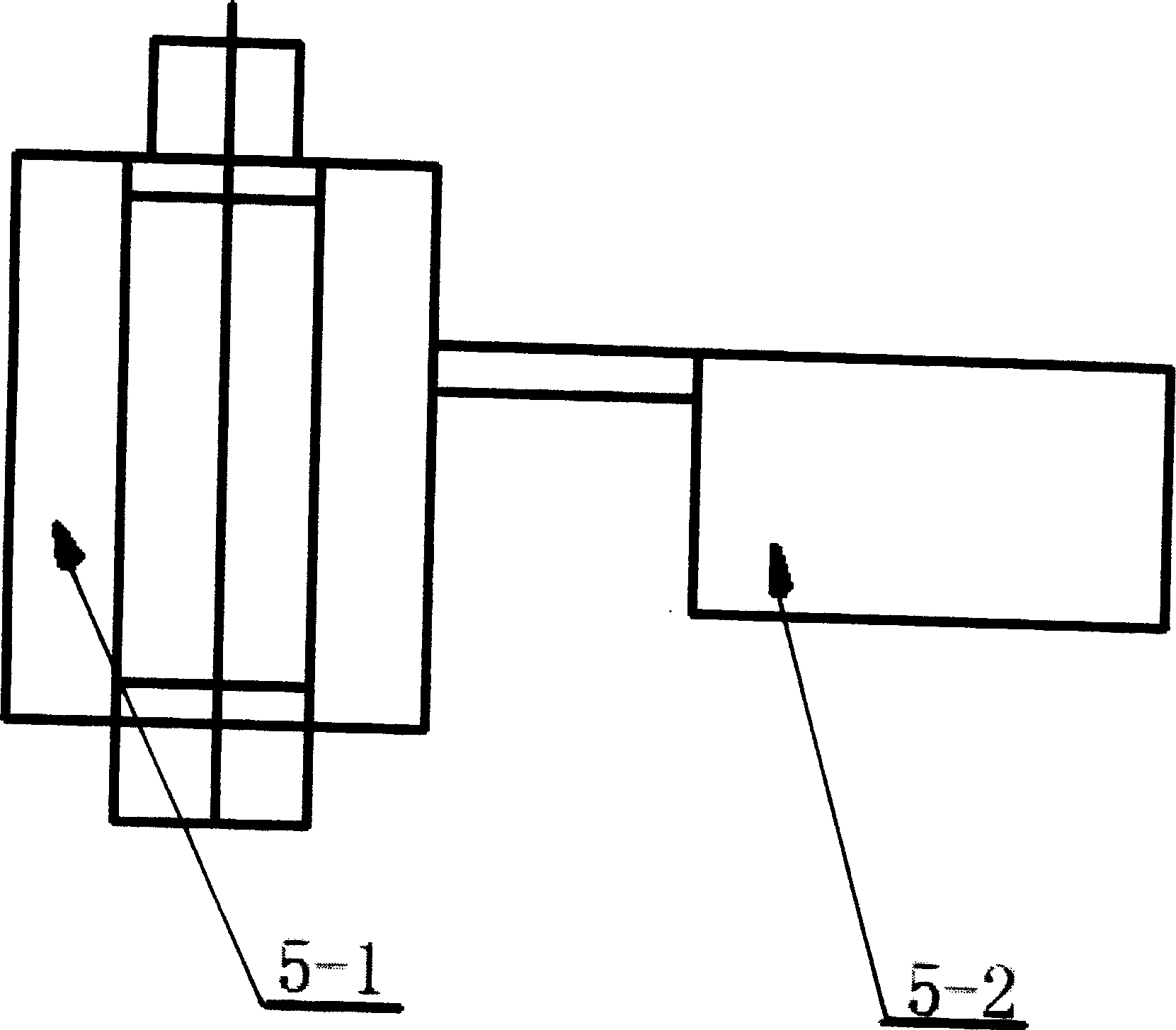

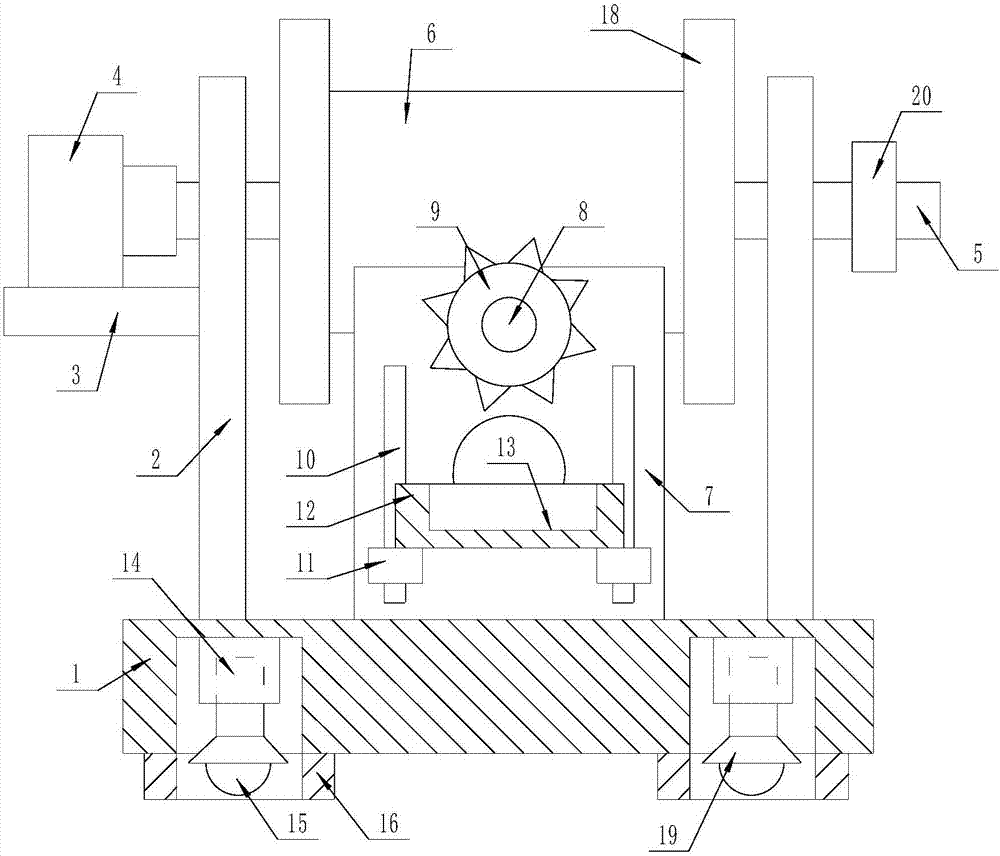

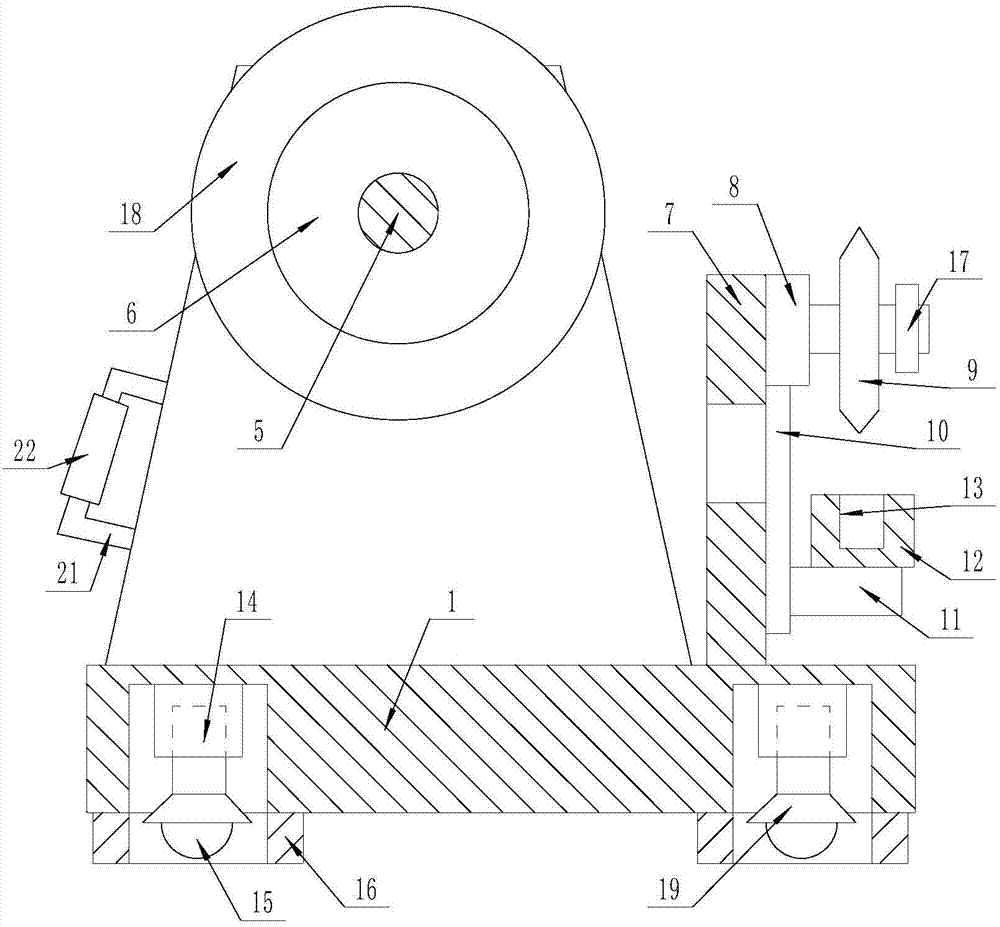

Desulfurization method of rubber and apparatus thereof

InactiveCN1908042AReduce energy consumptionReduce manufacturing costPlastic recyclingMicrowave ovenEngineering

The invention discloses a rubber desulfurizing method and device, which comprises the following steps: grinding the sulfured rubber; sieving; cobbing; placing the desulfurized material in the feed hole of squeezer; plasticizing; cooling; filtering. The device contains grinder, sieving machine, cobber, feeder, microwave oven, squeezer, filter and packer, whose specific technological flow path and equipments are displayed in the instruction.

Owner:马如琦

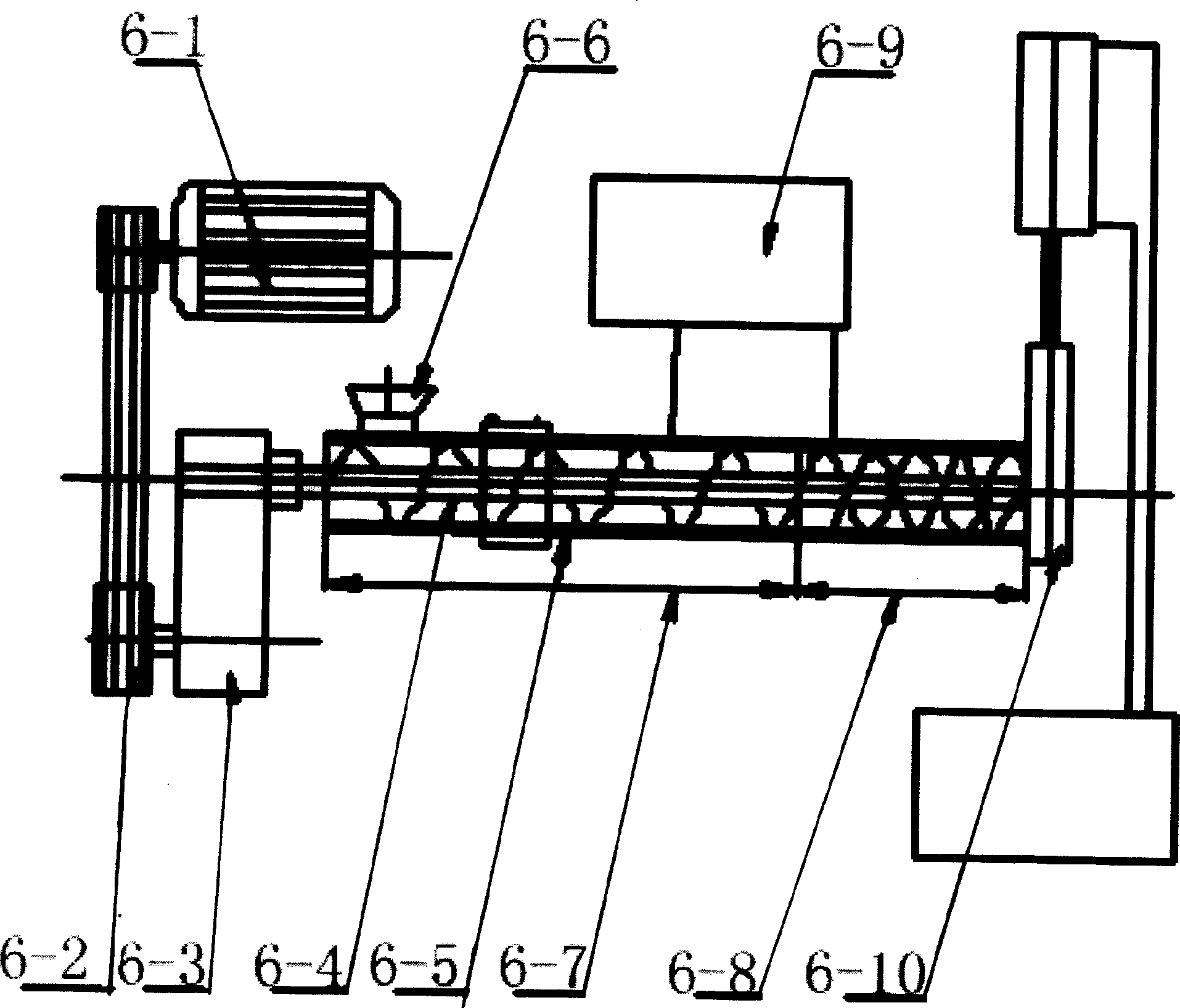

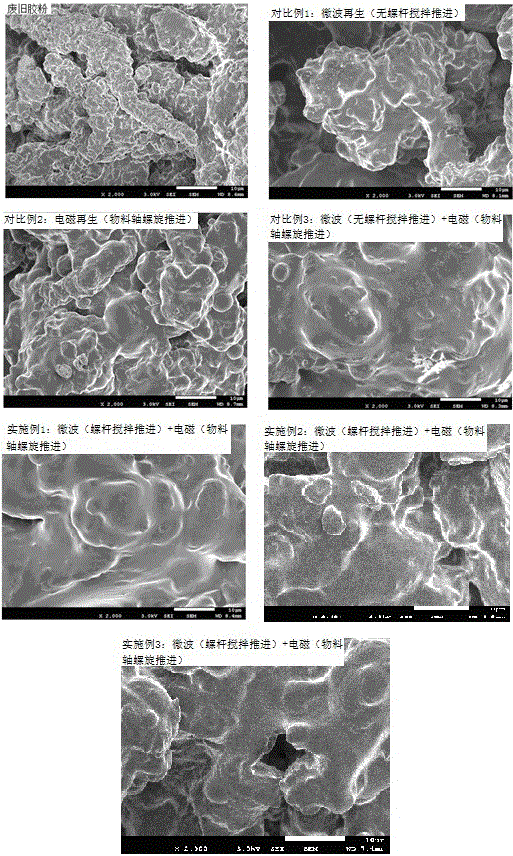

Waste rubber regeneration method and device

InactiveCN104672487AImprove heating efficiencyReduce energy consumptionPlastic recyclingThermodynamicsWaste rubber

The invention relates to a waste rubber regeneration method and device. The method is implemented through steps as follows: smashed vulcanized rubber granules are subjected to first-section microwave and second-section electromagnetic heating by a microwave-electromagnetic combined desulfurization device for desulfurization, the desulfurized vulcanized rubber granules directly enter a feeding port of an extruder from a discharge port of an electromagnetic desulfurization device and are subjected to plastification, cooling and filtering through the extruder, and finally, the whole process is completed. The device sequentially comprises the following parts: a feeding machine, a first-section microwave desulfurization device, a second-section electromagnetic desulfurization device, the extruder, a filtering device and a packaging device. The method and the device have the advantages that the production efficiency is high, the cost is low, the application range is wide, industrial production can be realized, the environment-friendly effect of the production process is good, and two efficient energy-saving heating manners are complementarily combined, so that defects of an original desulfurization method can be overcome, and efficiency and economy of the rubber regeneration process are greatly improved.

Owner:QINGDAO UNIV OF SCI & TECH

Cable bearing and transportation device having cutting function

The invention discloses a cable bearing and transportation device having a cutting function. The cable bearing and transportation device comprises a bearing base; a pair of trapezoidal supporting plates is fixedly connected with the upper surface of the bearing base; the surface of the left side of one of the trapezoidal supporting plates is fixedly connected with a motor bearing plate; a rotatingmotor of which the rotating end is in the horizontal direction is arranged on the upper surface of the motor bearing plate; the rotating end of the rotating motor is fixedly connected with a rotatingshaft stretching out through the trapezoidal supporting plates; the rotating shaft is sleeved with a cable drum; the part, located in front of the trapezoidal supporting plates, of the upper surfaceof the bearing base is fixedly connected with a cable limiting plate; a circular limiting hole is formed in the center of the surface of the front side of the cable limiting plate; the part, located above the circular limiting hole, of the surface of the front side of the cable limiting plate is fixedly connected with a high-speed cutting motor of which the rotating end is in the horizontal direction; and the rotating end of the high-speed cutting motor is sleeved with a circular sawtooth cutting knife. The cable bearing and transportation device has the beneficial effects of simple structureand high practicability.

Owner:陈志军

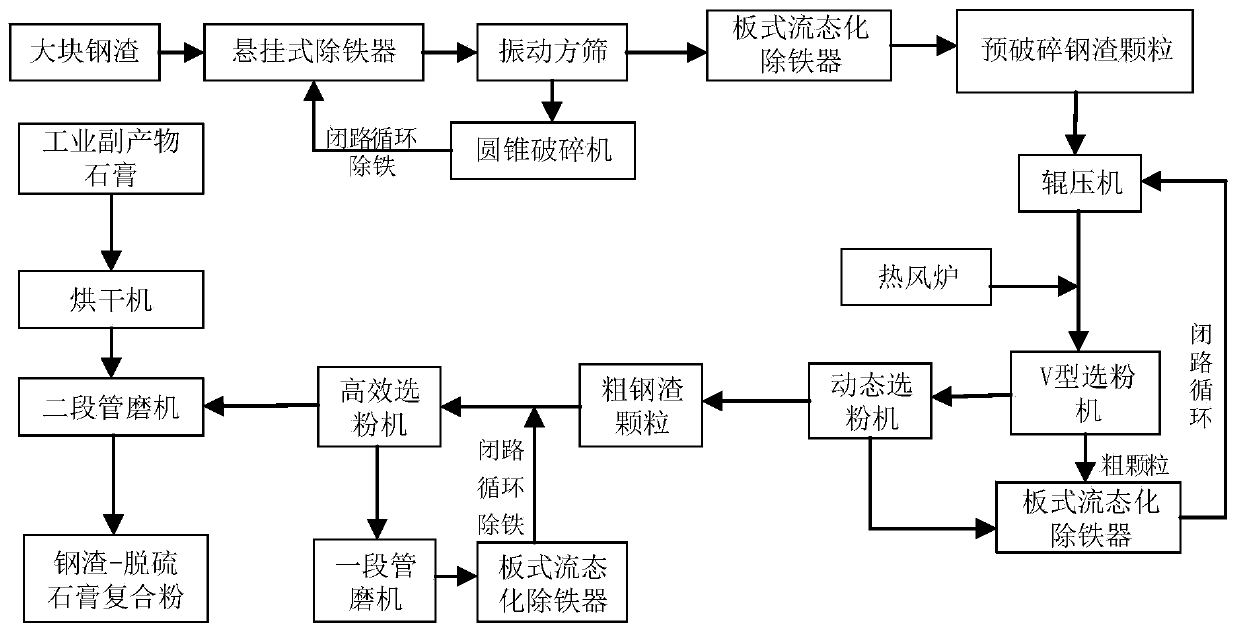

Stage grinding method for steel slag and industrial by-product gypsum composite powder

ActiveCN110711762AReduce moisture contentReduce energy consumptionSolid waste disposalGrain treatmentsSlagIron removal

The invention discloses a stage grinding method for steel slag and industrial by-product gypsum composite powder. Through iron removal in advance, large-particle metallic iron in large-piece steel slag is removed, and the conditions that the large-particle iron enters a crusher and the crushing efficiency is affected are avoided; two-stage crushing is combined with sorting as well as iron removal,so that the problem that the circulation load of a pipe mill is increased if a large amount of metal iron with the poor grinding performance enters the mill is solved; during second-stage grinding, industrial by-product gypsum and the steel slag are mixed and ground, the condition that the industrial by-product gypsum is prone to adhering to equipment, is prone to being excessively ground and isprone to agglomerating during single grinding is avoided, materials are effectively mixed to obtain the steel slag and industrial by-product gypsum composite powder with the low iron content, the highspecific surface area and the low water content, and the coordinated utilization of two industrial solid wastes including the steel slag and the industrial by-product gypsum is promoted.

Owner:QIANAN WEISHENG SOLID WASTE ENVIRONMENTAL PROTECTION IND CO LTD +1

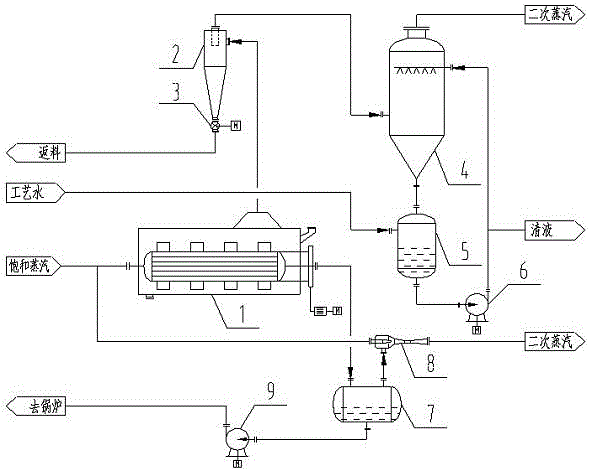

Method for vinasse tube bank type drying and exhaust gas and steam condensed liquid heat recycling

InactiveCN105865191AThe process is simple and reliableContinuous operationEnergy recuperation in distillationDrying solid materialsEnvironmental resistanceLiquid storage tank

The invention relates to a method for vinasse tube bank type drying and exhaust gas and steam condensed liquid heat recycling. The method comprises the following steps: (1), after centrifuging vinasse, obtaining a wet vinasse material and vinasse clear liquid, and after concentrating the vinasse clear liquid, feeding concentrated liquid into a concentrated liquid storage tank; (2), conveying the wet vinasse material and the concentrated liquid to a material return spiral conveyor, conveying the wet vinasse material and the concentrated liquid to a mixing spiral conveyor together, mixing, and after mixing uniformly, feeding the mixture into a tube bank type drying machine; (3), feeding saturated steam into the tube bank type drying machine, and heating and drying the material mixture in a reverse flow manner so as to obtain a dried material, exhaust gas and condensed water; (4), after separating the exhaust gas by a cyclone separator, obtaining a separated material and separated exhaust gas, feeding the separated material into the material return spiral conveyor, and cyclically utilizing the separated material; (5), feeding the separated exhaust gas into a sprinkling tower, washing the exhaust gas, and separately producing secondary steam A and washing water left after heat exchange; and (6), feeding the condensed water into a condensed water flash evaporation tank, carrying out flash evaporation on the condensed water, and separately producing secondary steam B and condensed liquid. The method is simple and reliable, is continuous in running, saves energy, reduces consumption and is safe and environment-friendly.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +1

Municipal landscaping seedling planting culture apparatus

InactiveCN108353693AImprove survival rateGuaranteed growing conditionsBatteries circuit arrangementsSelf-acting watering devicesLandscapingEngineering

The invention discloses a municipal landscaping seedling planting culture apparatus. The apparatus comprises a fixing base; a seedling bearing table is fixedly connected to the upper surface of the fixing base, a plurality of circular plant bearing grooves are machined in the upper surface of the seedling bearing table, a rectangular groove is machined in the lower surface inside each circular plant bearing groove, the lower surface inside each rectangular groove is fixedly connected with an electric control stretchable supporting rod with an upward stretching end, the stretching end of each electric control stretchable supporting rod is fixedly connected with a circular plant bearing plate matched with the corresponding circular plant bearing groove, a pair of n-shaped supporting frames are fixedly connected to the upper surface of the fixing base, a transverse sliding rail is fixedly connected to the upper surface of a beam of each n-shaped supporting frame, an electric control trolley is arranged on each transverse sliding rail, and a strip-shaped bearing box is fixedly connected to the upper surfaces of one pair of n-shaped supporting frames and on the left side of the transverse sliding rail. The apparatus has the advantages of being simple in structure and high in practicability.

Owner:周培弘

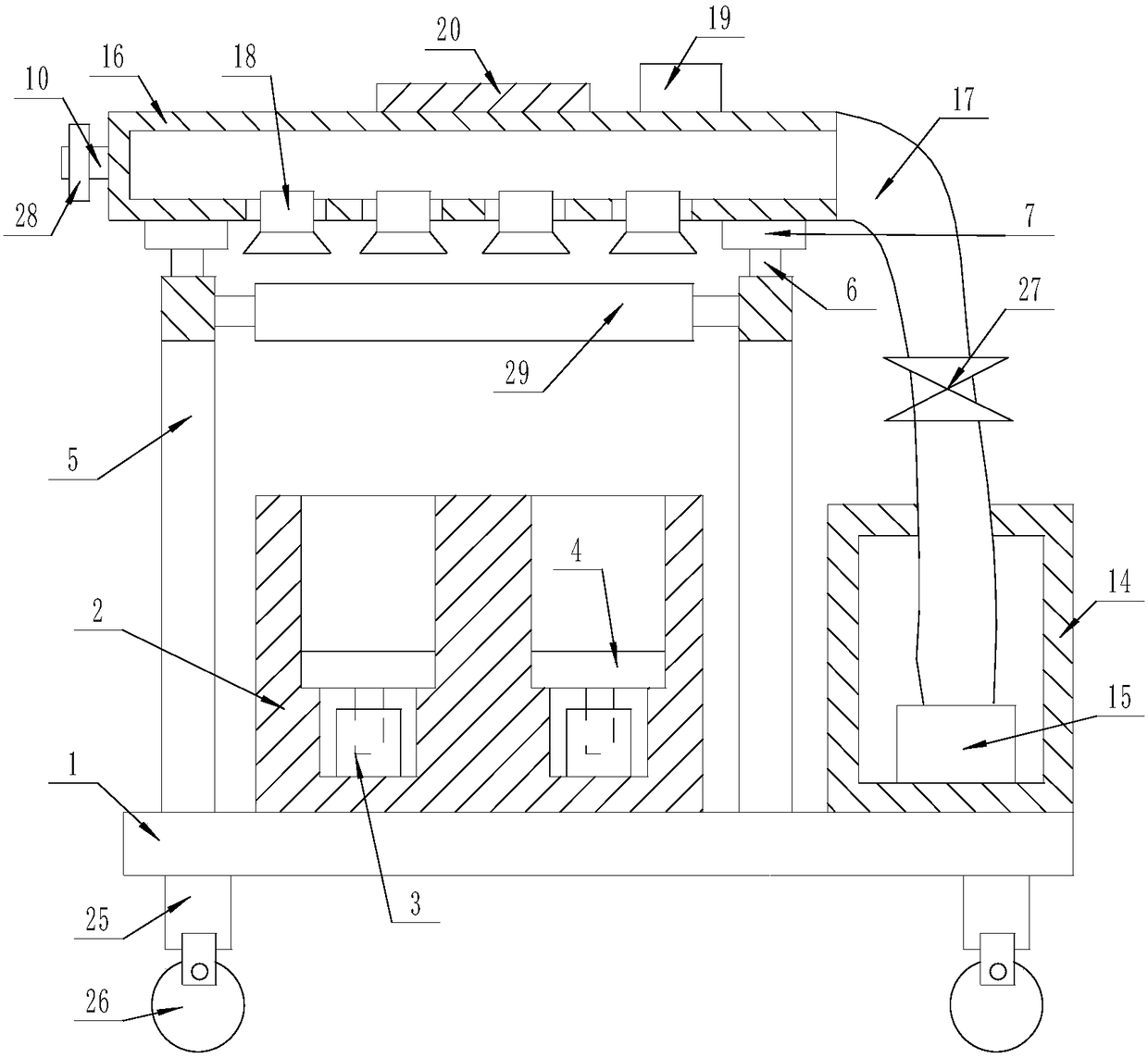

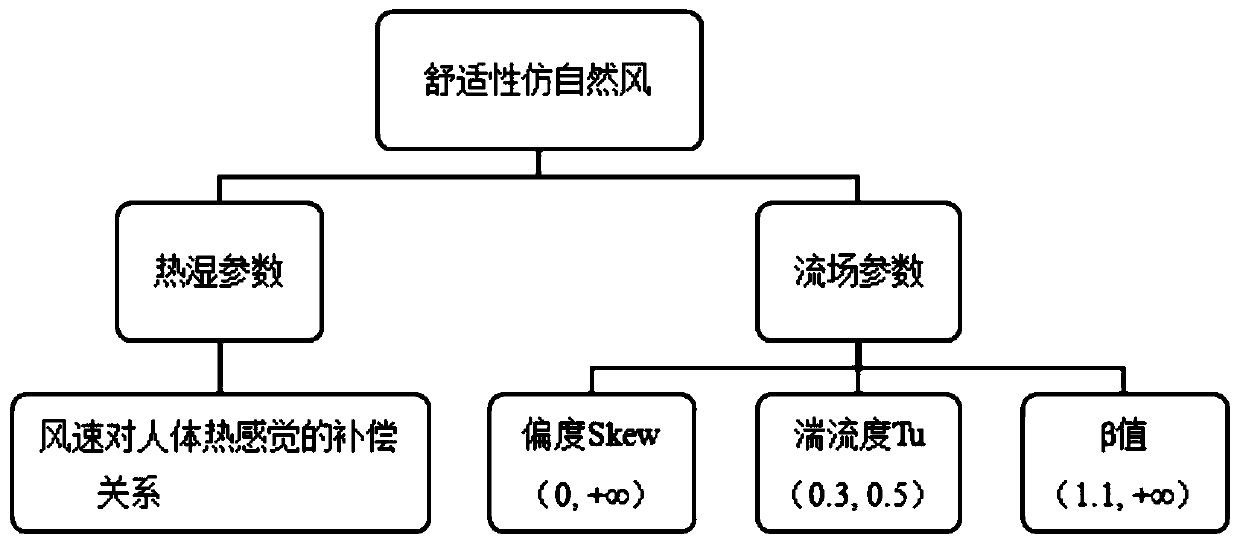

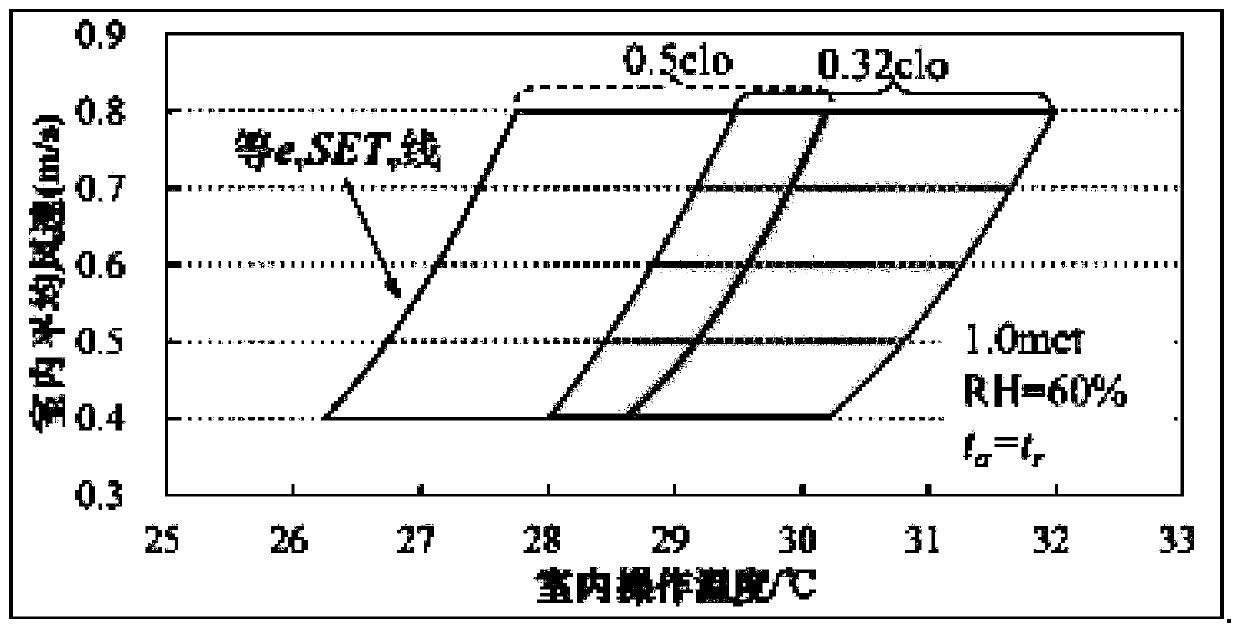

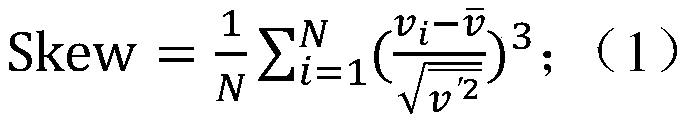

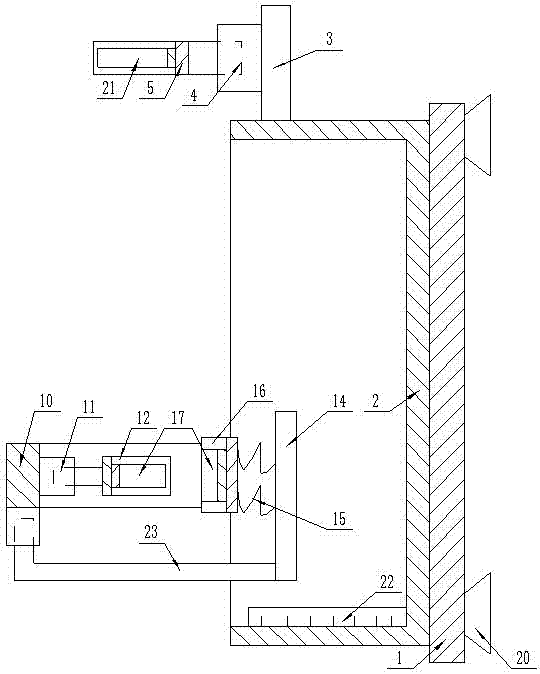

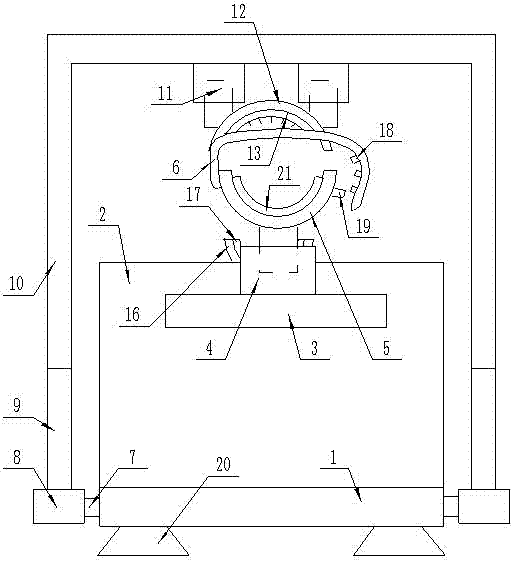

Mechanical building device and method for comfortable simulated natural wind

ActiveCN110440385AHigh value availableEnergy-saving and comfortable blowing environmentMechanical apparatusSpace heating and ventilation safety systemsEngineeringWind speed

The invention discloses a mechanical building device and method for comfortable simulated natural wind. The device mainly comprises a fan, a comfortable natural wind identification module, an environment parameter acquisition module, a mechanical wind speed acquisition module, a mechanical wind characteristic parameter calculation module, a processing module, a control module, a wind speed adjusting module and a period adjustment module. The method mainly comprises the following steps that 1) the environment parameter acquisition module is used for acquiring the temperature and the humidity ofthe environment where the fan is located; 2) the processing module is used foe judging working conditions of the current fan; 3) the control module generates fluctuation regulation function signals;4) the wind speed adjusting module is used for adjusting the wind speed of the fan; 5) the mechanical wind characteristic parameter calculation module is used for calculating current mechanical wind flow field characteristic parameters; and 6) the comfort natural wind identification module is used for judging the simulated natural wind degree of the current mechanical wind. According to the fan provided by the invention, the simulated natural wind mode regulation of the mechanical wind can be realized and changing the flow field parameters in real time by testing the change of the indoor heatenvironment.

Owner:CHONGQING UNIV

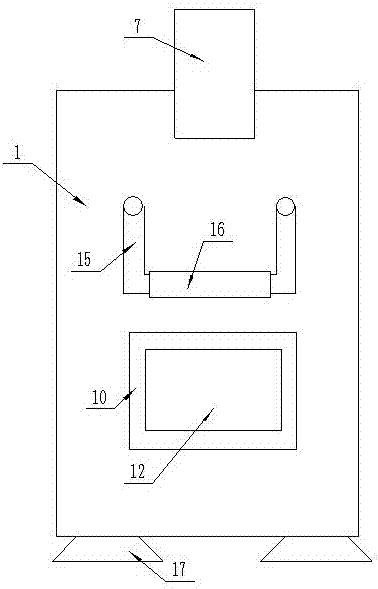

Novel device for bathing pet dog

The invention discloses a novel pet dog bathing device, comprising a rectangular base, a rectangular cleaning box without a cover is fixedly connected to the upper surface of the rectangular base, and a rectangular bearing plate is fixedly connected to the upper end of the right side surface of the rectangular cleaning box without a cover , the upper surface of the rectangular bearing plate is fixedly connected with a telescopic rod with an upward telescopic end, the telescopic end of the telescopic rod is fixedly connected with an arc-shaped bracket, and the upper surface of the arc-shaped bracket is movably connected with an elastic band, and the rectangular base A pair of horizontal slide rails are fixedly connected to the front and rear sides of the seat, and each horizontal slide rail in the pair of horizontal slide rails is equipped with an electric control trolley, and the upper surface of each electric control trolley is fixedly connected to There are supporting columns, the upper surfaces of the pair of supporting columns are fixedly connected with a door-shaped support frame, and the lower surface of the beam of the door-shaped support frame is fixedly connected with an electronically controlled telescopic support rod with the telescopic end facing downward. The invention has the advantages of simple structure and strong practicability.

Owner:景宁唯雅玩具设计工作室

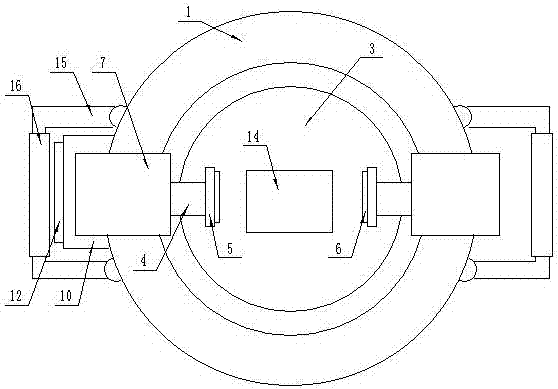

Multifunctional punching die capable of rotating automatically

PendingCN107552650AFlexible adjustment of upper and lower mold anglesIncrease diversityShaping toolsPunchingIndustrial engineering

The invention discloses a multifunctional punching die capable of rotating automatically. The multifunctional punching die comprises a lower fixing seat. A round lower die seat is fixedly connected tothe upper surface of the lower fixing seat. The interior of the round lower die seat is of a hollow structure. The round lower die seat is internally provided with a noise reduction sponge. Multiplelower dies are fixedly connected to the upper surface of the round lower die seat. A female die cavity is machined in the upper surface of each lower die. A rectangular groove is machined in the lowersurface inside each female die cavity. An electronically-controlled extending-and-contracting support rod is fixedly connected to the lower surface inside each rectangular groove, wherein the extending-and-contracting end of each electronically-controlled extending-and-contracting support rod faces upwards. A pair of folded type support frames are fixedly connected to the positions, located at the two sides of the round lower die seat, of the upper surface of the lower fixing seat. The multifunctional punching die has the beneficial effects of being simple in structure and great in practicability.

Owner:天津冰一科技有限公司

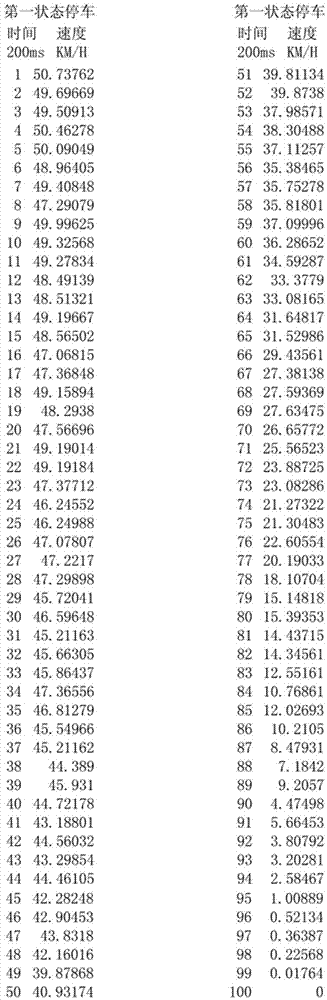

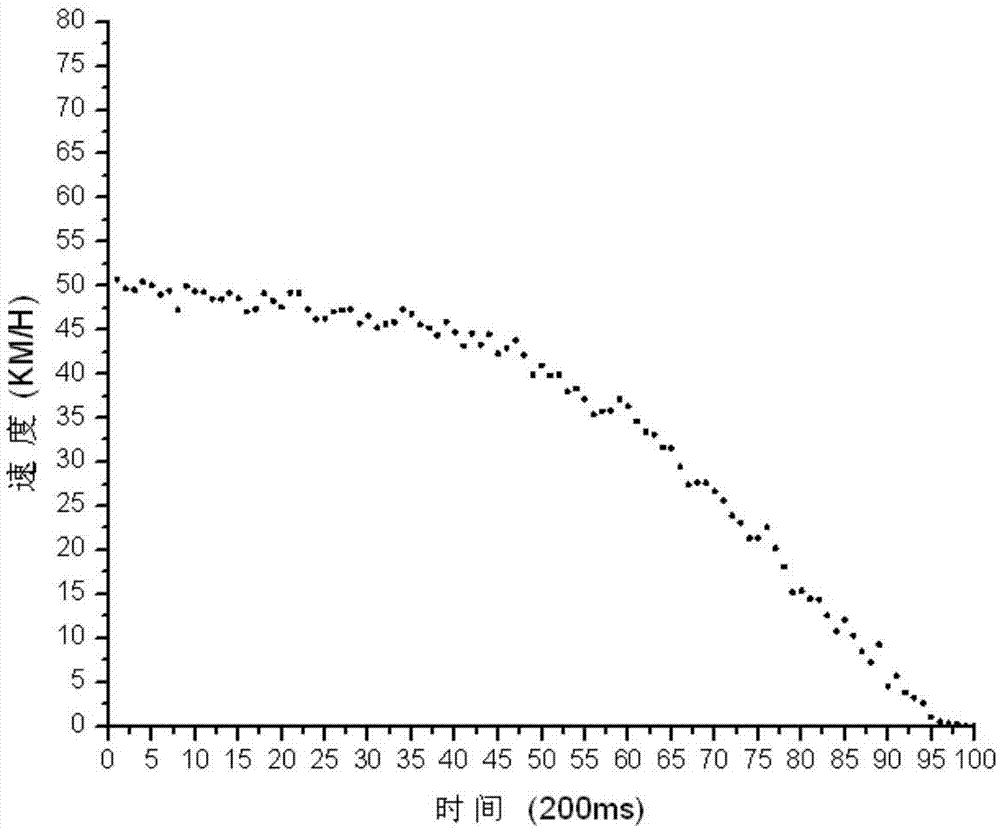

Method for judging accident doubt on basis of vehicle-mounted travelling data recorder

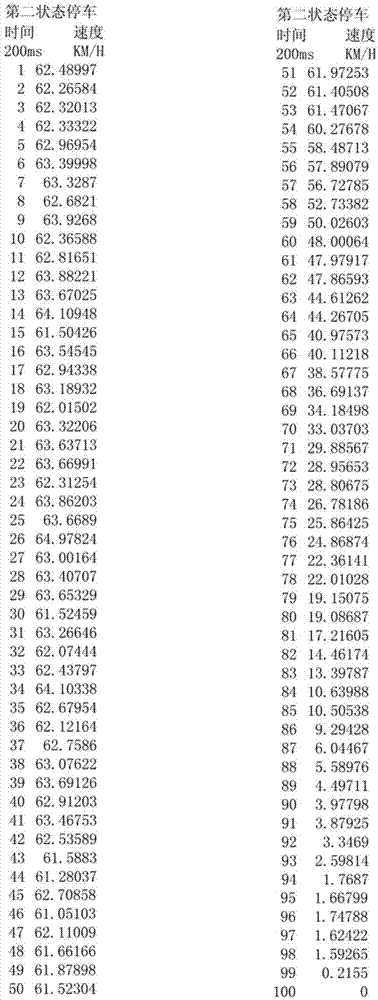

ActiveCN103679849AHigh value availableEffective filteringRegistering/indicating working of vehiclesReal-time computingVehicle accident

The invention relates to the technical field of vehicle accident early warning, in particular to a method for judging accident doubt on the basis of a vehicle-mounted travelling data recorder. The urgency degree of vehicle speed change before parking is analyzed by calculating the standard deviation of speed values collected by the travelling data recorder before vehicle parking, recorded data of non-accident parking are further filtered in combination of different characteristics of speed change of normal parking and accident parking, and the available value of accident doubt data of the recorder is improved. The method can effectively filter recorded data of normal parking, and the recorder can store more effective accident doubt data.

Owner:XIAMEN YAXON NETWORKS CO LTD

Waste rubber continuous cracking device and use method

InactiveCN107760354AImprove cracking efficiencyGood cracking efficiencyLiquid hydrocarbon mixture productionHydrocarbon oils treatmentWaste rubberEconomic benefits

The invention discloses a waste rubber continuous cracking device, and belongs to the technical field of waste rubber. A first rotating shaft is arranged on the left side of a grinding box, a grindingreamer is fixed on the first rotating shaft, and a crushed product feeding port is arranged on the bottom of the right side of the cavity of the grinding box. The crushed product feeding port is arranged on the top of a cracking box body, and an air blower is arranged at one side, far from the crushed product feeding port, of a hot air inlet. A temperature sensor is arranged on the top of the cavity of the cracking box body, a tube type auger is arranged in a cracking bin, the tube type auger is fixed on a second rotating shaft, a hot air outlet is arranged on the right side of the cracking box body, a catalyst feed port is connected with a catalyst atomizer by a flexible rubber hose, and a vacuum heat preservation room is arranged in the cavity of the cracking box body. The waste rubbercontinuous cracking device realizes real-time monitoring of temperature, has good cracking effect, uniform quality and high usable value, realizes energy recycling in the entire process, and also ensures environmental friendliness, and the economic benefit is relatively high.

Owner:叶子毓

Efficient cement board manufacturing mould for building construction

InactiveCN108340476AGuaranteed Simultaneous ProductionHigh value availableMouldsMould auxillary partsCement boardMaterials science

The invention discloses an efficient cement board manufacturing mould for building construction comprising two pairs of rectangular bases. The upper surface of each rectangular base is fixedly connected with an L-shaped supporting rod, the side surface of each L-shaped supporting rod is fixedly connected with a mould base, and a plurality of cement board mould cavities are machined in the upper surfaces of the mould bases; circular positioning through holes are machined in the lower surfaces of the cement board mould cavities correspondingly, and the side surfaces of the mould bases are fixedly connected with a turning-shaped supporting plate; the upper surface of the turning-shaped supporting plate is fixedly connected with a plurality of electrically controlled telescopic pushing rods with the upward telescopic ends; and the telescopic end of each electrically controlled telescopic pushing rod is fixedly connected with a circular jacking rod matched with the corresponding circular positioning through hole. The efficient cement board manufacturing mould for building construction has the beneficial effects that simultaneous production of a plurality of cement boards is ensured, theproduction efficiency is improved, rapid drying is facilitated, the energy-saving effect is good, demoulding is convenient, the structure is novel, and the usable value is high.

Owner:肖品玉

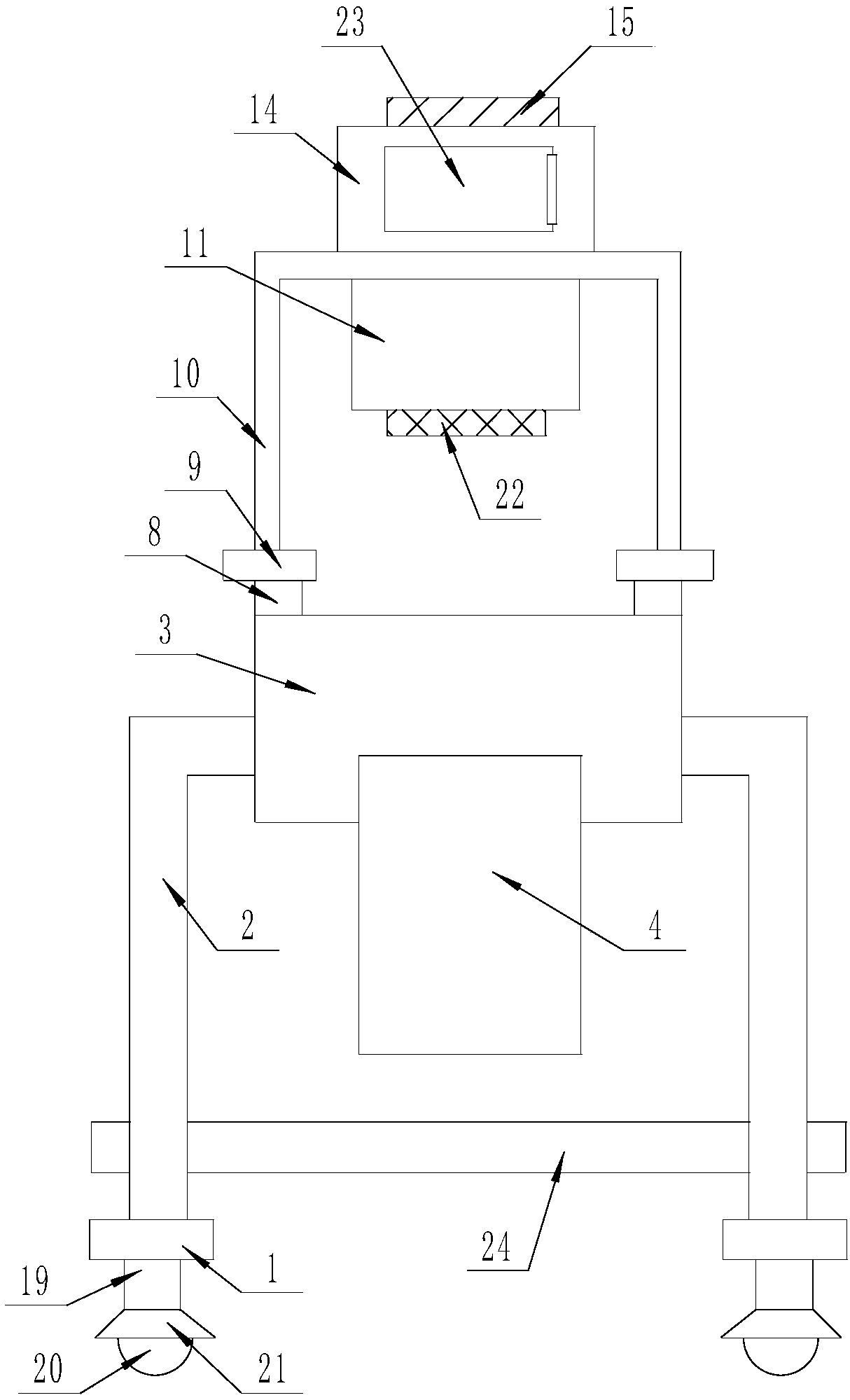

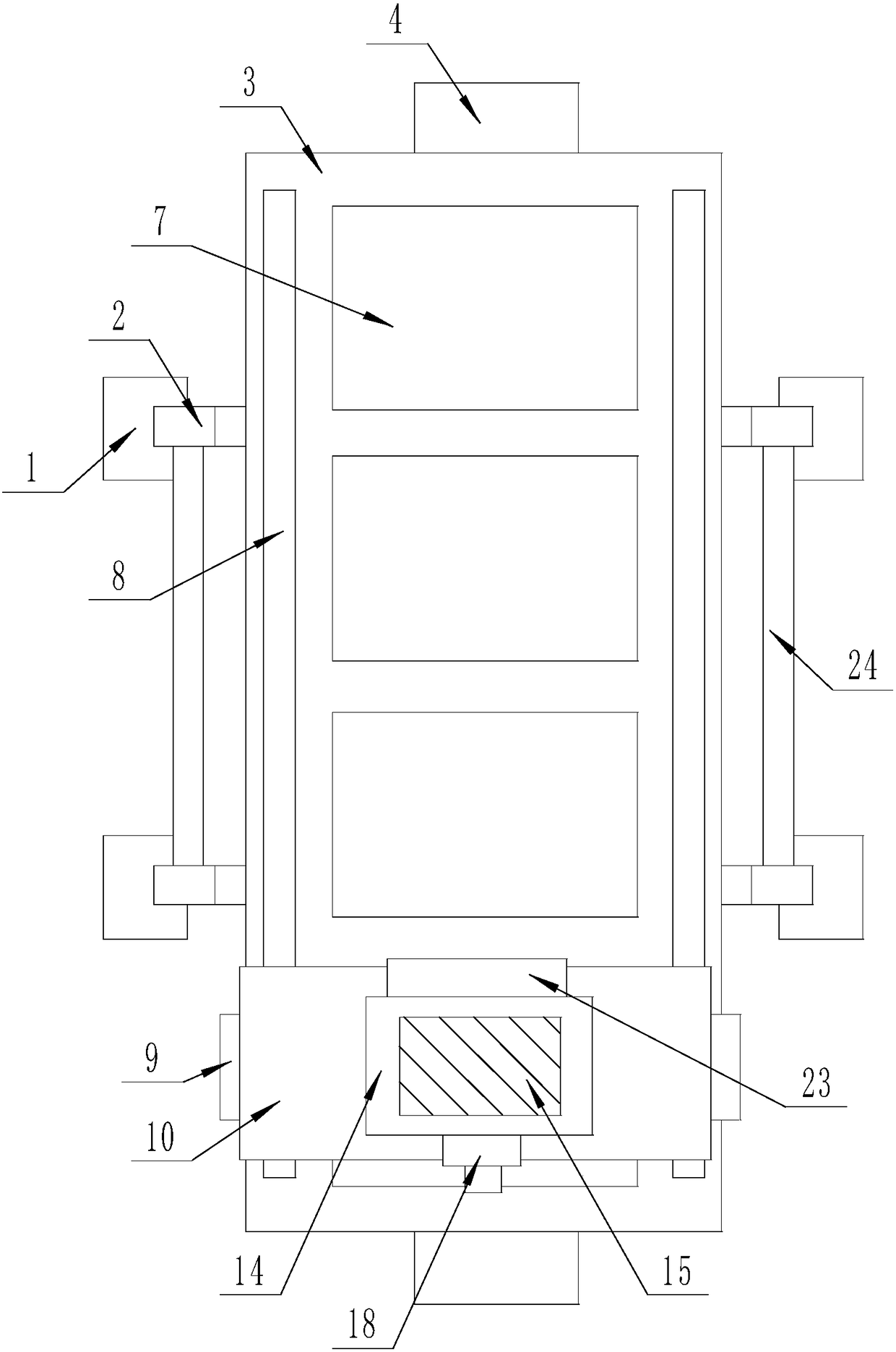

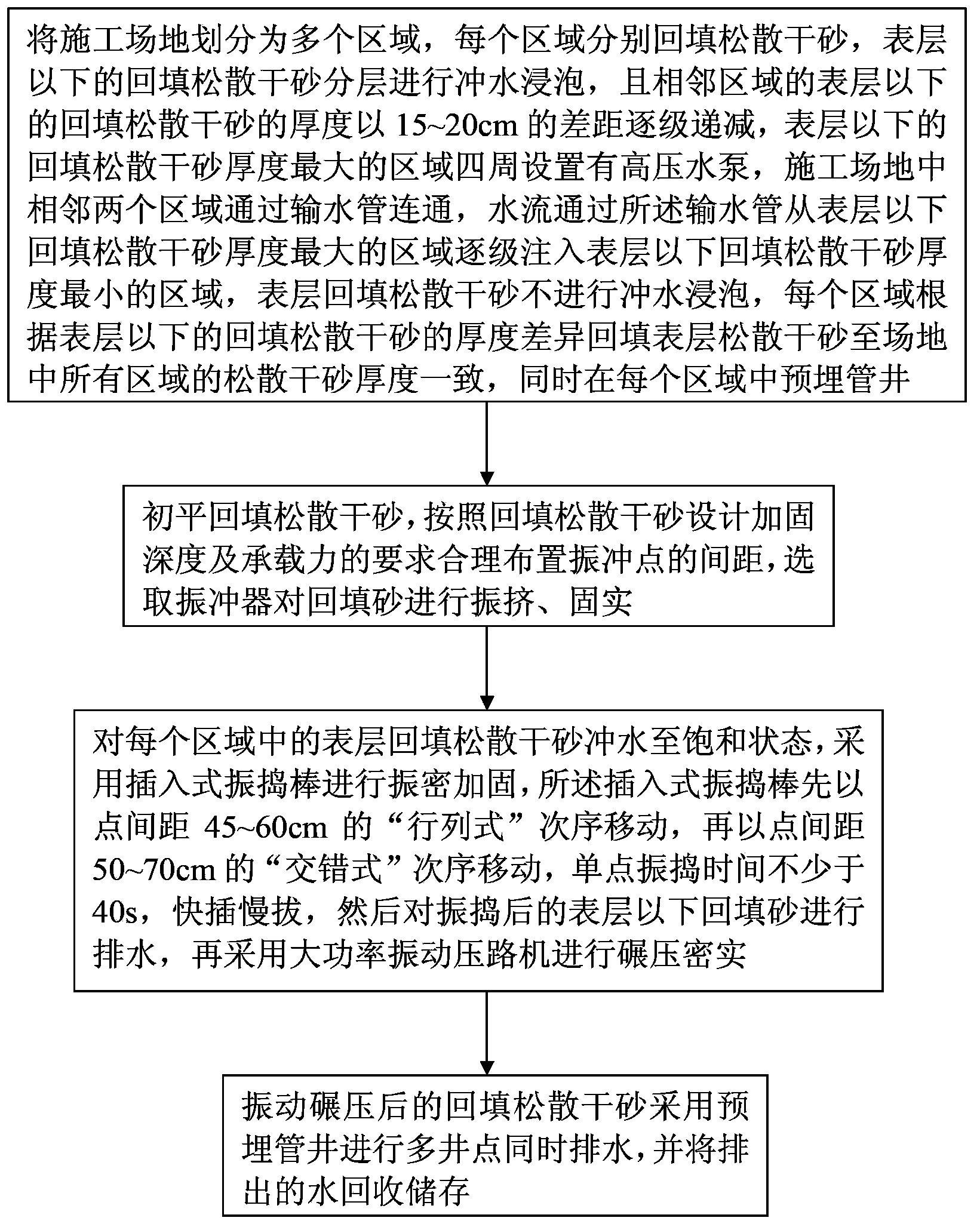

Dry-sand preconsolidation vibrating foundation reinforcing method

ActiveCN103352456AImprove bearing capacityGuaranteed uniformitySoil preservationSurface layerWater discharge

The invention relates to the technical field of foundation reinforcing treatment, in particular to a dry-sand preconsolidation vibrating foundation reinforcing method. The dry-sand preconsolidation vibrating foundation reinforcing method comprises the following steps of backfilling loose dry sand on a construction site, conducting water filling soaking on backfilled loose dry sand which is arranged below the surface layer in a layered mode, guaranteeing that water filling soaking is not conducted on surface-layer backfilled loose dry sand, embedding a tube well simultaneously, arranging the intervals of vibroflotation points, selecting a vibroflot to conduct vibro-densification and solidification on the backfilled sand, conducting water discharging on the backfilled sand after vibro-densification is conducted, conducting roller compaction densification through a high-power vibratory roller, and conducting water discharging on multiple well points. The dry-sand preconsolidation vibrating foundation reinforcing method improves the bearing capacity of the backfilled loose dry sand, effectively reduces the deformation amount of a foundation, improves the usable value of the surface-layer backfilled loose dry sand, and reduces production cost.

Owner:化学工业第一勘察设计院有限公司

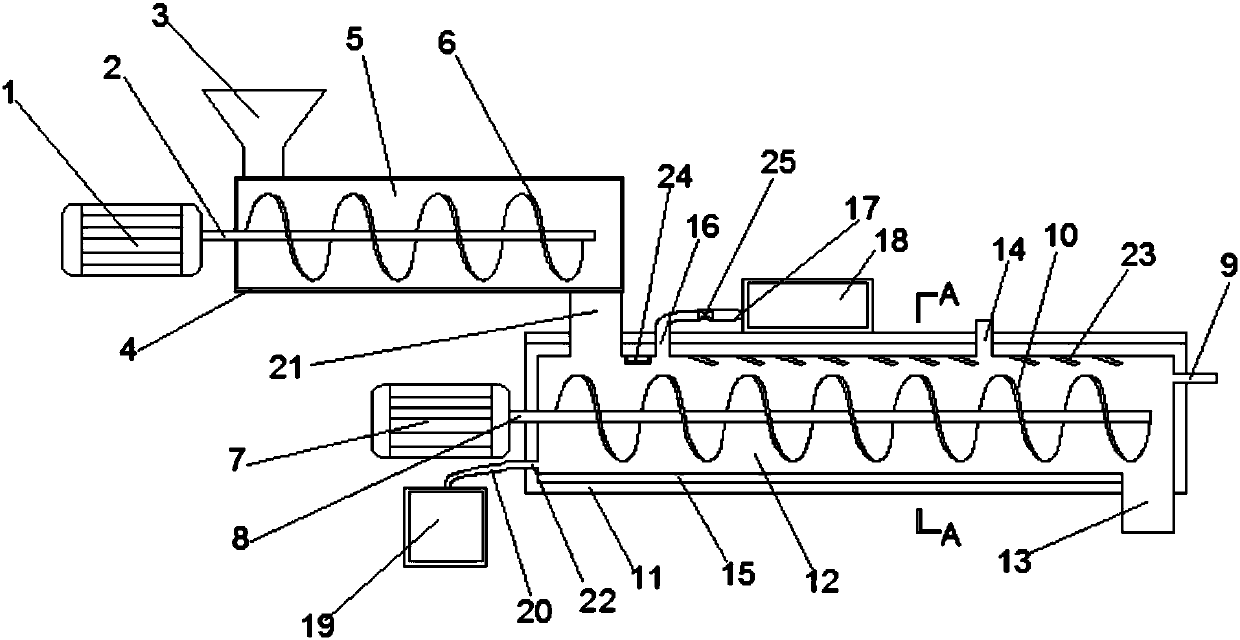

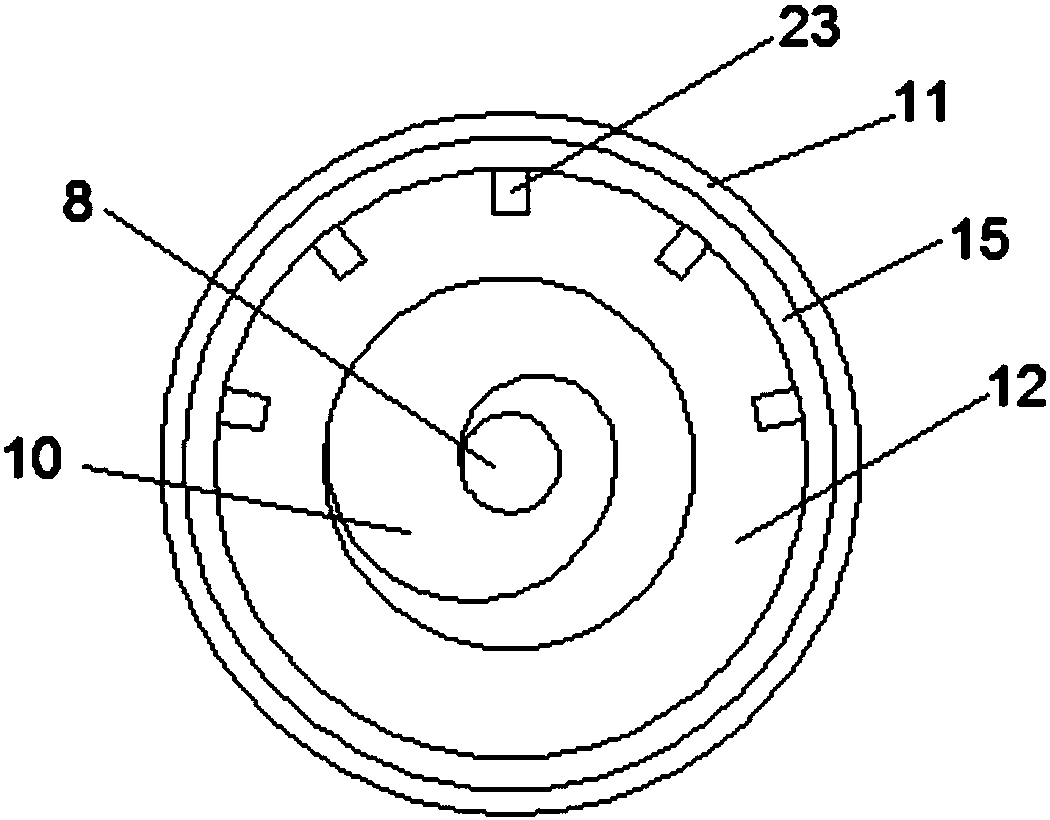

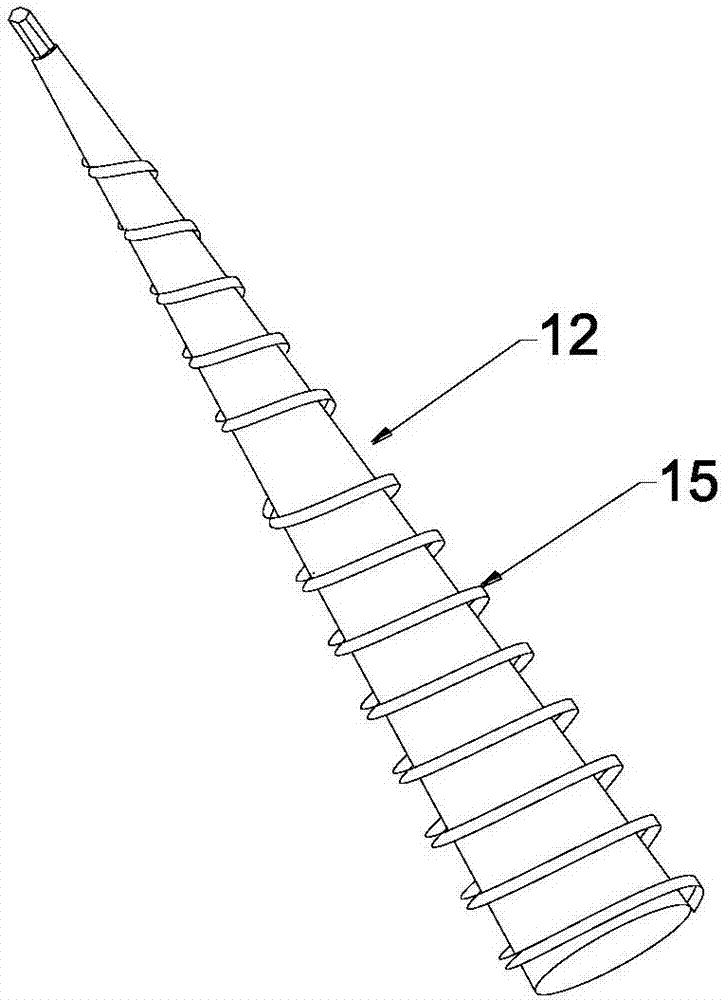

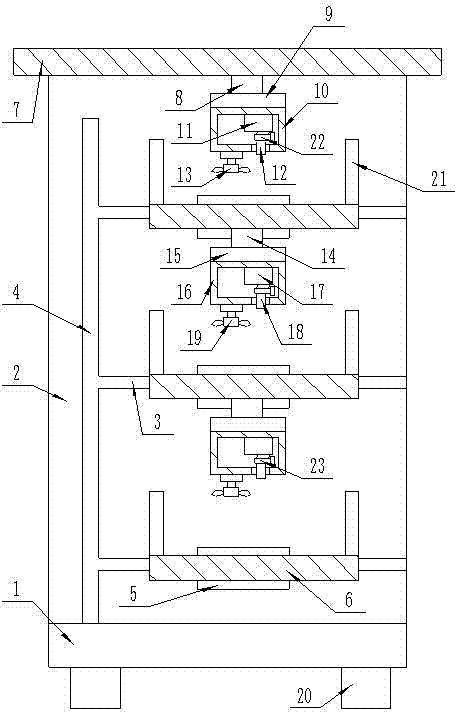

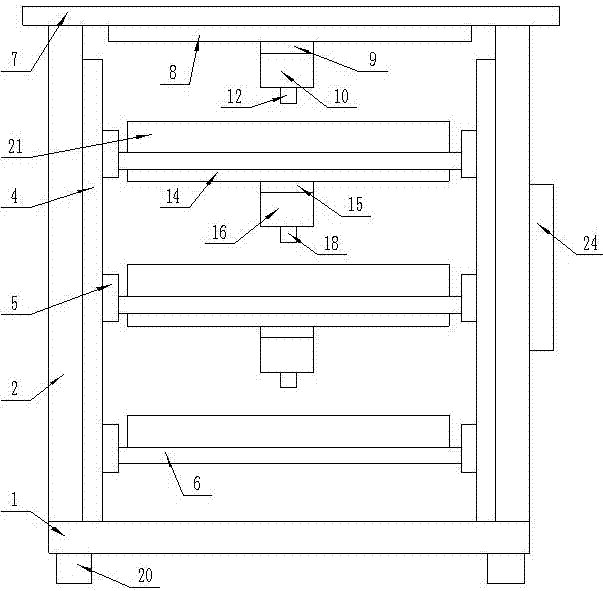

Gradually expanding type screw-feed thermal decomposition furnace integrated in vertical shaft flue behind pulverized coal boiler

ActiveCN107964405AIncrease added valueEfficient use ofEnergy inputSpecial form destructive distillationWater vaporTar

The invention relates to a gradually expanding type screw-feed thermal decomposition furnace integrated in a vertical shaft flue after a pulverized coal boiler. The furnace comprises a cylindric furnace body which is arranged at a connecting part between a horizontal flue and the vertical shaft flue; the upper end of the furnace body protrudes from an upper wall or a sidewall of the horizontal flue and is communicated with a feed chamber, and the lower end of the furnace body is communicated with a charcoal collecting bin which is arranged outside the vertical shaft flue through a charcoal outlet slideway; the upper part of a sidewall in the middle area of the furnace body is provided with a tar gas outlet and is communicated with a tar gas condensation bin, and a sidewall at the upper endof the furnace body is provided with a water vapor outlet and is communicated with a combustible gas collecting bin through a water vapor separator; and a spiral pushing arm whose radial dimension isgradually increased from up to bottom along an axial direction is arranged in the furnace body, and the upper end of the spiral pushing arm is connected with a motor in transmission connection through a gear case. The product is advantageous in that the furnace body is inclinedly arranged at a connecting part of the horizontal flue and the vertical flue, in order to effectively utilize waste heatof the flue; the spiral pushing arm with gradually increased radial dimension is arranged in the furnace body, in order to guarantee smooth feeding and effective fragmentation of the raw materials.

Owner:HUAZHONG UNIV OF SCI & TECH

Lifting bookshelf with dust collection function

InactiveCN107307615AGood cleaning effectEasy accessBook cabinetsFurniture partsElectric carsEngineering

The invention discloses a liftable bookshelf with dust-absorbing function, comprising a bookshelf bottom plate, a pair of vertical vertical plates fixedly connected to both ends of the upper surface of the bookshelf bottom plate, each of the pair of vertical vertical plates The side surfaces of the vertical vertical plates are fixedly connected with a plurality of horizontal slide rails, and one end of the side surface of each vertical vertical plate is fixedly connected with a vertical slide rail communicating with the interior of the multiple horizontal slide rails. Each horizontal slide rail in the plurality of horizontal slide rails is equipped with an electric control trolley, and the side surfaces of each pair of electric control trolleys are fixedly connected with a book carrying plate, and the pair of vertical vertical plates The surface is fixedly connected with a rectangular cover plate, and the lower surface of the rectangular cover plate is fixedly connected with a No. There is a No. 1 rectangular box on the surface. The invention has the advantages of simple structure and strong practicability.

Owner:刘海峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com